Cast iron is used everywhere in everyday life, from batteries and other plumbing elements to fence structures, car parts and machine tools. The difficulties begin when it comes to welding this metal. Welding cast iron with an electrode at home is not an easy job. If you can work with ordinary steels without particularly careful preparation, then simply welding a seam onto a cast iron part, without preliminary preparation, is very difficult. Failure to comply with basic technologies can lead to overheating of the metal, which means increased fragility and other problems. Let's look at how to brew cast iron at home using an inverter.

Features of welding cast iron, types of cast iron

Experienced welders can determine the weldability of cast iron from just a cut. It is believed that if the structure of the metal is finely dispersed and close to gray in color, then such cast iron can be welded much easier than coarse-grained metal of dark shades. If we are talking about welding parts that were in an oil environment or were subject to regular oxidation in an aqueous environment, soil or other similar conditions, then such a welding material will not be suitable. Since cast iron is a metal with limited weldability, it is worth taking into account its following features:

- The metal is fluid, so the main and only correct welding position is the bottom one.

- If you do not observe temperature conditions and chop the metal, then when the carbon burns out, pores will form.

- Low ductility and non-compliance with temperature conditions are the main causes of stress at welded joints.

- Molten iron can create oxides that will have a higher melting point than the parent metal.

The main problem you may encounter is the formation of cracks at the welding points when the part cools.

This can only be solved if we fully adhere to the technology, in our case - cold welding.

Features of the material

Cast iron is a mixture of iron and carbon. There are several types of cast iron with impurities:

- Gray (1.9% - 2.5% silicon, 3.2% - 3.5% carbon, manganese, phosphorus and sulfur are also present) - plastic and viscous, processed by cutting, used in artistic casting;

- white (2.14% - 6.67% carbon) - brittle but hard, later melted down into steel;

- malleable (2.4% -3.0% carbon) – obtained from white cast iron by heating;

- high-strength (3.2% - 3.8% carbon) - obtained using the addition of magnesium, the properties of this material are close to the properties of carbon steels.

The difficulty of processing cast iron is as follows:

- microcracks and pores form on the surface, which affects the strength of the alloy;

- reddened formations appear;

- metal cutting tools quickly become dull;

- a thin layer of material crumbles under the influence of high temperature.

Gray cast iron is used for welding.

Cast iron welding methods

There are three ways to weld cast iron:

- Hot welding. The main and most correct method. It consists in the fact that before working with the electrode, the workpiece is heated to 600 - 650 degrees. This allows you to avoid the formation of compounds with a high melting point, overheating and tension of the metal at the joint. Heating is carried out in ovens, gas or other burners. For home conditions, this method is a stretch, because in addition to the heating device, you need to know at what moments you can work at the welded joint, how to cool the metal and many other nuances.

- Semi-hot welding. It is practically no different from the previous method, with the exception of the heating temperature. Here the product is heated to 300 - 350 degrees.

- Cold welding. The method does not involve heating the workpiece, but it is based on many other technological aspects, failure to comply with which will lead to the impossibility of making a high-quality seam. Welding cast iron at home with an electrode is carried out in this way.

Why cast iron may not cook as it should

Cast iron is a difficult-to-weld metal, and therefore the quality of welding depends on many factors. If the regimes are not followed and the consumables are chosen incorrectly, the process may not go as planned. This is, first of all, low joint strength, heterogeneity of the weld, the presence of unwelded areas, and poor-quality appearance.

Causes of defects

The following main reasons for poor quality welding are identified:

- Formation of flake graphite in gray cast iron, which causes cold cracks under tensile stress.

- Violation of temperature conditions (overheating and too rapid cooling) leads to the formation of hot cracks.

- Rapid crystallization leads to the formation of pores in the weld due to the release of hydrogen, nitrogen, water vapor, and carbon monoxide.

- Excessive speed of weld formation can lead to the appearance of unwelded areas.

