What is a die?

A die is a tool for creating threads on the outer surface of cylindrical workpieces. Uniform twisted grooves appear on the machined side, onto which the connecting part is screwed. Smooth threads are obtained thanks to the complex arrangement of edges located on the inside of the tool. As the tool rotates, the sharp edges create uniform turns.

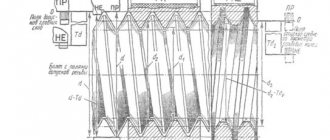

The design of the die is cylindrical in shape with precise placement of cutters on the inside. The diameter varies depending on the size of the workpieces being processed. The equipment has holes that are needed to secure the knob. With its help, force is transmitted to the equipment.

Tool selection

Let us note in advance that threads can be cut in different ways. You can work either manually or by machine. In the first case, as we noted above, you need to have a set of tools with you for creating threads, in the second, the work is carried out on a lathe.

Manual threading is recommended if your task is to machine only a few parts. For example, when assembling plumbing equipment, creating household pipelines, etc.

Processing parts on a lathe involves performing large-scale tasks. A person with experience with this type of equipment is able to cut threads on an industrial scale, up to a hundred parts per hour, and sometimes more. However, you are unlikely to need such performance.

Most often, a set of hand tools covers all the household needs of home craftsmen. With their help, you will also be able to cut threads correctly and efficiently, but it will only take more time and effort.

The set of equipment mentioned above is mainly represented by taps and dies, as well as various additional parts.

Features of taps

Taps are cone-shaped or cylindrical parts that are designed for cutting internal threads. In particular, they are used to make threads on pipes, nuts, small washers, various kinds of clamps and even flanges.

The taps are quite convenient to use. They consist of a working and a rear part. The working part has a unique shape and diameter. On its edges there are special incisors or teeth with a certain pitch. The teeth, when rotated, cut the metal in parallel with the removal of chips.

The back side is made in a certain shape, which makes it easier to fix the tap on the working tool.

A variety of taps for household use

Taps with the ability to cut threads without forming chips are also used, but much less often, because they are more expensive.

Roughers make the first pass, remove most of the chips and form rough grooves for the threads. This is not a full carving yet, but the preparation has already been completed.

Semi-draft models are extremely rare. They are intended for finishing rough grooves, cleaning them and forming a workpiece for a clean thread. Semi-rough taps are used primarily in the manufacture of complex parts.

The last sample, a finishing tap, forms a ready-to-use thread of precise dimensions and shape.

Classification

In construction stores you can see different types of tools. Equipment is classified according to the following criteria:

- hull design;

- a method for creating coils on the surface of a workpiece;

- equipment form.

If we talk about classification by form, we can distinguish the following types of instruments:

- round dies;

- tubular equipment;

- square dies;

- equipment in the shape of a polyhedron.

Speaking about the design of the tool, we can distinguish the following groups:

- One-piece equipment. The most popular option. It is a round cast form whose body cannot be disassembled. It has several holes for securing the knob. This type of tool gained popularity due to its ease of use, reliability, and durability. The sharpening of the cutters lasts for a long time.

- Cutting tools. Special devices that have certain design features. Thanks to this, the process of creating threads is simplified.

- Sliding structures. They are modern devices that can be expanded to the required diameter. These are expensive models.

Another classification concerns the purpose of the equipment. There are 3 groups:

- production of round threads;

- creating a cylindrical threaded connection;

- production of conical threads.

Devices are made in factories in compliance with a number of standards specified in government documents GOSTs.

Types of dies for thread cutting

How to cut threads by hand

Threaded connections are widely used in various mechanisms and machines. Bolts, studs, screws, nuts are universal, interchangeable fasteners. However, there are times when it is necessary to cut threads by hand. A specialized tool will help you do this job efficiently.

In mechanical engineering, there are three main systems of fastening threads: metric, inch and pipe.

Metric thread has become the most widespread. It has a triangular profile with an angle of 60˚. Its main parameters, diameter and pitch, are expressed in millimeters. Designation example: M16. This means that the thread is metric, has a diameter of 16 mm with a coarse pitch of 2.0 mm. If the step is small, then its value is indicated, for example, M16 * 1.5.

