When installing a new sewer system or replacing old pipes, you should know how to cut threads on a pipe, as this will simplify the selection of the necessary plumbing fixtures and the pipes themselves. Let's get acquainted with the types of thread, for what purpose it is needed, the main ways in which its size can be determined, and also what tool can be used to make it. We will also consider the process of slicing manually or using automatic devices.

Threaded pipe Source static.tildacdn.com

What is a thread and why is it needed?

Threading is one of the most popular types of fastening parts or mounting structures. It is used to connect several parts, such as pipes, into one structure. To do this, grooves are cut out on their side or inner part, which have a certain shape, angle of inclination and distance between the recesses (turn pitch).

Also, the notch can be on connecting parts, for example, taps or tees. Using this installation method, you can make collapsible or permanent structures, such as water supply, sewerage and other types of pipe systems. You can cut threads only on round or conical parts, since for other surfaces it will be inconvenient and impractical.

The most common thread profile option is triangular. It is very simple and affordable, but is not suitable for frequent system disassembly. If you need to frequently disconnect pipes or other parts, a round profile is used. It is most often used in plumbing. Other types of profiles are used in kinematic systems (for example, transmissions), but are not used in plumbing.

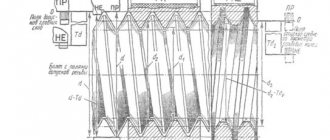

A type of kinematic cutting Source findpatent.ru

Main reasons for marriage

The cause of defects in work is the inattention of the worker or the use of low-quality tools. Common pipe cutting defects when working with a tap or die:

- Torn threads - a problem occurs when using a dull die, untimely removal of chips, or insufficient lubrication.

- Incomplete thread - the diameter of the thread hole exceeds the recommended one.

- Skewed helical grooves – incorrect installation of the die or tap.

- Thread failure is caused by clogging of the grooves with chips, poor quality of the tool, or the pipe diameter is larger than specified.

- Tap failure - excessive force applied in a narrow hole, insufficient chip removal, lack of lubrication.

Self-preparation of parts for threaded connections is quite accessible if you have the tools. In order for the work to be done efficiently, you must follow the rules. The use of sharp tools and accuracy compensate for the lack of professional skills.

Types of thread

Thread cutting greatly depends on the surface on which it will be turned and for what purposes it will be used. For example, a conical one is good for sealing a joint, but it is difficult to make. There are 2 types of thread direction: right and left. The first one is the most common. It can be seen on bolts, screws, pipes and other connection elements. To screw a part onto such a notch, you need to turn it clockwise, and for the left - in the opposite direction.

Also, the thread can be single-start or consist of several parallel threads. In such connections, in addition to the pitch (P), the Ph parameter is used, which shows the distance between the grooves that are cut in one go. This is necessary in order to understand whether another turn will fit between the adjacent notches. You can see what thread cutting on pipes with several turns looks like in the picture below.

Example of the distance between turns Source https://ng.sibstrin.ru/wolchin/umm/in_graph/ig/004/000.files/102.jpg

There are several types of threads that perform different functions and are suitable for specific tasks:

- Metric (M) is its most common type in everyday life, but is completely unsuitable for pipes, since it is not standard. When cutting such a notch on a pipe yourself, problems may arise with the installation of additional modules or connection with a standard product due to a mismatch in pitch, angle and profile. The metric notch has a triangular profile with an angle of 60°, and the pitch is from 0.5 to 2 mm. The dimensions of the thread in the marking indicate its outer diameter, for example, M10 is 10 mm.

Metric notch Source upload.wikimedia.org

- Cylindrical (G) - referred to as BSPP and was invented in Britain. Because of this, all measurements for its standardization are carried out in inches, which is why it received the corresponding name. This notch is used in more than 90-95% of all systems that are connected to pipes and it is cut on all fittings that are used in plumbing, common in our market. The size marking of such a thread shows the diameter of its nominal bore, not the outer circle, and can range from 1/16 to 6 inches. This notch has rounded cuts at the tops and a profile angle of 55°.

Video description

This video shows how to make inch cutting with a die and die:

- Conical (R) - designated as BSPT and also has British roots. It has a pitch and profile angle similar to cylindrical threads. It is used for cutting notches into cone-shaped parts. In some cases, it is possible to connect parts with R and G notches. By creating additional tension on the turns during the joining process, the conical notch provides additional reliability of the docking units.

- Round (R) is a very rare type of pipe connection, which is used in places where it is necessary to frequently assemble and disassemble the joint. Even after frequent dismantling, such a mount does not lose its shape, reliability and tightness. The disadvantage of such a thread is that it cannot be combined with other types of notches. The round variety has a profile in the form of a circular arc with an angle of 30°.

There is an American standard for conical and cylindrical parts, which is labeled NPSM or NPTF. It has an angle not of 55°, but of 60°, similar to the metric one. This type of thread has its own thread size and profile height, but is found almost nowhere, since it is being replaced on the market by the British standard.

