A car muffler, operating in an aggressive environment at high temperatures and humidity, quickly becomes unusable. Corrosion, corroding the metal, destroys the muffler. In addition to the negative effects of rust, the muffler is easily holed on rough terrain due to its low location. The consequences of such damage are very unpleasant. The roar of a running engine begins to grate the ear, and the exhaust gases, losing their directional flow, enter the car interior. Of course, replacing the muffler with a new one solves all these problems. But you can get by with a less expensive method - welding. At first glance, welding a muffler may seem like a difficult task, but there is nothing difficult in this process if you understand a little theory.

For work we will need:

- Welding machine. Almost any low-power unit is suitable for welding a muffler, but it is better to use a semi-automatic machine with protective gas (CO2) with a wire diameter of 0.8-1 mm,

- Wire brush or sandpaper. With their help, it will be necessary to clean the surface from dirt and rust,

- Angle grinder (grinder),

- Degreaser. Before welding, they need to clean the surface from metal chips and dust after working with sandpaper and a grinder,

- Pieces of sheet metal. They must be cut so as to completely cover the defect. The thickness of the pieces should not exceed two millimeters.

- Small hammer or chisel. After welding with their help, it will be necessary to remove scale in order to inspect the quality of the welds.

- Protective primer and heat-resistant paint. The final procedure will be painting the repair areas. The paint will provide additional protection from moisture.

Muffler welding

What electrodes should be used to cook a muffler?

One of the systems of any car is a system for removing used gases.

Malfunctions in the operation of the recycled product removal system lead to an increase in the volume of noise that is formed in the car muffler, like a uniform, constant hum. There is also the possibility of a loss in engine power due to a clogged exhaust system, which in turn prevents the supply of incoming air flow. Another negative factor in system damage is an unpleasant odor inside the car, as well as the appearance of soot on the bottom of the car. The gas exhaust system is one of the main “vital” systems, so you should carefully consider problems associated with repairing the muffler and other parts of the system. Welding the muffler . Welding a muffler yourself requires that the welder has the appropriate experience to perform high-quality welding work. It is worth noting that the muffler can be repaired by welding only if a breakdown or mechanical damage was caused by hitting an obstacle. However, if a crack in the muffler is caused by corrosion processes, then welding will be ineffective, since the metal around the crack is often too thin for welding. First you need to prepare a patch, preferably made of sheet metal, and apply it to the place on the engine where the damage is located. Next, you should treat the surface of the edges of the damage and the applied metal with sandpaper, and you also need to clean the surfaces from rust and carbon deposits. For safety reasons, before starting welding work, do not forget to turn off the car's ignition and disconnect the battery. To avoid burning through the muffler metal, the patch should be applied where the metal thickness is higher. It is most effective to repair damage to the muffler using electrodes with a diameter of 2 mm and adjust the current supply on the device accordingly. Welding should be carried out with arc separation, and the movement of the electrode should be from thicker to thinner metal, that is, from the patch to the muffler metal. The resulting weld seam must be hammered away from slag deposits and visually inspected for the presence of pores on the seam. Operation is possible only if there are no pores, but if there are pores, then you need to boil it again and make an additional seam on top of the first one. After completing all welding work, it is necessary to remove scale by sanding.

The highest quality and most accurate welding can be achieved using a semi-automatic welding machine, however, to use it effectively, experience with it is required. It is more convenient to carry out welding work in an inspection pit. A more economical way to weld a muffler is cold welding , but its quality will be much lower. In this case, it is also necessary to prepare the surface, degrease it using acetone. After this, apply the prepared cold weld to the hole in the muffler, while carefully covering all the irregularities. The weld must freeze.

Source

Symptoms

How to determine the need for repair of this element? Everything is very simple - while the engine is running, you will hear a characteristic sound of exhaust gases being discharged. It will be very loud, whistling in places.

Also, some of the exhaust gases may leak into the cabin (in this case, welding of the muffler corrugation is also necessary). The smoke will dissipate not from the exhaust pipe, but from the bottom itself, and from different sides. Thus, if the muffler begins to behave this way, it means that it has warmed up or is rusty. Experts recommend a complete replacement of the element. However, a cheaper way is to weld the muffler yourself.

What electrode should be used to weld the muffler pipe?

Tell me what kind of electrode can be used to properly weld the exhaust gas system pipe. An annular crack appeared on the pipe near the clamp connecting the additional and main mufflers on Kalina (as in the picture, but the photo is not mine), and, accordingly, a loud exhaust. There is only a Resanta 160 welding inverter, and a regular old trans, but we don’t consider it by default; there are no other possibilities or welding options. What brand and dia. Is the electrode suitable for this pipe? The pipe is not rotten, there is some rust, but it is superficial.

