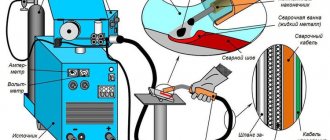

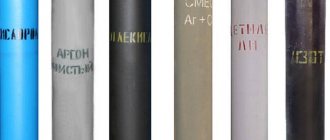

Nowadays, in both small and large industries, you can increasingly find cylinders with protective gas. The use of shielding gas during welding improves the quality of the welded joint, speeds up work and does not allow oxygen to penetrate into the welding zone. In addition, a gas cylinder is inexpensive and, especially for home welding, manufacturers produce compact cylinders that easily fit into the trunk of a car.

If you are a home welder, then you simply purchase a compact cylinder in the store and use it without worrying about consumption. If the gas runs out, you can quickly buy another cylinder. But what if you are a welder in production and you are subject to rather strict gas consumption requirements? How to choose the volume so that there is exactly enough gas for the entire welding process? In this article, we tried to briefly tell you how to calculate the optimal carbon dioxide consumption when welding with a semi-automatic machine.

What does consumption depend on?

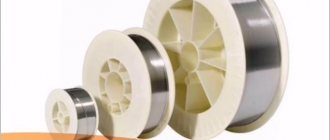

First, let's figure out what the gas consumption or the consumption of a welding mixture of several gases generally depends on. First of all, you must consider the metal you will be working with, the diameter of the filler wire and the strength of the welding current. The combination of these three components is what determines the consumption.

Next, we will give several recommendations on what the gas consumption should be during semi-automatic welding, taking into account the diameter of the filler wire and the strength of the welding current. Please note that these are fairly average values, you can deviate from them.

So, if you use wire with a diameter of 0.8 to 1 millimeter and set the amperage to 60 to 160 Amps, then the average flow rate should be about 8 liters per minute.

If you use 1.2mm wire and set the amperage to 100 to 250 Amps, then the average flow rate should be about 9-12 liters per minute.

If you use 1.4mm wire and set the amperage to 120 to 320 Amps, then the average flow rate should be about 12-15 liters per minute.

If you use 1.6mm wire and set the amperage to 240 to 380 Amps, then the average flow rate should be about 15-18 liters per minute.

If you use a wire with a diameter of 2 millimeters and set the current strength from 280 to 450 Amps, then the average flow rate should be about 18-20 liters per minute.

This is the average gas consumption for semi-automatic welding. Indeed, in addition to direct factors increasing consumption (such as wire diameter and metal thickness), there are also indirect ones. For example, if you cook outside or simply not in a closed box, then the consumption can increase significantly, because the gas will quickly evaporate. The consumption will especially unpleasantly surprise you if there is wind blowing outside.

Also important is the quality of the gas itself and how well it interacts with the metal. After all, if low-quality diluted gas is supplied to production, you simply will not be able to maintain normal consumption rates. There will be overspending in any case.

Basic information about gas welding torches

Torches of the G2 type “Malyutka” and “Zvezdochka” are the most common and universal welding torches, and when purchasing a torch for general purposes, it is worth purchasing them. Burners can be equipped with different tips and, depending on the installed tip, have different characteristics:

Tip No. 1 - thickness of welded metal 0.5 - 1.5 mm - average acetylene/oxygen consumption 75/90 l/hour Tip No. 2 - thickness of welded metal 1 - 3 mm - average acetylene/oxygen consumption 150/180 l/hour Tip No. 3 - thickness of welded metal 2 - 4 mm - average acetylene/oxygen consumption 260/300 l/hour

It is important to know and remember that acetylene torches cannot operate stably on propane, and for welding, soldering, and heating parts with a propane-oxygen flame, it is necessary to use GZU type torches and others specifically designed to operate on propane-butane. It must be taken into account that welding with a propane-oxygen flame gives worse weld characteristics than welding with acetylene or electric welding, and therefore it should be used only in exceptional cases, but soldering or heating with propane can be even more comfortable than with acetylene. The characteristics of propane-oxygen burners, depending on the installed tip, are as follows:

