Inch threads are used primarily to create pipe connections: they are applied both to the pipes themselves and to metal and plastic fittings necessary for the installation of pipe lines for various purposes. The main parameters and characteristics of the threaded elements of such connections are regulated by the corresponding GOST, providing tables of inch thread sizes, which experts rely on.

Plumbing products with inch pipe threads

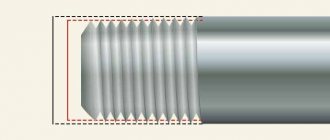

Main settings

The regulatory document that stipulates the requirements for the dimensions of cylindrical inch threads is GOST 6111-52. Like any other, inch thread is characterized by two main parameters: pitch and diameter. The latter usually means:

- outer diameter, measured between the top points of the threaded ridges located on opposite sides of the pipe;

- internal diameter as a value characterizing the distance from one lowest point of the cavity between the threaded ridges to another, also located on opposite sides of the pipe.

Inch thread parameters

Knowing the outer and inner diameters of an inch thread, you can easily calculate the height of its profile. To calculate this size, it is enough to determine the difference between these diameters.

The second important parameter - the pitch - characterizes the distance at which two adjacent ridges or two adjacent depressions are located from each other. Throughout the entire section of the product on which the pipe thread is made, its pitch does not change and has the same value. If such an important requirement is not met, it will simply not work; it will not be possible to select a second element of the connection being created for it.

You can familiarize yourself with the provisions of GOST regarding inch threads by downloading the document in pdf format from the link below.

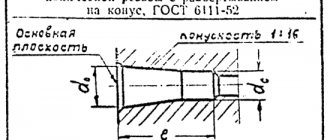

GOST 6111-52 Conical inch thread with a profile angle of 60°

Use nuts and bolts of the same strength and material

An important factor that affects the reliability and durability of the connection is the compatibility of bolts and nuts in terms of strength and material. The nut's load resistance should be equal to or even stronger than the bolt. That is, a stronger nut can be used with a weaker bolt, but not vice versa. For example, a grade 8 nut is acceptable for use with a grade 5 and grade 8 bolt.

Differences from metric threads

In terms of their external features and characteristics, metric and inch threads do not have many differences, the most significant of which include:

- profile shape of the threaded ridge;

- procedure for calculating diameter and pitch.

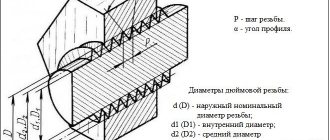

Differences in thread profile

When comparing the shapes of threaded ridges, you can see that in inch threads such elements are sharper than in metric threads. If we talk about exact dimensions, the angle at the top of the ridge of an inch thread is 55°.

The parameters of metric and inch threads are characterized by different units of measurement. So, the diameter and pitch of the former are measured in millimeters, and the latter, respectively, in inches. It should, however, be borne in mind that in relation to an inch thread, it is not the generally accepted one (2.54 cm), but a special pipe inch equal to 3.324 cm that is used. Thus, if, for example, its diameter is ¾ inch, then in terms of millimeters it will correspond to the value 25.

To find out the basic parameters of an inch thread of any standard size, which is fixed by GOST, just look at the special table. The tables containing inch thread sizes contain both whole and fractional values. It should be borne in mind that the pitch in such tables is given in the number of cut grooves (threads) contained in one inch of product length.

Drawing. Main profile parameters according to GOST

Table 1. Main thread profile dimensions

Table 2. Basic parameters of pipe threads

To check whether the pitch of the thread already made corresponds to the dimensions specified by GOST, this parameter must be measured. For such measurements, carried out for both metric and inch threads using the same algorithm, standard tools are used - a comb, a gauge, a mechanical gauge, etc.

The easiest way to measure the pitch of an inch pipe thread is using the following method:

- As a simple template, a coupling or fitting is used, the internal thread parameters of which exactly correspond to the requirements given by GOST.

- The bolt, the external thread parameters of which need to be measured, is screwed into the coupling or fitting.

- If the bolt has formed a tight threaded connection with the coupling or fitting, then the diameter and pitch of the thread that is applied to its surface exactly correspond to the parameters of the template used.

Inch thread pitch is the number of threads per inch

If the bolt does not screw into the template or screws in but creates a loose connection with it, then such measurements should be carried out using another coupling or another fitting. The internal pipe thread is measured using a similar technique, only in such cases a product with an external thread is used as a template.

