Milling is a quick and reliable way to give wood the desired shape. The working cutting tool of CNC machines is a milling cutter. Structurally, it is a rotating part with sharpened teeth. Milling cutters for CNC machines for wood are made from different alloys and are divided into categories. Their choice depends on the characteristics of the surface being treated, the type of work and the degree of hardness of the wood. It is also necessary to take into account not only the compliance of the cutter type with the task being performed and the milling mode, but also the design features of the cutting area. Our article will help you choose the right tool for programmed machines, which will introduce you to the types of cutters and their purpose.

- Types of edge cutters

What is a cutter?

The tool is a multi-blade part. Depending on the type, it can be mounted on the machine spindle or installed on the working shaft. For the manufacture of products, different types of alloys of durable metals are used.

In order for a tool to work efficiently, it is important to choose it, taking into account not only your needs, but also the technical characteristics of the machine.

Sharpening cutters

Today, cutters for a CNC milling machine have a higher price than for conventional machines. Therefore, very often, after a long period of useful use of a given cutting part, they do not buy it, but simply sharpen it.

Sharpening a cutter with a diamond wheel

It should be noted that sharpening with standard equipment or at home is almost impossible. Therefore, in order for you to end up with a high-quality sharpened part, you need to process it on a special mini CNC machine with Program Control.

Types of cutters depending on manufacturing method

There are prefabricated and monolithic instruments. The prefabricated type is a blank onto which blades were soldered at the factory. The sharp part of the part is made from special tool steel or from carbide types of metals.

Monolithic types of wood cutters are made from solid metal. Most often, manufacturers use tool steel. They initially include blades. Both options have proven themselves well in woodworking enterprises.

It must be taken into account that cutters with soldered blades cannot be sharpened.

There are also cutters with replaceable blades (a subtype of prefabricated tools). They can and should be changed as they wear out. This is the most practical option for those who do milling all the time.

General information

Milling cutters for various types of processing differ in the shape of the cutting edges and methods of sharpening. Backed ones have a curved shape and frontal sharpening; They are used when working with profiles. Pointed ones with a straight profile are used for drilling; they are sharpened on the front or back sides. There are cutters with two cutting edges. This design makes it possible to make tools and processing cheaper, increase work speed and improve the quality of the finished product.

Over time, the cutting edge of the tool becomes dull and wears out. To avoid frequent replacement, cutters are made from high-strength alloys with a long service life.

Take the test

Types of blades

Types of cutters for a wood router also differ in the type of blades. They come in high-speed (marking: HM) and carbide (marking HSS). The first option is great for working with soft woods, and the second is great for hard woods.

The blades can be positioned vertically or at an angle. The inclined type of blades makes it possible to carefully cut a layer of wood without chipping along the edges. Vertical blades cut lumber.

Milling cutter capabilities

As mentioned above, using this tool you can process almost all types of materials, from wood to metals and alloys. You can also process steel, cast iron, copper and other materials.

Today, CNC machines have an excellent ergonomic design, high safety, and sensors that control the speed at which the cutter rotates. Therefore, if you choose the right cutting tool and sharpen it in a timely manner, this will allow you to work with maximum efficiency and high precision.

This way you can give the part the required and precise shape.

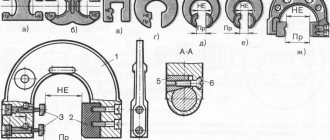

Variants of parts depending on geometry and design

There are many options for cutters to meet production needs. The main ones are: cylinders, corner, end, shaped, end. Each of them is designed for a specific type of woodworking.

If you want to find out more information about the types of wood cutters for machines, the specialists of the Mnogofrez online store are always ready to advise you on all technical issues. You can also buy tools for machine tools from us at an affordable price.

Contact us and you will be pleased with your choice!

SEE ALSO: Woodworking cutters • Purpose of cutters by number of passes • DJTOL tool series and alloys

How to choose a cutter

They are very different in their variety: you can choose them based on the type of operation you will perform; the material of manufacture and other parameters, such as wear resistance, also play an important role.

Good cutters usually have the following properties:

- strength;

- wear resistance;

- balance.

Practical advice: if you want to choose a quality tool, then pay attention to the above characteristics.

For further work with the cutter over a long service life, it will be necessary to either purchase a new cutting tool or sharpen it. Here it is important to pay attention to the manufacturing company, since it is best to buy sharpening tools directly from the equipment supplier.

Basic requirements for tools used in the manufacture of 3D products

The optimal choice is considered to be a milling cutter that has the best ratio of such indicators as tool cost, quality of workpiece processing, and speed of work.

It is impossible to combine the best indicators for all mentioned positions in one cutter. Examples:

- the higher the quality of processing that a tool provides, the more expensive it is;

- during operation, the cutter allows you to achieve the proper quality, but only when working in time-consuming modes (it does not support optimal speed modes);

- processing is carried out in the shortest possible time, but the finished workpiece must be finished (finishing).

Therefore, the customer independently determines the priority for each of the three positions, based on which he selects cutters with indicators that are optimal for solving a specific task.

Further material is considered taking into account the following tolerance: the machine used has a control program optimized to solve the required production problem:

- taking into account the required number of transitions when performing the necessary technological operations, part processing modes (taking into account the type of cutters used);

- allowing you to build an optimized processing route.

