Where to get good steel for a knife

Most often, in the manufacture of blades, stainless steel is used - an alloy of iron, carbon with alloying additives: chromium, nickel, tungsten, manganese, vanadium, and others - they are responsible for strength, fusibility, corrosion resistance and other characteristics. The properties and value of a knife directly depend on the quality and material. Today, high-quality steel grades are supplied by countries such as Germany, Finland, Sweden, the USA, Taiwan, and Korea. Cheaper, but also lower quality raw materials are offered by Indian and Chinese manufacturers.

Manufacturers often use domestic tool steels - they have high strength indicators. You can buy them from metal trading companies that sell metals for various enterprises - some of them sell sheets and long products at retail.

Good grades of steel

- D2 is a popular American knife brand with a high carbon content of 1.4 - 1.6%. The 12% chromium content gives it high resistance to corrosion, for which it is called semi-stainless (real stainless steel has less carbon and is more fusible). Analogue D2 - Russian weapons X12MF, Japanese SLD.

- AISI 420 is a high-alloy martensitic steel with a high carbon content, which gives it greater strength and corrosion resistance. Russian analogues - 20Х13, 30Х13, 40Х13. Also used for the production of knife tools, turbine and carburetor parts, fasteners, because has high heat resistance.

- 65Х18, 95х15 - domestic martensitic steels with an even higher carbon content of up to 0.95%, which makes this type of metal very hard. Used to create industrial tools, cutters, bearings, etc.

- Х12МФ – alloy tool steel for the production of dies. Knives made from this material hold an edge well.

- XB5 - The most durable, for which it bears the proud name of diamond. Very difficult to work with, but knives made from it last forever.

In fact, there are many more brands. These are just a few of the most popular ones that have already proven themselves in mass production.

Where to buy good steel for a knife

The sale of sheets and long products is carried out by metallurgical companies that work directly with the manufacturer; you can also buy the necessary raw materials in specialized stores of materials for knives and in workshops. It has all the certificates and chemical examination results, which confirm the content of the required percentage of alloying additives in the metal, which means its high characteristics. If you are engaged in the manufacture of knives professionally, then you are unlikely to have read this far, since you are already ordering large quantities of rolled metal from trading companies.

For hobbyists, it’s better to immediately call a workshop or store and order a small batch at retail price. Some enthusiasts buy knife blanks from China on AliExpress and Ebay. But the quality remains in question - no one will show you certificates for it.

Source

The best steel grades for knives

Depending on the percentage of carbon in the alloy, steel is divided into three types: high-carbon, medium-carbon, low-carbon. If the alloy contains other chemical elements, it is called alloyed. If the percentage of alloying elements that change its properties is from 10 to 50, the steel is highly alloyed. Since when chemical elements are added to a steel alloy, its composition can change, this suggests that while some qualities of steel increase, others may not change for the better. Therefore, it is difficult to say unequivocally which steel grade is the best. Rather, the best characteristics of a knife depend on the quality of the heat treatment of the blade, the technology of which varies among different manufacturers.

Where can I get steel for knives? Stop by the metal collection points! Showing the results

I needed to find some ventilation ducts for the exhaust hood in the workshop. Well, remembering that I had not visited metal collection points for a long time, I decided to drive to the nearest one.

In general, it should be a rule for a craftsman to visit such places at least once a month. Sometimes people bring such interesting things to scrap metal that you are amazed.

I saw a suitable box right away. An excellent corner box suited my needs perfectly. A bunch of old tools hinted at take me! but they didn't interest me. Although I left a mark for myself. Deciding not to stop there and continue searching for something more interesting.

By the way, the box cost me 60 rubles, almost a freebie))) Let’s look through the gallery!

After a couple of minutes, the search led to excellent circular saws for wood. They were modestly hiding under a bag with something metal. Such saws are made from steel types 9xc or 9xf. Both steels are suitable for making good knives. You can do it right away without heat. There is quite enough hardness there. Approximately 55-56 units on the Rockwell scale. But I usually do a new heat treatment and get a fair 60 units.