The required dimensions can be determined using a thread gauge, which is a plate with notches, the shape and other characteristics of which exactly correspond to the parameters of the thread with a certain pitch. Such a plate, acting as a template, is simply applied to the thread being checked with its serrated part. The fact that the thread on the element being tested corresponds to the required parameters will be indicated by a tight fit of the jagged part of the plate to its profile.

Using a thread gauge for inch threads

To measure the outside diameter of an inch or metric thread, you can use a regular caliper or micrometer.

The main dimensions of inch UNC fasteners are given in the table of inch threads

| Standard size | Outer diameter, inches | Outer diameter, mm | Drilling diameter, mm | Threads per inch | Pitch, mm |

| N 1 – 64 UNC | 0,073 | 1,854 | 1,50 | 64 | 0,397 |

| N 2 – 56 UNC | 0,086 | 2,184 | 1,80 | 56 | 0,453 |

| N 3 – 48 UNC | 0,099 | 2,515 | 2,10 | 48 | 0,529 |

| N 4 – 40 UNC | 0,112 | 2,845 | 2,35 | 40 | 0,635 |

| N 5 – 40 UNC | 0,125 | 3,175 | 2,65 | 40 | 0,635 |

| N 6 – 32 UNC | 0,138 | 3,505 | 2,85 | 32 | 0,794 |

| N 8 – 32 UNC | 0,164 | 4,166 | 3,50 | 32 | 0,794 |

| N 10 – 24 UNC | 0,190 | 4,826 | 4,00 | 24 | 1,058 |

| N 12 – 24 UNC | 0,216 | 5,486 | 4,65 | 24 | 1,058 |

| 1/4″ – 20 UNC | 0,250 | 6,350 | 5,35 | 20 | 1,270 |

| 5/16″ – 18 UNC | 0,313 | 7,938 | 6,80 | 18 | 1,411 |

| 3/8″ – 16 UNC | 0,375 | 9,525 | 8,25 | 16 | 1,587 |

| 7/16″ – 14 UNC | 0,438 | 11,112 | 9,65 | 14 | 1,814 |

| 1/2″ – 13 UNC | 0,500 | 12,700 | 11,15 | 13 | 1,954 |

| 9/16″ – 12 UNC | 0,563 | 14,288 | 12,60 | 12 | 2,117 |

| 5/8″ – 11 UNC | 0,625 | 15,875 | 14,05 | 11 | 2,309 |

| 3/4″ – 10 UNC | 0,750 | 19,050 | 17,00 | 10 | 2,540 |

| 7/8″ – 9 UNC | 0,875 | 22,225 | 20,00 | 9 | 2,822 |

| 1″ – 8 UNC | 1,000 | 25,400 | 22,25 | 8 | 3,175 |

| 1 1/8″ – 7 UNC | 1,125 | 28,575 | 25,65 | 7 | 3,628 |

| 1 1/4″ – 7 UNC | 1,250 | 31,750 | 28,85 | 7 | 3,628 |

| 1 3/8″ – 6 UNC | 1,375 | 34,925 | 31,55 | 6 | 4,233 |

| 1 1/2″ – 6 UNC | 1,500 | 38,100 | 34,70 | 6 | 4,233 |

| 1 3/4″ – 5 UNC | 1,750 | 44,450 | 40,40 | 5 | 5,080 |

| 2″ – 4 1/2 UNC | 2,000 | 50,800 | 46,30 | 4,5 | 5,644 |

| 2 1/4″ – 4 1/2 UNC | 2,250 | 57,150 | 52,65 | 4,5 | 5,644 |

| 2 1/2″ – 4 UNC | 2,500 | 63,500 | 58,50 | 4 | 6,350 |

| 2 3/4″ – 4 UNC | 2,750 | 69,850 | 64,75 | 4 | 6,350 |

| 3″ – 4 UNC | 3,000 | 76,200 | 71,10 | 4 | 6,350 |

| 3 1/4″ – 4 UNC | 3,250 | 82,550 | 77,45 | 4 | 6,350 |

| 3 1/2″ – 4 UNC | 3,500 | 88,900 | 83,80 | 4 | 6,350 |

| 3 3/4″ – 4 UNC | 3,750 | 95,250 | 90,15 | 4 | 6,350 |

| 4″ – 4 UNC | 4,000 | 101,600 | 96,50 | 4 | 6,350 |

Slicing technologies

Cylindrical pipe threads, which are of the inch type (both internal and external), can be cut manually or mechanically.

