If you look from the outside, it may seem that welding is very simple. Indeed, after several unsuccessful attempts, the person who picks up the holder for the first time will connect the two workpieces. However, the quality of the seam will be so low that even with a slight load the parts will fall apart. Therefore, only those who have the ranks of welders, confirmed by documents of the established form, are hired.

Welder - who is this?

A welder is a worker who is engaged in fastening metal products without the use of fastening devices.

The duration of use of the equipment and the strength of the created products depend on the quality of the welder’s work. This specialist is in demand in a variety of areas: from utilities to metallurgy.

Due to the fact that the range of activities is very wide, there are quite a lot of professional and personal requirements for representatives of this profession.

What does a welder do?

Using a welding machine, he heats parts of the product in a special way, as a result of which the metal is connected at the interatomic level. To perform this kind of work, special welding machines are used.

A specialist can perform various types of welding work. There are currently three recognized and used welding classes:

- Thermal class. A worker performs welding using heat.

- Thermomechanical class. Parts are welded by heating and applying pressure.

- Mechanical class. A welded joint is obtained using only mechanical energy.

Necessary equipment for welding work

Welders

Welding inverters

Semi-automatic welding machines

Argon-arc devices

Consumables

Welding electrodes

Wire for semi-automatic machine

Tungsten electrodes

Welder personal protective equipment (PPE)

Welder masks

Gaiters, protective gloves

Other protection

Welding Accessories

Electrode holders

Ground terminals

Magnetic holders

Welding discharges

Upon completion of their studies at the college or courses, candidates pass theoretical and practical exams by a special commission. The welder is given a diploma indicating his profession and is assigned a certain rank. The level of complexity of the work performed, to which a specialist can be admitted, and the amount of wages depend on the rank.

Usually after college they graduate with the 3rd category, and those who are especially successful in mastering the profession - with the 4th. You can further increase your rank in production or in advanced training courses. There are 6 categories in total. Let's take a closer look at what each digit means in practice.

1st category

This rank is assigned to college students after the first year of study. Essentially, these are students who already know how to hold an electric arc and perform tack work, so they will be able to participate in the assembly of structures.

2nd category

An employee who has mastered his specialty, but not well enough, can be released from college with this rank. It is capable of welding in the lower and vertical positions, surfacing layers of metal for grooving, but is not allowed for connecting pipes through which liquids and steam flow. A second-class welder is able to weld a crater, a crack, and heat the metal before straightening. It is expected that he himself will be able to prepare cylinders for gas welding and set up an acetylene generator. Second-class welders are used in non-critical processes.

3rd category

The specialist must be able to weld vertical, corner, and T-seams using electric arc and gas welding, and hermetically connect pipes. A 3rd category welder understands welding equipment and is able to service and set it up himself. The employee is expected to be able to read blueprints. The welder is allowed to weld carbon steels and structures of medium complexity, but such a specialist will not be able to perform ceiling welding efficiently. When flame cutting, the welder must be able to maintain specified dimensions and apply preliminary markings.

Immediately after college, it is difficult to get a well-paid job with a 3rd category. Employers argue this by lack of practice. But after a couple of years of work, great prospects open up.

4-digit

The specialist is able to assemble parts and structures of medium complexity and conduct high-quality welding in all spatial positions. Can weld pipes hermetically at permanent joints (when it is impossible to rotate the pipe along its axis by 180 degrees to bring the lower part to the top). A 4th category welder can weld using electric, gas, or semi-automatic welding. Can connect cast iron, high-carbon steel, non-ferrous alloys, and is proficient in air arc gouging. Reading drawings of medium complexity is required here by default.

5th category

The specialist is able to weld low-carbon and high-carbon steels, alloy metals, non-ferrous metals in all spatial positions. Suitable for working with critical structures that will undergo high dynamic loads. Welds pipelines, inside of which there will subsequently be high pressure. Able to cut parts of complex shapes to precisely specified dimensions.

6th category

A welder of the highest category, who can do everything as the previous ones, is only able to work with experimental alloys, independently determining the welding method, current strength, type of gases and filler materials. The specialist knows how to cook under water, so he is allowed to repair pipelines and ships that operate in difficult specific conditions under high loads.

In this article:

Video source: Power Machines

In addition, the welder must understand the equipment involved in joining metals in order to competently operate it, change consumables and maintain it. To do this, some welders are issued a separate certificate at the enterprise with access to installations operating with voltages up to 1000 V. All welders must know the instructions on labor protection, safety precautions, first aid methods for burns and electric shock.