I'm definitely saving up for purchases. A competitor really caught their eye on them, bringing some kind of metal frame for acceptance. In a hungover voice he asked, “Let me take them.” I responded with a categorical refusal. Moreover, the receiver announced the price of fifty rubles per kilogram. In total, the saws cost five hundred rubles.

And the icing on the cake was this extremely strange unit. I didn’t expect to take anything else at the reception, but missing out on this Pepelats was simply beyond my strength. At first glance it was something medical. Weights, pedals, adjustments said that this was some kind of rehabilitation simulator, perhaps someone will recognize it and write in the comments in more detail.

Seeing him, the future abs immediately appeared in my head. In my dreams, I have an idea to start making knife handles from plastic. And that’s what the press is for. This is such a gift of fate. I was afraid that the bars were made of pipes, but no, the bars turned out to be solid when disassembling the simulator later.

Types of knives and their purposes

There is nothing perfect in this world. This also applies to knives. Each product is intended for specific purposes. Its qualities and characteristics will correspond to the assigned tasks.

Giving a knife hardness inevitably adds fragility.

A lot depends on the quality of the steel, but you can’t fool physics. Experts identify four main product areas:

- Kitchen knives. The most popular can easily be called kitchen knives . The blades of such products are required to have increased hardness and at the same time eliminate fragility.

A knife that is used to cut small carcasses of birds and animals must have good sharpness and not break on a bone under load. This is achieved by using special grades of steel and its hardening in the manufacture.

The knife must cope with all the tasks listed in the previous paragraphs. If necessary, it becomes a kitchen appliance, it should solve camping tasks with ease, and, in extreme cases, become a survival knife.

Some tasks cannot be solved with one blade. Purely structurally it is not advisable. It is recommended to use several small products rather than clutter one knife with a bunch of functionality.

The best steel grades for knives: characteristics

The steel from which the knife is made determines its main characteristics - strength, wear resistance, and anti-corrosion qualities. Depending on a number of ingredients added to the carbon-iron alloy, as well as the degree of hardening and heat treatment, we obtain a certain grade of steel for hunting, kitchen, and utility knives. These factors also determine how long the knife will remain sharp, its resistance to various deformations, as well as blade breakage. The brand that is closest to high performance in all characteristics will be the best, but not always the most expensive.

Advantages of homemade knives

The production of knives has become widespread. This often affects the quality of the product itself. Especially thanks to the Chinese brothers, consumer goods are often found that can hardly be called a knife. People want quality at a low cost.

In stores, they charge indecently large sums of money for original blades from well-known brands. Turn to a professional blacksmith - the price tag will be even more expensive, given the uniqueness and originality of the product.

Branded Japanese knife from the HATTORI company.

The only hope left is for yourself. But how to make a knife without proper experience is not an easy question. The article is aimed at answering it. But first, the advantages of making knives with your own hands:

- there is no need to pick it up in a store or explain to the master what is required - you have a perfect idea of what your soul wants;

- Having studied the surface characteristics of steels, you can choose the alloy yourself;

- The knowledge gained will help you to correctly forge and harden a blade;

- the handle and design of the product are completely in your hands.

Making a knife with your own hands at home is quite possible. During the first attempts, unforeseen situations may occur, you should not despair, patience and work are the key to a successful result.

What steel is best to make a knife from?

Steel blanks. When choosing steel for making a knife, you need to carefully study its characteristics. Knowing the behavior of metal under various conditions, it is easy to choose the option that interests you.

