0 0

Read Time:1 Minute, 45 Second

When working on a homemade device, you may have a bearing that is smaller in diameter than the existing socket or support. A transition housing will help to get out of this situation, which will compensate for the discrepancy between the actual sizes of the interacting elements. To implement the upcoming idea, you need to have some experience working with metal, completely simple, accessible and inexpensive materials, as well as quite standard equipment and tools. Of course, we must not forget about personal protective equipment: glasses, gloves, etc.

Bearing housing and its types. DIY bearing housing

In the mechanisms that people use in everyday life, you can often find such a part as a bearing. They are found in systems of both household and industrial appliances. The bearing housing is part of the workpiece assembly. It comes in different shapes, varieties and sizes. To better understand its structure, it is necessary to study the bearing housing. Self-repair of many types of equipment will become clearer and more effective. If desired, you can create bearing housings yourself.

Installation of rolling bearings

Installation of support units of this type requires compliance with certain rules and standards. Thus, the transmission of forces through the bodies providing rocking is not allowed, so as not to damage the parts. Therefore, special equipment is used in the process. The variety of types of rolling units dictates certain features. They must be taken into account, otherwise the procedure will become much more complicated. Here's what you need to take note of first:

- • Radial roller bearings require special additional support to securely fix the shaft in the direction of the axis.

- • Proper installation of the needle bearing is carried out first on the journal if there are no rings.

- • Thrust single assemblies are mounted with a smaller diameter on the shaft and a larger diameter in the housing.

- • If the angular contact type of parts has a removable ring, separate assembly is necessary. In this case, these types of devices should be located in pairs towards each other.

- • Press fit is carried out only on one of the load-bearing rings – the inner one. Otherwise, there is a high risk of damage to the device.

general characteristics

The bearing housing is a special part. It is usually made of cast iron or other alloys. A bearing housing is used to seat the main shaft on the main platform. It secures the part tightly.

The housing and the bearing itself - rolling, sliding and other varieties - together create a unit. It is easy to find in the equipment and technology of enterprises in all industrial sectors.

Since quite a few types of the presented parts have been developed, there are even more cases for them. Moreover, manufacturers are ready to produce both standard configuration products and housings for specially shaped bearings. In the latter case, an individual drawing is created, on the basis of which the master produces the required part. This makes it possible to ensure that the unit complies with existing production conditions.

SKF flanged bearing housings

SKF manufactures prefabricated sealed Y-type flange assemblies filled with lubricant. To compensate for shaft misalignment, the manufacturer installs radial single-row ball bearings, the outer rings of which are spherical.

Their bodies are made from:

- composite materials;

- stamped sheet steel;

- casting from cast iron (gray).

Cast iron housings have oilers, as well as channels intended for supplying lubricant. Stamped steel housings do not have such a lubrication supply system. The manufacturer supplies protective covers for the shaft ends. Cast iron housings are designed for increased loads. For lighter loads, the company produces stamped sheet housings available with oval, triangular and round flanges.

For the pharmaceutical, food and chemical industries, a special series of Y units are manufactured, enclosed in stainless steel housings.

Modern bearing housings

Today, the manufacturing process allows the mechanism to be manufactured with some additional part or as a separate product. The housings differ in the bearing mounting system inside the housing; for example, it can be mounted on legs. It depends on the type of part.

Housings for rolling, sliding and other types of bearings are made from high-quality materials. It can be cast iron, pressed or stamped steel, synthetic rubber.

In the modern market of bearing units, imported mechanism elements predominate. Their popularity is explained by the increasing number of different foreign equipment. During operation, it requires bearing units of a certain type, which our production does not produce.

How to remove the outer bearing race of a washing machine?

In this article we will analyze the installation diagram of angular contact bearings and tell you how they are mounted on the shaft and in the housing in different ways. The choice of the most suitable one depends on the type of support unit, its size, the load taken and many other factors. Sometimes the process requires the use of additional devices for more reliable installation. Let's consider the most popular paths recommended for installation, as well as possible problems associated with incorrect implementation of the procedure.

Case types

There is a certain classification of bearing housings. Each type differs in its purpose, mounting method, configuration and size. The following varieties are standard today:

- stationary solid;

- stationary detachable;

- flanged.

The one-piece stationary type of case is made of pure nickel, which makes it more rigid and simpler. The axial fit of bearings in the housing has a complex axial type of installation. Therefore, this variety is used in low-speed mechanisms that have a small shaft diameter.

The detachable stationary housing is made of gray cast iron. It consists of a lid and a base. These body elements are connected with bolts. This design makes it easy to change the bearing when it wears out, make a secondary bore of the liner, and also adjust the gap. This is a common type of housing in mechanical engineering.