- Excessive heating of the metal most often leads to the appearance of defects. The melt simply flows out of the weld pool if the process is too long. Timely stops help avoid overheating.

Error correction

If significant defects are identified during a visual inspection or using special quality control techniques, the error must be corrected. The main method is to fill defects by fusing. A poor-quality seam should be treated as much as possible with a grinder and a wire brush. Cracks are specially treated. Electrodes MNCh-2, OZZHN, OZCh-2, TsCh-4, T-590 are used for surfacing. Before the procedure, it is advisable to preheat the welded area to the highest possible temperature to increase the ductility of the metal.

You can use a simple and cheap method. Steel wire grade Sv-08 (Ss-08A) is wrapped with thin copper wire and immersed in liquid glass. It can be wrapped around a poor-quality joint, and then welded by melting it with an electrode.

Preparing cast iron for cold welding with an inverter

Before welding cast iron, it must be prepared. First, the desired area is cleaned with a grinder with a flap wheel or other suitable attachment. After stripping the top layer to non-oxidized metal, it is necessary to carry out mandatory degreasing with gasoline or any other solvent. If you decide to repair the crack, then you need to clear the metal until it ends, and drill a hole with a diameter of 10 mm in this place.

It is worth talking separately about the following preparation features:

1. Hairpins. Arc welding of cast iron can be carried out either layer by layer without the use of supporting elements, or using studs. The studs are made of steel. Their dimensions are strictly regulated, for example, the diameter should not exceed 40% of the thickness of the cast iron. The protrusion of the stud above the metal is limited to 4-6 mm, and the distance between the studs should not be more than 6 diameters. The amount depends only on the size of the connection, but not more than 25% of the fracture area

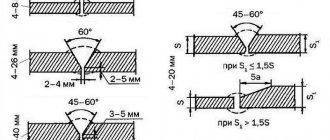

2. Cutting edges.

Note! The edges should not have a sharp cut at the junction of two parts of metal; the optimal shape is spherical.

3. Electrodes must be special. It is almost impossible to weld such metal with conventional electrodes on steel, so it is worth purchasing an electrode with the addition of copper, chromium, nickel and other alloys that facilitate welding onto fastidious cast iron.

Welding process

In the previous paragraph, we discussed the preliminary preparation, and before starting welding, we need to consider the main technological points:

- Connection polarity is reverse;

- The power of the welding machine is minimal for a given electrode thickness;

- The length of one continuous weld should not exceed 30 - 50 mm;

- It is necessary to prevent overheating of the metal due to frequent breaks;

- The first and last layers of multilayers are hammered with minimal force.

The table below will help you decide on the welding mode:

We have considered the main preliminary points, but the main question remains: “How to cook cast iron using electric welding?” There are two ways: on studs or in layers. Let's look at each option separately.

Welding cast iron using an inverter using studs

After installing the studs, you can begin welding the seam. Metal is placed layer by layer around each pin to form a patch. You can prevent heating above 80 degrees by doing the work in a checkerboard pattern or alternately at opposite ends. The final point in this type of welding is the connecting seam, which connects the welded metal between the studs.

Multilayer welding

First you need to make sure that the chamfers are created correctly. Then, using a special electrode, observing the temperature regime, we begin to fuse the first layer. It is fundamental and will determine the success of further work. Each layer, while still hot, must be hammered. If there is access to the back side of the part, then after the first layer on one side you should turn the product over and fuse a similar seam on its back side and only then proceed to complete the multilayer welding of the upper and then the lower part.

Surfacing must be done from the edges, and many layers must be gradually created. The main thing is not to forget to forge each layer. If you don’t know how to check the temperature of a part, then use the random technique. It consists in forming a seam alternately at different joints. When the weld is completely ready, the surface deposited on the cast iron must be ground.