Vidis wrote: What brand and diameter. Is the electrode suitable for this pipe?

well, for example TsU-5

Klez wrote: if your Resanta “digests” them

I don’t know whether this inverter digests these electrodes, because I recently purchased and so far only burned a dozen MP-3 red electrodes, so it was not without reason that I indicated the brand in 1 post.

cook with any, it won’t last long anyway

Resanta 220A LBekha digests exactly. But this junk is cooked by LBekhoy. It will break off next to the seam. It doesn’t matter what you use to weld it with. Can I put my words in the bank?

I used two TsL-11 to repair such a crack at the turn of the pipe from the resonator to the same joint with the plug. But my current pipe was closer to stainless steel. It seemed so dark, but there was no obvious rye, the surface was clean, without layers. It brewed very well.

Garik_31 wrote: There is a cast-iron-graphite donut between the halves, and everything moves on it.

Well, I don’t know how it “moves”, I just installed a piece of pipe, everything held on, didn’t break.. This “donut” is stuck to the pipe so that you simply can’t get it off. Although with corrugation, the option is ideal, the only question is its price.

Klez wrote: it’s easier to cut off the pipes (cones) and connect them with a spacer. for 2 clamps.

How to connect without cones? it is necessary to precisely adjust the spacers to the diameter or make cuts on it like a collet, but then gases will escape from under the cuts.

Should it really move there? After all, if you don’t tighten the clamp well, the gases will leak.

Vidis wrote: Should it really move there? After all, if you don’t tighten the clamp well, the gases will leak.

Definitely. That's why the donut lies between the hemispherical surfaces.

Garik_31 wrote: That's why the donut lies between the hemispherical surfaces.

and not just for sealing?

Vidis wrote: it is necessary to precisely adjust the spacers to the diameter or make cuts on it like a collet, but then gases will escape from under the cuts.

That’s exactly what I did, adjusted it tighter, made cuts, and actually wrapped the seal with asbestos cord. Nowadays there are a lot of all kinds of thermo-sealants, I think this is not a problem, but about the corrugation. The idea is very good, it’s worth thinking about. (You can always brew it, the question is how long will it last?) And with such experience as yours, 10 el, it will be problematic to apply the seam is high quality.

Main elements of the exhaust system

The design of the exhaust system becomes more complex, but with each new car model it includes all the same elements.

Collector

The exhaust pipe is an intermediate link between the car engine and the converter (catalyst). The collector is responsible for the removal of gases. Since in this case there is a very strong mechanical and temperature load, which can reach up to 1000 degrees, quite strict requirements are imposed on this part of the muffler. Therefore, in the manufacture of the intake pipe, only the best alloys of cast iron and steel are used.

Also, a vibration compensator (corrugation) is sometimes installed on this part, thanks to which engine vibration is damped and does not pass further through the exhaust system.

Neutralizer

The catalytic converter (or catalyst) “afterburns” unburned fuel residues and processes carbon monoxide. This element of the exhaust system is a special chamber or tank in which a ceramic or metal element in the form of a honeycomb is located. Thanks to these honeycombs, gas mixtures are purified through chemical reactions.

Now manufacturers have begun to produce multi-section neutralizers that meet all international standards, which process a wider range of harmful substances.

Front muffler (resonator)

The resonator is, in fact, one of those parts that are commonly called mufflers. This element performs the function of reducing noise, but not cleaning exhaust gases. When gases pass through the resonator, a lot of noise is created. Therefore, the internal “filling” of the front muffler consists of numerous grilles and holes that reduce the speed of escaping gases, as well as vibration. By and large, a resonator is a tank with a perforated pipe.

Front mufflers are:

- Active. Such mufflers are made of special sound-absorbing materials, and their design is simple.

- Reactive. Silencers of this type use combinations of expansion and resonator chambers.

Do not confuse the resonator with the rear muffler, as their design is very different.

Rear muffler

When we say “muffler,” we most often mean the rear part of the exhaust system. This element provides the final absorption of noise and also carries out the final removal of gases.

Unlike the resonator, the internal “filling” of the rear muffler is heterogeneous. Several chambers with special fillers are installed inside it. Thanks to the porous structure, the system of partitions and air ducts, it is possible not only to get rid of strong noise, but to reduce the temperature in the system.