Tip No. 1 - average consumption of propane-butane/oxygen 50/175 l/hour Tip No. 2 - average consumption of propane-butane/oxygen 100/350 l/hour Tip No. 3 - average consumption of propane-butane/oxygen 200/700 l/h hour

For proper and safe operation of the burner, it is very important to set the correct gas pressure at the inlet. All modern burners are injection burners, i.e. The suction of combustible gas into them is carried out by a stream of oxygen passing through the central channel of the injector, and therefore the oxygen pressure must be higher than the pressure of the combustible gas. Typically the pressure is set to:

Oxygen pressure at the burner inlet - 3 kgf/cm2 Acetylene or propane pressure at the burner inlet - 1 kgf/cm2

Injector burners are the most resistant to flame backlash and it is recommended to use them. In old, injection-free torches, the pressure of oxygen and combustible gas is set equal, due to which the development of a backstroke of the flame is facilitated, this makes such a torch more dangerous, especially for novice gas welders, who often manage to dip the torch mouthpiece into the weld pool, which is extremely dangerous.

You should also always follow the correct sequence of opening/closing the burner valves when igniting/extinguishing it. When igniting, oxygen is always released first, then flammable gas. When extinguishing, the flammable gas is closed off first, and then the oxygen. Please note that when extinguishing the burner in this sequence, a pop may occur - do not be afraid, this is normal.

It is imperative to correctly set the gas ratio in the burner flame. With the correct ratio of combustible gas and oxygen, the flame core (the small bright glowing area right at the mouthpiece) is fat, thick, clearly defined, and does not have a torch veil around the flame. If there is an excess of flammable gas, there will be a veil around the core. With excess oxygen, the core will become pale, sharp, and prickly. To correctly set the composition of the flame, first give an excess of combustible gas so that a veil appears around the core, and then gradually add oxygen or remove the flammable gas until the veil completely disappears, and immediately stop turning the valves, this will be the optimal welding flame. Welding should be carried out with a flame zone at the very tip of the core, but under no circumstances should the core itself be pushed into the weld pool or carried too far.

Shielding gas consumption

Now let's look at the topic of gas consumption in more detail using a specific example. As an example, let's take a standard 40 liter gas cylinder, which is available at most enterprises. One such cylinder contains about 24 kilograms of pure carbon dioxide; when evaporated, it forms up to 12 thousand cubic decimeters of the gas phase. This information is already enough for us to roughly understand the consumption.

Let's say you're using 1mm filler wire and you've set the amperage to near minimum. Let's say 100 Amps. Judging by the reference literature, with this welding mode, one 40 liter cylinder will be enough for exactly one day, that is, 24 hours. But, naturally, you don’t sit at work for days, so let’s divide this into 6 hours of work. We get 10 liters of gas.

You can also calculate the consumption based on how many kilograms of metal we deposited. We know that for 1 kilogram of surfacing we must spend about 1.1 kilograms of carbon dioxide and 1.30 kilograms of filler wire. Knowing this data, it is easy to calculate how much gas and wire you will spend. Let's give you a hint: if you spent about 1.2 kilograms of filler wire, then the gas consumption was about 1 kilogram.

Now that we know these values, we can calculate how much metal can be melted using a 40 liter gas cylinder. Answer: 29 kilograms of metal. Of course, these are always approximate figures, but our practice has proven that usually the consumption varies within these limits. For beginners, we recommend using the table below.

How long does a carbon dioxide cylinder last for welding?

As with other protective gases, to determine how long carbon dioxide cylinders last, you need to know the thickness of the metal being processed, the diameter of the wire and the current strength. These are the main parameters affecting gas consumption.

Below are the average CO2 consumption values, depending on the wire diameter and current:

- 0.8-1.0 mm (60-160 A) – 8-9 l/min;

- 1.2 mm (100-250 A) – 9-12 l/min;

- 1.4 mm (120-320 A) – 12-15 l/min;

- 1.6 mm (240-380 A) – 15-18 l/min;

- 2.0 mm (280-450 A) – 18-20 l/min.

Consumption depends on wire diameter, current and speed

Consumption indicators are greatly influenced by external factors. Outdoors, more shielding gas will be required to ensure normal welding conditions, especially if the work is carried out in windy conditions. Therefore, indoors one cylinder lasts for a longer period.

