Specialists who often use lathe cutters when performing metal work, as well as those who sell these products or supply machine-building enterprises, are well aware of the types of these tools. For those who rarely come across turning tools in their practice, it is quite difficult to understand their types, which are presented in a wide variety on the modern market.

Types of turning tools for metal processing

Lathe cutter design

In the design of any cutter used for turning, two main elements can be distinguished:

- holder with which the tool is fixed on the machine;

- a working head through which metal processing is performed.

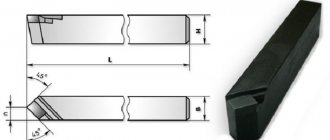

The working head of the tool is formed by several planes, as well as cutting edges, the sharpening angle of which depends on the characteristics of the workpiece material and the type of processing. The cutter holder can be made in two versions of its cross section: square and rectangle.

Cutter design

According to their design, turning cutters are divided into the following types:

- straight - tools in which the holder together with their working head are located on one axis, or on two, but parallel to each other;

- curved cutters - if you look at such a tool from the side, you can clearly see that its holder is curved;

- bent - the bend of the working head of such tools in relation to the axis of the holder is noticeable if you look at them from above;

- drawn - with such cutters the width of the working head is less than the width of the holder. The axis of the working head of such a cutter can coincide with the axis of the holder or be offset relative to it.

Types of cutters by design

Types of cutter wear

The cutting tool wears out during use.

- Wear on the rake edge occurs due to friction of the chips on the tool surface. As a result, a depression is formed on the edge, located behind the build-up of the stagnation zone (1–2 mm from the edge).

- Flank wear occurs due to its friction against the machined surface. As a result, a wear area appears on the edge.

Typically, the front edge wears during roughing, and the back edge wears during finishing.

There are several stages of tool wear:

- running-in;

- steady wear;

- critical wear.

We recommend not bringing the cutter to the last stage, as this leads to its destruction and shortening its service life. Sharpening will allow the tool to return to its original geometry.

Classification of cutters for turning

The classification of turning tools is regulated by the requirements of the relevant GOST. According to the provisions of this document, cutters are classified into one of the following categories:

- one-piece tool made entirely of alloy steel. There are also cutters that are made entirely of tool steel, but they are used extremely rarely;

- cutters, onto the working part of which a plate made of hard alloy is soldered. Instruments of this type are most widespread;

- cutters with removable carbide plates, which are attached to their working head using special screws or clamps. Cutters of this type are used much less frequently compared to instruments of other categories.

Basic concepts regarding the operation of a turning tool and its main angles (click to enlarge)

The cutters also differ in the direction in which the feeding movement occurs. Yes, there are:

- left-hand turning tools - during processing they are fed from left to right. If you place your left hand on top of such an incisor, then its cutting edge will be located on the side of the bent thumb;

- right incisors - the type of tool that has become most widespread, the feed of which is carried out from right to left. To identify such a cutter, you need to place your right hand on it - its cutting edge will be located, accordingly, on the side of the bent thumb.

Difference between left and right incisors

Depending on what work is performed on turning equipment, cutters are divided into the following types:

- for finishing metal work;

- for rough work, which is also called roughing;

- for semi-finishing work;

- for performing delicate technological operations.

Human incisor anatomy – information:

The incisors, dentes incisivi , four on each jaw, have a crown shaped like cutting chisels that cut food into inappropriate sizes. The crown of the upper incisors is wide, the lower ones are twice as narrow. The root is single, compressed from the sides of the lower incisors. The root apex is deviated somewhat laterally. The upper medial incisor is the largest of the group of incisors. The labial surface of its crown is convex in the transverse and longitudinal directions. It has 3 small longitudinal ridges, each of which ends at the chewing edge with a clove. On both sides of the median ridge there is one longitudinal depression. The lingual surface of the crown is concave in the longitudinal and transverse directions. In the cervical region it has a tubercle, tuberculum dentale, from which ridges extend along the distal and mesial edge of the lingual surface to the chewing edge of the tooth.

Of the 3 signs of a tooth, the sign of crown curvature is the most pronounced. The root is conical and longer than the crown; the lateral grooves on it are weakly expressed. It has 3 surfaces: labial and two approximal. The upper lateral incisor is smaller than the medial incisor, from which it differs in the following features: on the labial surface of the crown there is often a median longitudinal groove, on both sides of which there is one small tuberculate prominence on the cutting edge of unworn teeth. On the lingual surface, the lateral ridges are usually better defined than those of the medial incisors. Often on this surface there is a depression located occlusally (below) from the dental tubercle.

