How to cook hardened steel

Technical sciences/ 1.Metallurgy

Ph.D. Semenov V.M. 1, Kozobrod D.B. 1, Yarmonova M.V. 2

1 Donbass State Engineering Academy, Ukraine

2 Azov State Technical University, Ukraine

WELDING OF HARDENED ALLOY STEEL 40ХН

When manufacturing welded structures, it is usually necessary to solve two problems; ensuring the mechanical properties required by technical specifications and preventing the formation of defects in welded joints. The most dangerous and unacceptable defects are cracks. Cracks occur in the seams during crystallization (hot cracks) and in the heat-affected zone (cold cracks). Welded structures can be made from rolled products, castings or forgings that have undergone isothermal annealing before welding. There is a fairly large amount of information regarding the formation of hot and cold cracks during arc welding in welded products made from workpieces that have undergone preliminary heat treatment (annealing). In some cases, when the part, due to operating conditions, requires high hardness provided by hardening. you have to weld a pre-hardened workpiece.

In connection with the task of manufacturing welded cylinders from poorly weldable steel 40X, the purpose of this work was to study its weldability in a hardened state and to develop a technology for arc welding of this steel with steel 20

To solve this problem, one of the nodes was selected as a test, reproducing the shape and dimensions of a full-scale welded joint. and subjected to heat treatment, hardening and tempering after welding. The sample consisted of a cylindrical body of 40X steel with an internal thread, into which a bottom made of steel 20 was screwed and welded around the perimeter with a circular seam (Fig. 1)

1 – weld; 2 – bottom; 3 – cylinder.

Fig.1. Welded sample to determine the weldability of 40X steel:

Before welding, to obtain the required hardness H = 2860-3020 MPa, the sample was subjected to heat treatment, hardening and tempering according to the regime shown in Fig. 2

The microstructure of the sample before welding was sorbitol-like pearlite. The bottom was welded as follows.

Fig. 2 - Sample heat treatment schedule

The part was subjected to general heating in an electric furnace to a temperature of 350-400 0 C, then welding was carried out in the lower position, in two layers, with mandatory layer-by-layer stripping of slag from the seam according to the following mode: welding current strength - 160-200 A; The type of current is constant, the polarity is reverse. When welding, the following welding materials were used: UONI 13/55 electrodes, electrode type - E50A, electrode diameter - 4 mm, weld leg - 8 mm.

After welding, the sample was cooled together with the furnace. and controlled. As a result of X-ray examination of the welds, no defects were found. Checking the outer surface of the seams by grinding followed by acid etching showed that there were also no surface cracks. To determine the quality of the welded joint, macrosections were made.

Nuances for beginners in welding

There are several nuances that can be useful to anyone who wants to learn how to cook correctly:

- Do not forget about grounding and the importance of regularly checking the quality of contact between the clamp and the workpiece.

- Check the cable insulation regularly.

- The current strength is selected immediately after connecting the ground.

- Before igniting the arc, the electrode should be installed at an angle of approximately 60 degrees to the plane of the part, and the distance between its end and the part should be about 0.5 cm.

Electrode positions when welding

By mastering increasingly complex types of seams and joint configurations, the home craftsman will be able to learn how to weld correctly and will provide his household with all the necessary welded structures.

Effect of carbon content on steel weldability

Many low carbon steels are easy to weld. Welding medium-carbon and high-carbon steels is a more difficult task, as martensite can form during welding in the heat-affected zone of the weld, which will lead to a significant decrease in the toughness of the weld.

To increase the weldability of steels, various measures are taken, such as heating the material or minimizing the absorption of hydrogen by the steel. The absorption of hydrogen by steel makes the steel more brittle.

Heat treatment when welding metal

Heat treatment (HT) is the process of heating metal products to a critical point, above which the microstructure and characteristics of the metal change; holding and subsequent rapid or slow cooling. The question is often asked: can heat-treated steel be welded? Heat treatment does not affect weldability. You can cook both hardened and “raw” steel, or annealed steel. Maintenance is allowed before, during and after welding work.

