The main thread pitch is highlighted in color

| Metric thread, M | |||

| Tap | Drill | Tap | Drill |

| M1.4x0.3 | 1.1 | M14x1.25 | 12.8 |

| M1.6x0.35 | 1.25 | M14x1 | 13 |

| M2x0.4 | 1.6 | M16x2 | 14 |

| M2.5x0.45 | 2.05 | M16x1.5 | 14.5 |

| M3x0.5 | 2.5 | M16x1.25 | 14.8 |

| M3.5x0.6 | 2.9 | M16x1 | 15 |

| M4x0.7 | 3.3 | M18x2.5 | 15.5 |

| M4x0.5 | 3.5 | M18x2 | 16 |

| M5x0.8 | 4.2 | M18x1.5 | 16.5 |

| M5x0.5 | 4.5 | M18x1 | 17 |

| M6x1 | 5 | M20x2.5 | 17.5 |

| M6x0.5 | 5.5 | M20x2 | 18 |

| M7x1 | 6 | M20x1.5 | 18.5 |

| M7x0.5 | 6.5 | M22x2.5 | 19.5 |

| M8x1.25 | 6.8 | M22x2 | 20 |

| M8x1 | 7 | M22x1.5 | 20.5 |

| M8x0.75 | 7.2 | M24x3 | 21 |

| M8x0.5 | 7.5 | M24x2 | 22 |

| M9x1.25 | 7.8 | M24x1.5 | 22.5 |

| M9x1 | 8 | M27x3 | 24 |

| M10x1.5 | 8.5 | M27x2 | 25 |

| M10x1.25 | 8.8 | M27x1.5 | 25.5 |

| M10x1 | 9 | M30x3.5 | 26.5 |

| M11x1.5 | 9.5 | M30x3 | 27 |

| M11x1.25 | 9.8 | M30x2 | 28 |

| M11x1 | 10 | M30x1.5 | 28.5 |

| M12x1.75 | 10.2 | M33x3.5 | 29.5 |

| M12x1.5 | 10.5 | M33x3 | 30 |

| M12x1.25 | 10.8 | M33x2 | 31 |

| M12x1 | 11 | M33x1.5 | 31.5 |

| M14x2 | 12 | M36x4 | 32 |

| M14x1.5 | 12.5 | M42x4.5 | 37.5 |

| Pipe thread, G | |||

| Tap | Drill | Tap | Drill |

| G 1/8 | 8.8 | G 1 1/4 | 39.5 |

| G 1/4 | 11.8 | G 1 3/8 | 42 |

| G 3/8 | 15.25 | G 1 1/2 | 45.5 |

| G 1/2 | 19 | G 2 | 57.5 |

| G 5/8 | 21 | G 2 1/4 | 63.5 |

| G 3/4 | 24.5 | G 2 1/2 | 72.5 |

| G 7/8 | 28.25 | G 2 3/4 | 78.5 |

| G 1 | 30.75 | G 3 | 85.5 |

| G 1 1/8 | 35.5 | ||

| Inch UNC thread | |||

| 1/4x20 | 5.1 | 7/8x9 | 19.5 |

| 5/16x18 | 6.5 | 1x8 | 22.25 |

| 3/8x16 | 8 | 1 1/8x7 | 25 |

| 7/16x14 | 9.4 | 1 1/4x7 | 28.25 |

| 1/2x13 | 10.8 | 1 3/8x6 | 30.75 |

| 9/16x12 | 12.2 | 1 1/2x6 | 34 |

| 5/8x11 | 13.6 | 1 3/4x5 | 39.5 |

| 3/4x10 | 16.5 | 2x4 | 45 |

| Inch fine thread UNF | |||

| 1/4x28 | 5.5 | 3/4x16 | 17.5 |

| 5/16x24 | 6.9 | 7/8x14 | 20.5 |

| 3/8x24 | 8.5 | 1x12 | 23.25 |

| 7/16x20 | 9.9 | 1 1/8x12 | 26.5 |

| 1/2x20 | 11.5 | 1 1/4x12 | 29.75 |

| 9/16x18 | 12.9 | 1 3/8x12 | 33 |

| 5/8x18 | 14.5 | 1 1/2x12 | 36 |

| Trapezoidal thread Tr | |||

| Tr 8x1.5 | 6.6 | Tr 14x3 | 11.25 |

| Tr 10x1.5 | 8.6 | Tr 14x4 | 10.25 |

| Tr 10x2 | 8.2 | Tr 16x4 | 12.25 |

| Tr 10x3 | 7.5 | Tr 18x4 | 14.25 |

| Tr 12x2 | 10.2 | Tr 20x4 | 16.25 |

| Tr 12x3 | 9.25 | Tr 22x3 | 19.25 |

| Tr 14x2 | 12.2 | Tr 22x5 | 17.25 |

To cut internal threads with a tap, you first need to drill a hole of a certain diameter. The table shows the most popular threads and drill diameters required for drilling holes for threads.

For which materials are the values indicated in the table?

