One of the parameters that determines the capabilities of an angle grinder is the maximum diameter of the disk that is installed on it. It determines the speed, engine power and torque. The choice of disk size is closely related to the nature of the work performed by the grinder.

Types of circles

The circles (disks) of grinders differ according to the following indicators:

- work performed that determines the purpose of the tool;

- composition of the material;

- dimensions.

Technological features

The necessary processing technology is provided by the following consumables.

- — Cutting wheels. Mainly used for processing metals, less often for other types of materials.

- — Grinding wheels. Different designs allow you to perform both roughing or cleaning, and bringing the surface roughness to the desired condition.

- — Polishing discs and attachments. Bring the surface to a shine using felt or other fabric with similar properties.

By material

The operating modes are influenced by the material component from which the tool is made.

- — Abrasive disc. The basis that served for the manufacture of the tool is the abrasive material itself, a binder, for example, bakelite and various fillers. Mainly used for metal processing.

- — Diamond wheel (with diamond coating). With its help, you can process materials of any strength (various types of stone, ceramics, quartz glass and many other similar ones consisting of solid fractions).

Dimensions

The main classification criterion here is the diameter of the disc. The depth of the cut depends on its size (it is approximately a quarter of the diameter). The functionality of an angle grinder is determined by the size of the tool: a small diameter makes it possible to process a light angle grinder in hard-to-reach places, while a larger size angle grinder with greater productivity will be difficult and unsafe to hold “in weight”.

Scope of use

The equipment in question can be classified by application into specific categories of materials - wood, metal or concrete. Each type of this device will have its own distinctive properties, but most often cutting wheels are used for cutting metal. Such metal objects of work may include the following products:

- From metals and their alloys;

- Of steel;

- Made of cast iron;

- Stainless steel;

- From non-ferrous metal (copper and aluminum);

- Made from galvanized products.

Fundamentally, an abrasive cutting disc differs from other attachments designed for processing wood or concrete. It's all about the consistency of the abrasive material, which for concrete and wood is applied to the disc much less.

Marking

The choice of the right tool is facilitated by the presence of markings. It contains the technical parameters of consumables in encrypted form. For example, this is what an alphanumeric set of markings for a cutting disc looks like, produced by a Russian manufacturer:

- — The image shows the tool manufacturer — Luga Abrasive Plant (Luga, Leningrad Region).

- — Tool name:

- cutting wheel - in Russian;

- cut –off – wheel – in English translation.

- — Purpose: for processing steel (inscriptions “steel”, “steel” on the circle).

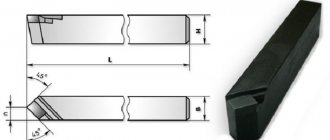

- — The dimensions of the circle are indicated (outer diameter x thickness x bore diameter):

- in mm – 200 x 2.5 x 22.23;

- in inches – 8”x 1/10”x 7/8”;

- digital designation "41". This is a characteristic of the design of the circle - here it is flat.

- — The circle is designed for 7650 rpm, while the maximum peripheral speed should not exceed 80 m/s.

- — Technical parameters of the wheel material are determined from the designation “A 30 S BF”, where:

- A – means that the abrasive is based on white electrocorundum, which is specifically used for metal processing;

- 30 – abrasive grain size, here it is average;

- S – hardness of the circle, here the circle is hard;

- BF - denotes the type of bond, here synthetic resins with glass fiber reinforcement.

- — Rules for safe work in the form of signs indicating the required action.

- - GOST 21963 - 2002, GOST R 52588 - 2011, EN 12413 - Russian and European regulatory documents to which this tool complies.

The marking of a foreign manufacturer of tools for angle grinders is as follows:

- — Tools under the NORTON VULKAN brand are produced by the Saint Gobain corporation, headquartered in France.

- —The purpose of the cutting disc (the company produces only such a tool for angle grinders) for processing steel (in addition, for visualization purposes, the label for wheels intended for metal processing is blue) is duplicated in several languages.

- — The circle is designed for 12250 rpm with a maximum peripheral speed of 80 m/s.

- — The dimensions are the same as on the Russian disk - in mm and inches.