The flanged body is similar to the previous type. It consists of a base and a cover connected by bolts. It is used for very demanding parts. It serves as a support for both the end and through shafts.

Let's look at what the design of a bearing puller is

A bearing puller is a device, usually made of steel, consisting of several claws and a metal rod. This type of tool is used to firmly grip the bearing in order to remove it. The bearing removal process occurs due to tightening force. The ease of operation of the puller and the absence of the risk of injury depend on the quality of the design. Types of mechanical pullers:

- Pullers with two gripping arms.

- Pullers with three gripping arms.

- Internal pullers.

Pullers with two gripping arms are a fairly simple and reliable mechanism. Made from high strength steel alloys. Allows you to easily control the work process.

Pullers with three claws are the same pullers with two claws, but improved. As a rule, they are made of hard alloy tool steel.

Internal pullers are used to remove coupling shafts when the part is firmly attached to the structure.

There is also another unofficial type of puller - this is a special one. As a rule, it is used to remove generators, cylinders, and motors. These pullers are exclusive, made to your specific dimensions. This is the main advantage of such a product; you can be sure that the puller one hundred percent fulfills its promises.

Today we will look at how to make a reliable and, most importantly, simple puller that will help you out in difficult times. For this we need:

- A piece of thick pipe.

- Steel plate.

- Nut, bolt.

- Dye.

- Kernel.

- Welding machine.

- Bulgarian.

- Drill.

- Lathe.

- Sanding disc.

Features of operation

The bearing housing must provide the entire assembly with the required operating parameters. It operates under heavy loads and should not create an increased noise level. Extreme operating conditions of the unit should not reduce the durability of the housing and the entire mechanism.

Depending on the purpose, there are a large number of types of structures. Each manufacturer labels them differently. You can highlight the most popular manufacturing companies.

The housing has a spherical shape for installing the bearing itself. This allows the elements of the mechanism to be installed independently. Oil-repellent ring-shaped rubber seals are installed between the bearing and the housing.

Rules for installing roller assemblies

Roller bearings are often used to minimize the friction force during operation of the mechanism. They are durable and efficient, and therefore are often installed in complex technical structures, such as industrial machines. But to achieve a productive result, you must follow certain rules.

It is better to carry out the process using a hydraulic or manual press so as not to damage the parts. There are other recommendations:

- • To begin with, the seats are coated with a special lubricant. Its layer should be thin, but sufficient to freely accommodate the unit.

- • Depending on the specific type of support and the actual design of the mechanism, the installation side is determined.

- • Next, the mounting cup with stop is aligned with the roller bearing ring strictly along the axes.

- • Once compliance has been ensured, an initial test load is applied to see how smoothly the movement occurs.

- • If the result is satisfactory, final installation is carried out and the gap is adjusted.

- • At the last stage, all elements are fixed.

If you do not skip a single step in the process of installing the part, the subassembly will smoothly fall into place. Otherwise, distortions often occur. They interfere with wear resistance and lead to rapid breakdowns. You can check how successfully the work has been completed not only during the first test run, but also during a simple inspection of the product. Obvious problems will be immediately obvious, which means they must be eliminated immediately.

Features of fastening to the body

There are several types of bearing fitment on the shaft in the unit housing. The most common of them today are the technologies described below.

One of the most common is a bearing in a housing on legs. It has the ability to lubricate and is involved in the creation of high-speed mechanisms. These could be fans, emergency energy saving systems, flywheels. Their distinctive feature is the ability to work at elevated temperatures.

The inner ring can also be secured to the shaft using set screws. There are cases whose inner ring has a conical hole. The part is secured in it using an adapter sleeve.

There are also cases in which the installed product is secured with a special eccentric ring.

Installation of sliding assemblies

Such parts can be one-piece or detachable. The installation features primarily depend on what type of product is planned to be replaced. If we are talking about the first group, the bearings are first pressed onto the shaft and secured in the housing. This can be done not only using special pressing equipment, but also manually. In this case, the step-by-step instructions look like this:

- • The sleeve fits onto a mandrel that is centered in the hole.

- • Using a hammer, the structure is carefully inserted into the seating slot. It is important to avoid distortions.

- • The already pressed bushing is secured with special stoppers.

If you press the bearing onto the shaft correctly, you can achieve high wear resistance from the nodal support. The external condition of the element used is important. If there are scratches, chips and other damage on it before starting work, it is better to replace the part. When receiving a strong load, the damaged element will continue to collapse. A small abrasion can quickly become a serious problem. Especially if there are accompanying problems with lubrication or incorrect installation.