Speaking of noise reduction, we cannot ignore another type of system that reduces excessive noise in the exhaust pipe.

A cross-section of a car muffler operating on the principle of noise absorption is shown in the diagram.

As in the resonator, partitions and jumpers in the form of tubes are installed here. Only in the latter are many holes of different diameters (perforation) made, and non-flammable absorbing material is laid on the sides. As a rule, basalt or kaolin wool is used for these purposes, which can easily withstand gas temperatures of 600–700 °C.

Sound waves, passing through adjacent pipes with holes, are partially scattered and damped by overlapping each other. The second part of the vibrations is absorbed by the filler, and the third is smoothed out due to partitions and a change in the direction of flow.

How to properly weld a muffler?

How to properly weld a muffler?

If a crack has formed in the muffler of the car's exhaust system (in the can or in the connecting pipes), then the muffler can be welded, but there are some restrictions. And not in all cases it is possible to weld the muffler. It is also very important to choose the right type of welding machine. And so, let's start by deciding in what cases the use of welding is justified, and whether it is possible to weld the muffler in principle.

Situations when welding the muffler is impossible

If the exhaust muffler has suffered a breakdown as a result of hitting an obstacle or as a result of mechanical damage, but it itself remains in good condition and retains the thickness of the steel on all surface areas, then in this case the use of welding is justified.

Low prices for spare parts for cars, click here!

If the muffler has been subjected to corrosion processes, a burnout has formed in it, and the muffler itself has been used for several years without replacement, then in this case there is no point in welding it, if at all. Here the simplest solution would be to completely replace the muffler with a new one, especially since its cost is not so high as to try to restore or extend the life of the old part. The remaining thickness of the steel in the old muffler may not allow it to be welded effectively.

What type of welding is used to make mufflers?

Is it possible to weld a muffler using electric welding? If you are a very experienced welder and are willing to spend a lot of time, then you can try welding the muffler using electric welding. In this case, the muffler should be welded by electric welding only spotwise and without moving the electrode, and this will take a very long time. Here we are talking about repairing the muffler can; the steel on the connecting pipes is thicker, and therefore the use of this type of welding is acceptable. If you don’t have good experience welding a muffler using electric welding, then you shouldn’t even try. You are almost 100% guaranteed to ruin this part of the exhaust system.

Silencers are made semi-automatically. It is also important to have sufficient experience. If you doubt your abilities, then finding out how much it costs to weld a muffler at the nearest service station is not difficult. It's better to leave this to the professionals.

How to weld a car muffler?

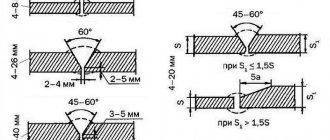

Before carrying out welding work, you should prepare the patch and also clean the surface at the site of future welding work. What electrode should be used to weld a muffler? It is better to weld the muffler with an electrode with a diameter of 2 mm; if you have an electrode with a diameter of 1.6 mm, then even better. The current on the welding machine is set to the corresponding electrode.

Welding a muffler - is it easy to do it yourself or is it better not to try

One way to extend the life of a long-suffering exhaust system is to weld the muffler.

This part of the car is subject to a barrage of destructive factors, including: sudden temperature changes; aggressive exhaust gas environment; excess moisture; inability to use effective protective and anti-corrosion compounds; mechanical and abrasive damage during movement; constant vibration. As a result, the new muffler turns into a corroding pipe quite quickly. However, you shouldn’t run to the store and buy a new muffler when you can extend the life of the old one.

How to weld a muffler in a garage

Muffler repair

Until hints of through corrosion appear in the muffler housing, resonator or exhaust system pipes, there is no need to begin repairing it. When the time comes for repairs, you will hear. With the appearance of “fistulas,” the sound of the running engine changes, smoke begins to spread from under the bottom, often making staying in the cabin unbearable.

The most reliable method of repair is welding. Having the skills to use a welding machine, any car enthusiast can carry out the necessary repairs even in a garage. There is absolutely no point in hiring specialists for this.

To carry out welding work you must have:

- welding machine (preferably semi-automatic with wire with a diameter of 1 mm);

- a set of automotive tools (wrenches, hammer, screwdrivers);

- angle grinder (grinder) with a set of cutting and cleaning discs;

- fragments of sheet metal 1-2 mm thick;

- metal brushes, sandpaper;

- heat-resistant paint for mufflers.

Repair of the muffler is local in nature, that is, where it burned out, we “patch it” there. Corroded areas are completely removed.