The diameters of inch and pipe threads are expressed in inches. The pitch is characterized by the number of threads per inch. The specified parameters are standardized, so it is always possible to select the necessary tool.

Rules for cutting threads using dies

Cutting threads with a die manually requires compliance with certain rules. Knowing the principles of working with the tool, you can create a high-quality, durable connection. In order to work with the device for creating a threaded connection, you need to use a die holder. Work rules:

- Determine the exact diameter of the pipe, select equipment according to the markings indicated on its surface.

- Prepare the workpiece. Remove the chamfer using a file. The chamfer angle should be no more than 45 degrees. A larger angle will make the connection poor quality.

- To make the cutting edges last longer, you need to use lubricant during operation. It could be motor oil. They lubricate cutting parts and workpieces.

- The die holder must be turned clockwise two turns, then make 1 turn in the opposite direction. When the cutting edges move backward, the resulting chips come out and do not become clogged in the finished turns. It is important to hold the tool with the crank strictly vertically so that the threads are straight.

- After creating the first 3-4 turns, you need to reduce the stroke of the die in the opposite direction. It will be enough to make two turns clockwise and half a turn counterclockwise. You cannot continue working if the equipment is overheated; you need to take breaks.

When the required number of turns has been made, the quality of the finished connection needs to be checked.

To do this, you need to take a nut of the selected diameter and try to screw it onto the pipe. The first times the nut will be screwed on slowly, with difficulty. Gradually these problems will disappear. Uneven threads can cause damage to the connection during operation. Dies are used to create external threads on cylindrical parts. It is important to choose the right diameter and know the rules for working with equipment. The inside of the round parts is processed using swords. The equipment is suitable for both manual work and industrial equipment.

Tapping internal threads

Using a tap, cut the internal thread in the pre-drilled hole. The hole should be smaller by approximately the thread size (the thread size is indicated on the tap). Approximately as in the table:

Hole diameter for internal thread with tap

It is worth remembering that the drill will not give an absolutely accurate diameter; it will be larger by a few fractions of a mm. This is especially noticeable on diameters up to 3 mm. This should be taken into account and take a drill less than a tenth of a mm.

Just like with dies, there is a tap holder.

There are rough and finishing taps. Sometimes they cut first with a rough tap, then with a finishing tap, but mostly they use finishing taps straight away.

Manual cutting of internal threads with a tap (video)

The process is almost identical to thread cutting with a die. The tap is attached to the holder and installed perpendicular to the hole. The part with the hole must be securely fastened.

The tap and hole are lubricated and this is done periodically, after several turns. Just like with a die, you need to make 1-2 turns and 0.5 turns back to remove chips.

To check the accuracy of thread cutting, use a square, checking the verticality of the tap after several turns.

Required Equipment

Manual tapping is only possible with the following tools:

- An electric drill that can operate at low speeds.

- A high-quality drill, the diameter and sharpening angle of which is selected from table values or calculated.

- To chamfer the edges of the hole, you will need a countersink or large diameter drill.

- One or a whole set (depending on the type) of taps of the appropriate size.

- A hand holder that is suitable for the tool used.

- A bench vise in which the product will be fixed. When cutting a thread, a certain layer of metal is removed, which is only possible when a lot of force is applied. If the workpiece or finished product is poorly fixed, the quality of processing will be low.

- Core and hammer.

- In order to simplify the task, it is recommended to use machine oil to lubricate both the tool itself and the surface being processed. If you do not use machine oil or another substance with similar properties, the process may be significantly delayed.

- Rags.

After finding everything you need, you can begin the actual work.

What is a tap? Design types and how to use them

The difference between die taps and nut taps is that the former has a large intake cone and its purpose is to cut threads in one pass in the dies. Well, the last type, the master type, is usually used to clean the threads in dies after it has been cut with a die tap, and for a similar process with threads in working dies. The grooves of the master taps are made with a spiral to the right.

Fluteless swords differ from conventional machine tools, as the name implies, by the complete absence of longitudinal grooves, and the receiving cone on them is much shorter. At the tip of the threaded part there is a pair of small grooves, with the axis inclined towards the center of the tool. Grooveless taps are an order of magnitude stronger than others, rarely break, and do not produce defects. Since they have a longer thread, they can be re-sharpened many times, so they have a longer service life.

