Instructions: how to vulcanize a chamber with raw rubber using a homemade vulcanizer

In order to repair a flat tire on a bicycle or car, you need a vulcanizer for inner tubes. The device can be purchased in a store or made by yourself.

Raw rubber is used as the patch material. It consists of rubber sheets covered with polyethylene film on both sides.

Due to its plasticity, under pressure and high temperatures it is welded to the chamber.

Features of Electric Vulcanizer

An electric vulcanizer is a household appliance that is used to repair chambers. It consists of 2 round elements. The camera is placed between them and clamped with a clamp. The device is connected to a voltage of 220 V.

There are electric car vulcanizers. They are also called road ones. Their operating principle is the same. The only difference is that the voltage is supplied to the terminals at 12 V. A machine battery is used for this.

Vulcanization of the chamber with raw rubber

The vulcanization process of a bicycle tube is carried out according to the following principle:

- The place in the chamber where the hole is located is prepared.

- Raw rubber is applied to this place.

- Compression is carried out using a heated press.

The heating temperature of raw rubber is 147 degrees. If you raise it to 150, it will collapse, and at 160 the charring process will begin. Exposure time - 8-10 minutes.

Instructions for vulcanizing a chamber at home consist of the following steps:

- Use sandpaper to clean the location of the hole. For this purpose, the use of an abrasive stone is allowed.

- A patch is cut out of raw rubber, usually round in shape. Its dimensions should cover the hole by at least 2 cm.

- Raw rubber is dipped in gasoline and placed over the hole in the chamber.

- Paper is placed on the rubber so that it does not stick to the vulcanizer.

- A vulcanizer element with a spiral is installed on top, and a lining is installed on the bottom.

- The clamp is used to apply pressure.

- Voltage is applied to the terminals.

- Cooking takes place for 8-10 minutes.

- The device turns off.

- The clamp is not removed until the device and chamber have cooled down.

Once removed, the connection appears as one piece.

Making a device from an iron

You can make a vulcanizer for repairing tires with your own hands from an iron.

You can do this as follows:

- Take 2 steel plates with a thickness of 8 mm and dimensions of 40 × 60 mm. They will be used as a press.

- All edges are chamfered so that the sharp edge does not cut the rubber.

- In one plate, 4 holes are drilled in the corners and an M12 thread is cut. In the second - in the same 4 places, holes with a diameter of 13 mm.

- Both halves are held together with bolts.

You can use the machine in this order:

- The damaged area of the camera is being processed.

- A patch is cut out of raw rubber, soaked in gasoline and applied to the hole.

- The camera with the patch applied to it is inserted into the mold and clamped with bolts.

- An iron is located below, and a mold is installed on it. It is important that they touch at the bottom.

- The iron heats up for 10-15 minutes.

When vulcanizing, you need to ensure that the rubber parts do not touch the heated iron.

Homemade device from an electric stove

A homemade vulcanizer can be made from an electric stove. To do this, select an old device with an open spiral.

The manufacturing procedure is as follows:

- The heater body is manufactured. To do this, take a sheet of metal 5 mm thick.

- Using welding, the body is formed to the size of the ceramic base of the tile.

- Rod legs are welded on the bottom and a clamp on the side.

- A sheet of asbestos is laid, and a ceramic tile base with a spiral is placed on top.

- The heater is closed with a metal lid, which is secured with bolts.

- The thermostat is removed from the iron and attached near the clamp.

The vulcanization process is no different from working with an iron. In this case, the heater automatically turns off the coil when the temperature reaches 147 degrees.

Piston mechanism

A piston from a car or motorcycle is used as a design element. This vulcanizer does not require electricity. This requires a supply of 50 g of gasoline.

Manufacturing procedure:

- The base is cut out of wood. Wood does not interfere with the heating of the rubber.

- A beam 10 mm thick is made of metal.

- In the wooden base and beam along the edges, 2 holes are drilled for M12 bolts.

A camera with a patch is placed on a wooden plank. A cylinder filled with gasoline is placed on top. And the entire structure is bolted together. The gasoline is set on fire. After it burns, time is given to cool. And then he sorts it out.

A vulcanizer is a very important device for a motorist. It is especially necessary on the road in case of an unforeseen situation. There is no point in making an expensive purchase at home. Since such a device can be made from used devices.

Source: //chebo.pro/stroyka-i-remont/vulkanizatory-dlya-remonta-shin-svoimi-rukami.html

Homemade vulcanizer from available materials

If you are a real man, you probably have a workshop, as well as a car, or you probably have two-wheeled equipment such as a motorcycle or even a bicycle. One way or another, you will puncture your tires, especially when driving through fields, rural roads and other areas where there are a lot of nails and other objects in the ground that can puncture a wheel. The best method to seal a broken wheel is vulcanization. We actually seal the broken area with rubber. This approach cannot be compared with any glue-based patches and so on. But what to do if you don’t have a vulcanizer at hand? There is only one conclusion - do it yourself. If you assemble such a machine, you can easily provide vulcanization services and make money from it.

