Russian knife craftsmen never look for easy ways. Because this is a hobby and passion for many. It happens that a simple activity turns into a real small business. But for the most part, for people it’s still a relaxation and distraction from everyday life. Each person determines his own leisure time. Forging enthusiasts quite often make their products from unusual things, for example: a knife from a bearing. A very interesting and difficult process.

Homemade knife from a bearing.

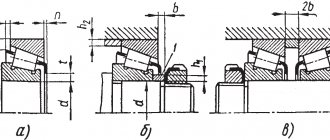

Forging a knife from a bearing

It is recommended to saw the bearing diagonally - when we forge it, we can shape the nose in an easier way.

The author used the Shx15 alloy - this is steel alloyed with chromium. Before starting forging, we anneal the alloy and leave it in a furnace or forge to cool slowly - about 20-60 degrees per hour. After annealing, steel acquires plasticity and is now more convenient to forge.

We straighten the clip and form a blade. To determine the required forging temperature for steel Шх15 - and this is in the range of 800...1100°C, it is worth using a pyrometer. But if there is no such device, we determine the heating level by the color of the heat - somewhere from cherry-red to dark yellow.

When the forging process is completed, normalization is done, otherwise stress will remain in the metal and, in the best case, the blade will lead during hardening, and in the worst case, it will burst in the cold, possibly causing injuries. To carry out normalization, we heat the blade to 800...950°C, hold this temperature for a short time - and then expose it to air, on a flat surface, to cool.

Then you can move on to metalworking. We make rough slopes by forging, the rest - using a grinder or grinder. The main thing is that the thickness of the bevels must be at least 1 mm, otherwise the blade will lead during hardening.

Now is probably the key point in making a knife. This is heat treatment.

To harden, slowly heat the blade to 830°C - light red in color. To determine the required temperature, you can use a magnet - if the metal is no longer magnetic, then the lower hardening temperature has been reached. After holding at this temperature for 1 minute for each mm of blade thickness, cool it in oil. In this case, the oil should be heated to approximately 50°C.

The process of tempering the metal is no less important - it can be done in the oven, t200°C, duration - one and a half hours. The main thing here is that the wife does not see this =)

The result is a moderately hard blade, the file can barely be caught, and springs back when loaded.

Next let's move on to the handle. The author used birch suvel, boiled in salt water with pine sawdust, as the material for the handle.

The finished handle is soaked - for this we take hot linseed oil.

For a full-fledged knife you need appropriate clothing - that is, a sheath.

The Yakuts use ox tail to make sheaths for their blades. In our latitudes, tails and bulls are in short supply, but there is enough birch bark. Unfortunately, there is a limitation on photographs, so for those who are interested, I will make a continuation - about the sheath.

Hardening. Problem.

Since I make knives mainly from bearings from cars, the size is usually 10-15 centimeters in diameter, and I started out as a complete woodpecker, after purely intuitive attempts the following problems arose: • After hardening in water, the steel is so brittle that it shatters like glass upon a strong impact

Actually, that's all. Everything else suited me. But I wanted something that “won’t rust,” “cut well,” “keep an edge,” “don’t splinter.”

I don’t have a bolometer, “everything is by eye”, and when I read the recommendations “withstand two hours at a temperature of 453 degrees” - this is not for me. In the end, plus or minus hardness or viscosity is purple to me. I am quite satisfied with “more or less” decent quality according to the listed parameters.

That's why.

Solution to the problem:

1. I forge, making sure to observe the following conditions:

• When heating, I would rather underheat than overheat. I try not to heat it up to a white glow, I work in the red-yellow range. I’d rather stick it in and out more often than burn it out. • We carefully monitor the part when it is in the forge: trying to save money and make two parts at the same time leads to the fact that you will either burn it out or spoil something. • It has heated up to a bright red with pieces of a yellow glow - take it out • Periodically spray it from a plastic bottle (like on a shish kebab) - you can better see the temperature, where what is heated, and it saves coals • Especially carefully when there are thin parts (a blade, for example) – don’t burn it!

2. NEVER HIT COLD METAL!

• When you forge, the metal is ductile. And you can see from the glow if it starts to cool down. Of course, I want to forge “more” at one time. We must fight this temptation. • As soon as you hit it with a hammer (and I do everything manually, there are no mechanics) you feel that the plasticity is decreasing - we stop and heat further.