The main advantage of fluteless taps is undoubtedly their high productivity during thread cutting, especially considering their use in through and blind holes, and not just in one. Combined taps are represented by two parts and a neck separating them, and they are divided into grooveless, two-stage and drill-tapping taps. Using them saves a lot of time, because here you need to use only one tool, and not a whole set.

Existing threading options

Pipe threads are divided into five types, but the most popular options are conical and cylindrical. Household members often encounter such types of pipe threads. There are two methods for threading a water pipe:

- Automatic, which involves cutting threads on water supply pipes using special machines and power tools.

- Manual. For this, special hand tools are used.

If, as part of his job, a person needs to cut threads on a large number of pipes, then it is appropriate to purchase a special power tool, which will facilitate manual labor.

When the need to obtain a threaded connection is an isolated case, then manual technology is suitable for such purposes. On water pipelines, as well as pipes of heating systems, thread cutting is performed using a die.

The die is a steel disk, and its inner diameter has axial holes in different numbers, which depends on the size of the product. The edges of these holes form cutters, with the help of which thread cutting is performed. To ensure the reliability of such a tool, it is made of alloy steel or hard alloys.

Dies can have different shapes (round, square, hexagonal or prismatic), but most often disc options are used. Disc dies are intended for making threaded connections on water pipes. To make it convenient to work with the die, they are equipped with additional knobs, as well as clamps in the form of screws. Dies are also solid, split and sliding.

Solid dies for threading pipes have one significant drawback - rapid wear of the cutters. This is due to the rigidity of the product’s own design. Split or spring-loaded dies have a less rigid design, which significantly increases the service life of the product. Due to the spring-loaded mechanism, such a tool for cutting threads on pipes allows you to vary the diameter of the resulting threaded connections in the range from 0.1 to 0.3 mm. A device of this type is highly resistant to cutter wear, but is not capable of providing high accuracy.

Sliding dies are 2 working parts intended for installation in a mounting module. A die with a special fastening module forms a tool called a pipe clamp. The die is fixed in the die using a cracker and an adjusting screw. It is with the help of the adjusting screw that the thread diameter is adjusted.

Classification of taps and their scope of application

Lathes or drilling machines have been used for cutting threads for quite a long period. They are designed to rotate a workpiece or tool. In almost all cases, the working tool is a tap.

The classification of such a tool is carried out according to a number of different characteristics:

- Depending on the method of driving them into rotation, they can be divided into machine or machine-hand taps. A special feature of the machine-manual variety of the tool is the presence of a square shank, which is suitable for a holder with two handles. Thanks to such a holder, you can rotate the tool and cut threads. As for the machine variety of the tool in question, it is installed in the chuck of various machines and can have a shank of various shapes and sizes.

- There are universal and complete taps based on characteristics related to the specific application. The universal version has a working part, which is divided into several sections. They differ from each other in geometric shape, the first is intended for roughing, the second and subsequent ones are for bringing the surface to a suitable state. The complete version is designed for the phased use of several taps. As a rule, a set for cutting threads in ordinary metal is represented by three tools, and for processing hard alloys - five.

- Taps are classified based on the type of hole being machined: blind or through. To work with through holes, a tool with an elongated conical tip is used, which is a continuation of the working part. Universal taps often have this type of shape. If you need to cut a thread in a blind hole, then use a tool that has a cut tip resembling a milling cutter. Due to this shape, it is possible to cut threads along the entire length of the hole.

- Thread cutting tools are also classified according to the type of working surface. Examples include helical, straight or shortened grooves. On sale you can find a version that also has a combined surface. It is suitable for processing metals with low hardness. For hard alloys, a tool with cutting elements arranged in a checkerboard pattern is used.

As a rule, high-quality tool steel is used in the manufacture of tools. It can withstand long-term use and does not heat up during operation. A high quality tap has a strict geometric shape and looks neat. A similar tool is often used for cutting metric threads, but there are versions for producing inch threads. The shape of the base can be cylindrical or conical.