The question of how to cut a thread with a tap arises in cases where a pre-made hole needs to be prepared to accommodate a bolt, screw, stud or any other type of threaded fastener. In such situations, it is the tap that is the main tool that allows you to quickly and accurately cut an internal thread with the required geometric parameters.

Manual cutting of internal threads is performed using metalworking taps complete with a wrench

Types and areas of application of taps

Internal thread cutting can be done manually or using various types of machines (drilling, lathe, etc.). The working tools that perform the main work of cutting internal threads are machine-hand or machine taps.

Taps are divided into different types depending on a number of parameters. The following principles for classifying taps are generally accepted.

- According to the method of rotation, a distinction is made between machine-manual and machine taps, with the help of which internal threads are cut. Machine-hand taps equipped with a square shank are used in conjunction with a special device with two handles (this is the so-called tap holder). With the help of such a device, the tap is rotated and cuts the thread. Thread cutting with a machine tap is carried out on metal-cutting machines of various types, in the chuck of which such a tool is fixed.

- Based on the method by which internal threads are cut, a distinction is made between universal (through) taps and complete taps. The working part of the former is divided into several sections, each of which differs from the others in its geometric parameters. The section of the working part that first begins to interact with the surface being processed performs rough processing, the second - intermediate, and the third, located closer to the shank - finishing. Cutting threads with complete taps requires the use of several tools. So, if a set consists of three taps, then the first of them is intended for roughing, the second for intermediate, and the third for finishing. As a rule, a set of taps for cutting threads of a certain diameter includes three tools, but in some cases, when products made of particularly hard material are processed, sets consisting of five tools can be used.

- Based on the type of hole on the inner surface of which it is necessary to cut a thread, taps for through and blind holes are distinguished. A tool for processing through holes is characterized by an elongated conical tip (approach), which smoothly passes into the working part. Universal type taps most often have this design. The process of cutting internal threads in blind holes is carried out using taps, the conical tip of which is cut off and performs the function of a simple milling cutter. This design of the tap allows it to cut threads to the full depth of a blind hole. To cut a thread of this type, as a rule, a set of taps is used, driven manually using a wrench.

- According to the design of the working part, taps can have straight, helical or shortened chip removal grooves. It should be borne in mind that taps with grooves of various types can be used for cutting threads in products made of relatively soft materials - carbon, low-alloy steel alloys, etc. If threads need to be cut in parts made of very hard or viscous materials (stainless, heat-resistant steels, etc.), then for these purposes taps are used, the cutting elements of which are arranged in a checkerboard pattern.

A good tap is made of high-quality tool steel, looks neat and has smoothly machined turns and grooves

Taps are usually used for cutting metric threads, but there are tools that can be used to cut pipe and inch internal threads. In addition, taps also differ in the shape of their working surface, which can be cylindrical or conical.

How internal threads are cut on a rod - general information

The device is called a tap. It can be of two varieties - manual and machine, in accordance with the methods of making furrows. The material that is processed is metal, but not only it. There are also lightweight models that cut into plastic or wood. The last option cannot be called the most common.

Factories use mechanized technology - metal drills make through holes (or a blind cavity), and after the blade, several turns are applied with a predetermined pitch. The advantage of such a prima is high accuracy. Calculations are made using computer-aided design programs, then the data is entered into the control module - manually or using CNC. The second advantage is that skew of the spiral angle and errors are virtually impossible.

But at home and in small industries, a simpler, but less accurate procedure is often used - cutting the internal thread with a tap manually (you can cut it evenly even with your own hands). The work can be carried out on site; for this you need to buy the device itself and a drill to make a preliminary hole.

The tool resembles a herringbone shape due to the fact that the working surface is a ribbed blade. Structurally, the product is a rather complex configuration made of tool steel. This material is used because of its strength and ability to process most alloys, even cast iron. It is not very good to work only with hardened metal - it has stress inside, so it is considered fragile and can crumble in the process.

Preparing to cut internal threads

In order for the process of cutting internal threads using a tap to not cause any particular difficulties and result in a high-quality result, it is necessary to properly prepare for this technological operation. All methods of cutting threads using a tap assume that a hole with the appropriate diameter has already been made in the workpiece. If the internal thread that needs to be cut has a standard size, then a special table with data in accordance with GOST can be used to determine the diameter of the preparation hole.

Table 1. Diameters of holes drilled for standard metric threads

If the thread that needs to be cut does not belong to the standard category, you can calculate the diameter of the hole to make it using a universal formula. First of all, it is necessary to study the marking of the tap, which must indicate the type of thread being cut, its diameter and pitch, measured in millimeters (for metric). Then, to determine the cross-sectional size of the hole that needs to be drilled for the thread, it is enough to subtract the pitch from its diameter. For example, if a tool marked M6x0.75 is used to cut a non-standard internal thread, then the diameter of the preparation hole is calculated as follows: 6 – 0.75 = 5.25 mm.