Do-it-yourself vulcanization - repair features, advantages and disadvantages

With the modern development of the car service network, many car owners prefer to entrust minor repairs and maintenance of their car to professionals: the work is relatively inexpensive, and in many cases it is easier and easier to take the car to a service station. However, rubber vulcanization is often done by hand and is used not only for repairing tire cuts and restoring inner tubes, but also for domestic purposes.

Cold vulcanization of rubber

In total, there are two ways to repair tires and tubes - cold and hot vulcanization, the second of these methods began to be used in the mid-19th century. The cold vulcanization method was discovered in 1939; now a kit for sealing inner tubes can be purchased at almost any auto store. For vulcanization, rubber or a special patch is used; the repair kit usually includes:

- “patches” of different sizes;

- "fungi";

- means for treating rubber surfaces;

- spool;

- special glue;

- spool cap;

- special cutter or awl.

Cold repair of a car tire is carried out according to the following principle:

- the edges of the cut/damaged area are treated with sandpaper;

- rubber dust is blown out with compressed air; the presence of moisture or oil is not allowed in it;

- the surface is degreased, then special glue is applied to it;

- The patch is also coated with glue and pressed firmly onto the damaged area.

The glue drying time is approximately 20-30 minutes, after which the tire is inflated and the seal is checked for tightness. But this method mainly only helps to get to the tire repair shop; normal operation of the tire can only be restored with the help of hot vulcanization.

Another point is that using the cold method you can repair rubber with longitudinal damage of no more than 35 mm, and with transverse damage of no more than 25 mm. The repair kit is often accompanied by instructions that describe the entire technology for repairing tubes and car tires.

Hot vulcanization using raw rubber

Raw rubber is a material that can change its properties under the influence of high temperature, weld into a single composition with the base of a tire or tube, turning into ordinary rubber as a result of heat treatment. The reverse process is no longer possible here, but due to the property of reliably setting rubber, it is able to repair quite serious cuts and punctures, and restore the performance of the tire/tube by 90-100% (in many cases).

Hot vulcanization of tires and tubes is always carried out using a press; welding of rubber with rubber is carried out over a certain period of time; the time of welding of rubber depends on the depth/area of the damaged area.

It takes 4 minutes to seal every millimeter of cut; therefore, a hole 3 mm deep will require vulcanization for 12 minutes.

But the process of heating the rubber itself is not limited to these minutes; here it should be taken into account that a standard industrial vulcanizer must warm up for 20 minutes, another 40 minutes are spent on warming up the pressure equalization pads (if they are provided in the design of the vulcanizer).

The standard vulcanization temperature is 140-150 degrees, and you can repair a tire, bicycle or car tube not only with a factory vulcanizer, but also with the help of a home-made device; for this you can use household heating devices, various proprietary designs.

How to hot vulcanize a tire

Repairing a car tire using a vulcanizer is a rather labor-intensive process that has many of its own nuances, so let’s look at the most basic points. Repairing a cut in a radial tire is done in the following order:

- First of all, the wheel is dismantled, it is necessary to provide access to the inside of the cut/puncture;

- then the cord (rubber) is cleaned around the damage; after treatment, the surface should become rough;

- rubber crumbs and dust are blown off with compressed air, the damaged area is treated on both sides with a special compound, the exposed cord wire should be removed by biting it off using side cutters;

- a patch of the appropriate size is installed on the inside of the tire using the rolling method; they begin to attach it from the tire bead to the center;

- from the outside, the damaged area is filled with raw rubber, cut into pieces of 10-15 mm; before filling, they are preheated on a stove; an extruder is used to speed up the heating process.

The rubber is carefully pressed and leveled on the surface of the tire, stripped, and the repair layer should be 3-5 millimeters higher than the general level of the rubber.

Afterwards, you need to use a grinding wheel to remove a small layer of raw rubber on top; if the surface is loose (with air), all the repair compound should be removed from the cut, and the whole operation should be repeated again.

If, when filling a cut with raw rubber, there is no air in the patch, the tire is sent under a hot press. To accurately apply pressure to the patch, it is recommended to mark the center of the damaged area with chalk.

To prevent the heater plates from sticking to the rubber, it is necessary to place thick paper or other similar material between the metal and the rubber compound.

Homemade vulcanizer

Any vulcanizer must have two important components - a heating element and a press. A vulcanizer can be made from different components, the most common options are:

- using an ordinary iron;

- based on electric stove;

- with a piston from a car engine.