Detachable structures are installed separately in the base and cover of the mechanism. This leaves a small gap allowing normal operation. An important feature is the need to adjust this type of nodal supports, regardless of whether the replacement is made in a home workshop or in mass production. Moreover, this is already accomplished during the initial inspection. Correct installation is assessed by how freely the part slides in the structure.

Advantages of non-lubricated and lubricated housings

Today, manufacturers produce both lubricated and non-lubricated bearing housings. The bearing housing, the design of which is designed for standard re-lubricated units, contains a lubricator.

The advantages of housings that are not refilled with additional lubricant include savings on maintenance and compact design. There is no risk of oil leakage in such parts. This results in increased cleanliness of the part.

Re-lubricated housings are used at high temperatures and in dusty environments. If it is not possible to use a part with a lid, such a unit is used in conditions where it is splashed with water or other liquids.

If such a housing is not used regularly, the bearing will work properly. Such parts are used when the unit moves at an accelerated rate, under increased loads and the need to reduce noise during operation.

Preparing parts for connection

To successfully perform work, it is necessary to create comfortable conditions. It is best to secure the supports in a clean room, where there are no working machines that could create excess dust, shavings, or dirt during the production process. If the installation is carried out in a room where it is impossible to avoid the negative influence of the environment, the part should be additionally covered with paper or foil. In addition, other preparatory steps need to be taken:

- • Collect in advance all required spare parts, tools, instructions for use and installation.

- • Carefully study the existing drawings of the structure into which it is planned to install the support unit.

- • Clean all surfaces from dust and other particles.

- • Check whether the shape and size of the products really matches the holes in the structure.

- • Immediately before starting installation work, thoroughly rinse the support to remove the factory preservative. The only exception can be made if the unit is filled with special lubricant necessary for uninterrupted efficient operation in the future.

Manufacturers and labeling

Depending on the type of manufacturer, there is a certain marking of parts. If this is not a bearing housing created with your own hands, it will definitely have the designation of the corresponding company that created it.

There are a large number of brands, but the following manufacturers are considered popular today:

- China and Singapore produce parts marked FBJ.

- Italian bearing mechanism elements can be marked as KDF or TSC.

- Japan labels their cases as ASAHI or NSK.

- SKF products are so expensive that they are practically not found in equipment in our country.

Rules of use and tips

When using bearing adhesive, you must adhere to some rules:

- Despite the fact that some structures are used on uncleaned surfaces, if possible, it is still necessary to clean and degrease. This will have a positive effect on the gluing result.

- A stronger connection will occur on rough surfaces.

- Do not allow material to get on the bearing balls, as this will lead to damage to the part.

- The glue must be distributed evenly over the entire plane of the element being connected. Some compounds can be applied to one of the planes being connected.

- for applying its compositions it provides for manual use, semi-automatic and automatic methods.

- For better distribution of the mixture on the planes, it is necessary to rotate them relative to each other with the composition applied to them.

- If re-gluing occurs, then previous applications must be removed from the surface.

We recommend watching the video review:

Housing marking depending on design

The bearing housing may be identified by different markings depending on the type of assembly. Made for radial parts that are installed in flanged assemblies, the mechanism is secured with set screws. The bearing in them is designated UC, and the housing for them is F, P, T, FL, FC. If this node is connected together, the part will look like, for example, UCP, UCT, UCFL.

For supporting structures, the housing is designated as SD, and the bearing itself is designated SN.

It is better to purchase such products from a direct representative of a particular manufacturer. This guarantees the quality of the purchased parts.

Bearing flange units from NTN-SNR

The manufacturing company NTN-SNR is a French-Japanese joint venture that produces bearings for aircraft, missiles, helicopter transmissions, etc. Among the extensive product range of this manufacturer are flanged bearings, as well as housings of various types.

The company produces ball bearing units with cast iron bodies and round, oval, and triangular flanges. It produces special corrosion-resistant models for chemical, medical and food equipment. These include parts made of thermoplastic, characterized by low weight and increased resistance to aggressive external influences.

Textile equipment uses models enclosed in flanged housings for three-point fastening.

Homemade bearing housing

Making a bearing housing with your own hands is not that difficult.

A good material for making the case is graphite caprolon. It is characterized by increased wear resistance, strength and slip. You need to cut out the hole by holding the material in a vice. Using a drill, knife and file, make a straight hole in the caprolon.

A sliding gasket should be inserted inside. It is better to make the housing split and clamp it with a screw on the shaft. The smoother the hole, the better the part will work.

