Among the abundant variety of welding machines on the modern market, the manual welding extruder occupies a special place.

A manual extruder for welding is a device for joining products made of polyethylene, polypropylene, propylene, other types of plastics, plastic sheets, films, containers (barrels, swimming pools, etc.), wells, children's slides, and so on. Rarely used for joining PVC products. It is not suitable for use in welding pipelines, since the strength of such joints is no more than 80%, they will not be airtight. The operating principle of this device is as follows: hot air is supplied from the extruder nozzle and heats the space (welding groove or joint) between the planes of the parts, bringing them to the state of plastic. At the same time, the rod is fed into the working area of the equipment, heated and mixed with the screw (or disk), and then forms a homogeneous mass of plastic. The polymer in a molten state is extruded through a die or welding shoe, then after complete cooling, a finished seam is obtained. Squeezing the polymer can be thought of as squeezing toothpaste out of a tube.

The requirement for perfect cleanliness in this type of welding is the most stringent. Surfaces must be thoroughly cleaned immediately before welding.

The surfaces to be joined must be identical. This concept in this vein refers to the same chemical composition, density and fluidity of the material. According to these indicators, the rod must be identical to the parts being welded.

Types of Manual Welding Extruder

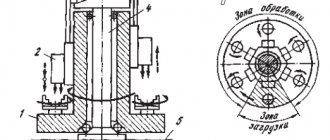

- Screw (filler material is melted in the screw (extrusion) compartment of the apparatus and squeezed out using a screw). The filler material is a rod or special granules that are placed in the screw compartment and there, under the influence of high temperature, when interacting with the screw, they become a homogeneous mass, ready for use.

- Screwless or plunger type. The rod in such extruders is first heated using electric heaters around the heating area, and the rear solid part of the filler material acts as a piston for the front, already viscous mass.

- Combined (the two above types are combined).

Screwless welding extruders have lower productivity compared to screw extruders. But there are also advantages: lightness and compactness, which allows you to use it in hard-to-reach places.

The peculiarity and priority of use is determined by the following factors.

- The manual welding extruder can weld products with thick walls.

- Fast welding speed.

- Minimizing the human factor. There is no need to monitor the condition of the weld pool, as when welding metal, to control the correct removal of welding slag, to remove “herringbones” and “zigzags”. This equipment will be easiest for a beginner to use.

Homemade device

The welding extruder is a complex mechanism for professional use. Its price starts from 30 thousand rubles for the simplest model, and can reach one hundred thousand or more for a powerful and high-performance one. Domestic developments are also presented on the market; they are 10-20% cheaper than imported ones, but are still quite expensive.

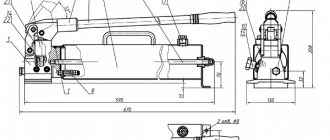

Therefore, if a one-time need arises to weld, for example, two water pipes (their usual material of manufacture is polypropylene), it is easier to use a home-made extruder. The simplest version of the design is a powerful construction hair dryer, equipped with a nozzle for a rod - either homemade, made of tin, or industrially made .

In this case, the bar will be fed manually. The power of the hair dryer is enough to melt it, but the quality of the seam, of course, will be lower than that of industrial models.

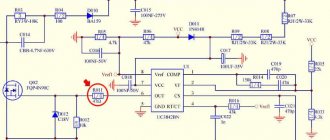

If possible, the hair dryer can be connected to a screw or plunger drive to supply power. In this case, if you install a receiving chamber, it will be possible to use granulated raw materials.

A commutator motor is recommended for the drive, since the operation of the extruder implies a constant change in torque. Engines of other types are less resistant to this operating mode.

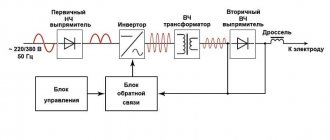

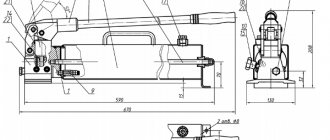

Manual welding extruder: operation diagram

When making a connection, both parts must be heated. For the purpose of heating surfaces before extruding filler material, a manual welding extruder may contain in its design a special air flow heater or, in other words, a hot air gun. Also, the heated air flow can come from external equipment: a compressor or an organization’s pneumatic network. The filler material is heated using special electric heaters around the screw (extrusion) chamber. But in older extruders, the chamber is heated using hot air, which is used to heat the welding zone. Before heating the welding area, air flows around the screw compartment and melts the filler material. The filler material in molten form flows out into the welding zone through the welding shoe.

Extruder welding is most often used for low-density polyethylene, polypropylene and other types of thermoplastics of the first group. For this type of thermoplastic, the temperature difference between the molten state and the state of thermal destruction is about 50 degrees. This suggests that even large overheating of the material (by about 30-40 degrees) is not capable of severely damaging it.

Thermoplastics of the second group include PVDF and PVC. Their temperature difference between thermal destruction and the fluid state of the material is insignificant, so when welding there are strict requirements for the operation of the heating department. When working with thermoplastics of the second group, there are special requirements for the screw; it must be of a special shape in order to mix the mass more thoroughly, preventing overheating.