In the design with an iron, the heating plate is the sole of the household appliance; in the version with tiles, a metal plate is placed on the spiral so that the rubber does not stick to the metal; paper or asbestos is laid between the materials. A homemade vulcanizer with an electric heater must be equipped with a thermostat so that it turns off the heating device at a temperature of 140-150 degrees Celsius.

It is most convenient to use a regular clamp as a press (clamping device); if, when heated, the rubber begins to emit an unpleasant odor, the vulcanization temperature should be slightly reduced. The most ideal homemade option is an iron with a thermostat plus a clamp; the manufacture of such a simple device requires a minimum of design and financial costs.

A vulcanizer with a piston works according to the following scheme:

- the chamber to be repaired is placed on a flat metal surface;

- the section of rubber subjected to vulcanization is pressed from above by the bottom of the piston, the engine part is fixed using a homemade clamp;

- Thick paper is laid between the metal and rubber;

- river sand is poured around the piston (so that the paper does not catch fire);

- Gasoline is poured into the piston and the fuel is ignited.

A piston vulcanizer can become an indispensable assistant when puncturing a chamber on the road, where connecting an electric heater to the network will be very problematic.

Advantages, disadvantages of hot and cold vulcanization

Vulcanizing tires and tubes primarily allows you to save money; it is known that repairing tires is significantly cheaper than buying new wheels. But restoring rubber is not always advisable; much depends on the degree of damage. Each vulcanization method has pros and cons, so the main advantages of the cold method are:

- simplicity and ease of operation; sealing a tube or tire with special glue is not difficult;

- low time investment;

- low cost of repairs.

The most noticeable disadvantage of cold vulcanization is the low reliability of the seal: even when repairing a small cut or puncture, it is not recommended to use the car for a long time, it is advisable to drive with low pressure in the tire, and if possible, it is better to immediately contact a tire shop. Direct small punctures can be repaired using a “fungus”, but only when the angle of the damage does not exceed 25 degrees.

Advantages of hot vulcanization:

- low cost of repairs;

- reliability of rubber welding;

- the ability to operate the car immediately after the tube/tire has been repaired;

- admissibility to carry out work in any temperature conditions.

The disadvantages of any vulcanization are the need for balancing after repair work, the impossibility of restoring rubber in case of serious damage. And mostly, do-it-yourself vulcanization is still performed as a temporary measure (for example, to get to your destination); tire fitting should be trusted to experienced professionals, at least for the sake of your own safety.

Source: //avtobrands.ru/vulkanizatsiya-svoimi-rukami-osobennosti-remonta-preimushhestva-i-nedostatki/

Piston mechanism

A piston from a car or motorcycle is used as a design element. This vulcanizer does not require electricity. This requires a supply of 50 g of gasoline.

A camera with a patch is placed on a wooden plank. A cylinder filled with gasoline is placed on top. And the entire structure is bolted together. The gasoline is set on fire. After it burns, time is given to cool. And then he sorts it out.

A vulcanizer is a very important device for a motorist. It is especially necessary on the road in case of an unforeseen situation. There is no point in making an expensive purchase at home. Since such a device can be made from used devices.

Do-it-yourself vulcanizer: design of a universal device and principle of operation (120 photos)

Punctured tires in a car have happened to almost every car owner. Many people immediately went to a tire repair shop, but if you are outside the city, far from a service center, and this happens to you regularly, which is not cheap, then it is worth fixing the breakdown on your own. To do this, you must have special materials.

A vulcanizer made on your own will help patch up damage to the camera in a car, bicycle, or motorcycle. Our article will help you build this device with your own hands, and the photo of the vulcanizer will help you look at it in more detail.

What is the principle of operation of this device? A vulcanizer is simply irreplaceable when restoring the integrity of tires, and after this, their service life is significantly extended.

Device design

The main element is the base, which includes a slab of 200x400x20 mm, located on top of horizontally laid channels of sufficient width.

On the sides of it, in a vertical position, there are racks (channel No. 65), which are securely fixed using conventional welding.

An arc is attached to the side verticals, through the center of which a pressure screw passes, secured with a clamp at the end. The lower part of the vulcanizer is equipped with a heating element.

Operating principle

The operation of the vulcanizer is very simple, since the device is simple. Using a heating device, preliminary preparation of the damaged part is carried out. Then a rubber patch is applied over the puncture site.

Due to the high temperature, two elements adhere: the camera and the lining. The result is a strong and durable grip, which gives the tire a new and longer life.

It is possible to strengthen a damp rubber chamber at a temperature of 147 degrees; at a higher temperature (from 150 degrees), the rubber material is destroyed, and at 160 degrees. - the rubber will simply turn into coals.