Commonly used heat treatments for steel

Annealing – relieves stress, improves ductility, and forms fine grains. Temperature (650±10) oC. The holding time is calculated depending on the maximum thickness of the part and averages 2.5 minutes. At 1 mm thickness. During annealing, the parts are always cooled along with the furnace. When fully annealed, the parts are heated to 800-900 °C. Recrystallization and strengthening of the weld occurs. Holding time and cooling conditions are the same as in the previous case. The data given here is for informational purposes; exact data can be obtained from the reference book. Normalization is a process very similar to annealing, with only one difference - cooling is done in air (self-tempering). Rest is carried out at low temperatures of 200 ... 300 ° C for 2 ... 3 hours. This procedure reduces the content of diffusion hydrogen and reduces the amount of internal stress. All types of maintenance are carried out in furnaces with electrical resistance heating in an air atmosphere.

Heat treatment of aluminum

Preheating of aluminum is necessary due to its high thermal conductivity. The formation of a normal weld pool and the formation of a weld will be difficult due to the lack of temperature, which is constantly “taken away” by the body of the aluminum alloy. If we are talking about small-sized parts, the lack of heating will not be catastrophic, but when you are dealing, for example, with welding defects in a large casting body, then the difficulties will become obvious even to a person not privy to the intricacies of welding art. You can heat the entire product, or perform local (local heating) of the area being welded using oxygen-acetylene, propane and other burners. It is also possible to preheat directly during the welding operation, provided that this is technically feasible. Preheating is also used for some types of steels prone to cracking (for example, 30KhGSA). Post-weld heat treatment for aluminum is hardening + aging. True, such maintenance is fraught with large warping. If the products being repaired have ready-made drawing dimensions, such a procedure becomes impossible. In this case, you will have to do without any maintenance at all, or use half measures: heating to the aging temperature and holding for a certain time (the mode is selected based on the grade of the aluminum alloy). The impact of such a measure is debatable, but it is better than doing nothing at all. If after welding it is necessary to increase ductility and reduce hardness, it is advisable to perform partial or complete annealing . You also need to understand that if you are welding heat-treated aluminum, the weld, even with subsequent complete maintenance, will be soft (significantly different from the hardness of the base metal). Write in the comments if there are filler rods that may experience polymorphic transformations.

Transformations of steel in the weld zone

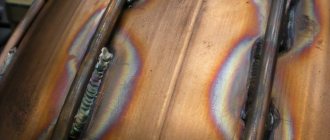

During welding, the steel near the weld is heated above the critical temperature A1 and austenite is formed (Figure a). When cooled, austenite in this heated zone transforms into a new structure, the type of which depends on the cooling rate and the thermokinetic transformation diagram of the steel.

Ordinary low-carbon steel has such low hardenability that at normal cooling rates in air, martensite almost never forms (Figure b).

Alloy steel is specially heated before welding in order to reduce the cooling rate of the weld or the welded joint is subjected to additional heat treatment to temper the formed martensite (Figure c).

Figure - Transformations of steel in the heat-affected zone of welding: a) structure of steel at the maximum heating temperature in the welding zone; b) structure of steel with low hardenability in the welding zone after cooling; c) structure of steel with high hardenability in the welding zone after cooling.

Recommendations on how to weld metal correctly

To weld metal correctly, it is not enough just to learn how to make seams. The welder must also be a materials scientist - know a lot about the properties of the materials being welded, their interaction with each other and with high temperatures.

The technology includes many operations before and after the actual seam is completed.

Before starting the main operation, the parts to be welded must be thoroughly cleaned of mechanical impurities, old paint, rust and must be degreased. It is also necessary to correctly position them relative to each other and fix them in this position.

When connecting thin-walled structures or simply long seams, the parts are clamped to each other at several equally spaced points to avoid thermal deformation.

The future welder must know and anticipate in advance:

- potential problems;

- types of defects

and think about how to avoid them.

Start with the three simplest types of connections

- Butt. The edges of the parts to be joined are in the same plane with a small gap between them, and this gap is filled with suture material.

- Overlapping. The parts are arranged with some edge overlap.

- Tavrovy. One plate is welded end-to-end in the middle of the other, usually at a right angle.

Three main types of connection

In general, a welder's job is half welding and half planning and preparation. Learning to cook properly means learning to plan and prepare.

Weldability of hardened steel

Weldability of steel

, which has been quenched and tempered before welding, has two kinds of problems. First, the portion of the heat-affected zone of the weld that is heated above temperature A1 may form martensite upon cooling. Secondly, a portion of the weld's heat-affected zone that is heated below temperature A1 may be subject to excessive tempering. In a good way, steel in a quenched and tempered state cannot be welded.

Source: steel-guide.ru

How to choose electrodes for welding

Today's market for welding materials offers customers a large selection of electrodes.