Quite a lot of metal alloys have suitable characteristics for making a blade. The main advantages are:

- the hardness of the alloy and its strength - subject to less deformation, but fragility increases. These two qualities certainly overlap;

- wear resistance - eliminates frequent sharpening of the cutting edge. Otherwise, the blade will be worn down to the state of an awl;

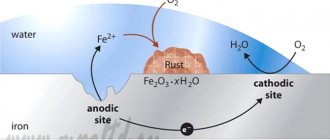

- Corrosion resistance - consists of resisting moisture. Stainless steel contains a large amount of chromium, which affects the strength and hardness of the product;

- resistance to mechanical stress - characterized by the cutting edge's resistance to dulling.

Craftsmen try to maintain a balance of these qualities in one product. This is not easy to do. But some blades require one specific quality, this makes the task easier. Brands have become necessary for the average person and are available in specialized organizations.

Broken blade.

Alloys produced in Russia have many foreign analogues, similar in structure. Abbreviations contain other letters and numbers. A few examples:

- 8Cr13Mov – excellent for sharpening, contains a lot of carbon, a good option, price – quality. It is widely used due to its affordable price;

- ATS-34 is a Japanese version with good corrosion resistance and considerable strength. Holds an edge well, belongs to premium class alloys;

- 440C – stainless steel, which has versatility in use and is characterized by low cost. Chrome and carbon make it wear-resistant and give good resistance to rust.

To make knives with your own hands, study the properties of metal. Metallurgists are not greedy people and will always share useful information. Having it, metal processing will become much easier.

A knife can be made from anything

Today, I would like to continue the topic of accessible material from which you can quickly and easily make a knife with good characteristics. Many people are interested in the question of what can be used to make a good knife without resorting to complex technologies. This is written about in some detail in this article. Here we will try to further highlight some of the details of suitable material for knives. The easiest thing is to use old broken stainless steel kitchen knives. Knives should preferably be Soviet-made, and not Chinese consumer goods. From such a fragment you can make a good knife with excellent cutting characteristics.

Also, good knives can be made from high-speed steel, which is used in the production of hacksaw blades for power saws. The disadvantage of this material is that it is quite fragile and tends to rust. But it holds an edge well.

An excellent material is knives for a wood planer. This metal is very well processed and polished. The planing knife is burned red-hot with a blowtorch and then cooled. After annealing, the metal can be easily sawed with a hacksaw, shaped, or sharpened with a file. After the knife is given its final shape, it must be hardened, either in oil or in water. But, unfortunately, knives made of this metal also rust.

The next metal we'll look at is a regular file. It is very easy to make a knife from a file, without any special machines. Take a file, heat it well, again with a blowtorch until red-hot, and let it cool. After this, it is very well processed with another file, sawed with a hacksaw to give it the desired shape. Next, hardening is carried out again in oil or water. The main thing is that in order to get a good knife from this metal, you need proper heat treatment. There is no need to unforge this metal. We simply burn, sharpen, file, remove excess metal with a hand tool or sandpaper. And we get a pretty good knife.

You can also make a budget knife from an ordinary hacksaw for wood. It is also very easy to process, very elastic steel. It can be adapted, for example, to make a kitchen knife that will cut well and hold an edge well.

Car springs are also good for making knives. The only bad thing about a spring is that it needs to be unchained and properly heat treated. This is quite a time-consuming task. But if you build a homemade forge on your property, you can make a good knife from a piece of spring. Or just take it to the blacksmith, who will forge anything for you for a bottle of vodka. You can make a knife from a car valve. It also makes good stainless steel. The valve is heated to high temperature and hammered on an anvil. Then you need to shape the blade and harden it.

Very good knives are made from large drills. Clamp the drill in a vice, heat it until soft, take the gas keys and begin to slowly unscrew it. After this, you heat it up again and begin to unforge the resulting part, giving it the desired shape. The drill will not be sharpened with a file. All work on shaping the blade must be done on sandpaper.

The knife can be made of spring steel. There is no need to anneal this metal. You can immediately make a knife blade from the workpiece. This steel cannot be drilled with a regular drill. It is necessary to use a pobedit drill.