For standard threads belonging to the inch category, there is also a table that allows you to choose the right drill with which to carry out the preparatory work.

Table 2. Diameters of holes drilled for inch threads

An important question to obtain a high-quality result is not only the question of what is used to cut the thread, but also what drill to use to make the preparation hole. When choosing a drill, you need to pay attention to the parameters and quality of its sharpening, as well as to ensure that it rotates in the chuck of the equipment used without runout.

The sharpening angle of the cutting part is selected depending on the hardness of the material that needs to be drilled. The higher the hardness of the material, the greater the sharpening angle of the drill should be, but this value should not exceed 140°.

When drilling blind holes, control the drilling depth

How to cut threads correctly? First you need to select tools and consumables:

- an electric drill or drilling machine capable of operating at low speeds;

- a drill whose diameter is calculated or selected using reference tables;

- a drill or countersink, with the help of which a chamfer will be removed from the edge of the prepared hole;

- a set of taps of the appropriate size;

- manual holder for taps (drives);

- bench vice (if the product in which the thread needs to be cut needs to be fixed);

- core;

- hammer;

- machine oil or other composition, which during the processing process must be used to lubricate both the tap and the thread section being cut by it;

- rags.

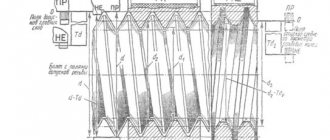

Diagram of thread cutting with a tap

Technology: how to use a thread tap

There are several stages, each of which is important. These are preparatory procedures, 1, 2, 3 or more approaches of rotation, finishing grinding. We'll talk more about preparation below. The manipulation of the tool itself is relatively simple. It is necessary to direct the tip, set it level, and then use the crank to make rotational movements.

Special recommendations:

- We do not recommend starting to cut unprepared workpieces. If you already have a sheet of metal where the through hole was obtained by stamping or other metalworking, you need to drill it out and then countersink it - cut off the edges.

- Remove the top 0.5 cm of chamfer from the sample. This must be done at an angle of 60 degrees.

- The device must be lubricated and cooled during the process, otherwise it will result in thermal treatment, during which the metal surface can acquire additional strength.

- Apply reverse stroke every 1-2 turns. This allows you to clear the working area from chips sticking to it.

Let's watch the video. It shows how to make a hole not only with a tap for cutting internal threads, but also with a die for cutting external threads:

Features of the technology

When cutting internal threads with a tap, the following algorithm is used.

- In the place on the surface of the workpiece where the hole for threading will be drilled, it is necessary to form a recess for a more accurate entry of the drill, using a core and a regular hammer. The drill is fixed in the chuck of an electric drill or drilling machine, on which low rotation speeds of the tool are set. Before starting drilling, the cutting part of the drill must be treated with a lubricating compound: a lubricated tool enters more easily into the structure of the material being processed and creates less friction in the processing area. You can lubricate the drill with a piece of ordinary lard or grease, and when processing viscous materials, machine oil is used for these purposes.

- If it is necessary to cut threads in small parts, they should first be fixed using a bench vice. When starting drilling, the tool fixed in the equipment chuck must be positioned strictly perpendicular to the surface of the workpiece. You should lubricate the tap regularly and ensure that it does not warp and moves strictly in the given direction.

- At the entrance to the hole, as mentioned above, it is necessary to remove the chamfer, the depth of which should be 0.5–1 mm (depending on the diameter of the hole). For this purpose, you can use a larger diameter drill or countersink, installing them in the chuck of drilling equipment.

- The process of cutting internal threads begins with tap No. 1, which is the first to be installed in the driver. We should not forget about the lubricant, which must be applied to the tap for threading. The position of the tap relative to the hole being machined must be set at the very beginning of the work, since later, when the tool is already inside the hole, this will not be possible. When cutting a thread with a tap, you must adhere to the following rule: 2 turns of the tap are made in the direction of cutting the thread, 1 - against the direction. When the tap makes one revolution back, chips are thrown off its cutting part and the load on it is reduced. Thread cutting with a die is performed using a similar technique.

- After cutting the thread with tap No. 1, tool No. 2 is installed in the driver, and after it – No. 3. They are processed according to the method described above. When cutting threads with taps and dies, you need to feel when the tool begins to rotate with force. As soon as such a moment occurs, you should turn the knob in the opposite direction to throw the chips off the cutting part of the tool.

The harder the material being processed, the more abundantly the tap must be lubricated during the thread cutting process.

Before making internal threads with a tap or cutting threads with a die on external surfaces, you should thoroughly study these procedures and strictly follow the rules for their implementation. Only in this case can you count on the result satisfying you with its quality and accuracy.