1 / 1

The first time we heard about it was argon arc welding in an inert gas environment. Then they began to use various gases and even mixtures of them. With the advent of inverter welding current sources, the English abbreviation TIG (tig) welding

.

Nowadays the correct name is considered to be the following expression: “ welding with a non-consumable electrode in a shielding gas environment

. ”

Argon gas gave birth to another very promising type of metal joining: semi-automatic welding with consumable electrodes in a shielding gas environment. In this case, other gases, welding wire with coating, and submerged arc welding are increasingly used, but argon was the foundation. Let's get to know him better in this article.

Content

- Tig welding process diagram

- Argon grades used in welding

- Scheme of a mechanized argon arc welding station

- Scheme of manual argon arc welding

- DC welding diagram

- AC welding diagram

- Advantages and disadvantages of argon arc welding

- Features of welding in argon environment

- Manual argon arc welding technique

- Scope of argon arc welding

- Video: argon arc welding

Principle of operation

Equipment for argon welding consists of: a welding machine - which includes an inverter converter for generating an electric arc, an oscillator, a torch, an argon cylinder, gas hoses and welding cables.

Argon arc welding (tig) with a non-consumable electrode

Before starting work, the device is turned on and argon is supplied. To form an electric arc, the welder brings the tungsten (when welding with a non-consumable electrode) electrode a short distance to the workpiece. There is one important nuance at this stage. An arc cannot be formed when the electrode is directly connected to the workpiece, as with electric welding. This is due to the fact that high ionization is required to create an arc in an argon environment. And since the tungsten electrode is refractory (melting point about 5000 °C) and practically does not burn, there is no formation of gases that promote ionization and ignition of the arc. Therefore, in such cases, an oscillator is used. An oscillator is a device, usually installed in a TIG welding machine, that starts the electric arc in the case of a non-consumable electrode. This happens as follows: by bringing a torch with a tungsten electrode a short distance to the part, the oscillator delivers a high-voltage, high-frequency pulse to the electrode, which electrically penetrates the distance to the part, forming ionization in a gaseous environment. Thanks to this, the arc is ignited and continues to burn.

When using direct current welding, a straight polarity connection is used. That is, “plus” is applied to the body of the product, and “minus” to the electrode. This is done because with such a connection, up to 70% of the heat is released on the part, that is, the “plus”, and only 30% on the electrode, the “minus”. As a result, the metal of the part melts, and the electrode is less susceptible to combustion. The exception is aluminum welding. In this case, the best results are obtained by welding with alternating current, since this destroys the formation of the oxide film. As for the oscillator, when using alternating current, after ignition of the arc, it goes into stabilization mode, delivering breakdown pulses every time the polarity changes. This ensures stable combustion of the electric arc.

Due to the fact that the tungsten electrode does not melt, to form a weld, a filler material is added to the place where the arc burns, which the welder holds with his left hand and, if necessary, applies.

Under the influence of temperature, a bath of molten metal is formed in the parts being joined. Since the burner has an inlet for connecting a gas hose, argon passes through a special cavity to the gas nozzle and escapes between it and the tungsten electrode. Thus, as if “enveloping” the electrode and the cooking bath.

In addition to the gas cavity, the burner also has inlet and outlet pipes for supplying cold liquid and removing heated liquid. This is necessary to cool the burner nozzle due to severe overheating.

TIG welding with consumable electrode

In this case, the role of the electrode is played by a metal rod coated with rutile. When the electrode directly touches the part, a short circuit occurs (as in conventional electric arc welding), as a result of which vapors of molten metal are formed, which give ionization in an argon gas environment. The arc is ignited thanks to these vapors, so the use of an oscillator in this case is not necessary. The filler wire is fed manually or by a special automated mechanism, in the form of a drum with wire, rollers and an electric motor with a gearbox. Typically this type of equipment is located at a specialized welding station.

Tig welding process diagram

Argon is one of the main gases used in metal welding to protect the welding zone from harmful environmental influences.

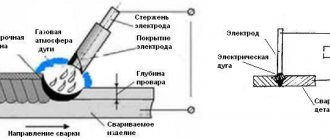

Welding in an argon environment is called argon arc welding in the technical literature. In colloquial language there are also such terms as: welding in argon, argon welding, argon welding, argon welding, etc. Welding in an argon environment can be carried out with both consumable and non-consumable electrodes. A tungsten, carbon or graphite electrode is used as a non-consumable electrode. The essence of the welding process in an argon environment is shown in the figure.

1 - electrode; 2 - filler rod; 3 - product; 4 - weld; 5 - electric arc; 6—shielding gas flow; 7 - welding torch; 8 - air.