Also, when working with PVC and PVDF, the extruder should not be turned off and/or remain in standby mode for a long time.

Operating principle

A welding extruder is a specialized apparatus for so-called extrusion welding, which is used to join polymer materials of various classes - high-density polyethylene (HDPE) and low-density polyethylene (HDPE), polypropylene, polyvinyl chloride (PVC) and other plastics most commonly used in everyday life and industry.

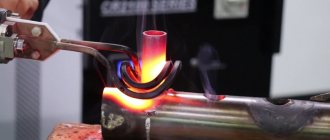

Extrusion welding is the process of joining polymer materials using a mass of material melted to the consistency of thick sour cream that is homogeneous with the ones being welded or similar in physical and chemical properties.

Unlike the more well-known welding of metals, joining plastic parts by extrusion does not involve melting the edges of the parts being joined, although heating to a certain extent still occurs.

The seam is formed when the semi-molten extruded mass hardens and sets with the edges. In this case, high strength of the welded joint is achieved - up to 0.8 of the strength of the base material.

Welding plastic with an extruder is most often used in plumbing - for connecting water pipes, in construction, in various works, the purpose of which is the manufacture of any plastic structures - tanks, pontoons, greenhouses.

The production of the extruded mass is carried out either from polymer granules - the starting material for creating any plastics, or from so-called filler rods, which are ground to a granular state inside the extruder itself.

In some (not all) models, the role of a rod can be a narrow piece of the same material that is planned to be welded. For example, when welding a product made of polypropylene sheets, you can use an unnecessary piece of polypropylene as a rod, but not other plastic.

Most Western-made welding extruders are designed to be used with filler material from the same manufacturer. Domestic developments are less demanding on the additive. A manual welding extruder is often called an extrusion gun in everyday life. \

Extruder welding

If the device is not used for the first time, then it is necessary to remove the filler material used previously. Even if it is of the same composition. Repeated heating of the filler material reduces its strength.

Before directly starting welding, it is necessary to remove the cold start locks, heat the machine and welding shoe to the temperature required for work, and adjust the performance.

During the welding process, it is necessary to maintain the desired angle of inclination of the welding machine, depending on the type of seam being made. If you need to take a break, the extruder must be placed on a special stand. If you are planning a long break, reduce the temperature by about 40-50 degrees. Such a decrease in temperature will allow the heating of the filler material to be stopped and operation to be resumed quickly.

Thus, welding with a manual welding extruder is one of the easiest to use among other types of welding and with the use of other devices. You don't need to be a professional at all. You just need to follow the operating instructions for the extruder and follow the above rules when working with the device and the materials being welded.

Welding equipment for welding plastics

The most popular welding equipment are hand-held welding extruders and welding guns. They are easy to use, relatively inexpensive and, due to their low weight, very convenient to use. If you have such equipment, you can manufacture products from polypropylene sheets not only in the workshop, but also on site.

The principle of operation of the equipment is to supply hot air, which heats the surfaces to be welded and the additive (welding rod or granules) to a molten state, thereby achieving a strong connection of the parts being welded.

You can learn more about the features of using welding equipment by familiarizing yourself with the technology of welding polypropylene.

Leister hand-held devices Professional welding guns and extruders Leister (Switzerland)

Weldy hand guns Construction guns and kits for welding plastics

Welding machines Leader Compact and reliable manual extruders Leader

Automatic welding machines Convenient professional automatic welding machines and testing equipment.

Welding machines Semi-automatic machines for butt welding of sheet plastics

Stitching rollers

Nozzles

Types of nozzles for welding plastics

Welding attachments differ in the type of seam that will be produced during the manufacture of the product. The seam can be butt, corner (external and internal). Depending on the type of seam, the welder selects the optimal cross-section of the welding rod that he will use. The rod can be round, oval, triangular, flat. Accordingly, the nozzles for welding will be for a round rod, for a triangular rod or flat-slit. These nozzles can be considered quick welding nozzles; in addition to them, there are also adapter nozzles that are used to switch to quick welding nozzles.

Attachments for welding polypropylene sheets with extruders also differ in the type of seams and rods that will be used in the work.

Should I choose a hair dryer or an extruder?

If in the manufacture of products you use sheet plastics with a thickness of more than 10 mm, if you require a high-quality and durable connection and you have a budget of 100,000 rubles or more, then choose a welding extruder. For this money, the device will be equipped with an air heater with a built-in temperature controller, it will have good power and performance, and the welding seam will be performed in one pass. In addition, you can adjust the auger speed in the range from 20 to 100 percent.

A welding hair dryer is 4-5 times cheaper than a welding extruder, 1.5 times smaller in size and weighs no more than 1.3 kg including the cord, while even the smallest extruder weighs from 4 kg.

A welding gun is a universal little helper, without which no production can do. Consumables for a hair dryer are relatively inexpensive, so even a novice welder can afford to operate it. The hair dryer is great for repairing car bumpers and welding containers with a wall thickness of up to 6mm, as well as for use in hard-to-reach places when repairing plastic products.

To perform various welding seams, you will need welding attachments, which you can also purchase from our company.