After a fragment of the resonator or muffler body is cut out, it is imperative to determine the condition of the internal elements. It often happens that partitions or pipe sections inside the muffler are also destroyed.

In this case, you will have to cut out a technological window in the surface of the “barrel” through which the internal parts are restored.

Welding of the muffler or pipes is carried out using a semi-automatic welding machine. This type of welding is more gentle, since the carbon dioxide that accompanies the welding process does not allow the metal to overheat and change its structure. When working on the exhaust system, it is necessary to make continuous welds.

Quite often, through corrosion forms at the junction of the muffler body and the pipe. In this case, it is necessary to completely cut out the corroded section that has become unusable, replace the pipe section and re-weld the muffler.

Painting the muffler after repair can significantly increase its service life. Factories often use low-quality dyes. That is why the exhaust system quickly becomes unusable. If the exhaust pipe has been repaired, care should be taken to further protect it.

To do this, use brushes and abrasive materials to clean all parts of the exhaust, rinse and degrease the surface. For coloring, dyes such as KO 8111, KO 8101, KO 828 or their analogues are used.

When selecting paint, it is important that it is specifically designed for surfaces that are heated to high temperatures. These brands are used if it is necessary to paint parts that can heat up to 600º C.

The paint is applied by spraying or brushing in 2-3 layers.

Urgent repair of a silencer without a welding machine

Argon welding of a motorcycle muffler

New composite materials have begun to appear among drivers' repair kits, which make it possible to repair the exhaust system very quickly.

Cold welding for the muffler is available on sale - a special elastic or viscous composition, which, when mixed with a hardener, firmly adheres to the site of damage. To do this, you can use materials such as “Desan”, “Polyrem” or other types of cold welding.

Their advantage is fast preparation, rapid hardening, and strong adhesion.

To repair leaky pipes, special bandages are used. The kit includes a “bandage” and a viscous polymer for wetting. A reinforcing layer impregnated with a special composition is wound onto a section of pipe, after which the exhaust system is heated with gases from a running engine. Under conditions of elevated temperature, a very strong connection is formed that tightly closes the hole.

Such compositions are universal, as they glue not only different types of metals, but also glass, wood, and plastic. They are very convenient to use on the road if the service is unavailable. They should be treated no differently than a kind of “ambulance”, but at the first opportunity a full repair of the exhaust system should be carried out.

see also

Comments 36

everything would be fine, but the icebestos cord is nowhere to be found now

milkweed! Half of Russia travels like this and nothing happens.

It will last for some time until the asbestos sticks, becomes hard and cracks from vibration. It will definitely last 3 months, but in the meantime, save up for a new spare part; there’s no point in cooking either, as experience shows, it won’t last long.

I did this: I took an asbestos sheet and soaked it in liquid glass. Then it wraps easily. It was in the same place. I've been riding for about 7 months. And he did everything right.

Quiet muffler

Making a quieter muffler with your own hands is not so difficult. Let's take a pipe. Its walls should not be thick. This will be our resonator.

The end part should be made in the form of a funnel. We take a sheet of metal. You need to make it perforated. Let's make a tube out of it and connect it to the end part.

Along the entire length of the resonator pipe, you need to push washcloths made of iron filings. Housewives usually use them in the kitchen. We weld the end part to the resonator, finishing the seams. Such a muffler can eventually be treated with heat-resistant paint.

The disadvantage of such a muffler may be an increase in the mass of the entire system. You need to add additional brackets or shock absorbers.

As we can see, there is nothing complicated in making a muffler with your own hands. The main thing is to remember to always check them before installation.

How to weld a muffler using electric welding yourself

A car muffler, operating in an aggressive environment at high temperatures and humidity, quickly becomes unusable. Corrosion, corroding the metal, destroys the muffler. In addition to the negative effects of rust, the muffler is easily holed on rough terrain due to its low location. The consequences of such damage are very unpleasant. The roar of a running engine begins to grate the ear, and the exhaust gases, losing their directional flow, enter the car interior. Of course, replacing the muffler with a new one solves all these problems. But you can get by with a less expensive method - welding. At first glance, welding a muffler may seem like a difficult task, but there is nothing difficult in this process if you understand a little theory.

Using Cold Welding

Cold welding is an adhesive substance suitable for repairing parts made of almost any material. The choice of many motorists is this method of repair, as it is famous for its incredible resistance to negative factors and ease of use.