If you are faced with the need to weld cast iron and you only have an inverter, then at home you can repair cracks or apply patches to non-load-bearing structural elements. You will already have almost everything you need, such as a mask, protective gloves and clothing. You will only have to purchase special cast iron electrodes, or make them yourself. This article describes two ways to weld cast iron at home. Which one suits you best – decide for yourself. But remember - when there is a need to restore a product that requires heavy loads, it is better to turn to professionals.

Source: svarkagid.ru

COMMENTARE • 0

If it weren't for the plates, the pussy would be in a vice.

Why wasn’t it treated with a burner and then cooled in its own environment in a shelter?

It wouldn’t give anything global, I’ve already done it, it didn’t make any sense. Ideally, you need to heat the cast iron until red and then cook, so the penetration will be more effective.

So here the entire load goes on the plates, and not on the weld. Testing what, weld seam or plates? What was the point of welding them then?

The fact is that the jaws did not touch, since the rear jaw moved away a little due to a crack, and after welding the vice, the jaws rose to the desired position and touched at full compression. I decided to leave the plates just in case, which, by the way, helped in the future. Under heavy load, the seam split and the crack is back in that place. If you use a vice with loads, then this welding is not suitable. But if it doesn’t require a lot of effort, then it will do. In the future I will try to weld them again, but using the technology of welding cast iron, there are not yet the necessary conditions for such work.

I didn’t quite understand the meaning of the work. I mean, the steel plates (crutches) still remained. Before welding, was there a lot of play or some other strong nuance? In other words, what has changed, except for the psychological part? It seems to me that with crutches and without welding everything worked well for you.

@Easy Master clear

The fact is that the jaws did not touch, since the rear jaw moved away a little due to a crack, and after welding the vice, the jaws rose to the desired position and touched at full compression. I decided to leave the plates just in case, which, by the way, helped in the future. Under heavy load, the seam split and the crack is back in that place. If you use a vice with loads, then this welding is not suitable. But if it doesn’t require a lot of effort, then it will do. In the future I will try to weld them again, but using the technology of welding cast iron, there are not yet the necessary conditions for such work.

Welding cast iron at home

Welding cast iron, electrode for steel.

If you have recently built a house and have not yet connected it to the power supply system, and indeed have not done anything related to electricity in the house, then I advise you to look at this website: electrical installation work center-energo.com/. This company provides high-quality electrical work. Electricity was installed in my dacha, the work was done efficiently and at an affordable price. The company has all the necessary documents to carry out this activity. All you need to do is go to the website and use the services of this company. I recommend it to everyone, this is a company I have verified

Welding cast iron vices at home

Cast iron is a rather brittle metal due to its high carbon content. But if a welder breaks a vice in his garage or workshop, he won't throw it away. They can be restored by electric welding. Practitioners will share their experience and tell you how to weld a cast iron vice using electric welding. This can be done at home using a regular electrode and copper wire.

Methods for welding cast iron vices

Cast iron welding technology has been developed for welding rail joints. To do this, use a gas welding machine or electric arc welding and “rail” electrodes OZCh-2, MNCh-2. You can use UONI 13/45 and ANO-4, they give good seam quality. Gray cast iron is easier to weld than dark cast iron. Oiled - practically impossible to process. Welding is carried out:

- multilayer welding with an inverter with preliminary cutting of the crack, each seam is forged before applying the next one;

- using the pin method - they are screwed into the edges 2/3 of the way.

Cutting before screwing in the studs is only necessary for parts thicker than 12 mm. The diameter of the reinforcing elements should not exceed ½ the thickness of the welded layer. A preliminary circular seam is applied around each pin, then the voids between them are filled with rollers. The second layer is welded perpendicular to the filling rollers. After surfacing each of the welded surfaces, a butt weld is formed. Using pins, restoration of the vice is carried out without dismantling.

Features of working with cast iron:

- the part must be preheated to + 600°C;

- permissible heating temperature of the welding zone is not higher than +100°C;

- the continuous length of the seam does not exceed 3 cm;

- The electrode connection is reverse polar.

The seam must cool for a long time; if it cools quickly, the joint will burst.