Explanation: As far as I understand, everything is explained simply. As soon as I hit the cooled metal with a hammer, micro-cracks appear that are difficult to “heal” even with good heating, and then everything breaks along them. That's all.

3. Actually, hardening.

I tried it in the water. With any (almost) options, the result is brittle steel. So I took it and poured it into a canister of used machine fuel (not a problem to get it). I read pictures and about what temperatures are for what grades of steel... I understood the glow and color of the metal. Dry residue:

• When the shape of the part is constrained - I try to be as close as possible to the final shape in order to sharpen less - I start hardening • I heat it to (on average) a color-glow between red and yellow (by eye) - but there are theoretical justifications for this, I will say below , — and I lower it VERTICALLY BY THE TAIL with the tip of the blade down quickly and quickly into the oil. Let it cool for a few minutes until it cools completely. • I heat it to a dark red color and harden it again • If the knife “leads”, which happens - it simply becomes bent - I heat it to a dark red color (minimal plasticity) and correct it, if necessary, I harden it again. • I put it on a tray next to the coals, turn off the forge - let it all cool down together.

The result is everything is gorgeous, and without any problems. I can summarize a long base, but such a repetition of quenching with a decrease in the upper heating temperature experimentally gives an excellent result on average, regardless of the bearing taken (I haven’t tried Japanese exotic ones, I won’t take them - mainly our AvtoVAZ, Uralaz, KamAZ, Gas, etc. Soviet factories.)

Now the theory.

If we take a picture of the transitions of different austenites into martensites and other cementites,

...then let us note that ON AVERAGE the range of correct heating is above 850, but below 900 degrees. Therefore, it is necessary to heat up to approximately the range of colors as in the picture below.

Repeating doesn't make it WORSE, it makes it BETTER. That's all.

Since this is a “peasant” approach, I present it simply and that’s all.

Shx15 steel for knives: description, pros and cons

Since time immemorial, the knife has entered human life as a necessity. In ancient times, a knife was a sharpened stone that people used for hunting and protection from predators. Over time, the knife has changed a lot, it has found more and more uses and has become an integral part of everyday life and household use.

Now it is impossible to imagine the life of a modern person without a knife. It has become a necessary tool for cooking, hiking, hunting and fishing, as well as military affairs. Even in sports, the knife has found its use.

general characteristics

The bearing housing is a special part. It is usually made of cast iron or other alloys. A bearing housing is used to seat the main shaft on the main platform. It secures the part tightly.

The housing and the bearing itself - rolling, sliding and other varieties - together create a unit. It is easy to find in the equipment and technology of enterprises in all industrial sectors.

Since quite a few types of the presented parts have been developed, there are even more cases for them. Moreover, manufacturers are ready to produce both standard configuration products and housings for specially shaped bearings. In the latter case, an individual drawing is created, on the basis of which the master produces the required part. This makes it possible to ensure that the unit complies with existing production conditions.

How do knives differ from each other?

Nowadays, there are knives of completely different, sometimes even intricate shapes, depending on where they are used. The handle and blade are given the necessary aesthetic and practical appearance. But the deciding factor that differentiates one knife from another is what it was made from. Specifically, we are talking about the chemical composition of the steel from which the blade itself is made. Not everyone is able to choose exactly the knife steel they need, since there are a huge number of different variations of this alloy, the chemical composition of which determines their properties, advantages and disadvantages, strengths and weaknesses. But to choose a knife, it is not necessary to study the entire periodic table; it is enough just to know what properties a particular grade of steel has.

Sharpening and polishing the blade

Let's move on to such an important point as sharpening the knife. When doing this, symmetrical sharpening on both sides of the blade is important. It is also necessary to create the required bevel angle of the knife blade, which for ordinary knives is 15 - 25º. On razors, the smallest angle is 8–15 degrees, on tourist knives 25–30º. Manually sharpening a knife blade on a whetstone is unproductive. This is done simply and efficiently on a belt sanding machine called a grinder.

If you need to sharpen a knife to razor sharpness, special sharpening devices with replaceable abrasive bars are used. With the help of such equipment, it is not a problem to create any angle of descent from the butt of the knife or descent of the cutting edge of the knife.

Once the rough shaping and sharpening of the knife is complete, it's time to fine-tune the metal using a grinder and Dremel attachment. Through holes are drilled for the pins for attaching the knife handle. In order to better bond the wooden plates to the metal, about a dozen blind holes are made on both sides of the knife shank.