The indicated hole diameters provide cutting of metric threads in:

- gray cast iron

- carbon steels of ordinary quality

- quality structural steels

- alloyed structural steels

- high alloy steels

- corrosion-resistant, heat-resistant and heat-resistant alloys

- heat-resistant steels

- aluminum casting alloys

- copper

A complete list of threads and diameters can be found in GOST 19257-73 - an official technical document with all the nuances and details.

Before you begin, we recommend that you read the practical tips in the article How to properly cut a thread with a tap. And there you can find suitable coolant for different materials.

Tables - diameters of threaded holes.

Tables - diameters of threaded holes.

A tap hole is a hole in a material into which an internal thread is cut. The threaded hole is pre-drilled with a twist drill with a diameter of a certain thread size.

There are metric thread types and inch thread types. For metric thread types, dimensions are specified in millimeters. The thread pitch is calculated by measuring the distance between the first and second tooth. On the other hand, thread sizes for inch threads are given in inches, 1 inch is equal to 25.4 mm. Here the thread pitch is determined by the number of threads per inch.

Internal threading holes have a specific size adapted to a specific thread size. This means that the size of the diameter of the twist drill for drilling a hole is determined by the size of the thread being cut.

Important!

The hole for cutting blind threads must be pre-drilled deeper than the length of the thread being cut.

We recommend that you lower the thread hole by the thread diameter.