The cold method involves using:

- protective environment (argon);

- fluxes with borax;

- filler rods made of copper-nickel alloys with aluminum;

- refractory electrodes (tungsten, graphite). The current strength is set at the rate of 50 amperes per 1 mm of additive diameter.

Properties of cast iron alloys

The carbon content in cast iron exceeds 2.14%. This is precisely the borderline state of transition of carbon into the form of austenite, that is, into a state where, at a concentration less than indicated above, it is dissolved in iron. This phenomenon is used in the manufacture of steels.

In cast iron, carbon is found in the form of tiny undissolved particles, which determine its hardness and wear resistance, as well as its immunity to aggressive environments.

There are several types of cast iron depending on the chemical composition - white, gray, high-strength and malleable.

White is practically impossible to process with cutting tools due to its hardness and brittleness. Ready-made cast iron parts are cast from it, which do not need to be processed.

Gray cast iron tolerates static loads very well and is wear-resistant, but does not work well in tension and resists impacts. This cast iron welds better than all others.

https://youtube.com/watch?v=Xoamtv9bsXs

Ductile iron, as the name suggests, is used in heavily loaded structures.

Malleable cast iron allows the creation of a hardened outer layer on the surface of parts, allowing this type of cast iron to withstand significant bending loads.

Technology of welding cast iron vices with electrodes

In auto repair shops, conventional electric welding is used to restore cast iron parts. Experienced welders in garages weld cast iron with a conventional medium-power inverter. They use a standard electrode for ferrous metals, but pre-wind it with thin copper wire. This is necessary for even heating. This additive fully replaces expensive cast iron electrodes. Before work, the crack is cut at an angle of 30° to 1/3 of the thickness of the broken part.

To hot weld a broken vice, it is not necessary to fully heat it in the oven. Practitioners use a blowtorch to heat the welding area. When the cast iron warms up and begins to turn red, you can begin to work. Before applying the next, each layer is heated well and tapped with a hammer to compact it.

When the multilayer connection is completed, it must be periodically heated with a blowtorch for two to three hours. This technology does not create a temperature contrast between the inner and outer layers. Those who have stoves leave the boiled vise on the coals for six hours. When the seam has completely cooled, the roller is leveled with abrasive. Refurbished vices will last a long time. They can withstand heavy loads without damage at the seam.

How to brew cast iron correctly

The special properties of the metal cause increased demands on the welding process. The right approach requires careful preparation. The work area must be well cleaned of any contamination. Used: grinder, metal brushes, sandpaper. Oil stains are removed with solvents. For severe contamination, use torches or sandblasting.

A common occurrence is cracks on the surface along the edges of cast iron products. Their sealing requires a special approach. The cracks are cut and cleaned to their full length to ensure complete filling with the melt. If necessary, the workpieces are drilled along the edges, and the ends are cut at the angle required for welding.

Welding cast iron with an electrode at home

Cast iron is an alloy of carbon and iron, which also contains alloying additives and impurities.

Cast iron parts are widely used not only in industrial and production areas, but also in everyday life. Cast iron products for private use: plumbing elements, fence structures, car parts and much more. The active use of this alloy leads to the need for welding work. The main difficulties in welding cast iron that home craftsmen encounter:

- due to the fluidity of the alloy, it is recommended to carry out welding in the lower spatial position;

- non-compliance with temperature conditions leads to overheating of cast iron, which can cause the formation of pores and stress in welds;

- cast iron in a molten state can release gases , which will negatively affect the quality of the connection;

- Accelerated or uneven heating or cooling can promote cracking .

In order to obtain a high-quality connection of cast iron products at home, it is necessary to take into account these specific characteristics, as well as correctly prepare the working surface, select the correct welding mode and electrode.

Welding difficulties

Homemade mini welding at home

The structural features of cast iron determine a number of problems that arise when welding this material.

