Due to their high reliability and simplicity, threaded connections are widely used in various building structures, machines and mechanisms. Since the basic geometric parameters of threads are generally accepted, it is enough to have a small set of standard tools to create new connections and repair worn units.

Internal thread

The internal thread is cut into the hole using taps (1). They are metal rods with hardened teeth. Manufactured from tool or high-speed steel.

Types of taps

Taps are distinguished by purpose. They can be used for cutting metric, inch, tapered, pipe, and trapezoidal threads. According to the relevant technical specifications, as well as GOST 3266-81, the table shows the limits of applicability of this tool.

| Thread name | Nominal diameters |

| Metric | 1 - 52 mm |

| Inch | 1/4” - 2” (inches) |

| Conical | 1/16” — 2” |

| Pipe | 1/16” — 6” |

| Trapezoidal | 5.6 - 90 mm |

Taps for cutting metric and inch threads are manufactured in sets. The set can consist of either two, finishing and roughing, or three - roughing, medium and finishing taps. The roughing tap is designed to remove the bulk of the chips. Finishing is used for the final, precise shaping of the thread profile and calibration.

To identify the tap in the kit, its tail part is marked with one, two or three ring marks. It is also possible to designate using a number: I – rough, II – medium, III – finishing.

Nut taps are designed to cut threads in one pass. They are single-set, that is, sold individually.

To rotate the taps, use knobs (2). They can be non-adjustable with square holes for a fixed size shank, or adjustable. In addition, there are wrenches with a ratchet mechanism, providing ease of work in hard-to-reach places.

Cutting a thread on a pipe

You don't have to remove the old paint. We lubricate the place where the thread will be with solid or liquid lubricant: grease, lithol, engine oil.

We also coat the cutters on the die.

In neither case do you need to apply a lot of solid lubricant, since after cutting the chips will stick to it and will not fall down, and therefore be removed. We put the guide clamp on the pipe.

In theory, the clamp is rotated with a specialized tool - a ratchet, but since we have a one-time job, it will not be profitable to purchase an expensive tool. We take an adjustable wrench and adjust its size to the rear skirt of the clamp. Rotate the tool, making several turns around the pipe. The cutters are now engaged.

If the pipe is flimsy and unstable, it needs to be held with another adjustable wrench like this:

And use another adjustable wrench to rotate the nozzle. The cutting sequence is as follows: 2-3 turns of the die forward, 1 turn back. This must be done so that the chips break, fall off and do not interfere with further cutting. If this is neglected, chips can jam the threads.

In total, you need to cut 4-5 full turns of thread.

As a result, the thread on the pipe is cut.

Also keep in mind that the cutters in the die have a small cone. This is necessary so that you can start and cut threads with ease. As a result, I lead to the fact that the final turns may not be complete and not cut in depth. Therefore, in order to get 3-4 full turns of thread on a pipe, it is visually better to cut 6-7 turns. After all the work, the thread can be checked by screwing any adapter or fitting onto it.

The thicker the pipe, the greater the force required to rotate the nozzle. The method is not tricky, almost no proper skills are required, even a beginner can do it. It is impossible to skew the thread, so there is no need to be afraid.

External thread

The external thread is manually cut into dies (5) and plugs (4). The die is a round nut made of high-speed or high-hardness tool steel. In order to remove chips, special holes are provided in it. The dies are either solid or split.

Split dies have a slot up to 1.5 mm in size. Thanks to this, they allow you to adjust the diameter of the cut thread within 0.1-0.3 mm. Their disadvantage is less accuracy, so using such a tool in critical connections is not recommended. The diameters of the dies are presented in the table.

| Thread name | Nominal diameters |

| Metric | 1 - 76 mm |

| Inch | 1/4” - 2” (inches) |

| Pipe | 1/8” — 2” |

The rotation of the dies is carried out using die holders (3) and ratchets. These devices typically allow multiple cutting tool sizes, such as M16 - M20, 1/2" - 1". Ratchets are used for cutting pipe threads with dies in hard-to-reach places, for example, near a wall.

The dies are designed for cutting external pipe threads with a diameter of 1/2" - 3". Thanks to their design, they are securely fixed to the pipe, which ensures ease of operation, as well as high quality threaded connections. Clupps are usually equipped with replaceable cutters or heads. This significantly increases their service life. Depending on the design, both removable handles and ratchet holders can be used to rotate hand clamps.