| Threaded hole diameters (metric thread DIN 13) | ||

| ISO metric threads are measured in mm and are used mainly in Europe | ||

| size mm | thread pitch mm | thread diameter mm |

| M 1 | 0,25 | 0,75 |

| M 1.1 | 0,25 | 0,85 |

| M 1.2 | 0,25 | 0,95 |

| M 1.4 | 0,3 | 1,1 |

| M 1.6 | 0,35 | 1,25 |

| M 1.7 | 0,35 | 1,3 |

| M 1.8 | 0,35 | 1,45 |

| M 2 | 0,4 | 1,6 |

| M 2.2 | 0,45 | 1,75 |

| M 2.3 | 0,4 | 1,9 |

| M 2.5 | 0,45 | 2,05 |

| M 2.6 | 0,45 | 2,1 |

| M 3 | 0,5 | 2,5 |

| M 3.5 | 0,6 | 2,9 |

| M 4 | 0,7 | 3,3 |

| M 4.5 | 0,75 | 3,7 |

| M5 | 0,8 | 4,2 |

| M 6 | 1,0 | 5,0 |

| M 7 | 1,0 | 6,0 |

| M 8 | 1,25 | 6,8 |

| M 9 | 1,25 | 7,8 |

| M 10 | 1,5 | 8,5 |

| M 11 | 1,5 | 9,5 |

| M 12 | 1,75 | 10,2 |

| M 14 | 2,0 | 12,0 |

| M 16 | 2,0 | 14,0 |

| M 18 | 2,5 | 15,5 |

| M 20 | 2,5 | 17,5 |

| M 22 | 2,5 | 19,5 |

| M 24 | 3,0 | 21,0 |

| M 27 | 3,0 | 24,0 |

| M 30 | 3,5 | 26,5 |

| M 33 | 3,5 | 29,5 |

| M 36 | 4,0 | 32,0 |

| M 39 | 4,0 | 35,0 |

| M 42 | 4,5 | 37,5 |

| M 45 | 4,5 | 40,5 |

| M 48 | 5,0 | 43,0 |

| M 52 | 5,0 | 47,0 |

| M 56 | 5,5 | 51,5 |

| M 60 | 5,5 | 54,5 |

| M 64 | 6,0 | 58,0 |

| Diameters of holes for threads (metric thread with fine pitch DIN 13) | ||

| size mm | thread pitch mm | thread diameter mm |

| MF 2.5 x 0.35 | 0,35 | 2,15 |

| MF 2.6 x 0.35 | 0,35 | 2,15 |

| MF 3 x 0.35 | 0,35 | 2,65 |

| MF 3.5 x 0.35 | 0,35 | 3,15 |

| MF 4 x 0.35 | 0,35 | 3,65 |

| MF 4 x 0.5 | 0,5 | 3,5 |

| MF 4.5 x 0.35 | 0,35 | 4,15 |

| MF 4.5 x 0.5 | 0,5 | 4,0 |

| MF 5 x 0.5 | 0,5 | 4,5 |

| MF 5 x 0.75 | 0,75 | 4,25 |

| MF 5.5 x 0.5 | 0,5 | 5,0 |

| MF 5.5 x 0.75 | 0,75 | 4,75 |

| MF 6 x 0.5 | 0,5 | 5,5 |

| MF 6 x 0.75 | 0,75 | 5,25 |

| MF 7 x 0.5 | 0,5 | 6,5 |

| MF 7 x 0.75 | 0,75 | 6,25 |

| MF 8 x 0.5 | 0,5 | 7,5 |

| MF 8 x 0.75 | 0,75 | 7,25 |

| MF 8 x 1 | 1,0 | 7,0 |

| MF 8 x 1.5 | 1,5 | 6,5 |

| MF 9 x 0.5 | 0,5 | 8,5 |

| MF 9 x 0.75 | 0,75 | 8,25 |

| MF 9 x 1 | 1,0 | 8,0 |

| MF 10 x 0.5 | 0,5 | 9,5 |

| MF 10 x 0.75 | 0,75 | 9,25 |

| MF 10 x 1 | 1,0 | 9,0 |

| MF 10 x 1.25 | 1,25 | 8,8 |

| MF 11 x 0.5 | 0,5 | 10,5 |

| MF 11 x 0.75 | 0,75 | 10,25 |

| MF 11 x 1 | 1,0 | 10,0 |

| MF 11 x 1.25 | 1,25 | 9,75 |

| MF 12 x 0.5 | 0,5 | 11,5 |

| MF 12 x 0.75 | 0,75 | 11,25 |

| MF 12 x 1 | 1,0 | 11,0 |

| MF 12 x 1.25 | 1,25 | 10,8 |

| MF 12 x 1.5 | 1,5 | 10,5 |

| MF 13 x 0.5 | 0,5 | 12,5 |

| MF 13 x 0.75 | 0,75 | 12,25 |

| MF 13 x 1 | 1,0 | 12,0 |

| MF 13 x 1.25 | 1,25 | 11,75 |

| MF 13 x 1.5 | 1,5 | 11,5 |

| MF 14 x 0.5 | 0,5 | 13,5 |

| MF 14 x 0.75 | 0,75 | 13,25 |

| MF 14 x 1 | 1,0 | 13,0 |

| MF 14 x 1.25 | 1,25 | 12,8 |

| MF 14 x 1.5 | 1,5 | 12,5 |

| MF 15 x 0.5 | 0,5 | 14,5 |

| MF 15 x 0.75 | 0,75 | 14,25 |

| MF 15 x 1 | 1,0 | 14,0 |

| MF 15 x 1.25 | 1,25 | 13,8 |

| MF 15 x 1.5 | 1,5 | 13,5 |

| MF 16 x 0.5 | 0,5 | 15,5 |