Requirements for this tool

Machines with a computerized control system operate accurately and at high speed, but require careful equipment. To process metal, wood, synthetics and composite materials with different hardness coefficients, cutters with a certain sharpening angle of the cutting edge are needed.

There are factors that influence the result of work:

- the strength of the product itself and the ability to withstand loads;

- the location of the blades in the cutter and their geometric shape;

- wear resistance, allowing the tool to maintain its original sharpening for a long time;

- minimal vibration during the production process.

There is a design variety of cutters for CNC; they are made exclusively from special grades of hardened steel. But there are only two technologies:

- Specialists produce serial tools from a single piece, using high-speed hard steel for this. Among the main advantages are precise execution, guarantee of rigidity, and the ability to work with maximum load.

- The steel body, a hard alloy with a fine-grained structure, is soldered to reproduce the complex geometry of the cutting edge. Scope of application – production of tools (shaped, diamond or large-sized), cutters for woodworking (hand tools).

Comparison of cutter retraction geometry

Depending on how the flute spirals across the cutter, your cutter will eject chips either up or down. Wherever the chips fly, a force acting in the same direction acts on the workpiece. Thus, the upper notch will throw the chips upward from the machine, and this will pull the workpiece. By the way, in the world of end mills, some cutters are divided into left-hand and right-hand. This is not the same thing because it affects the actual rotation of the spindle. You may get a left-handed helix end mill that turns left (counterclockwise), but 95% of left-handed helix cutters turn right-handed and push chips down.

Why do we need cutters with downward chip removal? In essence, conventional end mills are characterized by upward retraction. In the case of wood and materials that can leave chips, there is a disadvantage - when pushed out, the chips lift up the top edge of the cut. Since the bottom notch guides the chips down, the cut remains cleaner, but the bottom edge may peel off.

Clamping the workpiece is another challenge. The upper notch lifts the workpiece. If it is flexible, it can tear it off the plane and the cut will be inaccurate. A vacuum table will help solve this issue.

Okay, why not always use a down cutter, with cleaner cuts and a tighter grip on the workpiece?

Because the downward retraction lowers the chips to the bottom of the hole, and this is not so good. In the case of wood, the problem is much less than in the case of metal, but the problem remains a problem.

Another tip: Use a left-handed end mill with a smaller diameter to remove a stuck screw. At the same time, a twisting moment acts on it; at the same time, the screw pushed upward is cut out from the inside and the tension in the thread weakens.

Classification of cutters taking into account the material of the part

Before choosing the right tool, it is necessary to take into account the grade of material from which the workpiece is made. Depends on:

- Selection of cutting part.

- Its configuration.

- Technical specifications.

The material being processed influences the choice of working tool. It can have several types:

- CNC cutters for wood.

- Milling of ferrous metals.

- Processing of colored materials.

- Milling of plastic.

Important! Do not use a tool for processing wooden or plastic surfaces on metal surfaces. They differ in their design. Completely different materials were used to make them.

What cutters to use for CNC routers

Compression cutters

Compression cutter

Imagine combining a top and bottom cut and you get a compression cutter. Some notches go one way for the lower half of the notch length, while others go the other way. Compression cutters are designed for plywood, composites and laminates. They are used because they guide the chips towards the middle of the cutter, which reduces the amount of chips being removed from both the top and bottom. Try cutting a sheet of plywood completely with them and get clean edges on both sides. Do not try to use a compression cutter on metal!

"Faceted" cutters, better known as "Corn" cutters

Corn cutter

Unusual shape of the cutter, huh? This “cut” is very similar to a rasp, and indeed, in essence it is a rasp. They do not cut large chips and do not guide them along long flutes. Corn cutters are great for finishing cuts, but their ability to remove material is limited compared to other types of cutters. Because they are more gentle on the material, they are often used for composites, textolite, printed circuit board materials and other laminates.

Chipbreaker

This tool is also often called a "grinding cutter." The edges are serrated to break chips into smaller pieces and actually move a lot of waste away from the cutting area. These cutters are great for removing large amounts of metal, especially aluminum.

Straight cutters

The helical flute of conventional cutters allows the cutter edge to gradually cut into the material and cut chips. For straight cutters, this happens immediately, the edge completely cuts into the workpiece. In the world of metalworking, you won't find a tool with a similar geometry, with the exception of a reamer, which has a completely different function. The reason these cutters are made and sold is because they are much cheaper than helical cutters. In CNC they are used only for wood and plastics.

See also:

How to choose cutters

Scope of application

There are quite a few tools used on CNC machines. Each of them is used for a specific purpose. Therefore, all the tools were divided into several groups, taking into account their area of application.

- Rough milling. A large layer of metal is first removed. The desired shape is formed. Used for cutting sheet metal.

- Drilling grooves. Such equipment for CNC machines is capable of performing the following technological operations:

- Formation of grooves.

- Formation of grooves.

- Processing of recesses.

- Cutting recesses.

- Precise work. Machining corners, milling the edges of the upper surface of the part.

- Finishing. The operation is mainly performed with diamond cutters. They create depressions of various shapes, having the most complex configuration. After such processing, it is enough to clean the finished part and completely remove the remaining chips.

- Artistic drawings.