The mesial surface is longer than the distal one and meets the cutting edge almost at a right angle, while the distal surface forms a significant rounding. The sign of the crown angle is well expressed. The root is shorter than that of the medial incisor, compressed in the mesiodistal direction; in most cases it is straight and has lateral grooves.

Its distal surface is more convex than the mesial one. Medial and lateral lower incisors. The lower incisors are the smallest in both jaws. In this case, the medial incisor is smaller than its distal neighbor. Both teeth have characteristics characteristic of all incisors. Their crown has the most typical chisel shape. On the front surface it is slightly convex in the longitudinal direction and flattened in the transverse direction, on the rear surface it is concave in the longitudinal direction and flattened in the transverse direction. The ridges are weakly expressed and sometimes absent. The root is significantly flattened. The medial incisor has no signs of angle or root curvature. To distinguish the right medial incisor from the left, a better defined lateral longitudinal groove on the root is important. The lateral incisor has a wider crown than the medial one, and the root is more massive. At the same time, this tooth has quite clearly expressed signs of angle and root and weakly - curvature.

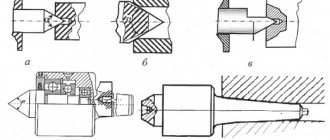

Prefabricated cutters for lathes

Considering the main types of turning tools, one cannot fail to mention tools with a prefabricated structure, which are considered universal, since they can be equipped with cutting inserts for various purposes. For example, by attaching cutting inserts of various types to one holder, you can obtain cutters for processing metal workpieces at different angles on a lathe.

Prefabricated cutters

As a rule, such cutters are used on CNC machines or on special machines and are used for contour turning, boring blind and through holes and other specialized work.

The classification of cutters for turning also includes slotted, shaped and some other types. You can understand the operating principle of such tools by reading the table at the beginning of the article.

Functions and structure of incisors

As already mentioned, the name of this type of teeth comes from the functions they perform:

- Grasping food: used for biting.

- Cutting: perform the function of crumbling and cutting pieces, as well as primary grinding in the first phase of chewing.

All teeth are located in the dental alveoli of the jaws. They consist of identical tissues and differ only in structure, location and quantity.

The incisor consists of three parts: the root (the hidden part), the neck (covered by the gum) and the crown - the part visible to the eye.

The crown has several surfaces:

- lingual (addressed to the tongue);

- vestibular or facial (facing the vestibule of the oral cavity);

- contact (facing the adjacent tooth);

- chewing (the surfaces of the lower and upper teeth face each other).

Now let's look at the inside of the root and crown.

The framework of the tooth is hard dentin, which is yellow in color. On top, dentin is covered with enamel, and near the root - with cement (which is bone tissue), near the neck - with thinned cement, which does not contain cells.

Inside the dentin there is a cavity in which the pulp is located. It consists of connective tissue and has many vessels and nerves.

Feeding vessels enter from the main artery into the root apex. An artery and nerve enter the cavity through the root hole, and a vein exits.

The crown cavity is filled with the root canal and root hole.

The pulp performs a protective function and, in case of any violations, signals this through the nerve endings located in it. The soft pulp is located along the entire tooth, starting from the root, then to the root canal and fills the space of the crown cavity.

Enamel is the strongest tissue in the human body and consists of inorganic substances. Its strength is comparable to that of diamond. It is enamel that makes our smile sparkling white.

Each individual tooth is held in the jawbone by the so-called periodontal ligament. It looks like a layer between the root and the jaw bone and has an elastic structure that allows the tooth to move when chewed. The periodontium communicates with the bone marrow of the jaw.

Not to be confused with the word periodontium. Periodontium is the gums, periodontium, cementum, alveolar processes.

Sequence of tooth formation in humans

The first teeth erupt by 6-7 months from birth - first 2 upper incisors, then 2 front ones. By the first year of life, the remaining 4 incisors appear. By the age of one and a half years, the child’s lower canines erupt, then the upper ones. Chewing teeth grow from the 20th to the 30th months of life, and by the age of 3 the child should have all 20 primary teeth.

Permanent teeth appear at 6-7 years of age. These are large molars - 2 on the lower and then on the upper jaw. Then the primary incisors are replaced by permanent ones, and at the age of 9 permanent lower canines and small chewing teeth appear. At 11-12 years old, the maxillary canines change and at the same time second molars grow on both jaws.

“Wisdom teeth” erupt in different ways: in the period from 18 to 25 years, and even later. The appearance of only two of them and even their complete absence is considered normal. The last teeth are difficult to care for, which contributes to the development of caries in them. Often they erupt with damage.