Example of American NPSM Source www.staniosind.com

See also: Catalog of companies that specialize in the installation of utilities: water supply, sewerage and heating

Tools

There are different pipe threading tools that can make notches inside or outside the structure:

- A tap is a device for cutting internal threads. In appearance, it resembles a rod or drill on the outer surface of which there are notches and grooves applied in order to retract the handle. Taps are used for cutting or calibrating threads. Most often, their working part consists of 3 sections, which perform the functions of rough, intermediate and final cutting. Some manufacturers make a set consisting of 2-5 taps, which perform the notching separately. The tap can also be made for manual cutting or for processing parts on a machine. They are most often used for cutting metric threads, but there are varieties for cutting internal notches for pipe standards.

Set of different taps Source prosto-instrumenty.ru

Video description

This video shows the features of thread cutting with a die:

- A clamp is a device for cutting threads in hard-to-reach places. In appearance, it resembles a wrench, but instead of attachments for bolts, it has a hole for attaching replaceable cutters. The principle of operation of the clamp is similar to a die, only instead of a whole washer it uses its cutting edge, and for turning it uses a mechanism similar to a wrench. There are devices that, instead of a solid body, use adjustable or open-end wrenches for turning. Such a device will cost less than a solid socket with a ratchet, but when using them you can get injured, since the key sometimes jumps off.

Example of a die with different heads Source otk-instrument.ru

How to cut threads

Before cutting a thread, you should decide on its size, pitch and standard used. If you need to make a cut on a part that should fit an already finished element, then it is recommended to first understand its dimensions. To do this, look for the appropriate marking next to the finished thread.

If it is not there, then for measurement you can use a caliper or a special set with templates for notches of different standards. You can also use marked plumbing fixtures for this if there are no other options. With its help you can understand the diameter of the pipe.

To determine the notch pitch, you can mark 10 turns with a marker, measure the length of the entire section and divide it by 10. The resulting number will be the pitch. The thread cutting tool should also be selected based on the diameter of the pipe and the pitch of the notch on the part with which the connection is required.

Before working with dies or dies, you should clean the surface of the pipe on which the notch will be made using a file, sandpaper or a grinder with a grinding wheel. The end part of the part also needs to be turned and an entrance chamfer made on it to start working.

Example of an entrance chamfer Source upload.ecvv.com

Grooving machine

The configuration is possible in different modifications, it all depends on the manufacturer. However, the essence of all machines is the same - they are used to cut threads on an industrial scale. The advantages include:

There is a function for programming diameter and pitch parameters with automatic reverse.

There is a chip removal mode. The kit includes a set of cartridges. Setting the speed of the rotating mechanism. Great time savings for the process. Full use of the machine's capabilities. Increased wear resistance. Compressing the material with a knurling roller ensures a clean surface. Increased strength by 10-30 percent compared to mechanical processing.

Video description

This video shows how to cut an internal thread using a machine and a tap:

Tapping with an electric die is similar to the conventional process, but this tool requires more space and additional fixation to operate. Its advantage is that the labor intensity of the process for the mechanic is reduced. For any type of cutting, it is recommended to add lubricant during operation to the places where the cutting edge is located.

Thread cutting can also be done using a lathe. This type of work is most often used for large volumes of production. Using such a device, you can make both external and internal threads, but you need a trained specialist to work with them. Without proper knowledge, operating the machine can cause injury.

Example of plumbing fittings with thread Source static-eu.insales.ru

Gutter cutting machine

Special machines are often used in production. In terms of design features, they are in many ways reminiscent of vertically oriented machines. Among the features we note:

- The diameter and thread pitch are adjustable.

- If necessary, you can carefully adjust the number and speed of rotation of the cutting element.

- Almost all models are characterized by the ability to process external and internal surfaces.

Modern machines can be used even when cutting thin-walled products. Difficulties can only arise if the workpiece cannot be removed and installed vertically.

Briefly about the main thing

Threading is a convenient and reliable way to fasten parts and mount various structures.

There are different types of threads, but for pipes the most commonly used standard is cylindrical or tapered.

The simplest and most accessible tool for cutting external threads is a die, and for internal threads, a tap.

With the help of a die, you can save time and effort when cutting threads in hard-to-reach places, for example, near walls, and the electric device can make the notch independently.

Rules for working with taps

When cutting threads in deep holes, in soft and tough metals (copper, aluminum, bronze, etc.), the tap must be periodically unscrewed from the hole and the grooves must be cleared of chips; You need to cut a thread with a full set of taps - rough, medium and finishing. The middle and finishing taps are inserted into the hole without a driver and only after the tap follows the thread correctly, a driver is put on the head and threading continues; during the cutting process, you need to use a square to carefully ensure that there is no skew of the tap; The thread cutting area should be lubricated with oil.