| MF 16 x 0.75 | 0,75 | 15,25 |

| MF 16 x 1 | 1,0 | 15,0 |

| MF 16 x 1.25 | 1,25 | 14,75 |

| MF 16 x 1.5 | 1,5 | 14,5 |

| MF 17 x 0.75 | 0,75 | 16,25 |

| MF 17 x 1 | 1,0 | 16,0 |

| MF 17 x 1.5 | 1,5 | 15,5 |

| MF 18 x 0.5 | 0,5 | 17,5 |

| MF 18 x 0.75 | 0,75 | 17,25 |

| MF 18 x 1 | 1,0 | 17,0 |

| MF 18 x 1.25 | 1,25 | 16,75 |

| MF 18 x 1.5 | 1,5 | 16,5 |

| MF 18 x 2 | 2,0 | 16,0 |

| MF 19 x 1 | 1,0 | 18,0 |

| MF 19 x 1.5 | 1,5 | 17,5 |

| MF 20 x 0.5 | 0,5 | 19,5 |

| MF 20 x 0.75 | 0,75 | 19,25 |

| MF 20 x 1 | 1,0 | 19,0 |

| MF 20 x 1.25 | 1,25 | 18,75 |

| MF 20 x 1.5 | 1,5 | 18,5 |

| MF 20 x 2 | 2,0 | 18,0 |

| MF 21 x 1 | 1,0 | 20,0 |

| MF 21 x 1.5 | 1,5 | 19,5 |

| MF 22 x 0.5 | 0,5 | 21,5 |

| MF 22 x 0.75 | 0,75 | 21,25 |

| MF 22 x 1 | 1,0 | 21,0 |

| MF 22 x 1.25 | 1,25 | 20,75 |

| MF 22 x 1.5 | 1,5 | 20,5 |

| MF 22 x 2 | 2,0 | 20,0 |

| MF 23 x 1 | 1,0 | 22,0 |

| MF 23 x 1.5 | 1,5 | 21,5 |

| MF 24 x 0.5 | 0,5 | 23,5 |

| MF 24 x 0.75 | 0,75 | 23,25 |

| MF 24 x 1 | 1,0 | 23,0 |

| MF 24 x 1.25 | 1,25 | 22,75 |

| MF 24 x 1.5 | 1,5 | 22,5 |

| MF 24 x 2 | 2,0 | 22,0 |

| MF 25 x 1 | 1,0 | 24,0 |

| MF 25 x 1.5 | 1,5 | 23,5 |

| MF 25 x 2 | 2,0 | 23,0 |

| MF 26 x 1 | 1,0 | 25,0 |

| MF 26 x 1.25 | 1,25 | 24,75 |

| MF 26 x 1.5 | 1,5 | 24,5 |

| MF 26 x 2 | 2,0 | 24,0 |

| MF 27 x 1 | 1,0 | 26,0 |

| MF 27 x 1.5 | 1,5 | 25,5 |

| MF 27 x 2 | 2,0 | 25,0 |

| MF 28 x 1 | 1,0 | 27,0 |

| MF 28 x 1.5 | 1,5 | 26,5 |

| MF 28 x 2 | 2,0 | 26,0 |

| MF 30 x 1 | 1,0 | 29,0 |

| MF 30 x 1.5 | 1,5 | 28,5 |

| MF 30 x 2 | 2,0 | 28,0 |

| MF 30 x 3 | 3,0 | 27,0 |

| MF 32 x 1 | 1,0 | 31,0 |

| MF 32 x 1.5 | 1,5 | 30,5 |

| MF 32 x 2 | 2,0 | 30,0 |

| MF 32 x 3 | 3,0 | 29,0 |

| MF 33 x 1 | 1,0 | 32,0 |

| MF 33 x 1.5 | 1,5 | 31,5 |

| MF 33 x 2 | 2,0 | 31,0 |

| MF 33 x 3 | 3,0 | 30,0 |

| MF 34 x 1 | 1,0 | 33,0 |

| MF 34 x 1.5 | 1,5 | 32,5 |

| MF 34 x 2 | 2,0 | 32,0 |

| MF 34 x 3 | 3,0 | 31,0 |

| MF 35 x 1 | 1,0 | 34,0 |

| MF 35 x 1.5 | 1,5 | 33,5 |

| MF 35 x 2 | 2,0 | 33,0 |

| MF 35 x 3 | 3,0 | 32,0 |

| MF 36 x 1 | 1,0 | 35,0 |

| MF 36 x 1.5 | 1,5 | 34,5 |

| MF 36 x 2 | 2,0 | 34,0 |

| MF 36 x 3 | 3,0 | 33,0 |

| MF 38 x 1 | 1,0 | 37,0 |

| MF 38 x 1.5 | 1,5 | 36,5 |

| MF 38 x 2 | 2,0 | 36,0 |

| MF 38 x 3 | 3,0 | 35,0 |

| MF 39 x 1.5 | 1,5 | 37,5 |

| MF 39 x 2 | 2,0 | 37,0 |

| MF 39 x 3 | 3,0 | 36,0 |

| MF 40 x 1 | 1,0 | 39,0 |

| MF 40 x 1.5 | 1,5 | 38,5 |

| MF 40 x 2 | 2,0 | 38,0 |

| MF 40 x 3 | 3,0 | 37,0 |

| MF 42 x 1.5 | 1,5 | 40,5 |

| MF 42 x 2 | 2,0 | 40,0 |

| MF 42 x 3 | 3,0 | 39,0 |

| MF 42 x 4 | 4,0 | 38,0 |

| MF 45 x 1 | 1,0 | 44,0 |

| MF 45 x 1.5 | 1,5 | 43,5 |

| MF 45 x 2 | 2,0 | 43,0 |

| MF 45 x 3 | 3,0 | 42,0 |

| MF 45 x 4 | 4,0 | 41,0 |

| MF 48 x 1 | 1,0 | 47,0 |

| MF 48 x 1.5 | 1,5 | 46,5 |

| MF 48 x 2 | 2,0 | 46,0 |

| MF 48 x 3 | 3,0 | 45,0 |