Now let's talk about rust, which is present in most metals. If you want to prevent your knife from rusting, you can treat it with sulfuric acid or phosphoric acid.

The article uses material from a video on YouTube

What tool will you need?

Making knives is not a simple matter. It requires not only experience, but also specific tools. Making a knife with your own hands from start to finish will take a lot of time. And devices such as a belt sander or machine will reduce it to a minimum.

Grinding machine.

Considering other power tools, the DIY practice itself can cost a pretty penny. Much depends on the manufacturing method and material.

If you need to forge a product, these are additional tools and devices. Beginners are recommended to start with simpler manufacturing options.

For these purposes, we will take 1095 steel with a high content of carbon, chromium and manganese. It is good for sharpening a cutting edge, but it is not recommended to use it under a razor - it will quickly become dull. The handle will be made of wood with an overhead mounting method. The following tools will be needed:

- paper, pencil;

- drill with a set of drills of different diameters;

- copper or brass rod for rivets;

- vice, hammer;

- belt sander or angle grinder with cutting and grinding wheels;

- muffle furnace or forge;

- gas stove oven;

- motor oil in a container;

- files of different grains;

- wood hacksaw, jigsaw;

- epoxy glue, clamps;

- oil, wax or special impregnation for wood;

- sandpaper of different grains.

The lack of a grinder can be replaced with a grinder. But it is more difficult to work with. If there is no furnace or forge, there is an option to use coal in the open air with an air supply.

A dangerous but necessary tool.

The point is that it is quite acceptable to replace some tools and devices with similar ones that are available. The use of ingenuity is not forbidden.

Homemade knife: features and advantages

There is a huge range of knives on the modern market. It would seem that such a huge variety only makes the task of choosing a weapon easier, but in fact this is not the case. Among the products offered on the market, it is not always possible to choose a hunting knife of optimal hardness and sharpness, and some characteristics of the weapon will not meet the individual requirements of the buyer.

We should not forget that some blades are made from low-quality metal or in violation of technology. As a result, the blade quickly loses its sharpness, and the knife itself becomes just a useless piece of metal.

If you have not been able to find a suitable model, there is only one way out - to forge a hunting knife with your own hands (Figure 1). Having a custom blade made by a qualified smith can be expensive, so many people prefer to do this kind of production themselves. For example, you can always make a simple knife from cable, but remember that in the process you will have to handle the metal correctly so that it acquires the necessary characteristics.

In general, homemade edged weapons have many advantages:

- You can choose the appropriate type of blade not from the offered range, but solely according to your own needs, and combine all the desired characteristics in a finished product.

- You will always have the opportunity to choose the right steel for the blade.

- During the manufacturing process, you will be able to independently select the optimal heat treatment mode (hardening and tempering), during which the blade will acquire the ideal ratio of hardness, strength and ductility.

- When making it yourself, you avoid unpleasant errors or defects that are often present in finished products and directly affect the operation of the weapon.

Figure 1. Homemade hunting knives

In addition, in a homemade knife you can develop an individual handle design or think about a unique decoration for the blade. As a result, your blade will become not only sharp and reliable, but also beautiful and original.

Steel grades for knives: decoding

Alloy steel has serious advantages over ordinary carbon steel, since strength, wear resistance, hardness and toughness depend on elements such as molybdenum, chromium, vanadium, nickel, silicon, tungsten, and manganese. The addition of molybdenum simultaneously increases strength and toughness, and the high chromium content improves the cutting properties of the blade, increasing hardness, wear resistance, and also giving the steel anti-corrosion properties.

In order to understand the types, it is necessary to consider the characteristics of steel grades for knives:

Steel grades for knives

A universal brand, similar in characteristics to those described above, but capable of corrosion during prolonged contact with water. With a high level of quality heat treatment, this steel produces hard and durable knives that hold an edge for a long time.