It happens that the body is even made of wood. The ring is made from sectors, which are then pulled together. This automatically compensates for bearing play.

Having examined the types and structure of such a part as a bearing housing, you can understand the principle of its operation and carry out independent repairs of quite a large number of equipment at home.

Bearings with split races

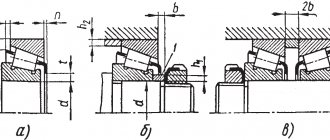

To carry increased axial and radial-axial loads, bearings with an outer (Fig. 757, a) or, less commonly, internal (type b) race that is detachable in the equatorial plane are used. The connector allows you to increase the number of balls and deepen the running grooves.

With a purely radial load, three contact points are formed in bearings of this type - two on a split race and one on a whole race (hence their conventional name “three-contact” bearings). Correct rolling of balls simultaneously on three surfaces is, of course, impossible. The balls, which are braked by two-point contact with a detachable race, slide along the entire race, so three-contact bearings are used to carry an axial or radial load while simultaneously acting as an axial load. The axial load presses the balls against only one surface (see c), on the other side the balls move away from the surface of the treadmill, and the result is a two-contact bearing.

The contact angle β depends on the ratio of radial and axial load. With a purely axial load in completed structures β = 20–30°.

Detachable clips are usually tightened with fastening nuts, and the mutual centering of the clips occurs along the seating surface.

Bearings designed to carry purely axial loads are installed in housings with radial clearance. In this case, bearings with half-clips are used, tightly connected using a sleeve rolled at the ends (type d).

How to make a bearing housing without a lathe

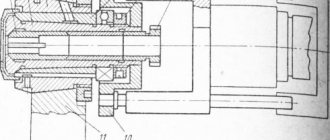

In this review, the author shows how to make a bearing housing from scrap metal. Moreover, in this case you can do without a lathe.

To make the bearing housing you will need a metal corner 32*32 mm, a metal strip 5 mm thick and 19 mm wide.

The author also uses a piece of steel pipe with an outer diameter of 60 mm (internal - 54 mm) and a steel washer with an internal diameter of 31 mm (external - 55 mm).

We also recommend reading the article: how to make a powerful bearing puller from a jack.

Main stages of work

First of all, you need to cut a piece of a suitable width from the pipe and clean the edges of the cut with a grinder to remove any burrs that have formed.

Then you need to make a slot in it - using the same grinder with a cutting wheel or on a band saw.

At the next stage, using a hammer and a bench vice, the master reduces the diameter of the holder to the required size and welds the edges together.

After this, we press the bearing into the housing and weld a metal washer to one of its sides.

Next, cut off a piece of strip and two pieces of corner. We weld them to the race with the bearing.

For details on how to make a bearing housing without a lathe, see the video below.

Source

This solution for a homemade linear bushing bearing or our hands is not for boredom. Part 1.

Subscribe to the author

Follow the author if you like his publications. Then you will receive notifications about his new posts.

You can always unsubscribe from notifications in the author's profile.

The article applies to printers:

Hello gentlemen 3D guys!

What prompted you to write? Yes, I just wanted to voice my thoughts out loud, consult and confer.

Like many of those present here, the journey of 3d_printing for me began with Rep-Strap.

I put together at least a printer and sculpt... for myself, for friends, I even bought some things.

Anyway. not about that.

In general, the problem is like many others with linear bearings and guides.

Guides. COMPLETE. I work as an IT specialist, so I've had a lot of inkjet experiences.

I bought stainless steel guides with diameters of 8mm, 10mm, 12mm. and corresponding medicinal products.

Everything seems to be working, only some play or grooves are forming on the axles.

Previously, carriages rode on caprolon bushings, which sometimes jammed.

I agree that in some places my handiwork was to blame, and in general the first damn thing was lumpy).

And also so that now, and free of charge, (those DADOM) (c) Owl), and so that it is printed quickly, efficiently, beautifully!)

Opinions also differ about ABS bushings.

But I liked it and decided to experiment with it.

In the video, the guy used Teflon tubes.

Print a clip from ABS, and there will be pieces of trimmer line as roller balls.

I won’t explain it with my fingers, I’ll show you in FreeCade.

And then Ostap suffered. And if like this:

In general, you can fantasize a lot.

Today is Friday and the printer is at work. Here's what I managed to implement today:

The ease of movement can be adjusted by the number of nylon inserts.

The downside is the appearance of backlash, but here apparently we need to look for a middle ground.

Nylon inserts are very reluctant to fit into the grooves.

This is actually what I have managed so far. After the weekend I will print the rest of the bushings and the mounting for them. They will go to the table.