An important advantage of this repair method is that there is no need for complex training, special skills, the availability of tools necessary for welding work, as well as the complete absence of high temperatures and contact with electricity. As for strength, the cold welding method is close in durability to classical brewing.

Muffler repaired by cold welding

Cold welding is more mobile, you can take it with you on the road. If there is a breakdown, it will not be difficult to fix the problem and repair the car right in the middle of the road. The rest of the way you will not irritate yourself and the people around you with the deafening sounds coming from the car.

A muffler with through cracks can be “patched” using a bandage tape wound around the pipe.

Which welding method is better to weld a muffler?

The type of welding does not play a special role if you adhere to two basic parameters:

Semi-automatic welding has advantages when repairing a muffler compared to conventional electric welding. Its modes are more gentle on thin metal, and protective carbon dioxide will prevent overheating and oxidation of the weld. Thanks to this, the structure of the base metal will not change and will not lose strength. When working with conventional electric welding, it is necessary to select suitable electrodes for the metal being used.

Before welding the muffler, the battery should be disconnected to avoid a short to ground. Moreover, it is not at all necessary to take it out. It is enough just to disconnect the ground - the wire with a minus sign. It is usually black.

Welding a muffler with argon - what are the features?

This is a modern technology that allows you to connect parts made of steel and metal alloys. The operation is carried out in several stages. First, the surface is prepared (cleaned with a metal cutter and degreased). Next, the parts are connected using tacks. A metal rod is then placed along the seam line. At the final stage, the rod and the part itself are welded. During welding, argon gas is used. Oxygen does not enter the part because argon enters the welding area under high pressure.

This technology ensures high joint strength and seam tightness. The service life of such a muffler is an order of magnitude longer than that of a repaired semi-automatic muffler. But the disadvantage of technology is the high cost of equipment. Fortunately, there are now a lot of companies that provide services such as muffler welding and corrugation replacement. The latter is also installed in the pipe using argon welding. The cost of such services is about three thousand rubles, including the price of the three-layer corrugation itself.

Damage Prevention

Muffler corrugation

Some motorists prefer to install a special corrugated tube where the muffler is attached to the manifold. The result is a flexible connection that dampens negative vibrations and reduces temperature.

It is recommended to regularly treat the muffler of your car with special anti-corrosion compounds, as well as heat-resistant paints. Thanks to this, you can really avoid burnout or the formation of holes due to rusting.

Progress

It is necessary to free the fire extinguisher from the old powder by first unscrewing the head from it. In order for the pipe to fit tightly into the hole in the fire extinguisher, you need to make it a little wider.

On the second side of the cylinder you need to make another hole, slightly moving it towards the wall of the fire extinguisher.

Next, we insert the pipes into the fire extinguisher and weld everything in a circle. Welding must be done carefully, without burning through the metal.

The next step is to remove the fasteners from the fire extinguisher. We weld it to our system. To make such a muffler with your own hands even quieter, the body can be filled with glass wool.Or, instead of the exhaust manifold, install a corrugation, preferably one that is flexible.

After manufacturing the product, you need to check it for leaks so that unpleasant noises do not arise later. This can be done by pouring regular water, after plugging one hole.

If no water flows out, then your muffler is ready and can be installed.

Do-it-yourself muffler repair using electric welding

To weld a muffler yourself, you only need to have a little skill in working with metalworking. The work can be done in any garage conditions. Penetrating corrosion must be completely cut out using an angle or straight grinder using a cutter.

Depending on the diameter of the defect, the work can be done in two ways. The first is to apply a patch, followed by welding it around the perimeter. This method is used for large defects or a large accumulation of pores in one place.

The second method allows welding without the use of patches, in which through holes are fused directly by an electric arc. This method is applicable only if the corrosion or defect is small. It will not be difficult to patch such holes either with an electrode, using simple welding, or with copper wire, when working on a semi-automatic machine.

Most often you encounter corrosion in the place where the muffler body and pipe are connected. After cleaning and removing rust, the gap between these parts increases significantly. You can increase the required thickness between them using a filler wire (electrode) or weld using pieces of prepared sheet metal. After applying the metal sheet, it should be grabbed, ensuring its fixation with the muffler body, and then proceed to the main welding.

Upon completion of the work, the heat-affected area and the weld itself should be painted over with paint. This treatment will protect the metal from corrosion and prolong the service life of the part. Before painting, do not forget to clean the seam from scale with a wire brush and degrease its surface. It should be remembered that not every paint is suitable for the muffler. For painting, choose heat-resistant paints or mastic.