Due to the chemical composition of cast iron, when melted it becomes very fluid. This prevents the creation of a uniform seam, since the metal tends to flow out of the weld pool during prolonged heating.

Due to the low ductility of cast iron and low melting point compared to steel, cracking of the material is possible during rapid cooling after exposure to an electric arc.

The presence of a large amount of carbon, which is released when heated and interacts with oxygen contained in the air, contributes to the formation of large pores in the welding zone, causing the weld to be heterogeneous and have low resistance to bending load.

Knowing these features, you can organize welding work in such a way as to obtain a weld of satisfactory quality. To eliminate the effects of material fluidity, graphite plates are placed under the joint of the parts being welded, which prevent molten cast iron from leaking out during accidental burning.

The third problem can be solved by using welding in an inert gas environment. You can cook cast iron by electric welding using, for example, carbon dioxide, which displaces air from the weld pool. It is allowed to use a mixture of carbon dioxide and argon in a proportion of ¼.

Preparation for welding

Preparatory operations must be carried out carefully and carefully, as this is one of the fundamental principles of obtaining a high-quality connection:

- the structure is cleaned of dirt, debris and dust;

- then you should degrease the parts with a solvent, for example, acetone;

- when working with thin cast iron, you need to use pads to remove heat ;

- edge cutting should be done before welding thick-walled products; for this, a file or grinder is used;

- cracks need to be drilled out along the edges and cut along the entire length; an alternative method is to cut out the cracks, ends round off;

- depending on the chosen welding method (hot or cold), the product is heated or not. heated using various equipment: ovens, gas burners, or using improvised means: a blowtorch.

Preparation

Cast iron must be carefully cleaned before welding. Even the slightest particles of dirt or films are unacceptable. Using solvents helps remove traces of oil. Coarse defects are removed with a grinding machine. The edges are expanded along the length with the same grinder.

But the metal must be cleaned extremely carefully. It is better to remove it layer by layer, spending more time rather than damaging the product. Cracks are welded by pre-drilling problem points. Otherwise, cracks will spread directly during welding.

Thin cast iron products must be cooked using graphite pads. If they are not there, the melt may leak out and burn through the metal completely. The welding wire is selected according to the welding method used. For the “cold” technique you need PP ANCH-1. For the semi-hot method, it is more correct to use PP ANCH-2, and for the hot method - PP ANCH-3.

Welding methods

Experts distinguish 3 methods of welding cast iron:

- Hot is carried out by heating the cast iron parts before making the connection, the temperature is 600-650°C. This method cannot be used at home.

- Semi-hot is practically no different from the previous method, the difference is only in the heating temperature, the product is heated to 300-350°C.

- Cold implies the absence of heating of work products. Welding cast iron with an electrode at home is carried out using this technology.

Preparation

Regardless of the welding method, cast iron must be thoroughly prepared for work.

In any case, all dirt and even lubricating oils of any kind are removed from the surface. Careful cutting of the edges will also be a mandatory requirement. If you plan to achieve increased strength, you need to install studs during cold welding. In hot mode, preheating is practiced, forming a specially designed “bath”. Even small cracks must be removed from the edges. Before installing the studs, the cutting is performed at an angle. In other cases this is not necessary. Steel studs should be 2-3 “gauges” (this is what the ratio of length and cross-section is called). The outer ends of the studs must be placed so that they can be welded to each other.

How to cook cast iron with an inverter and a consumable electrode

Welding cast iron using an inverter and a consumable electrode is most often carried out using the cold method. Important components of successful work are: the correct choice of electrode and optimal welding modes.