Manual thread cutting

Cutting a thread using a hand tool, which uses a tap (for internal) or a die (for external), is performed in several steps.

- The pipe being processed is clamped in a vice, and the tool used is fixed in a driver (tap) or in a die holder (die).

- The die is put on the end of the pipe, and the tap is inserted into the inside of the latter.

- The tool used is screwed into the pipe or screwed onto its end by rotating a driver or die holder.

- To make the result cleaner and more precise, you can repeat the cutting procedure several times.

Cutting threads on a lathe

Mechanically, pipe threads are cut according to the following algorithm:

- The pipe being processed is clamped in the machine chuck, on the support of which a thread-cutting tool is fixed.

- At the end of the pipe, using a cutter, a chamfer is removed, after which the speed of movement of the caliper is adjusted.

- After bringing the cutter to the surface of the pipe, the machine turns on the threaded feed.

It should be borne in mind that inch threads are cut mechanically using a lathe only on tubular products whose thickness and rigidity allow this to be done. Making pipe inch threads mechanically allows you to obtain a high-quality result, but the use of such technology requires the turner to have the appropriate qualifications and certain skills.

Tightening torques

Tightening torques for UNC inch fasteners for SAE grade 5 and higher bolts and nuts are shown in the following table.

| Thread size, inches | Tightening torque for standard bolts and nuts | N*m*lbf-ft** |

| 1/4 | 12± 3 | 9±2 |

| 5/16 | 25 ± 6 | 18± 4,5 |

| 3/8 | 47± 9 | 35 ± 7 |

| 7/16 | 70± 15 | 50± 11 |

| 1/2 | 105± 20 | 75±15 |

| 9/16 | 160 ± 30 | 120± 20 |

| 5/8 | 215± 40 | 160 ± 30 |

| 3/4 | 370 ± 50 | 275 ± 37 |

| 7/8 | 620± 80 | 460 ± 60 |

| 1 | 900 ± 100 | 660 ± 75 |

| 11/8 | 1300 ± 150 | 950 ± 100 |

| 1 1/4 | 1800 ±200 | 1325 ±150 |

| 1 3/8 | 2400 ± 300 | 1800 ± 225 |

| 1 1/2 | 3100 ± 350 | 2300 ± 250 |

*1 Newton meter (N*m) is equal to approximately 0.1 kgm. ** Pound-force-foot is the British and American equivalent of N*m.

Marking of inch fasteners

Inch fasteners have a more complex marking system that does not allow visually, without the use of special tables, to determine the mechanical properties of the fastener. The most common markings on the heads of inch bolts and their correspondence to strength classes are shown in the table below.

| Marks on the head | Strength class according to SAE | Strength class of the replacement bolt, not lower |

| 1 or 2 | 6.8 | |

| 5 | 8.8 | |

| 6 | 10.9 |

Setting the diameter of thermoplastic pipes

General technical conditions for pressure pipes made of thermoplastics (with changing linear dimensions depending on temperature) are regulated by GOST R 52134-2003; they cover all polymer products used in water supply and heating systems.

The standard is valid for pipelines made of basic, cross-linked and heat-resistant polyethylenes, various types of polypropylenes, regular, unplasticized and chlorinated polyvinyl chloride, polybutene.

GOST R 52134-2003 regulates the specification of dimensions of thermoplastic pipes according to their outer diameter, shell thickness and length.

Rice. 4 Dimensions of some pipes for domestic use made of thermoplastics according to GOST R 52134-2003

An ordinary user may encounter in everyday activities pipe products used for non-pressure domestic sewerage, made from unplasticized polyvinyl chloride PVC-U, their technical characteristics are regulated by GOST 32412-2013. Much less commonly used in households are PVC-U pressure pipes for cold and hot water supply, heating and sewerage, the dimensions of which are specified in GOST R 51613-2000.

In all of the above standards, pipe dimensions are specified by their outer diameter and wall thickness.

Thus, unlike steel pipes, plastic pipes are produced with standard outer diameters according to the standard range, while the size of their passage channel can vary depending on the wall thickness.

Rice. 5 Dimensions of sewer pipes according to GOST 32412-2013