Correctly selected welding material is a big contribution to the final success. Each type of electrical conductor is designed for use under certain conditions. In order to answer the question “How to choose electrodes for welding,” several factors should be determined:

- Metal thickness - the greater the thickness, the larger the diameter of the rod should be.

- Steel grade.

- Based on the electrode, you need to determine the type of current, and then the welding position.

Composition and properties of high-strength steels

Steels with a tensile strength greater than 1500 MPa are called high-strength. This limit is achieved by selecting the chemical composition and the most suitable heat treatment. This level of strength can be formed in medium-carbon alloy steels (40ХН2МА, 30ХГСН2А) by using hardening with low tempering (at 200...250оС). Alloying such steels with W, Mo, V complicates softening processes, which reduces the threshold of cold brittleness and increases resistance to brittle fracture. How to weld metal if you have high-strength steel in front of you? Welding of high-strength steels is characterized by the use of some additional technological techniques (welding in cascades, slides, sections, preheating, the use of a soft layer, and others).

Isothermal hardening of medium-carbon alloy steels gives them slightly lower strength, but greater toughness and ductility. Therefore, they are more reliable in operation than low-tempered and hardened ones. Low-tempered and hardened medium-carbon steels with a high level of strength have an increased susceptibility to stress concentrators and a tendency to brittle fracture. Because of this, they are recommended to be used for work involving smooth loading.

High-strength steels include so-called spring steels. They contain 0.5...0.75% C and are additionally alloyed with other elements. Heat treatment of alloy spring steels (quenching 850...880°C, tempering 380...550°C) ensures high strength and fluidity. Isothermal hardening can be used. Welding of spring steel is carried out with mandatory preliminary heat treatment, with heating during welding and further heat treatment.

Maraging steels (04Х11Н9М2Д2ТУ, 03Н18К9М5Т) also belong to high-strength steels. They are superior to medium-carbon alloy steels in structural strength and manufacturability. Such steels are characterized by high resistance to brittle fracture, a low threshold of cold brittleness and low sensitivity to cuts with a strength of about 2000 MPa. Maraging steels are carbon-free alloys of iron and nickel and are additionally alloyed with molybdenum, cobalt, aluminum, chromium, titanium and other elements. These steels have high structural strength in the temperature range from cryogenic to 500°C and are used in the manufacture of artillery and small arms barrels, rocket engine housings, gears, spindles, and so on.

Selecting Electrodes

First of all, we note that for welding thin sheet metal it is important to choose the correct electrode diameter. 4-5 mm rods will create excessive resistance and will not allow the arc to burn normally at low currents. Therefore, when welding thin sheet steel, electrodes with a diameter of 1.6-3 mm are used. The thinner the metal, the smaller the diameter of the rod.

Next, you should pay attention to the characteristics of the electrodes. Let's take for example Barsveld OZS-12 ⌀ 2.0 mm (Premium). They have a rutile coating, which provides:

- easy initial and re-ignition;

- absence of a dielectric tip at the end during attenuation (convenient for reuse after a while);

- beautiful seam;

- light welding on rusty or primed metal;

- low filler metal spatter;

- soft arc burning.

Having purchased OZS-12 ⌀ 2.0 mm (Premium), you will be able to weld thin metal with direct or alternating current in any spatial position. Slag after welding is removed very easily. Good electrodes for working with sheet iron are ANO-21 ⌀ 2.5 mm (Premium), belonging to the E46 type. From the ESAB brand, we recommend ESAB MP-3 electrodes ⌀ 3.0 mm if you are going to weld iron with a cross-section of 1.0-1.5 mm.

The listed electrodes have a rutile coating, so when the arc extinguishes, a “visor” does not form. Consumables with the main type of coating are prone to this effect. The presence of the visor makes it more difficult to re-ignite the arc, since more forceful tapping is required to break the tip of the coating and ensure contact of the conductive rod with the workpiece.

If more than 4 months have passed since the production date of the electrodes, we recommend calcining them first. At home, this can be done in an electric oven, heating it to a temperature of 170-200 degrees. Then excess moisture will be removed from the coating, during welding the arc will not crack much and splash the metal, the seam will be neater.