A grade of alloy steel used to make tools and bladed weapons. It is used to produce parts that are subject to heavy loads and which must have increased wear resistance and bending strength: these are drills, reamers, cutters, taps, etc.

High alloy steel with high hardness and good cutting edge properties. Designed for the manufacture of products with high strength and wear resistance. One of the best domestic steel brands.

Mild steel used only for making kitchen or gift knives. Subject to deformation and often requires sharpening. It is a good option for the kitchen because it does not rust and can be easily repaired with musat, but the material is not used for other uses.

Steel grades for knives

Good corrosion resistance, the material is easy to process. Used for making household and travel knives.

The brand is used for making tools, it is convenient and unpretentious when processing, but knives made from this material require constant care, because When exposed to an aggressive environment, the metal becomes covered with plaque and dark spots.

One of the most popular brands with low cost. Used mainly in private blade production. The decoding of the brand is as follows: “W” indicates bearing steel, “X” indicates the chromium content, 15 indicates its quantity, and the letter designation “SG” indicates the content of the alloying elements silicon and manganese. It makes durable, sharp knives, but susceptible to corrosion.

Foreign steel grades

An analogue of the domestic brand 65X13, which has the greatest hardness compared to the others.

A material that is highly resistant to corrosion, with a carbon content corresponding to the letter designation: A - with the lowest content, B - medium, and C - with the highest percentage of carbon in the composition (up to 1.2%). Grade 440C is the best of the three, but is the least resistant to corrosion.

An analogue of brand 440C, but with an admixture of vanadium, which gives greater wear resistance to the material.

Foreign steel grades

Currently recognized as the most high-tech steel used in the production of knives of the highest category. The hardness of the metal is 60 Rockwell units, but it is quite durable and holds an edge well.

Being analogues of the 440 grade, knives made of this metal are distinguished by high strength, sharpness, and anti-corrosion.

Foreign steel grades

The admixture of vanadium gives greater wear resistance to the metal; knives from this material are often made for hunting purposes, since they have great ductility, and therefore strength.

The brand, used today by only a few companies, has no analogues in terms of high levels of hardness, strength and toughness. This powder steel is used to produce the best knives that have a high price tag.

Step-by-step instructions for making a knife with your own hands

For the handle you need to find a block of good wood: beech, cherry, birch, oak, plum and other species work well. The workpiece should not be overdried. By following the instructions step by step, a novice master will cope with this difficult task. The process of making a knife without forging looks like this:

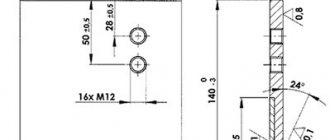

- It is imperative to depict the desired result in the form of a drawing. All work should be carried out in accordance with this template. If you lack imagination, take a look at specialized Internet resources. There are sketches with size markings.

- Then you should transfer the design to a metal plate. To begin with, just a general profile. On its base we cut out a workpiece using a band cutting machine. Having such a tool will reduce your time and wasted nerves. Otherwise, we clamp the plate in a vice and cast magic using a grinder. Sample.

Sketch on steel. Preparation.

- Prepare personal protective equipment: gloves, respirator and goggles. Working on a grinding machine is sparkling and dusty. It is necessary to bring the workpiece into proper form. Remove all burrs and bring it to the state of the sketch. It is necessary to monitor the temperature of the metal; the appearance of dark spots indicates overheating. It is advisable to avoid this, as it will further affect the quality of the product. Dip the workpiece into a container of water more often to cool.

- A critical stage in the formation of bevels. It is necessary to decide on the future use of the blade. For chopping and heavy tasks, leave the blade thicker. If a thin cut of the product is required or a razor sharpening is required, the product must be ground evenly on both sides. But you shouldn't overdo it at this stage. It is permissible to remove excess after hardening.

- The copper rod must be cut into small pieces for rivets into the handle. And in accordance with their diameter, drill holes in the shank of the blade. This is done before the product is hardened.

- Hardening.