Drawing

What are the threads used for cutting?The main methods for creating threads are as follows: 1 - cutting with thread cutters or thread dies; 2 - cutting with dies, threading heads and taps; 3 - rolling using flat or round rolling dies; 4 — milling using special thread cutters; 5 - grinding with abrasive wheels.

Thread cutting with cutters. Using thread cutters and combs on screw-cutting lathes, both external and internal threads are cut (internal threads, starting with a diameter of 12 mm and above).

The method of cutting threads with cutters is characterized by relatively low productivity, so at present it is used mainly in small-scale and individual production, as well as in the creation of precision screws, gauges, lead screws, etc. The advantage of this method is the simplicity of the cutting tool and relatively high accuracy the resulting thread. Schematically, it is as follows (Fig. 32): with simultaneous rotational movement of the part on which the thread is being cut and the translational movement of the cutter (on a lathe - II), the latter removes (cuts out) part of the surface of the part in the form of a helix (I).

Rice. 32

Thread cutting with dies and taps . In Fig. 33 shows the dies, which, according to their design features, are divided into round ones - I and II (lerks) and sliding ones - III (cloud ones).

Round dies, used in installation, procurement and other work, are designed for cutting external threads with a diameter of up to 52 mm in one pass. For larger threads, dies of a special design are used, which actually serve only to clean the thread after preliminary cutting it with other tools.

Sliding dies consist of two halves that are inserted into the die and gradually move closer together during the cutting process.

Rice. 33

When cutting threads on metal-cutting machines (II), the die is installed and secured in a special chuck or fixture (Fig. 34). The part is fed into the calibrating part of the rotating die. In the vast majority of cases, internal fastening threads are cut with taps.

The tap (Fig. 35) is a threaded steel rod divided by longitudinal straight or helical grooves that form cutting edges. These same grooves serve to release chips. According to the method of application, taps are divided into manual and machine.

Rice. 35

The sequence for obtaining threads in blind holes is as follows (Fig. 36): first, drill a socket into which a pin or screw will later be screwed. The drill diameter must be selected from the table. values recommended by GOST 9150-81 standard. The thread is cut with a set of two or three taps (small, medium and normal, fine) depending on the size of the thread. It is impossible to cut a thread with one tap (normal) in one go. This leads to breakage of the tap.

For metric threads with a large pitch and inch threads, the set consists of three taps, for metric threads with a fine pitch and pipe threads - of two.

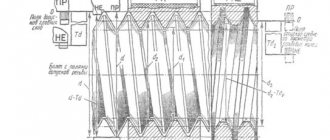

Thread rolling . The main industrial method of thread production at present is rolling on special thread rolling machines having a three-roller head housing 1, a roller holder 2 and a rolling roller 3 (Fig. 37). Part 4 is clamped in a caliper vice. In this case, high productivity ensures high quality of the product (shape, size and surface roughness).

The thread rolling process involves creating a thread on the surface of a part without removing chips due to plastic deformation of the surface of the workpiece. Schematically it looks like this. The part is rolled between two flat dies (Fig. 38. I) or cylindrical rollers (Fig. 38. II, III) having a threaded profile, and a thread of the same profile is extruded onto the rod. The largest diameter of the rolled thread is 25 mm, the smallest is 1 mm; length of rolled thread 60...80 mm.

Rice. 36

Rice. 37

Thread milling. Milling of external and internal threads is carried out on special thread milling machines. In this case, a rotating comb cutter, when fed radially, cuts into the body of the part and mills threads on its surface. Periodically, an axial movement of the part or cutter occurs from a special copier by an amount equal to the thread pitch during one revolution of the part (Fig. 39).

Grinding precision threads. Grinding as a method of creating threads is used mainly to obtain precise threads on relatively short threaded parts, for example, threaded plugs - gauges, threaded rollers, etc.

Rice. 38

Rice. 39

Rice. 40

The essence of the process is that the grinding wheel, located to the part at an angle of the lifting thread, with fast rotation and simultaneous slow rotation of the part with feed along the axis by the value of the thread pitch in one revolution, cuts out (grinds) part of the surface of the part. Depending on the design of the machine and a number of other factors, the thread is ground in two to four or more passes (Fig. 40).

Threading

Now that we've sorted out the tools themselves, let's move on to the question of how to use them correctly.

Almost anyone can cope with such tasks, but there are several details and nuances in the work that you should pay close attention to.

The standard stages of work differ little from each other, and it does not matter whether you use dies or taps. In any case, it is necessary:

- Prepare and assemble the instrument.

- Lubricate parts and work area.

- Perform a rough pass.

- Check the quality of the thread.