Stages of argon welding

Argon welding includes several stages. With the TIG process we can distinguish:

- cleaning from dirt, cleaning with a stiff wire brush and degreasing welding. The cleaner it is, the less oxides will form;

- turning on the welding machine;

- opening the argon cylinder reducer;

- switching on 20 seconds before gas supply. This is necessary to remove atmospheric oxygen from the working area;

- arc ignition. During operation, do not touch the part with the electrode - this can lead to the disappearance of the arc and a poor-quality weld;

- guiding the burner along the connection line;

- constant and uniform introduction of the filler rod into the arc zone with the other hand. This stage is the most difficult for novice welders. When the additive is introduced jerkily, the metal spatters, creating areas of lack of penetration and an uneven weld line. Uniformity can only be achieved through practice;

- the need to supply argon within 10-15 seconds after completion of welding work. If this is not done, the melt will react with atmospheric oxygen, oxide films will form, and the quality of the weld will deteriorate.

Argon grades used in welding

According to GOST 10157, there are three grades of argon used for welding, see table:

Compound

| Argon grade | |||

| A | B | IN | |

| Argon, % not less | 99,99 | 99,96 | 99,90 |

| Oxygen, % not less | 0,003 | 0,005 | 0,005 |

| Nitrogen, % not less | 0,01 | 0,04 | 0,1 |

| Moisture at р=760mm Hg. mt., no more | 0,03 | 0,03 | 0,03 |

Diagram of a mechanized welding station in argon with a consumable electrode

1 — ballast rheostat; 2 - contactor; 3 - welding torch; 4 - mechanism for feeding electrode wire; 5 — rotameter (device for monitoring gas flow); 6 - gearbox; 7 — gas cylinder; G - welding generator; A - ammeter; V - voltmeter; Sh - shunt.

Scheme of manual argon arc welding

Manual arc welding in an argon environment can be performed with direct and alternating current. Welding schemes with direct and alternating current are shown in the figures:

Manual DC welding diagram

1 - welding torch; 2 — cylinder with protective gas (argon); 3 - rheostat; 4 - generator; 5—weld seam.

Manual AC welding diagram

1 — cylinder with protective gas (argon); 2 - welding torch; 3 - weld; 4 - oscillator; 5 - transformer with regulator.

Automatic welding

Automatic equipment works the same as manual equipment. But control is carried out through a given program. The function of a specialist is to choose the right materials and mode, and then monitor the result.

The advantages of automatic welding include:

- increased speed, productivity, especially if identical parts are created;

- reliability and attractive appearance of seams;

- reducing the risk of specialist error.

However, the method also has negative sides:

- in the course of sequential work with different parts and modes, it is necessary to reconfigure the equipment each time;

- the device will cost more than a manual one;

- Massive defects of workpieces are possible if the failure was not noticed in time.

Advantages and disadvantages of argon arc welding

In general, it is impossible to recommend the use of any one gas for welding (argon, helium, nitrogen, etc.). The use of a particular gas depends on the welding technology of a particular metal or alloy, or on the basis of technical and economic indicators. But in general, argon arc welding has a number of advantages compared to welding in other gases:

1. Argon, like helium, is an inert gas that does not interact with any metals or other gases and does not dissolve in molten metal.

2. Argon is heavier than air and therefore reliably protects the welding zone, displacing air from it. The arc in an argon environment is highly stable.

3. Argon is a fairly common gas compared to other inert gases, in particular helium. Its content in the air is about 0.9%, and therefore argon is the cheapest of the inert gases.

4. Another advantage of argon (over helium) is that argon consumption is 30-35% less than helium consumption (all other things being equal) due to the fact that argon is 10 times heavier than helium.

Due to its advantages, welding in argon has become quite widespread when welding various materials. But argon arc welding also has its disadvantages. Manual welding in argon is difficult. When manual argon arc welding, it is not recommended to perform oscillatory movements with the electrode due to a possible violation of the protection of the welding zone. In this regard, the productivity of manual welding in an argon environment is low. But automatic welding is not possible in all cases.

Description of technology

A special feature of this technology is that welding occurs in an environment of protective inert gas argon. This improves the quality of the metal connection and provides the highest possible protection against oxidation. Argon is supplied to the burner under high pressure and, completely blocking the working area, does not allow oxygen to penetrate into the metals being joined, preventing the formation of rust.

If previously this technology was available only to professionals, today, with the advent of relatively simple and universal-to-use welding machines, anyone can perform such work.

Depending on the characteristics of the metals and equipment being connected, two types of electrodes are used: non-consumable and consumable.