Repair with silicate glue and fiberglass

Another well-known way to repair a damaged muffler without welding is to use improvised materials such as liquid glass and fiberglass cloth.

This method is sometimes used even in cases of multiple damage to the muffler body as a result of corrosion and burnout. The surface of the damaged case is cleaned of dirt and rust with a metal brush, after which a layer of liquid glass is applied.

After this, the muffler body is tightly, overlapping, wrapped in several layers with fiberglass tape. Each layer is impregnated with liquid glass. After winding the tape, it is secured on top with a wire bandage.

These methods are also suitable for repairing the connecting pipes of the exhaust system. Sometimes this method can be used to temporarily repair the muffler corrugation.

The corrugation is an elastic element that serves to dampen vibrations transmitted by the engine. Corrugation repair, as a temporary measure, is only advisable for sealing small individual holes.

The element should not completely lose elasticity, otherwise vibration will destroy either the results of the repair or other elements of the exhaust system.

Alternative muffler repair methods

It should be noted that there is another welding method that does not require the use of welding machines - cold welding. Here, composite materials based on resins and fiberglass are used to repair the surface.

These two components are mixed with a hardener and reliably glued to the defect site. Composite material is not subject to corrosion and is not afraid of high temperatures. This method does not require connecting to an electrical outlet and does not require special equipment, which makes it most convenient for travel. Preliminary work before cold welding should be performed in the same way as before conventional electric welding.

How to repair a muffler using cold welding? Advantages, disadvantages and feasibility of the method

The muffler is an integral part of the vehicle's exhaust system; its task is to accept the mixture entering through the pipe, reduce its intensity and feed it into the exhaust pipe. Due to its specific functions and lower location, the part is subject to rapid wear, which is caused by:

- high internal pressure and temperature during operation;

- chemical activity of individual components of exhaust gases;

- vibrations when driving, friction and impacts on the road surface.

From this it is easy to conclude that the most common damage to the muffler is burns and cracks.

Both problems become worse as the metal gradually thins out. The same factor makes it difficult to repair mufflers using classical welding methods, because even under the most gentle operating conditions, an electric arc or gas flame will almost certainly not eliminate the damage, but will deform the metal or burn new “holes.”

Is it possible to use cold welding to repair a muffler?

A good solution could be cold welding, that is, a two-component adhesive composition that, when hardened, forms a high-strength patch with good adhesive properties.

The use of this method is advisable only for eliminating minor damage , such as cracks, chips, holes of a relatively regular shape.

Serious multiple burns cannot be contained by cold welding alone and will require the installation of a patch (bandage) made of fiberglass or other similar material.

Advantages and disadvantages

The quality of muffler repair is largely determined by the skills of the technician, as well as the properties of the materials used. Preference should be given to proven brands of cold welding with a heat resistance of at least 150℃. To repair single damage, paste-like materials are better suited; in combination with a bandage, it is better to use a liquid composition. The use of cold welding will provide the following advantages:

- relative simplicity and low cost of repairs;

- high speed of work and rapid hardening of the mixture;

- no risk of thermal damage to the metal;

- sufficient reliability of the connection (up to 120 kg/cm2 during tensile testing).

At the same time, you should remember some significant disadvantages of cold welding, most of which are associated with its incorrect selection, storage and use. So:

- expired material becomes brittle;

- under the influence of the external environment and sunlight, the composition of cold welding may change;

- the use of cheap “universal” welding is unacceptable due to the high operating temperatures of the muffler;

- connection strength is lower than that of arc welding.

Remember that the hardening of a cold weld is a chemical reaction of its components. Until it is completed (the process can take more than an hour), toxic gases will be intensively released into the external environment, which requires work to be carried out outdoors using personal protective equipment.

How to choose a brand

As mentioned above, cold welding is a two-component composition. It includes the glue itself and the main substance that determines the mechanical properties of the material.

But this is not enough to repair the muffler, because the part operates under extremely difficult operating conditions.

It requires the presence of additional particles responsible for adhesion to the metal, as well as elements that increase the mechanical and chemical resistance of the joint. This limits the choice to three options:

- Cold welding on steel . Contains small iron crystals that form stable bonds with the muffler metal. If the part has an aluminum coating, aluminum welding is acceptable.

- Automotive cold welding . It also contains metal particles, and also includes additives that reduce the effect of vibrations and chemically active substances on the joint.

- Heat resistant cold welding . Supplemented with components that provide resistance to low (from -20 to -60℃) and high (from +150 to +900℃) temperatures, at which conventional products crack.