- — The digital designation “41” has been added to the technical parameters of “A60S – BF41”. This is a characteristic of the design of the circle - here it is flat.

- — Methods of safe work must be indicated.

- — The regulatory documents to which the instrument complies are issued by the European Union.

What are the sizes of wheels for angle grinders Bosch, Interskol and more?

Almost all large companies produce grinders covering the maximum number of works - from household to industrial designs. Each type has its own tool size. In addition to the production of angle grinders, such manufacturers (Bosch, Metabo, Interskol and others) have mastered the parallel production of consumables. They select a special composition and standard size of consumables in order to maximize the operating efficiency of the specific model they produce.

Outer and bore diameter, maximum and minimum value

The most popular range of angle grinder sizes consists of the following values.

External diameter . The most preferred sizes are: 115 mm, 125 mm, 150 mm, 180 mm, 200 mm and 230 mm. In rare cases, to perform, for example, jewelry work with small parts, portable battery-powered angle grinders with diameters of 76 mm or 100 mm are used.

The minimum diameter of 115 mm is used for simple work in the form of processing hard-to-reach surfaces in the household. Anglers with a circle with a diameter of 125 mm have greater ability to perform various household works.

The diameter of 230 mm is used in the professional context of angle grinders for large volumes of work, for example, in construction. Circles with a diameter of more than 230 mm are installed on stationary equipment.

Thickness _ Cutting wheels are available in thicknesses from 0.8 mm to 5.0 mm. Moreover, a larger diameter should have a circle with a correspondingly greater thickness.

You should know! A thin disc is easy to cut, but it is also more likely to break.

Landing diameter . The standard mounting diameter for angle grinder consumables is 22.23 mm. In the vast majority of cases, it is the same for all disk sizes. It is rare to find mounting diameters of 10 mm, 13 mm, 16 mm due to the limited use of angle grinders with a diameter smaller than 100 mm. A 32 mm bore diameter is used with circles of 300 mm and larger on stationary equipment.

Popular models

Let's consider the most popular models of disks for angle grinders:

BOSH

One of the most famous and reliable manufacturers of equipment and accessories. The disks of this company demonstrate high reliability, durability, and resistance to all loads;

INFORCE

A tool from a domestic manufacturer that demonstrates high performance, durability, a wide range of types and sizes. It has an optimal price-quality ratio;

KLINGSPOR

A German company approaching its 130th anniversary. The accumulated technological experience allows us to produce discs that demonstrate exceptional durability and strength. According to user reviews, nozzle wear is insignificant even after prolonged processing of the most problematic materials. The cost of the tool is quite high;

3M

An American company that produces a wide range of abrasive and polishing materials and accessories for various equipment. It was this company that took the lead in the discovery of corundum as an abrasive material. Products manufactured by 3M are distinguished by high quality, durability, and the absence of geometric deviations;

METABO

A trademark owned by Metabowerke GmbH (Germany). There is no point in talking about the quality and reliability of German technology for a long time; they are the standard for all manufacturers. Wheels for angle grinders produced under the METABO brand belong to the group of professional tools. According to experts and ordinary users, these attachments are practically free of drawbacks;

HITACHI

A Japanese company supplying high-quality technological equipment, tooling and tools to the world market. There are wheels on the market under the “HITACHI” brand, manufactured in Luga. They demonstrate quite decent qualities, are accurate, and durable. Relatively low cost;

Luga-Abrasiv

Domestic manufacturer of cutting and other attachments for angle grinders. The combination of price and quality allows us to consider these attachments as one of the most popular on the market, and user reviews are almost all positive;

Bison

Russian company producing power tools and consumables. Offers a wide range of attachments for angle grinders, characterized by affordable prices and high quality.

The list of manufacturers does not end there; they can be listed for a long time. Modern production technologies make it possible to produce strong, durable discs that demonstrate high quality, efficiency and precision in operation.

For large, medium and small angle grinders

The power classification into small, medium and large is closely related to dimensions and weight. The greater the power, the greater the weight and overall dimensions.

So, for example, grinders with disks of 115 mm - 125 mm and a power of 0.6 kW to 1.2 kW are classified as small equipment.

Angler grinders with discs of 150 mm - 180 mm and a power of up to 2.0 kW belong to the middle class of such equipment.