Of the non-melting materials, the most widely used technology is the use of tungsten wire, which makes it possible to obtain strong connections between two dissimilar metals. But consumable electrodes can be used in manual and semi-automatic welding, when metals that are identical or similar in their refractoriness characteristics are joined.

Features of welding in argon environment

A characteristic feature of argon arc welding with a non-consumable tungsten electrode when using alternating current is the appearance of a direct current component in the welding circuit, the value of which can reach 50% of the effective value of the alternating current of the welding circuit.

Current rectification, i.e. the appearance of the direct current component depends on the shape and size of the tungsten electrode, the material being welded and the selected welding modes (current strength, welding speed and welding arc length). The appearance of a direct current component in the welding circuit has a negative effect. This effect is especially pronounced when welding aluminum and alloys based on it.

If the direct current component is excessive, the stability of the arc decreases and the surface quality of the deposited metal decreases. Defects form in the weld (undercuts, scaliness), and the strength and ductility of the weld decreases.

How to choose the right mode

The quality of your work depends on the correct choice of electrode thickness and current strength. Remember: the thicker the metal being connected, the larger the diameter of the tungsten electrodes used, and accordingly, the higher the current. In the operating instructions that come with the device, you can find all the data on the current strength and diameter of the electrodes, depending on the thickness of the parts being connected.

The most popular today are AMA and RAD welding. But professionals who need to perform a large amount of work use powerful, fully automatic units.

Manual argon arc welding technique

In manual argon arc welding, the tungsten electrode is sharpened to a cone on one side. The sharpening length is two to three times the diameter of the electrode.

An electric arc is ignited on a special carbon plate. It is not recommended to strike an arc on the base metal due to the possibility of contamination and melting of the end of the electrode.

To excite the arc, you can use a power source with a higher open circuit voltage or an additional power source with a high voltage (oscillator), because the excitation potential and ionization of inert gases is much higher than that of oxygen, nitrogen and metal vapors. The arc discharge of inert gases is highly stable.

To protect the weld metal from oxidation from the root side, on the reverse side, it is recommended to provide the injection of protective gases. When welding pipelines, shielding gas is purged inside the pipe.

Manual arc welding, as we have already said above in the text, is performed without sudden, oscillatory movements of the electrode due to a possible violation of the gas protection. The welding torch is positioned at an angle of 75-80° to the product being welded (see figure on the left). The filler wire is positioned at an angle of 90° relative to the axis of the torch nozzle. In this case, the angle between the welded product and the wire is 15-20°. Welding is performed at an angle forward.

Recommendations

With a long welding arc, a wide seam is formed with a small penetration depth. This may cause the connection to deteriorate. In this case, it is recommended to keep the non-consumable electrode used as close as possible to the joints of the parts being welded.

To make deep and narrow seams, the longitudinal movement of the torch and electrode must be maintained. In this case, lateral movements should be avoided.

The non-consumable electrode and filler wire must be in the welding zone and completely covered with argon. This will protect the weld from exposure to nitrogen and oxygen.

The filler wire is fed evenly and smoothly, since fast and sharp wire feeding will lead to metal spattering, which will affect the quality of the weld.

The presence of a convex or rounded shape in the weld indicates that the connection was not made properly. In this case, surface penetration is not enough.

The filler wire should be fed in front of the torch, while holding it at a slight angle, which will ensure a minimum weld width and excellent metal penetration.

It is not recommended to stop the supply of inert gas immediately after welding is completed, as the anti-corrosion protection of the joint may be affected.

The joints of the parts to be connected should be degreased and cleaned before starting work.

Scope of welding with argon protection

Argon welding can be used to weld a variety of materials. It can be used for welding steels (carbon and alloy), for welding non-ferrous metals (copper, aluminum, titanium, nickel and their alloys), and for welding pipelines. Argon arc welding can be used to make all types of welded joints: butt, T, lap, corner.

Welding in argon can be successfully used both when welding small parts and when welding large-sized products, both in domestic conditions and in production and during construction and installation work.

In some cases, the use of a mixture of gases instead of technically pure argon increases the stability of the welding arc, reduces metal spatter, improves the formation of the weld, increases the penetration depth, and also affects metal transfer and increases welding productivity.

Safety precautions

When working with liquefied gases, you must follow safety rules. They are described in detail in GOST 12.3.003-86. Despite the fact that the approved safety precautions apply to industrial facilities, these rules should also be followed at home.

Basic GOST requirements when working with argon:

- Do not work near flammable substances;

- you need to remove all extraneous things;

- it is necessary to organize constant ventilation to quickly remove combustion products;

- equipment must be in good working order, materials must be certified;

- You cannot start work without prior instruction and obtaining basic theoretical knowledge;

- The welder must use a mask or safety glasses, preferably chameleon glasses.