When choosing a specific brand, you need to be guided by the nature of the damage that you plan to repair, as well as the operating characteristics of the car.

Approximate cost of cold welding on Yandex.market

In most cases, it is better to give preference to heat-resistant compounds. For example, the relatively cheap Almaz welding machine, which is supplied in the form of a plastic bar, or the more expensive, but also higher quality, “Thermo” welding machine in the form of a two-section syringe. The latter, by the way, is recommended specifically for repairing mufflers.

Muffler restoration process

Muffler repair by cold welding can be carried out either by removing the part or directly on the car. Don't expect much - if the muffler is old and badly damaged, you will only be able to seal it temporarily. But patches on small cracks and burns can last for thousands of kilometers. The general methodology for carrying out work includes the following stages:

- Determining the exact location of muffler damage.

- Preparation for welding : removal of dirt, rust, tatters of metal. Cleaning and degreasing the joint. Both mechanical tools and chemical solutions, such as rust converter, are used.

- Mixing cold welding components and applying them in a thin layer to the prepared metal.

- Installation of reinforcing lining made of fiberglass or other materials (if necessary).

- Apply new layers of cold weld and underlay until required thickness is achieved.

- Compact and shape the surface using a small trowel or other available tools.

The hardening of the material, depending on its composition and thickness, lasts from 15 minutes to 2 hours. In any case, you should not unnecessarily start the car within 24 hours of the repair.

Application

Adhesive sealants or cold welding based on epoxy resins are suitable for eliminating gas tank leaks and restoring the radiator . There is also a solution for a hot muffler that is not afraid of temperature aggression.

Adhesive compounds recommended for restoring the exhaust system tolerate vibration, shock loads and stress without consequences. They have diffusion adhesion to steel and cast iron.

Precautionary measures due to the toxicity of the compounds:

Sectional view of muffler

Let's see a cross-section of the car muffler device in this photo,

Here we see the required elements of a muffler or, so to speak, what a car muffler consists of:

- Exhaust manifold (popularly called pants or spider for its similarity in design)

- Flame arrestor or resonator

- Connecting pipes between muffler chambers

- Muffler main frame

- And the exhaust pipe itself

- The exhaust manifold is pipes that are directly attached to the engine terminals to actively draw exhaust gases directly from the vehicle's cylinders, so temperatures at the junction of the manifold and the engine can reach values of 1000 degrees Celsius

- Therefore, the requirement for the exhaust manifold is always high: the required thermal stability of the material and strength in relation to mechanical loads, which is why the manifold is often made of cast iron or heat-resistant steel.

- The muffler resonator is usually a pipe with holes drilled in it of different diameters, which is located in a closed chamber due to the expansion and release of gases through the holes of this pipe and they resonate, essentially damping the vibrations and changing the oscillatory circuit of the sound wave

- The main muffler is essentially like a multi-room apartment, only the rooms are not connected there by doors or hollow pipes, and sometimes in order to get into another room, exhaust gases have to pass through pipes from other rooms back and forth several times - this is done to extinguish the energy of the gas and convert it into heat energy, because of this energy conversion the sound wave decreases

Well, I think that we have answered the question of the muffler in a car, its purpose and structure, and now you have at least an idea of its structure.

Muffler repair

So, the most common malfunction is the formation of through holes and cracks. Depending on their number, size and location, you can decide whether you can do the repair yourself. If there are a lot of faults, then it is better to entrust this work to servicemen, otherwise you will simply waste a lot of effort and time. Well, if a small crack has formed, you can fix it yourself. Next we will talk about repair methods.

Welding

Let's start with the most complex and difficult to do at home - welding. Welding of the muffler is entrusted only to experienced craftsmen who have been holding the torch for many years. If you cook with an inverter at an amateur level, then think ten times before cooking a muffler.

Here the whole difficulty lies in the seams. They must be absolutely airtight, rigid and durable. In addition, you may simply not know when simple welding is enough for repairs, and when additional surfacing is required. Sometimes cracks literally grow along the surface of the exhaust pipe, and in this case you won’t be able to get by with just a seam.

Even if you are confident in your abilities, you need to have a semi-professional or professional semi-automatic welding machine in your arsenal. As well as a cylinder with protective gas, special filler wire and electrodes. This is a large and bulky piece of equipment that you are unlikely to store in your garage. So we do not recommend this kind of welding at home. It’s better to take the car to a service center right away.