| MF 48 x 4 | 4,0 | 44,0 |

| MF 50 x 1 | 1,0 | 49,0 |

| MF 50 x 1.5 | 1,5 | 48,5 |

| MF 50 x 2 | 2,0 | 48,0 |

| MF 50 x 3 | 3,0 | 47,0 |

| MF 50 x 4 | 4,0 | 46,0 |

| MF 52 x 1 | 1,0 | 51,0 |

| MF 52 x 1.5 | 1,5 | 50,5 |

| MF 52 x 2 | 2,0 | 50,0 |

| MF 52 x 3 | 3,0 | 49,0 |

| MF 52 x 4 | 4,0 | 48,0 |

| MF 54 x 1.5 | 1,5 | 52,5 |

| MF 54 x 2 | 2 | 52 |

| MF 54 x 3 | 3 | 51 |

| MF 54 x 4 | 4 | 50 |

| MF 55 x 1.5 | 1,5 | 53,5 |

| MF 55 x 2 | 2 | 53 |

| MF 55 x 3 | 3 | 52 |

| MF 55 x 4 | 4 | 51 |

| MF 56 x 1.5 | 1,5 | 54,5 |

| MF 56 x 2 | 2 | 54 |

| MF 56 x 3 | 3 | 53 |

| MF 56 x 4 | 4 | 52 |

| MF 58 x 1.5 | 1,5 | 56,5 |

| MF 58 x 2 | 2 | 56 |

| MF 58 x 3 | 3 | 55 |

| MF 58 x 4 | 4 | 54 |

| MF 60 x 1.5 | 1,5 | 58,5 |

| MF 60 x 2 | 2 | 58 |

| MF 60 x 3 | 3 | 57 |

| MF 60 x 4 | 4 | 56 |

| MF 62 x 1.5 | 1,5 | 60,5 |

| MF 62 x 2 | 2 | 60 |

| MF 62 x 3 | 3 | 59 |

| MF 62 x 4 | 4 | 58 |

| MF 64 x 1.5 | 1,5 | 62,5 |

| MF 64 x 2 | 2 | 62 |

| MF 64 x 3 | 3 | 61 |

| MF 64 x 4 | 4 | 60 |

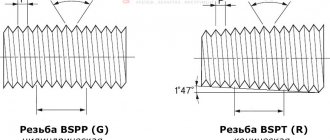

| British Standard Pipe (BSP/ G) - pipe cylindrical inch Whitworth thread | ||

| thread size/inch | number of turns/inch | hole diameter mm |

| BSP 1/8 | 28 | 8,8 |

| BSP 1/4 | 19 | 11,8 |

| BSP 3/8 | 19 | 15,3 |

| BSP 1/2 | 14 | 19,0 |

| BSP 5/8 | 14 | 21,0 |

| BSP 3/4 | 14 | 24,5 |

| BSP 7/8 | 14 | 28,3 |

| BSP 1 | 11 | 30,5 |

| BSP 1.1/8 | 11 | 35,5 |

| BSP 1.1/4 | 11 | 39,5 |

| BSP 1.3/8 | 11 | 42,0 |

| BSP 1.1/2 | 11 | 45,0 |

| BSP 1.5/8 | 11 | 49,6 |

| BSP 1.3/4 | 11 | 51,0 |

| BSP 2 | 11 | 57,0 |

| BSP 2.1/4 | 11 | 63,3 |

| BSP 2.1/2 | 11 | 72,8 |

| BSP 2.3/4 | 11 | 79,0 |

| BSP 3 | 11 | 85,5 |

| BSP 3.1/4 | 11 | 91,6 |

| BSP 3.1/2 | 11 | 98,0 |

| BSP 3.3/4 | 11 | 104,0 |

| BSP 4 | 11 | 110,7 |

| Unified National Coarse Thread (UNC) - American national inch thread, basic pitch. | ||

| thread size/inch | number of turns/inch | hole diameter mm |

| UNC Nr. 1 | 64 | 1,5 |

| UNC Nr. 2 | 56 | 1,8 |

| UNC Nr. 3 | 48 | 2,1 |

| UNC Nr. 4 | 40 | 2,3 |

| UNC Nr. 5 | 40 | 2,6 |

| UNC Nr. 6 | 32 | 2,9 |

| UNC Nr. 8 | 32 | 3,5 |

| UNC Nr. 10 | 24 | 3,9 |

| UNC Nr. 12 | 24 | 4,5 |

| UNC 1/4 | 20 | 5,2 |

| UNC 5/16 | 18 | 6,6 |

| UNC 3/8 | 16 | 8 |

| UNC 7/16 | 14 | 9,4 |

| UNC 1/2 | 13 | 10,8 |

| UNC 9/16 | 12 | 12,3 |

| UNC 5/8 | 11 | 13,5 |

| UNC 3/4 | 10 | 16,5 |

| UNC 7/8 | 9 | 19,5 |

| UNC 1 | 8 | 22,3 |

| UNC 1.1/8 | 7 | 25 |

| UNC 1.1/4 | 7 | 28,3 |

| UNC 1.3/8 | 6 | 30,8 |

| UNC 1.1/2 | 6 | 34 |

| UNC 1.5/8 | 5 | 37,1 |

| UNC 1.3/4 | 5 | 39,5 |

| UNC 1.7/8 | 4,5 | 42 |

| UNC 2 | 4,5 | 45 |

| UNC 2.1/4 | 4,5 | 51,5 |

| UNC 2.1/2 | 4 | 57,2 |

| UNC 2.3/4 | 4 | 63,25 |

| UNC 3 | 4 | 69,85 |

| Unified National Fine Thread (UNF) - American national inch thread, fine pitch. Analogue of metric thread with fine pitch. | ||