The performer must make the connection with special electrodes containing nickel and/or copper:

Recommended welding modes for some of the listed brands:

| Electrode brand | Current strength for an electrode with a diameter of 3 mm. | Current strength for an electrode with a diameter of 4 mm. | Current strength for an electrode with a diameter of 5 mm. | Current strength for an electrode with a diameter of 6 mm. |

| TsCh-4 | 65-80 | 90-120 | 130-150 | — |

| OZCH-2 | 90-110 | 120-140 | 160-190 | 220-250 |

| OZZHN-1 | 100-120 | 130-150 | 160-180 | — |

| MNC-2 | 90-110 | 120-140 | 160-190 | 210-230 |

The following technological features should also be highlighted:

- the length of one continuous seam should not be 30-50 mm;

- frequent breaks in the welding process will help eliminate the possibility of overheating; temperatures above 80°C are unacceptable;

- polarity is reversed.

This welding method can be performed in two ways: using studs and in layers.

1. The studs are equipped with threads, which allows them to be screwed into the edges of the product being welded. The studs should be staggered/staggered to prevent overheating during welding. The dimensions of the studs depend on the thickness of the workpiece; when selecting them, you should rely on the following recommendations:

- diameter - 0.3-0.4 product thickness, but not more than 12 mm;

- screwing depth - 1.5 times the diameter of the stud, but not more than half the thickness of the product;

- the height of the protruding part of the pin is 0.75-1.2 times the diameter.

After installing the studs, you can start welding. Metal is deposited around each pin, layer by layer. Then the performer needs to weld the space between the studs, which remains untouched, and make one or more connecting seams.

2. Multi-layer welding is performed after cutting the edges. The presence of sharp corners is not allowed. Surfacing should be done from the edges. The first layer is the main one, so during its deposition you need to carefully monitor the welding mode. Each subsequent layer, except the first and facing ones, must be forged with a hammer, without cooling.

The following video demonstrates the Zeller 855 cast iron electrode, but from the video you can see how welding is done.

This information will help the contractor learn how to cook cast iron with an inverter using electrodes on cast iron, and easily carry out the connection work.

Welding with conventional electrodes

In order to save money, you can use ordinary (steel) consumables instead of special ones. General purpose electrodes have a more affordable price. The technology of multilayer welding with conventional rods is practically no different from the method discussed above, which uses special rods coated with non-ferrous metals. The stages of work are similar. The only difference is that the layers following the first are deposited not with a special electrode, but with a regular one.

Welding with cast iron electrodes

This welding method can be carried out using a cold or semi-hot method. A little preheating will improve the structure of the weld metal.

Cast iron electrodes are cast rods coated with coating, used to correct defects in cast iron. This type of consumables includes the following brands: MNCh-1; OZCh-1; OZB-2M.

Welding is carried out using direct and alternating current. The current value is determined as follows: 50-60 A per 1 mm. electrode rod.

Technology

Installing buttons on clothes at home

Let's consider the technological features of welding cast iron with electrodes.

Preparation

When working with cast iron at home, it is the preparatory stage that you should pay maximum attention to. It depends on it whether defects will appear in the future. Cracks inside the metal are deep and have a very fine structure. They need to be cut as deeply as possible. The cutting practice is as follows:

- felling;

- grinding works;

- arc gouging;

- oxygen preparation;

- thermal cutting.

Regardless of the specific option, cracks are cut 5-6 mm wider than their boundaries. You need to come to the surface smoothly. The cutting depth of a through crack is 1-2 mm less than the thickness of the workpiece. If you are working with a blind crack, the cutting depth should be greater than its lowest point by the same 1-2 mm.

The cut cracks are drilled at the ends. If for some reason this is not possible, they are completely cut out and the ends are rounded. On the edges of thick parts, bevels are prepared at an angle of 45 degrees, while making sure that the edges themselves do not have sharp corners. It is necessary to clean the surface before starting work, otherwise no choice of modes will help.

Attention: if conventional mechanical and thermal cleaning methods do not help, you will have to use a gas burner

Process

Hot welding of cast iron is practiced mainly in industrial settings. At home it is almost impossible to warm it up to 600-650 degrees Celsius. Problems may also arise with ensuring fire safety.