Professional angle grinders with a power of up to 3.0 kW and a disc diameter of 230 mm conventionally belong to large angle grinders.

For metal, concrete, wood and other materials

To effectively process any material, it is important to choose the right power so that it matches the diameter of the tool and its thickness. In addition, the consumable must have suitable characteristics for processing a specific type of workpiece material.

The main difference between discs for steel, cast iron, and non-ferrous metals is in the composition of the fillers. To process alloy steels, a very strong additive is added to the disc material that can overcome the resistance of alloy steel. When processing non-ferrous metals, on the contrary, a soft filler is added, which works effectively when processing viscous materials.

Disc for aluminum

To process concrete (tiles, paving slabs), diamond discs are used (actually, these are metal circles coated with diamond).

Tile disc

It is not recommended to process wood with an angle grinder due to the high risk of injury. If such a need nevertheless arises, then the best option would be a grinder with a disk with a diameter of 125 mm. As a working tool, special angle grinder discs for wood should be used.

Wood disc

Advantages of diamond blades

- Abrasive blades are typically made from resin-bonded silicon carbide and/or aluminum oxide and wear out in a matter of days. Diamond blades are made of steel interspersed with artificial diamonds and can last hundreds or even thousands of times longer;

- Diamond blades have greater heat resistance and greater resistance. By reducing the heating of the angle grinder, diamond discs increase its service life. In addition, they are fireproof - unlike abrasive blades that throw out sheaves of sparks;

- The efficiency of diamond blades makes them incredibly cost-effective to use by significantly reducing equipment wear and operating time. In other words, you will have to change them much less often, and, therefore, you will also have to spend less on them;

- Abrasive discs are more dangerous than diamond discs. According to statistics from the US Department of Labor's Occupational Safety and Health Administration, the likelihood of death (as well as the likelihood of serious injury) from an abrasive blade failure is 6.3 times higher than from a diamond blade failure;

- Silicon carbide dust, released in large quantities when cutting material with an abrasive disc, can cause silicosis or, in particularly severe cases, lung cancer. Diamond blades do not contain silicon carbide, which makes them completely safe.

How to choose

The main criterion for choosing the disk size will be the nature of the work performed. In the household, these will be circles of smaller diameters; in a production environment, a tool of large diameter (230 mm) is used.

In addition to the dimensional characteristics, you should carefully check the compliance of the disc material with the material of the workpiece being processed.

Another determining factor is the power of the grinder. It is directly related to the weight and overall characteristics of an angle grinder. With approximately the same characteristics, preference should be given to a lighter specimen.

How to replace

The grinder disc is a consumable item. Therefore, it has to be changed frequently. There is a simple algorithm in which an important role is played by the original design of the key supplied to the consumer along with the grinder.

- — The protruding rods of a special key are installed in the grooves of the fastening nut.

- — At the same time, press the lock button located on the gearbox housing. It will lock the rotor from turning.

- — Turn the key counterclockwise to release the fasteners of the worn disk.

- — The old disk is replaced with a new one of the same technical characteristics and size. The new disk is installed with the markings facing out to remind you of the disk parameters and for other good reasons (see explanation in the video above).

- — The fastening nut is first tightened by hand and finally tightened with a special wrench.

The Bulgarian is ready to continue fulfilling its functional purpose.

Safety requirements

When working with an angle grinder, you must follow safety precautions. High speed and poor visibility of the cutting line impose certain conditions that must be met without fail

The most stringent of them are:

- It is prohibited to remove the protection from the angle grinder. The use of larger diameter discs is not permitted.

- Be sure to wear protective clothing, goggles, and gloves.

- Do not clean the cut with the side surface of the cutting disc.

- After installing a new disk, you should check its quality at idle speed and only then start working.

- The circle should be changed only after a complete stop and disconnecting the power cord from the network.

Expert opinion

Kuznetsov Vasily Stepanovich

The last rule is violated most often. This processing method is very simple and accessible, but it is the most common reason for the destruction of the disk and the scattering of debris in all directions. The consequences of such an action can be very disastrous, so before starting processing you should prepare all the necessary attachments and change them as necessary.