| thread size/inch | number of turns/inch | hole diameter mm |

| UNF Nr. 0 | 80 | 1,25 |

| UNF Nr. 1 | 72 | 1,55 |

| UNF Nr. 2 | 64 | 1,85 |

| UNF Nr. 3 | 56 | 2,1 |

| UNF Nr. 4 | 48 | 2,4 |

| UNF Nr. 5 | 44 | 2,7 |

| UNF Nr. 6 | 40 | 3,0 |

| UNF Nr. 8 | 36 | 3,5 |

| UNF Nr. 10 | 32 | 4,1 |

| UNF Nr. 12 | 28 | 4,65 |

| UNF 1/4 | 28 | 5,5 |

| UNF 5/16 | 24 | 6,9 |

| UNF 3/8 | 24 | 8,5 |

| UNF 7/16 | 20 | 9,9 |

| UNF 1/2 | 20 | 11,5 |

| UNF 9/16 | 18 | 13,0 |

| UNF 5/8 | 18 | 14,5 |

| UNF 3/4 | 16 | 17,5 |

| UNF 7/8 | 14 | 20,5 |

| UNF 1 (14) | 14 | 23,3 |

| UNF 1 (12) | 12 | 23,3 |

| UNF 1.1/8 | 12 | 26,5 |

| UNF 1.1/4 | 12 | 29,5 |

| UNF 1.3/8 | 12 | 32,5 |

| UNF 1.1/2 | 12 | 36,0 |

| Britisch Standard Whitworth (BSW/ WW) - British Whitworth carving. | ||

| thread size/inch | number of turns/inch | hole diameter mm |

| BSW 1/8 | 40 | 2,6 |

| BSW 5/32 | 32 | 3,2 |

| BSW 3/16 | 24 | 3,8 |

| BSW 1/4 | 20 | 5,1 |

| BSW 5/16 | 18 | 6,5 |

| BSW 3/8 | 16 | 7,9 |

| BSW 7/16 | 14 | 9,3 |

| BSW 1/2 | 12 | 10,5 |

| BSW 9/16 | 12 | 12,0 |

| BSW 5/8 | 11 | 13,5 |

| BSW 3/4 | 10 | 16,5 |

| BSW 7/8 | 9 | 19,5 |

| BSW 1 | 8 | 22,0 |

| BSW 1.1/8 | 7 | 25,0 |

| BSW 1.1/4 | 7 | 28,0 |

| BSW 1.3/8 | 6 | 30,5 |

| BSW 1.1/2 | 6 | 33,5 |

| BSW 1.3/4 | 5 | 39,0 |

| BSW 2 | 4,5 | 44,5 |

| British Standard Fine (BSF) British standard fine thread. | ||

| thread size/inch | number of turns/inch | hole diameter mm |

| BSF 3/16 | 32 | 4,0 |

| BSF 1/4 | 26 | 5,3 |

| BSF 5/16 | 22 | 6,8 |

| BSF 3/8 | 20 | 8,3 |

| BSF 7/16 | 18 | 9,7 |

| BSF 1/2 | 16 | 11,1 |

| BSF 9/16 | 16 | 12,7 |

| BSF 5/8 | 14 | 14,0 |

| BSF 11/16 | 14 | 15,7 |

| BSF 3/4 | 12 | 16,8 |

| BSF 13/16 | 12 | 18,5 |

| BSF 7/8 | 11 | 19,8 |

| BSF 15/16 | 11 | 21,5 |

| BSF 1 | 10 | 22,8 |

| BSF 1.1/8 | 9 | 25,5 |

| BSF 1.1/4 | 9 | 28,6 |

| BSF 1.3/8 | 8 | 31,5 |

| BSF 1.1/2 | 8 | 34,6 |

| BSF 1.5/8 | 8 | 38,1 |

| BSF 1.3/4 | 7 | 40,8 |

| BSF 2 | 7 | 47,2 |

| NPT - National Pipe Taper - national American pipe thread (tapered). | ||

| thread size/inch | number of turns/inch | hole diameter mm |

| NPT 1/16 | 27 | 6,25 |

| NPT 1/8 | 27 | 8,5 |

| NPT 1/4 | 18 | 11,1 |

| NPT 3/8 | 18 | 14,7 |

| NPT 1/2 | 14 | 18,0 |

| NPT 3/4 | 14 | 23,3 |

| NPT 1 | 11,5 | 29,3 |

| NPT 1.1/4 | 11,5 | 38,0 |

| NPT 1.1/2 | 11,5 | 44,3 |

| NPT 2 | 11,5 | 56,3 |

| NPT 2.1/2 | 8 | 66,5 |

| NPT 3 | 8 | 82,5 |

| NPT 3.1/2 | 8 | 95 |

| NPT 4 | 8 | 107,7 |

| 5″ – 8 NPT | 8 | 3,175 |

| 6″ – 8 NPT | 8 | 3,175 |

| 8″ – 8 NPT | 8 | 3,175 |

| 10″ – 8 NPT | 8 | 3,175 |

| 12″ – 8 NPT | 8 | 3,175 |

| NPTF - National Pipe Taper Fuel - American tapered pipe thread. | ||

| thread size/inch | number of turns/inch | hole diameter mm |

| 1/16″ – 27 NPTF | 27 | 0,94 |

| 1/8″ – 27 NPTF | 27 | 0,94 |

| 1/4″ – 18 NPTF | 18 | 1,411 |

| 3/8″ – 18 NPTF | 18 | 1,411 |

| 1/2″ – 14 NPTF | 14 | 1,814 |

| 3/4″ – 14 NPTF | 14 | 1,814 |

| 1″ – 11 1/2 NPTF | 11,5 | 2,209 |

| 1 1/4″ – 11 1/2 NPTF | 11,5 | 2,209 |

| 1 1/2″ – 11 1/2 NPTF | 11,5 | 2,209 |

| 2″ – 11 1/2 NPTF | 11,5 | 2,209 |

| 2 1/2″ – 8 NPTF | 8 | 3,175 |

| 4″ – 8 NPTF | 8 | 3,175 |

| Tr – Trapezgewinde – trapezoidal thread. | ||

| size mm | thread pitch mm | thread diameter mm |

| TR 9 x 2 | 2 | 6,5 |

| TR 10 x 2 | 2 | 7,5 |

| TR 11 x 3 | 3 | 7,5 |

| TR 12 x 3 | 3 | 8,5 |

| TR 14 x 3 | 3 | 10,5 |

| TR 16 x 4 | 4 | 11,5 |