Welding cast iron with an inverter with a consumable electrode is usually carried out in a cold mode. In this case, a tool containing copper or nickel is used. When using TsCh-4 with a diameter of 3 mm, you need to supply a current of 65-80 A. If an electrode with a cross-section of 4 mm is used, the current strength is increased to 90-120 A. Five-millimeter instruments are heated with a current of 130 to 150 A. For OZCh-2, these figures are respectively 90-110, 120-140 and 160-190 A.

Of course, there are a number of technological subtleties and nuances. A continuous seam can be made no more than 3-5 cm long. Breaks during work should be strictly avoided - they are done only in the most critical cases. Cook cast iron, unless otherwise indicated in a particular case, only with reverse polarity.

We should also talk about the processing of malleable cast iron. Its electric arc welding is possible in various ways, including using a variety of electrodes. Steel tools can only be used if additional annealing will be carried out later. Failure to do this procedure will cause excessive fragility of the seam and will greatly deteriorate the quality of the finished product. Therefore, it is much more practical to use brass or copper-nickel electrodes, which eliminate the problem of additional processing.

Welding tools with a copper rod with a cross-section from 3 to 6 mm have become quite widespread. The outside is wrapped with thin tin and additional coating is applied. Even copper tubes with iron cores are occasionally used. If you work correctly and carefully, you can form excellent seams with such electrodes. But you need to understand that there is a risk of pores forming, especially at the boundary of cast iron with deposited metal.

You need to cook cast iron using semi-automatic machines with the following grades of wire:

- Sv-08GS;

- Sv-08-G2S;

- Np-30GHSA.

Sometimes cored wire is also used. The current strength is always made less than when welding steel. In the heat-affected area the temperature should not rise above 80 degrees Celsius. After any pass, before the metal has time to cool, the roller is “forged.” Threaded studs can be staggered along the edges of the parts to be welded.

The following video presents a master class on welding cast iron with electrodes.

Welding with non-consumable electrodes

Welding cast iron using this technology is carried out in a protective environment of argon or fluxes, the main component of which is borax. Cast iron or special rods containing nickel, aluminum and copper are used as filler materials. Welding cast iron is carried out using tungsten, carbon and graphite electrodes.

The most common method is argon arc welding (AC TIG). In order for the work to be successful, you should adhere to several rules:

- Thorough cleaning of the surface from debris and dirt;

- the workpiece must be fixed at several points;

- It is recommended to use slight preheating of the product; for this you can use improvised means. It should be remembered that the presence or absence of heating depends on the type of cast iron being welded;

- the additive is supplied at an angle of 20-30 degrees;

- it is necessary to use small amounts of current;

- the connection should be carried out in stages : the performer welds a small section of 2-3 cm and forges the deposited metal so that

- avoid residual stress. Forging is done with a small hammer, the weight of which does not exceed 1.2 kg, the hammer is of a rounded type.

- Cooling of the part after welding is carried out gradually .

This method is not the main one when connecting cast iron products. This is due to certain difficulties that arise during the work process, as well as an increased level of labor and financial costs.

Recommendations

To reduce the risk of new cracks during welding, you must:

- remove phosphorus and sulfur;

- achieve finer grain structures;

- weld metal with short seams at low current;

- switch from single-pass to multi-pass welding.

Help combat the appearance of pores:

- meticulous removal of rust and other contaminants;

- converting hydrogen into insoluble form;

- fixation of nitrogen in nitrides;

- reduction in cooling rates.

Among the various types of gas welding, the optimal solution is a combination of acetylene and oxygen. In this option, it is necessary to use cast iron filler rods that comply with GOST 2671-80. Fluxes help increase the wettability of edges with the melt. If you plan to perform mechanized welding, it is advisable to use wire with a high concentration of graphitizers. When defects in the welding process are discovered at the final stage, they will have to be eliminated additionally - by special soldering with fluxes based on borax and boric acid.

Welding cast iron is presented in the video below.