Weldability of high-strength alloys

For the manufacture of heavily loaded engineering products, high-pressure vessels and other critical structures, medium-carbon high-strength steels are used, which, after appropriate heat treatment, have a strength of 1000...2000 MPa with a sufficiently high level of ductility. The required level of strength while maintaining high ductility is achieved by complex alloying of steel with various elements, the main ones of which are nickel, chromium, molybdenum and others. These elements strengthen ferrite and increase the hardenability of steel. Heating the product during welding does not reduce the cooling rate of the metal to values less than critical, and promotes grain growth, which leads to the occurrence of cold cracks and causes a decrease in deformability.

What does a novice welder need to get started?

To start training, you will have to select the appropriate equipment and equipment.

Particular attention should be paid to personal protective equipment, since welding work is a process harmful to vision and respiratory organs.

It will be necessary to equip a workplace; if it is in a workshop, then the room should be equipped with effective exhaust hood and sufficient lighting.

If you decide to start training outdoors, be sure to do so on dry ground and under a canopy that will protect you and the equipment from rain.

The workplace should be spacious, not cluttered, and not restrict the welder’s movements.

Cables should be laid out in such a way that they will not be stepped on or tripped over when moving around workpieces.

It is better to choose scraps of rolled stock and steel sheets as blanks for practicing skills. It is not recommended to start with critical structures.

Welding technology for joining high-strength steels

When welding medium-alloy, deeply hardening, high-strength steels, it is necessary to select welding materials that will ensure the production of welds with high deformation capacity with a minimum amount of hydrogen in the weld pool. This is achieved by using low-alloy welding electrodes, which do not contain organic substances in the coating and are subjected to high-temperature calcination (low-hydrogen electrodes). In this case, it is necessary to exclude other sources of saturation of the weld pool with hydrogen during welding (rust, moisture, etc.). High technological strength is obtained with the following content of alloying elements in the weld metal: C – no more than 0.15%; Si – no more than 0.5%; Ni – no more than 2.5%; Mn – no more than 1.5%; Cr – no more than 1.5%; V – no more than 0.5%; Mo – no more than 1.0%.

Increasing the weld properties to the required level is possible by alloying the weld metal at the expense of the base metal. The required strength characteristics of the weld metal are achieved by alloying it with elements that increase strength, but do not reduce its impact strength and deformability. To weld medium-carbon high-strength steels, you need to choose welding materials that contain less alloying elements than the base metal.

Manual arc welding with coated electrodes

For welding medium-alloyed high-strength steels, electrodes of types E-13Х25Н18, E-08Х21Н10Г6 and others are used in accordance with GOST 10052-75 and GOST 9467-75. If the steel before welding was subjected to heat treatment for high strength (quenching and tempering or normalization), and after welding - tempering to relieve stress and equalize the mechanical properties of the welded joint, then the criterion for determining the preheating temperature will be the cooling rate at which partial hardening would occur near-heat zone. This ensures that there are no cracks during the welding process and before further heat treatment.

In the case when heat treatment of a welded product cannot be done, for example, due to its large dimensions, a non-hardening layer of metal is deposited onto the edges of the part to be welded with austenitic or low-carbon electrodes. The thickness of this layer should be such that the temperature of the steel under the layer during the welding process does not exceed the tempering temperature during heat treatment of parts with deposited edges. Such parts are welded with austenitic or low-carbon and low-hydrogen electrodes without heating and further heat treatment. The welding mode is taken according to the recommendations for austenitic electrodes.

Welding work in shielding gases

High quality of welded joints made of medium-carbon high-strength steels with a thickness of 3...5 mm is achieved by argon arc welding with a non-consumable electrode. The filler material for gas shielded arc welding should be selected depending on the gas in which the welding takes place. The first layer is performed without an additive with full penetration of the joint edges, the second - with transverse low-frequency vibrations of the electrode and mechanical feed of the filler wire. It is also possible to perform the third layer with transverse vibrations of the electrode without filler wire at a low mode to ensure a gradual transition from the weld to the base metal.

To increase the penetration ability of the arc during argon-arc welding, activating fluxes are used, which make it possible to eliminate the cutting of edges with thicknesses of 8...10 mm. Flux is also used, which is a mixture of components (TiO2, SiO2, NaF, Cr2O3). This method with activating flux is effective with mechanized methods to obtain a uniform penetration depth. The non-consumable electrode for this welding method is selected from the most resistant grades of tungsten.

