Spring steel grades used in industry

Spring steel, grades of which are applicable in the manufacture of tight products, characterized by restoration of the original shape, with strong bending and significant twisting.

The most important parts in the production of mechanisms that experience variable, repeated loads, under the influence of which severe deformation occurs. As soon as the load stops, these elements return to their original shape. There is a feature in the operation of these parts that does not allow residual destruction; it must only be elastic. Excessive production requirements are placed on spring steels. Let's figure out what kind of steel springs are made of?

Model 31512-2912012

This UAZ spring is a rear small-leaf part, which in the standard version was mounted on models 31512, 31514-10, 3160. The element is also suitable for “Patriots” and “Hunters”, as well as their modifications.

Distinctive characteristics of the node in question:

- Control load – 504.7 daN.

- The weight of the assembled unit is 16.5 kilograms.

- Element length – 1.35 m.

- The number of sheets is three pieces.

- The height of the package is 37.2 mm.

- Material grade – steel 50Х-ГФА.

Why is spring alloy produced?

Both alloy steel and carbon steel can be used to produce parts; they have increased elasticity, toughness, endurance and ductility. Due to the properties of these types of steel, elastic destruction is limited.

Spring steels are affordable, technologically advanced, and have a high limit of relaxation resistance.

Interesting: to obtain high-quality products from carbon and alloy steel, it is hardened at a temperature of 420-520 degrees, which produces the effect of a troostite structure.

Spring steels resist fragile fracture and are characterized by increased ductility. They are used to produce products with high wear resistance, for example:

- clamping collets;

- brake rolling;

- edges;

- springs and leaf springs;

- thrust washers;

- bearing torsos;

- friction discs;

- gears.

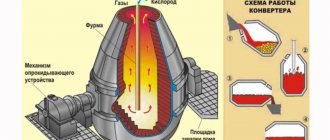

Technology of hardening and tempering of spring steel

To obtain metal with the desired physical properties, spring steel is tempered and hardened. Each stage has its own technological features:

- First, the spring steel is hardened at high temperatures. Thanks to hardening, the yield strength of the material increases significantly, which makes the steel elastic, malleable, and stable.

- However, during high-temperature hardening, martensitic compounds are formed inside the alloy, which sharply worsen the elasticity of the material, making it unusually brittle and hard.

- To get rid of martensitic compounds, spring steel should be tempered at low temperatures. During such processing, martensites are destroyed, which makes it possible to obtain a material with the desired properties.

Steel grades according to GOST 14959–79

These are steels with a high carbon content, but with low alloying. Gosstandart 14959 means alloyed alloy of the following grades:

- 3K-7 - used in the production of cold-drawn wire, from which non-hardening springs are made;

- 50ХГ – produce springs for cars and springs for railways. compositions;

- 50HGA - purpose in production as in the previous brand of spring steel;

- 50HGFA – produce special springs and spring parts for cars;

- 50ХСА – special-purpose springs and small parts for watch mechanisms;

- 50HFA - they produce parts with increased load, with the requirements of the highest stability and strength, which operate at high temperatures - up to 300 degrees.

- 51HFA – for spring wire;

- 55С2 - for the production of spring mechanisms and springs used in tractor construction, mechanical engineering, for railway rolling stock;

- 55С2А – produces auto springs, springs for trains;

- 55S2GF - for the production of very strong springs of a special type, autosprings;

- 55KhGR – produce spring strip steel, the thickness of which varies from 3 to 24 mm;

- 60G - for the production of round and smooth springs, rings and other spring-type products with high wear resistance and elasticity, for example, staples, bushings, tambourines for braking systems used in heavy engineering;

Interesting: torsion steel, grade 60C2 - high-load springs, friction discs, spring washers;

- 60С2А - produce the same products as from the previous type of steel;

- 60S2G – type of spring steel from which tractor and auto springs are produced;

- 60С2Н2А – produce responsible springs with a high load on the alloy;

- 60С2ХА – for the production of highly loaded spring products subject to constant load;

- 60S2HFA is a round steel with calibration elements, from which springs and spring plates are produced with high responsibility;

- 65 – produce parts with increased strength and elasticity, which are operated under high pressure, high static loads and strong vibration;

- 65G - produce parts that will work without shock loads;

- 65GA – hardened wire for springs;

- spring steel grade - 65S2VA, highly loaded leaf springs and springs;

- 68A – hardened wire for the production of spring devices with a caliber of 1.2-5.5 mm;

- 70 – parts for mechanical engineering that require increased wear resistance;

- 70G – for spring elements;

- 70G2 - produce digging knives and springs for various industries;

- 70С2ХА – spring elements for watch devices and large springs for special purposes;

- 70С3А – springs with high load;

- spring steel grade 70HGFA – wire for the production of spring elements with heat treatment;

- 75 – any spring and other parts used in mechanical engineering that are subject to heavy vibration loads;

- 80 – for producing flat parts;

- 85 – wear-resistant parts;

- SH, SL, SM, DN, DM – machine springs operating under static loads;

- KT-2 – for the production of cold-drawn wire, which is wound without heat treatment.

Spring from Moskvich. does it make sense to forge?

Hello, dear ones! Help me decide: I have a “humpbacked” Moskvich spring, does it make sense to reforge it on itself or anneal it, level it, etc. Sheets are a full package, do they differ in quality (short-long) With respect and gratitude to those who responded!

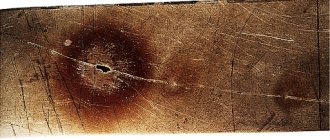

The springs, as I understand it, were running? Then there was information on this topic that in tired springs there are microcracks that are undetectable by the eye. Total - straightened, forged, hardened, burst. Do you need it? On the other hand, when producing “sergeant’s” katanas, the Japanese considered monometal, boiled on itself a couple of times, to be of higher quality than the same “simply forged.” On the third hand, for “just knives” anything will do.

Good material. 65G, I think. it will definitely work. And about the cracks. Well, he can really weld it with him and forge it thoroughly.

Old Muscovites had 65G. For indestructible knives (Leukku, Kukri) - this is it. But for delicate cutting, IMHO, not very good.

THANK YOU! Please write a few words about proper reforging for yourself! Best regards,

Correctly, this is not here, this is to Kuznetsov. And so, if it’s stupid from experience, then boiling it twice (a couple of dozen layers) is more than enough. Well, pull the blade back without overheating, if you’re not too lazy.

I looked in the book for Moskvich 407/403. Steel 50HGA

I looked in the book for Moskvich 407/403. Steel 50HGA

65G is not born on car springs. 65G is used for small things, which the spring does not belong to. there are collets, small springs, and other trinkets.

65G is not born on car springs.

Characteristics of material 65G

Brand: 65G Substitute: 70, U8A, 70G, 60S2A, 9ХС, 50ХФА, 60С2, 55С2 Classification: Structural spring steel Application: springs, leaf springs, thrust washers, brake bands, friction discs, gears, flanges, bearing housings, clamping and feed collets and other parts that require increased wear resistance, and parts that operate without shock loads.

this is all very cool. there's only one thing to eat there.

working without shock loads.

Udod

Old Muscovites had 65G. For indestructible knives (Leukku, Kukri) - this is it. But for delicate cutting, IMHO, not very good.

AND “DILICATELY” CUT EVEN VERY VERY MUCH. SINCERELY .

AND “DILICATELY” CUT EVEN VERY VERY MUCH. SINCERELY .

I believe that the biggest myth about springs is that they are made from 65G steel. Almost everyone understands this, spring = 65G. And in order to find this same 65G in the springs, you’ll have to “run around”!

Oh, yes, on topic - of course you can forge!