Sealant

But this is a simpler option. Using a special sealant, you can quite easily and quickly seal small cracks and holes. Typically, such sealants are very resistant to high temperatures and allow you to carry out repairs in any conditions, even near your own entrance. Additionally, you can increase the sealing of the exhaust system, which is also good.

Repairing exhaust system components using sealant is one of the most budget-friendly options. This is why unscrupulous services often resort to this method. The service is required to do full-fledged high-quality welding, and not to fill the cracks with cheap sealant. Pay attention to this if you decide to have your car serviced.

So, to make repairs, you must first thoroughly clean the metal surface. Wipe and degrease the metal. Apply the sealant to the problem areas, distribute it evenly and leave for half an hour. After this, start the car and let it sit for 15 minutes in this state. Excess moisture from the sealant should evaporate. After this, do not start the car for 10 hours. This is very important. After this time, you can safely use your car, but keep in mind that the sealant will completely harden only after using the car for a day.

When compared with a method such as welding a muffler, the sealant certainly wins. A cheap jack and one sealant gun will be enough for you to make a complete repair. Even a person who has no idea how to repair cars can cope with such work.

Protective tape

Ceramic-based protective tape is not the cheapest, but quite effective method. Specialty stores sell rolls of protective tape that can seal cracks and holes. At first it may seem to you that the tape is not the most durable option, but believe me, it can withstand very high temperature loads.

To repair a muffler using tape, you need to wet it with water and wrap it in several layers around the damaged area. This is all. No more wisdom. But keep in mind that this method is only suitable for small repairs. If you find that your damage is covered with corrosion, then do not use tape, it is better to buy a sealant. If you notice that the muffler has begun to rot, it is better to replace it with a new one.

Types of cold welding

There are only a few types. To carry out high-quality repairs, you need to know which composition is suitable in each specific case:

- Liquid composition. Such welding is always two-part, supplied by manufacturers in syringes. Simplicity and ease of use is its main advantage. The desired appearance after hardening can only be achieved using special tools.

- Plasticine-like composition. Such welding can be one- or two-part. The difference is that one-component welding reacts with air, while two-component welding reacts to mixing the compounds. Welding the muffler in this way is the most convenient, since it can be shaped immediately, without the use of additional tools.

Performance characteristics:

- “pull” strength up to 120 kg/cm3;

- wide temperature range from 150 and above, when using special heat-resistant compounds;

- physical and chemical indicators allow the use of cold welding to solve any problems in repair.

Important! Do-it-yourself repairs are best carried out in the warm season, since upon contact with negative temperatures the composition becomes unyielding.

Inverter welding

In recent years, an inverter is increasingly used when it is necessary to perform welding work on a body.

This is a technologically advanced, compact and lightweight welding machine that uses modern components and a special current conversion method. It is characterized by low sensitivity to low supply voltage and provides easy ignition of the arc.

Electrical diagram of a resistance welding machine.

For an inexperienced welder, an inverter-type welding machine is a real godsend. It is really worth choosing an inverter for car repairs at home, because only a child cannot cope with such a device.

And the electrodes used in the work are no different from consumables for standard welding. But in fairness, let’s add: for all the simplicity of inverter welding, its results are rarely of the highest quality.

Often the seams turn out to be thick and not even enough; due to uneven heating of the metal, deformations appear, even if you hold and operate the device skillfully.

For this reason, the inverter is used to cook places on the car body that are invisible to the eye: surfaces in the trunk of the car, under the wings, etc. To work, you will need to adjust the current depending on the thickness of the parts and material, select an electrode and connect the ground terminal to the working surface.

How to weld a car muffler with your own hands?

The muffler is one of the most important components in modern cars. And despite its simple function, namely suppressing noise from the engine and exhaust system, it makes a big difference. As part of the exhaust system, it also reduces the amount of exhaust gases entering the atmosphere. But due to its location, it is the muffler that often becomes a victim of breakdowns.

You will often hear if there is something wrong with the muffler. Even if there is a small hole in it, the sound will immediately change. Changes in sound will be especially noticeable when driving. And the higher the speed, the more suspicious the sound. Yes, a malfunctioning muffler does not in any way affect the driving characteristics of the car, but if you do not carry out repairs, you are guaranteed to receive a fine. In addition, you will simply not be allowed to travel abroad with a faulty muffler, since they have very strict requirements for the amount of exhaust gas emissions.

Don't be so quick to worry. There are several ways to repair a muffler, from budget to expensive. And if the damage is not very serious, then you can even do the repairs yourself. In this article we will talk in detail about repair methods and the main nuances.