But you shouldn’t keep the rubber tire in the vulcanizer for too long, about 8 or 10 minutes is enough.

Features of tire repair

In order for a tire repair to be of high quality, you must first carry out the preparatory work:

- using sandpaper or stone, it is necessary to clean the damaged surface, this will remove dirt and unevenness;

- The cuts should be sharpened carefully, without allowing the opposite edges to touch, in order to avoid rubbing them against each other, which could cause the applied patch to come off;

- the dimensions of the patch should be optimal and completely cover the damaged area with a small overlap of about 2 cm. The configuration of the patch may be different.

How to make a vulcanizer with your own hands

It is quite possible to make a vulcanizer at home, and even in several variations, and the costs will be minimal. First, you should choose the appropriate design option for the future device.

Making a device from an ordinary iron is perhaps the most well-known do-it-yourself option.

To do this you need:

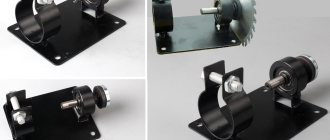

- prepare a mold from two steel plates measuring 40x60 mm or 6x8 mm;

- the edges of the plates must be ground off to avoid them cutting into the rubber surface of the tires;

- Using M4 thread, drill holes in the corners of the plates;

- tighten two plates simultaneously using screws;

- To repair unusual tire designs, the plates are given the desired configuration.

The repair process itself will look like this:

- at the site of damage, a cut is made at an angle of 45 degrees. and degreased with gasoline;

- a rubber patch is prepared and covers the restoration site;

- all parts are placed in a molding press and tightly compressed with screws;

- the mold is installed on the heated surface of the iron, while touching it with the lower part;

- within 10-15 minutes. the elements are heated;

- be sure to ensure that the rubber does not come into contact with the iron. Vulcanizers made with your own hands can actually be used in practice, repairing damaged tires and more. It is important to follow safety precautions, instructions for repair and use of the device.

DIY vulcanizer photo

Hot vulcanization

This method is most often used to eliminate side cuts on a tire that are larger than 1 cm. It is when the tire is hot that it is possible to achieve more reliable bonding of the rubber. This method is considered one of the most durable among all known. Hot gluing has a lot of advantages:

There are one-stage and two-stage vulcanization.

In the first case, the following happens:

All damaged areas are covered by the device and reliably glued together.

The two-stage process goes as follows:

You might be interested in Japanese tire manufacturers

This method closes the cut more tightly and ensures good hardening of the rubber.

Hot gluing

The temperature at which hot gluing is carried out is 120-140 °.

Homemade vulcanizer - production and use

If you have a punctured tire, the easiest option is to go to a tire shop. However, there are many who like to do everything themselves, and a tire service is not always nearby. Sometimes the costs associated with going to a tire shop (travel, time, the procedure itself) add up to a substantial amount, especially if you have to use this service often.

In general, for various reasons, for those who want to fix breakdowns at home, I offer several options for making a homemade vulcanizer at minimal cost.

Using a homemade vulcanizer, for example one made from an iron, you can quickly and reliably repair cars, motorcycle and bicycle tubes, air mattresses, heating pads, various beads, inflatable toys, etc.

One of the most common options for a homemade vulcanizer is the option using an old iron. The reason for this is new, more functional irons, and old (Soviet) irons in working condition (if you don’t have any left) will not be difficult to find from a neighbor. Here's a free basic vulcanizer part for you.

Below are a few designs. Which one to choose is up to you, the basic idea is the same, the difference is how to ensure a clamp connection at the place where the rubber product is vulcanized.

Raw rubber is soaked (for some time) in gasoline, the size is slightly less than the size of a patch. The puncture site is treated with sandpaper (the size is generous) and wiped with gasoline. A patch is cut from tube rubber, the edges are rounded. The patch is also treated with sandpaper and then with gasoline.

Next: put raw rubber on the hole, put a patch on it, clamp everything in our vulcanizer. You can place a piece of newspaper to prevent the rubber from sticking to the vulcanizer plate. Wait until water comes into contact with the vulcanizer (15-20 minutes).

Turn off the vulcanizer, wait a little, remove the vulcanizer, and let the rubber cool. They also check the temperature using granulated sugar: if its grains in contact with the hot vulcanizer begin to melt and turn yellow, then it’s time to turn off the vulcanizer.

If your thermostat is working, set it to 150 degrees. (approximately for ironing silk). The thermostat can be adjusted experimentally.

If the smell of burnt rubber appears, this is a sign of high temperature; if the patch has not merged well (vulcanized), this is a sign of insufficient temperature or short vulcanization time. After one or two times everything becomes clear and vulcanization can be started.