An equally important role is played by the quality of the mixture and its suitability for working with a specific metal. Read more about this in the article: welding mixture or carbon dioxide - choosing a shielding gas for welding.

Calculation of shielding gas consumption during welding

There are many methods for calculating the shielding gas used in welding, but it is necessary to take into account the type of production - serial, mass, individual, as well as nomenclatures. When producing metal structures in small-scale production, to draw up certifications for materials, you can use the following formula, which, we recall, is applicable only to small-scale production:

In this equation, Np represents the rate of wire consumption per product, determined in kilograms, and Rg is a coefficient that takes into account the cost of shielding gas per kilogram of wire.

For summary reports, the value of this coefficient can be used as 1.15.

But when producing prototypes or exhibition series of products at enterprises, we recommend using material consumption standards for welding with coefficients of no more than 1.3.

You can use the method of calculating the protective gas using the value Ng in cubic meters and liters per meter of seam, and this formula is applicable mainly for large-scale production of similar structures and parts, or for small-scale production. The formula is:

In this case, Нг is a symbol for the specific consumption of shielding gas, which is shown in the table below.

The T value is the main time required to weld a certain pass, measured in seconds or minutes.

Ndg is the additional amount of protective gas consumption that was spent on the preparatory and finishing operations of the passage. N is the number of passes, which can be any number.

To determine the calculation of carbon dioxide consumption for welding in kilograms, it is important to consider that when 1 kilogram of liquid carbon dioxide evaporates, about 509 liters of carbon dioxide are released. Additional calculation of shielding gas consumption during welding in liters or cubic meters is made using the following formula:

Read also: Rules for installing an air conditioner in an apartment

Here Tpz is a symbol of the time spent on completing the final preparatory operations (purging the torch before welding, setting up the welding machine, blowing the welding area after completion of work), measured in seconds, minutes. The latest calculation method for determining which gas consumption for welding is the most accurate and economical. In order to control the gas flow into the cylinders, we recommend installing flow meters and reducers.

In shielding gas environments, carbon dioxide welding is very common. For a general understanding of the picture, I propose to study this welding method better.

How long do carbon dioxide cylinders of different sizes last?

As you know, a standard 40-liter cylinder contains 24 kg of CO2, which, when evaporated, forms about 12,000 dm³ of the gas phase. Taking into account the above data, it is possible to determine how long a carbon dioxide cylinder lasts during a continuous working process.

Here is an ordinary 40 liter cylinder filled with carbon dioxide

So, for example, when using a 1 mm wire and an average current of 100 A, 40 liters of gas will last approximately 24 hours. Accordingly, a 10 liter cylinder should be enough for 6 hours of continuous use.

According to reference materials, 1.1 kg of CO2 and 1.35 kg of welding wire are consumed per 1 kg of deposited metal. Thanks to these data, the following proportion is determined: CO2/wire = 1:1.2 kg. That is, for 1.2 kg of wire material there is 1 kg of carbon dioxide in the liquid phase.

Based on the obtained coefficient, you can easily calculate consumption: 24 kg of carbon dioxide (40 liter capacity) is enough for 29 kg of welding metal. As practice shows, these calculations correspond to reality in most cases.

Gas saving

We said above that gas consumption is also influenced by indirect factors that the welder has virtually no influence on. But he can still, if possible, minimize the effect of these factors, thereby saving gas.

The simplest thing you can do is to weld in a closed workshop with good ventilation. There should be no drafts or wind. It is also better to involve qualified, experienced welders who perform the work quickly and accurately. After all, for beginners, in any case, gas consumption will be much higher.

Many novice welders are interested in whether there is any other way to reduce co2 consumption during semi-automatic welding? For example, simply supply less gas to the welding zone. Our answer: no. By deliberately reducing the amount of gas used, you will deteriorate the quality of the seam, since oxygen will enter the welding zone.

But this problem still has a solution. Experienced craftsmen advise using multi-component gas mixtures in their work; thanks to them, consumption is reduced, while the quality of welding remains at a decent level. But be prepared for the fact that the cost of multicomponent mixtures is much higher than that of standard gas. So make sure that using such mixtures is cost-effective.