| TR 18 x 4 | 4 | 13,5 |

| TR 20 x 4 | 4 | 15,5 |

| TR 22 x 5 | 5 | 16,5 |

| TR 24 x 5 | 5 | 17,5 |

| TR 26 x 5 | 5 | 20,5 |

| TR 28 x 5 | 5 | 22,5 |

| TR 30 x 6 | 6 | 23 |

| TR 32 x 6 | 6 | 25 |

| TR 34 x 6 | 6 | 27 |

| TR 36 x 6 | 6 | 29 |

| TR 38 x 7 | 7 | 30 |

| TR 40 x 7 | 7 | 32 |

| TR 42 x 7 | 7 | 34 |

| TR 44 x 7 | 7 | 36 |

| TR 46 x 8 | 8 | 37 |

| TR 48 x 8 | 8 | 39 |

| TR 50 x 8 | 8 | 41 |

| TR 52 x 8 | 8 | 43 |

| TR 55 x 9 | 9 | 45 |

| TR 60 x 9 | 9 | 50 |

| TR 65 x 10 | 10 | 54 |

| TR 70 x 10 | 10 | 59 |

| TR 75 x 10 | 10 | 64 |

| TR 80 x 10 | 10 | 69 |

| TR 85 x 12 | 12 | 72 |

| TR 90 x 12 | 12 | 77 |

| TR 95 x 12 | 12 | 82 |

| TR 100 x 12 | 12 | 87 |

| TR 105 x 12 | 12 | 92 |

| TR 110 x 12 | 12 | 97 |

| TR 115 x 14 | 14 | 99 |

| TR 120 x 14 | 14 | 104 |

| TR 125 x 14 | 14 | 109 |

| TR 130 x 14 | 14 | 114 |

| TR 135 x 14 | 14 | 119 |

| TR 140 x 14 | 14 | 124 |

| TR 145 x 14 | 14 | 129 |

| TR 150 x 16 | 16 | 132 |

| TR 155 x 16 | 16 | 137 |

| TR 160 x 16 | 16 | 142 |

| TR 165 x 16 | 16 | 147 |

| TR 170 x 16 | 16 | 152 |

| TR 175 x 16 | 16 | 157 |

| TR 180 x 18 | 18 | 160 |

| TR 185 x 18 | 18 | 165 |

| TR 190 x 18 | 18 | 170 |

| TR 195 x 18 | 18 | 175 |

| TR 200 x 18 | 18 | 180 |

| TR 210 x 20 | 20 | 188 |

| TR 220 x 20 | 20 | 198 |

| TR 230 x 20 | 20 | 208 |

| TR 240 x 22 | 22 | 216 |

| TR 250 x 22 | 22 | 226 |

| TR 260 x 22 | 22 | 236 |

| TR 270 x 24 | 24 | 244 |

| TR 280 x 24 | 24 | 254 |

| TR 290 x 24 | 24 | 264 |

| TR 300 x 24 | 24 | 274 |

Hole parameters

Threads are distinguished according to the following characteristics:

- Unit of measurement. Throughout the country, the metric system is predominantly used. Inch values were used in the pipe industry.

Abroad, the inch system is considered the main one. Owners of cars that were assembled for the American market know that there is not a single element with metric cutting.

- Thread pitch and number of thread starts. Non-standard parameters are used in the automotive and machine tool industries.

- Profile form. The figures differ in the type of cutting. There are elements of triangular, rectangular, trapezoidal and round shapes.

- Direction of turns. There are right- and left-handed cuts.

- View. External or internal.

- Surface type. It can be cylindrical or conical.

The main condition for a high-quality connection is the correspondence of the indicators of the external and internal threads. If one of the parameters does not match, the fastening will be unreliable.

The most common threaded connection methods are bolt and stud fasteners. In the latter case, in addition to the main device, nuts and washers are used as auxiliary elements.

Pre-drilling holes is an essential procedure prior to cutting. In this case, the diameter of the gimlet should be slightly smaller than the size of the bolt or stud.

Drilling depth is one of the most important indicators. When calculating, the following factors must be taken into account:

- screw-in depth of the threaded element;

- the size of the external thread;

- presence and chamfer parameters.

To calculate the screw depth, the type of material being processed must be taken into account. For steel, titanium, bronze and brass no corrections are needed, but for gray and ductile cast iron a multiplying factor of 1.25 is used. For light alloys this figure is even higher - it is doubled.