DIY electrodes for cast iron

In the absence of special electrodes for welding cast iron, you can independently make consumables that are similar in characteristics to the OZCH-2 and OZCH-6 grades. Next, we will look at two ways to make electrodes for cast iron with your own hands.

- The production of electrodes for cast iron is carried out using the following technology:

- It is necessary to take copper wire with a diameter of 2-5 mm, sand it with sandpaper, degrease it and cover it with homemade coating; The easiest way is to prepare a coating from the coating of conventional electrodes (ANO-4, UONI-13/55).

- The coating of general purpose consumables is scraped off the rod, crushed and mixed with steel filings or iron powder in a 1:1 ratio. Then silicate glue is added to the resulting mixture, after which all components are thoroughly mixed.

- The wire is lowered into a homemade coating until the applied coating thickness is 1.5-2.0 mm. Then you need to wait until the excess mixture drains.

- The next stage is drying, which is carried out in the open air; the electrodes are dried in a vertical position.

- The final procedure is calcination, which is performed in the oven or on the stove at a temperature of 200-250°C.

- Homemade electrodes for cast iron are ready for welding. The welding mode with self-made electrodes does not differ from the operating mode with branded consumables.

Types of electrodes used for cast iron

They work with cast iron workpieces with special electrodes marked SV-08 A and SV-08 or use universal consumables for this material:

- TsCh-4 - used for work at any temperature and allows you to create an even and durable connection.

- EMChS - the base is made of low-carbon steel, a three-layer coating is applied to it. During the combustion of the electrode, a gas protective layer is created around it, protecting the seam from oxidation and the formation of air inclusions in it.

- Ficast NiFe K - these rods are made of iron-nickel alloy and are intended for welding cast iron and steel.

- MNC-1 - made of an alloy of copper, nickel and monel metal, which increases their cost. The use of these consumables allows you to obtain a high-quality seam, which is then easy to process.

We recommend reading: How to work with cast iron using cold welding

How to do it yourself

High-quality electrodes for working with cast iron cannot be purchased at every hardware store; their cost is quite high. Many experienced welders and home craftsmen make their own consumables for welding cast iron.

You can make the electrode yourself.

To do this, you will need general purpose rods (ANO-4 or UONI), copper wire 1.5-2 mm thick.

The manufacturing process is simple, just wind the wire onto the selected electrode.

You can use another option; to implement it you will need:

- liquid glass;

- copper rods with a diameter of up to 5 mm;

- crushed coating removed from general purpose rods;

- metal powder.

In this case, the manufacturing process consists of the following steps:

- Cutting copper rods into pieces of the required length. Cleaning their surface with sandpaper and degreasing.

- Preparation of the coating composition. To do this, thoroughly pound the coating removed from the rod and mix it in equal proportions with metal powder. Then 30% liquid glass is added to the prepared mixture and everything is mixed well again.

- Creation of an electrode. The finished rods are dipped into the prepared composition several times until a coating 1.5-2 mm thick is formed on them.

- Drying the rods. They are placed vertically and left in the open air.

- Calcination. To do this, homemade products are placed in an oven, the temperature of which is in the range of +200-250°C.

The quality of self-made electrodes will be slightly lower than those purchased in a store, but with their help you can also reliably connect or restore cast iron parts, and the operating mode is the same as when using branded consumables.

Security measures

Carrying out welding work at home requires careful and precise adherence to safety precautions. The most important points:

- the room in which welding work is carried out must be illuminated and ventilated ;

- It is mandatory to use means for grounding ;

- Cast iron does not respond well to rapid cooling, so its surface must be protected from moisture ;

- personal protective equipment when working .

Source: weldelec.com

Safety precautions

When performing any welding work, cast iron is no exception; it is important to follow safety rules:

- if work is performed indoors, it must be well ventilated and have high-quality lighting;

- Grounding must be used;

- cast iron parts should not cool quickly, so when working with them they must be protected from moisture;

- The welder must work in a fire-resistant suit and shoes, gloves, and a protective mask.

Cast iron vices should not cool quickly.