Modern argon burner

When welding medium-alloyed high-strength steels in shielding gases (mainly inert or their mixtures with active ones), low-carbon alloyed and austenitic high-alloy wires are used, for example, Sv-08Kh20N9G7TT, Sv-03KhGN3MD, Sv-10KhGSN2MT, Sv-10Kh16N25-AM6, Sv-08Kh21N10G6 . However, it is not possible to obtain equal strength of the weld metal and the steel being welded. In this case, it is possible to ensure equal strength due to the effect of contact strengthening of the soft weld metal. This effect can be realized using the so-called slot groove, which is butt joints with a narrow gap.

Features of MMA welding

- Manual arc welding of parts made of high-strength steels is performed on a short arc using direct current of reverse polarity; in some cases, alternating current is acceptable.

- Calcination of the rod is required. Depending on the grade of steel and electrode, the calcination temperature can reach 420–450°C.

- Work is performed only on carefully cleaned (to a metallic shine) edges.

- For medium and large thickness parts (from 20 mm), it is recommended to preheat them at the joint at a temperature of 60–150°C.

Welding hardened steel with raw steel

#1 Us1981

- Participant

- Messages: 263

- City: Rybinsk

#2 Rust_eze

- City: Irkutsk region. Usolye-Sibirskoye

If you don't throw, throw or knock on them, they will hold up fine. And if something is rough, it will definitely burst at the seam, not immediately, but maybe.

#3 Sakhalin_Cat

- City: Yuzhno-Sakhalinsk

So if you cook, the bushings on the jig will pull, it will become crooked and you will break the drills. It’s easier to weld the raw ones, drill them, and then harden the heads of the bushings with a cutter. Or weld the blanks, then drill, bore and press the hardened ones.

Post edited by Sakhalin_Cat: 05 March 2015 06:50

#4 MityMouse

Us1981, Technologically correct it will be like Sakhalin_Cat, said. First, we cook it raw (the holes in the bushings can be pre-processed, leaving an allowance for processing the seats for the drills), then we heat it and release it, then we process it to size.

#5 cloudy

#6 Us1981

- City: Rybinsk

#7 Rust_eze

- City: Irkutsk region. Usolye-Sibirskoye

If you make a hole in the corner directly under the bushing, press it with a clamp and weld it. Then there will be no deviation from the size, or it will not be significant at all. If you weld from the ends of the bushings, then a shift in size is guaranteed!

It should look something like this.

But the main thing is not to overheat, and at the same time weld it securely

Preheating, plus welding, is guaranteed to release the part. And it will be problematic to harden them directly at the corners, and it can also take them away!

#8 VlaDon

Us1981, the best option would be to weld raw bushings and then press hardened ones into them.

#9 Face

Us1981 , the best option would be to weld raw bushings and then press hardened ones into them.

Not a bad move, but you need to know the purpose of the conductor.

#10 Sakhalin_Cat

- City: Yuzhno-Sakhalinsk

They wrote, to drill holes.

#11 Us1981

- City: Rybinsk

Rust_eze , I don’t quite understand what you want to show in the pictures

Us1981 , the best option would be to weld raw bushings and then press hardened ones into them.

A normal option, but there is nothing to press with. A metalworking and assembly shop, tools like in any garage, nothing more.

Not a bad move, but you need to know the purpose of the conductor.

#12 Yunat

#13 VlaDon

A normal option, but there is nothing to press with. A metalworking and assembly shop, tools like in any garage, nothing more.

As easy as pie! Find 2 parallel rigid surfaces. A drilling machine would be a good option, while a lathe would be ideal. You attach the jig itself to one surface and place the bushing on it. You can press using a regular hydraulic car jack. If you have a lathe, you will simply turn the tailstock.

#14 Face

It seems to me that it is enough to grab the bushings with a semi-automatic device and apply a damp (not wet) rag. Nothing will drag you anywhere away from 4 points! When they wear out, they are easy to replace with new ones.

Tools and protective equipment

Uniforms and personal protective equipment include:

- welder's mask with a built-in light filter to protect the eyes from bright light and ultraviolet radiation from the arc;

- split-leaf gloves—gaiters to protect hands from splashes of hot metal;

- thick clothing made of non-flammable fabric;

- cap under the mask;

- durable shoes.

- a respirator to protect the respiratory system from generated gases and dust, especially when working with non-ferrous metals.

Tools, materials and equipment you will need:

- Angle grinder (grinder) for cutting workpieces and cleaning seams;

- A set of hand tools - hammers, chisels, pliers, etc.;

- Metal brush for cleaning workpieces;

- Clamps and clamps for connecting workpieces;

- Electrodes.

And finally, the inverter with the included cables and holder.