Drill diameters for pipe (inch) taps

Pipe thread pre-hole size chart:

| G | Thread pitch, mm | Number of threads per 1 inch | ⌀ threaded drills, mm | ⌀ threaded holes, mm | ||

| Nominal | Limit deviations for accuracy classes | |||||

| A | B | |||||

| G1/8 | 0.907 | 28 | 8.7 | 8.62 | +0.1 | +0.2 |

| G1/4 | 1.337 | 19 | 11.5 | 11.5 | +0.12 | +0.25 |

| G3/8 | 1.337 | 19 | 15 | 15 | +0.12 | +0.25 |

| G1/2 | 1.814 | 14 | 18.75 | 18.68 | +0.14 | +0.28 |

| G5/8 | 1.814 | 14 | 20.75 | 20.64 | +0.14 | +0.28 |

| G3/4 | 1.814 | 14 | 24.25 | 24.17 | +0.14 | +0.28 |

| G7/8 | 1.814 | 14 | 28 | 27.93 | +0.14 | +0.28 |

| G1 | 2.309 | 11 | 30.5 | 30.34 | +0.18 | +0.36 |

| G1 1/8 | 2.309 | 11 | 35 | 35 | +0.18 | +0.36 |

| G1 1/4 | 2.309 | 11 | 39 | 39 | +0.18 | +0.36 |

| G1 3/8 | 2.309 | 11 | 41.5 | 41.41 | +0.18 | +0.36 |

| G1 1/2 | 2.309 | 11 | 45 | 44.9 | +0.18 | +0.36 |

| G1 3/4 | 2.309 | 11 | 51 | 50.84 | +0.18 | +0.36 |

| G2 | 2.309 | 11 | — | 56.7 | +0.18 | +0.36 |

| G2 1/4 | 2.309 | 11 | — | 62.8 | +0.22 | +0.43 |

| G2 1/2 | 2.309 | 11 | — | 72.27 | +0.22 | +0.43 |

| G2 3/4 | 2.309 | 11 | — | 78.62 | +0.22 | +0.43 |

| G3 | 2.309 | 11 | — | 84.97 | +0.22 | +0.43 |

| G3 1/4 | 0.907 | 11 | — | 91.07 | +0.22 | +0.43 |

| G3 1/2 | 1.337 | 11 | — | 97.42 | +0.22 | +0.43 |

| G3 3/4 | 1.337 | 11 | — | 103. 77 | +0.22 | +0.43 |

| G4 | 1.814 | 11 | — | 110. 12 | +0.22 | +0.43 |

| G4 1/2 | 1.814 | 11 | — | 122. 82 | +0.22 | +0.43 |

| G5 | 1.814 | 11 | — | 135. 52 | +0.22 | +0.43 |

| G5 1/2 | 1.814 | 11 | — | 148. 22 | +0.22 | +0.43 |

| G6 | 2.309 | 11 | — | 160. 92 | +0.22 | +0.43 |

How to choose drills for UNC/UNF taps

Inch cylindrical threads UNC (large) and UNF (fine) are less common in Russia; their profile is similar to the metric 60°, but the size is calculated in inches.

Table of hole diameters for the most common American UNC/ UNF threads:

| Inch UNC thread | |||||||||||||||

| Thread x Threads per inch | Drill diameter, mm | Thread x Threads per inch | Drill diameter, mm | ||||||||||||

| 1/4x20 | 5.1 | 7/8x9 | 19.5 | ||||||||||||

| 5/16x18 | 6.5 | 1x8 | 22.25 | ||||||||||||

| 3/8x16 | 8 | 1 1/8x7 | 25 | ||||||||||||

| 7/16x14 | 9.4 | 1 1/4x7 | 28.25 | ||||||||||||

| 1/2x13 | 10.8 | 1 3/8x6 | 30.75 | ||||||||||||

| 9/16x12 | 12.2 | 1 1/2x6 | 34 | ||||||||||||

| 5/8x11 | 13.6 | 1 3/4x5 | 39.5 | ||||||||||||

| 3/4x10 | 16.5 | 2x4 | 45 | ||||||||||||

pp

| Inch fine thread UNF | |||||||||||||||

| Thread x threads per inch | ⌀ drill, mm | Thread x threads per inch | ⌀ drill, mm | ||||||||||||

| 1/4x28 | 5.5 | 3/4x16 | 17.5 | ||||||||||||

| 5/16x24 | 6.9 | 7/8x14 | 20.5 | ||||||||||||

| 3/8x24 | 8.5 | 1x12 | 23.25 | ||||||||||||

| 7/16x20 | 9.9 | 1 1/8x12 | 26.5 | ||||||||||||

| 1/2x20 | 11.5 | 1 1/4x12 | 29.75 | ||||||||||||

| 9/16x18 | 12.9 | 1 3/8x12 | 33 | ||||||||||||

| 5/8x18 | 14.5 | 1 1/2x12 | 36 | ||||||||||||

End of table