- Perform a finishing pass.

- Perform final check.

There are also nuances that we will now pay attention to.

How to restore a thread with a tap

Before restoring a thread with a tap, determine whether it is possible to increase its diameter or cut a new one in a different location. If yes, then the repair will take place very quickly.

Photo: tapping a thread

When working, observe the following basic rules.

Drill the hole strictly at a right angle

Use two new taps of the required diameter (for roughing and finishing).

Be careful when cutting threads. Avoid distortions and sudden movements.

It is advisable to cut the thread using a wrench. If you don't have one, take an adjustable wrench.

Remember to use lubricant and remove chips regularly.

Using Epoxy Glue

This method is not suitable for restoring and strengthening connections subject to high loads and vibrations. There is also no point in using epoxy glue if components and structures operate at high temperatures.

Photo: epoxy glue for thread restoration

If there is no need to ensure high connection reliability, proceed this way.

Welding the hole and then cutting a new thread

This method is rarely used due to the fact that the strength of the new thread obtained using this technology will be lower. This method is also chosen in the absence of special devices (screws and spiral inserts).

READ How to Disassemble a Bosch Gbh 2 24 Rotary Hammer

This method of thread restoration includes the following steps.

Removing old threads by drilling.

Welding the hole. The choice of technologies depends on the materials of the parts.

How to thread a bolt without a tool.

To weld holes in steel products, electric arc or gas welding is used in protective environments.

When working with cast iron parts, gas or electric arc welding is used in a cold state or with general/local heating.

Electrodes (MNCh-1, OZCh-1, TsCh-1), cast iron rods with increased m silicon and other materials are used as additives.

Machining the hole flush with the base metal.

Note! When working with aluminum products, this method of thread restoration is usually not used. This is due to the fact that the metal actively absorbs gases during welding. Pores form in the deposited layers. With severe shrinkage, cracks appear.

How to restore a thread with and without a tap

How to restore a thread with and without a tap

You can restore damaged internal threads with or without a tap in various ways. We will talk about them in detail in this article.

Repairing threads using a spiral insert

Spiral (also called wire and spring) inserts are also often used to restore damaged threads.

Photo: spiral inserts for thread restoration

These devices have high-precision rhombic threaded profiles on the inside. Almost all models are equipped with special driving tongues designed for screwing in devices.

For the manufacture of such products, especially durable high-quality stainless steel is used. This guarantees the resistance of the restored thread to deformation and corrosion.

Restoring threads using a spiral insert includes 4 stages.

Drilling. Drill out the hole. Select the diameter of the cutting tool according to the table that manufacturers provide with spiral inserts.

Image: Drilling out a hole for a spiral insert

Thread formation. Note! To cut threads, use special taps that differ from standard ones and come with spiral inserts. Follow all rules and recommendations.

Image: Forming a thread for a spiral insert

Installation of the device. Place the spiral insert onto the supplied special tool and screw it into the hole.

Image: Screwing the spiral insert into the hole

Removing the drive tongue. You can get rid of it using a special tool (manufacturers also supply it). To remove tabs from large-diameter inserts, ordinary pliers are suitable.

Using professional spiral thread inserts has the following advantages.

The required tension is ensured at the insert landing site. This completely prevents twisting. The devices are located in the receiving threads with virtually no gaps. There is no need to use glue for additional fixation of products.

Due to the elasticity of the inserts, loads and stresses are distributed evenly. This creates ideal conditions for the transfer of forces between the bolts and the receiving threads.

Spiral inserts are universal. They are used not only to restore threads, but also when it is necessary to strengthen connections. Spiral inserts are used when working with products made of low-medium and high-strength metals, as well as plastic and wood.

Selecting a workpiece for thread cutting

The diameter of the threading rod or hole is not equal to the nominal value of the finished product. When cutting external threads, select a rod having a diameter several hundredths of a millimeter smaller than the thickness of the finished product. This is due to the fact that when removing chips, the metal is partially squeezed out, completely filling the threaded profile of the die. For cutting internal threads, the hole is also made with a small allowance to the smaller side. The exact diameters of workpieces for cutting metric threads are specified in GOST 19257-73.

READ How to cut trapezoidal threads on a lathe

If drills of the appropriate size are used to drill holes with an inaccurate diameter, then finding a rod suitable for cutting external threads is quite problematic. This problem can be solved by preliminary grinding of a rod of standard thickness. To do this, the product is clamped into a drill chuck and treated with sandpaper evenly along its entire length, periodically taking measurements with a caliper.