Hardening of steel is necessary to give hardness to the blade. Having studied the metallurgical reference table for carbon alloy 1095, it becomes clear that hardening must be carried out at a temperature of 800 degrees. This will allow you to obtain a hardness ranging from 59 to 63 HRC. Heating the blade to the required temperature, cooling is carried out in engine oil for three seconds. Then leave to air cool. - After the hardening procedure, the blade must be tempered, otherwise it will be fragile and at the slightest blow there is a chance of splitting it. We heat the gas stove oven to 200 degrees. Then carefully place the workpiece in it and leave for two hours. Afterwards, the product will receive all the necessary qualities of a good blade.

- Now we need to bring the descents to fruition. And remove the cutting edge. Having previously removed all carbon deposits from the product with a grinding machine.

- Installation of the handle begins with halving the block. Then the two parts should be marked in accordance with the sketch and symmetrical blanks should be cut out with a jigsaw. Drill holes in them with precision, as on the shank, and rivet them with copper splines. Pre-coated with epoxy for reliability. Leave to dry for 24 hours, squeezing the product with clamps. Then use a grinder to give the handle the desired look, and coat the wood with linseed oil or impregnation.

Making your own knife for hunting or fishing

Recently, the topic of self-production of knives, called “knifemaking,” has gained enormous popularity in Russia. Making a knife at home may seem complicated at first, but it is not so if you look at the catalog of our store. For self-assembly of a knife, we can find a large assortment of blades for knives, exotic wood for handles, castings for knives from cupronickel brass and bronze.

How to assemble a knife yourself?

For this you will definitely need a high-quality blade. The basis of any knife is the blade; it must hold an edge for a long time, be resistant to corrosion, and withstand shock loads well. For the handle, when assembling a knife, stabilized Karelian birch or exotic wood species are ideal. A pritin, guard, backplate or bolster from our knife casting catalog will help give your future knife a beautiful look.

How to make a blade for a knife?

Making blades for knives is a labor-intensive and quite complex process that requires considerable experience and attention. In order to make a blade you will need a belt grinder and material for the blade. In the knife workshop Istok it became possible to order forgings and buy steel for knives. Forged blanks (forgings) made of steel X12MF and 95X18 are very popular in the production of blades. Powder steel blanks Elmax (Elmax) and Bohler M390 have received wide distribution and positive reviews. You can order a forging or buy steel for a knife by contacting us on the contacts page.

Steel grades for hunting knives

For hand forging a hunting blade, a good option would be to choose the 9XC brand. A knife made of this steel will have good cutting qualities and will also hold an edge perfectly. Steel 95X18 perfectly combines high quality and affordable price, has high strength and hardness, but because of this the blade is difficult to sharpen. The X12MF grade will allow you to create a very durable, wear-resistant hunting blade, provided that it is carefully cared for. Based on this brand, many domestic manufacturers produce damask steel, which indicates the quality characteristics of this brand.

Damascus knives are an excellent option for hunting or hiking. Damascus is very durable and resistant to corrosion. Thanks to the high carbon content of Damascus, the blade is very sharp, but also fragile enough to do household work.

The domestic brand 65G is suitable for making a hunting knife, the purpose of which is not cutting, but chopping. It has excellent viscosity, but should be protected from moisture, because metal is susceptible to corrosion.

Rules for sharpening the finished product

Properly using the blade under the conditions of its intended purpose, it will inevitably lose its sharpness. This process occurs at the microscopic level when the metal rubs against the objects being cut. A completely natural loss of sharpness requires a lot of cutting effort. It gradually becomes clear that the knife requires sharpening.

If the knife is made by hand from start to finish, then it definitely needs to remove the cutting edge.

The process is labor-intensive, requiring attention and precision of hand. But today there are many devices to simplify this action.

Progress does not stand still. Mechanical devices allow you to secure the blade in one position and remove the cutting edge without fear of losing the angle.