What is ShKh 15 steel?

Steel ШХ 15 is a representative of the class of low-alloy chromium steels . This means that the steel composition, in addition to the main elements, includes special additives. They give it the necessary properties of strength, resistance to corrosion and aggressive environments. ShKh 15 steel contains the following chemical elements:

In steels of this group, the amount of chromium is quite small, which is the main difference from high-chromium steels. For this reason, chromium does not form its own carbides, but remains in solid solution and is also part of cementite. If we talk about structural features, it is worth noting that all carbides are small . This is what determines the high contact endurance and uniformity of this steel. In general, like other “carbon” steels, ShKh 15 holds a thin edge very well.

This grade of steel is widely used in industry due to its increased hardness, wear resistance and corrosion resistance. It is mainly used to produce rollers and balls for bearings. This is where the name “bearing steel” comes from. Knives made of this steel are characterized by high wear resistance, hardness and contact strength.

ШХ 15 is widely used among knife manufacturers due to the fact that it is perfectly amenable to heat treatment , after which it not only acquires the desired shape, but also improves its strength indicators several times. It also achieves very high wear resistance, which in turn is ensured by the high hardness of the steel. It is worth noting the high resistance to crushing, while maintaining such parameters as ductility and viscosity.

For hardening, the optimal temperature is around 810 - 850 degrees , and the tempering temperature, in turn, varies from 150 to 160 degrees. The final result is a hardness of 61-64 HRC.

Steel of this grade also has a number of the following characteristics: a tendency to temper brittleness or flake sensitivity. The proportionality limit for this material is 370-410 mPa, and the short-term strength limit for this steel is in the region from 590 to 750 mPa. ShKh 15 steel has a relative contraction of 45% and an impact strength characteristic of approximately 440 kJ/m2.

Assembly

You need to dilute the epoxy glue. Marks should be applied to the dies being joined or shallow dents should be pressed for better adhesion of the epoxy layer. Be sure to degrease the metal part of the knife, which will be located inside the handle. Assembly is carried out in the following sequence:

- Epoxy glue is applied to the surface of the overlays from the scratch side;

- the halves are placed on both sides of the shank, pins are inserted into the holes, the assembled handle is wrapped in paper and tightly compressed with a clamp;

- after the epoxy has hardened, use a wood cutter to remove chamfers from the edges of the knife pads;

- Using sandpaper on a fabric base with a grit of 80, rough processing of the wooden dies of the knife handle is carried out;

- Polish the handle clean with strips of sandpaper.

The polished surface is covered with linseed oil heated to 50–60 degrees. After absorption, the procedure is repeated 2-3 times. There is no need to varnish the knife handle later. Under the influence of ultraviolet rays, the oil polymerizes, turning into a hard elastic substance. It fills the smallest pores of the wood, protecting the knife handle from moisture and external influences better than any varnish.

Results

Having studied in detail steel grade ШХ 15, we can clearly indicate its advantages and disadvantages.

- Uniformity.

- High contact endurance.

- Easily processed.

- Fairly high hardness.

- High wear resistance.

- Thin edge when sharpened.

- Resistance to crushing.

- Plasticity and viscosity.

- Relatively high susceptibility to corrosion.

- Difficult to sharpen.

There are many different grades of steel. Each of them has its own advantages and disadvantages. ShKh 15, in turn, is a very versatile steel, suitable for almost any type of knife. At the moment it is one of the most popular brands with low cost and is used mainly in private forging of blades. A product made from such steel can give the desired result from the work, while significantly saving the budget due to its low cost.

Preparation of overlays

The ergonomics and overall perception of the knife depend on the correct choice of material for making the handle. Metal alloys, plastics, genuine leather, and elastomers are used as the starting material for the manufacture of knife handles. Hard and valuable wood species are irreplaceable for this purpose.

The overhead handles, most suitable for the shank of the bearing knife, consist of 2 identical halves. You will need to stock up on scraps of metal rod for the knife handle pins. In the case of using wood, the following sequence should be followed:

- the antiseptic-treated block is clamped in a vice and sawn into 2 identical parts;

- to eliminate gaps, thoroughly sand the sides in contact with the metal;

- the contour of the knife handle is drawn, two dies are cut out with a jigsaw;

- the halves are placed on the shank, the holes for the pins are marked and drilled.

Handle preparation