One of the educational subjects for future welders is drawing. It is important to understand the cross-section of materials, their spatial position, and the locations of welding seams visible and invisible from the outside. Welders are taught the symbols of the types of welded joints.

The responsibilities of a welder are established at each enterprise individually, in accordance with the internal charter and the terms of the employment contract and contact. Most often they include:

- preparing parts for welding (cleaning edges, grinding, cleaning from rust and dirt);

- assembly of structures according to drawings and specified dimensions;

- welding of metals using designated methods;

- subsequent inspection and treatment of seams (cleaning of slag, grinding).

- construction (construction of columns using monolithic technology, welding of parapets, railings, ramps, mortgages, flights of stairs);

- automotive industry (assembly of housings, parts);

- car repair (service stations, auto repair shops, straightening, replacement of thresholds, etc.);

- heating installations (installation of boilers, circulation pumps, radiators);

- laying water and gas pipelines;

- production of metal doors, gates, gates.

There are enterprises where the welder is engaged only in welding, and all related processes are performed by mechanics and other workers. In other places, the welder is required to be more versatile, so the specialty may be called a welder-assembler, or a welder.

Where are welders in demand?

First-class welders will always find work in such companies as Gazprom, Tatneft, Transmash, Gazmash, etc. But, even if you are not a 6th category welder, there are always vacancies in the public utilities sector (water utilities, heating networks, housing and communal services , management companies). In addition, welders are regularly required for:

Without welders, it is impossible to create greenhouses, barbecues, gazebos, and sheds. Often, the services of a welder are necessary for landscape design. If you know how to cook well, you can open your own business providing the above services. The work can be done independently or with a partner. To start, you will need an MMA or MIG, TIG welding inverter, depending on the chosen direction. As well as protective equipment (mask, leggings, clothing, shoes) and tools (grinder, drill, sets of keys).

general description

Workers in this specialty are graded based on knowledge and experience working with equipment. Improve the qualifications of a welder - receive a higher rank, respect, honor, increase in salary, and the ability to perform complex tasks.

Disadvantages of the profession:

- work in difficult conditions;

- high eye strain;

- industrial dust that causes asthma and silicosis.

A master of any qualification must have knowledge of:

- in the field of chemistry and physics;

- safety precautions;

- operating principle of the equipment;

- basics of electrical engineering.

Responsibilities include:

- work with proper preparation of the place and materials;

- produce quality products;

- comply with deadlines for completing assignments;

- comply with labor protection rules;

- increase productivity and efficiency of processes;

- place orders for necessary consumables for welding.

People cannot work in this position:

- too irritable;

- having heart disease and allergies;

- with visual and hearing defects;

- with mental disorders;

- with respiratory diseases;

- with impaired motor functions.

Advantages and disadvantages

Representatives of this profession are constantly in demand on the Russian market. At the same time, specialists receive high salaries on average throughout the country. However, representatives of this profession work in difficult conditions with increased stress on the body (the eyes are considered the most vulnerable). There are also cases when electric and gas welders are forced to perform tasks at extremely low temperatures.

The following diseases are typical for this profession:

- asthma;

- silicosis;

- pneumoconiosis and other pathologies of the respiratory system.

But despite the above, an electric and gas welder is a profession in demand. The demand for such specialists is constantly at a high level.

Welding categories

Depending on the technology used, welding is classified as:

- Press room. The connection is made on a pressing machine using high temperature and high pressure using a point or contact method. Weld all types of metals, including non-ferrous ones.

- Diffuse welding. Employees in this category work with piece orders and perform operations with experimental samples. The parts are connected in honeycomb furnaces. To increase strength, the metal is enriched with nitrogen.

- Electron beam. The joining process takes place in a vacuum chamber of an automatic installation, which is configured for piece work or mass production. The technology allows you to weld small jewelry and thin-walled parts that cannot be heated too much. The quality of the connection depends on the accuracy of the system settings, so the installation is serviced by an employee with the highest rank.

- Termite. The connection is made on a welding press, the workpieces are heated by burning the thermite mixture. A specialist in this category must be able to correctly install the press, prepare the surfaces of the parts and the mold, prepare the mixture and pour the precisely calculated amount into the crucible. Responsibilities also include heating the surface of the workpieces before welding, and after completion, processing the joint.

- A gas welder can connect workpieces to assemble complex structures and weld pipes in any position. Works with all types of metals. Cutting is performed with a gas cutter.

- An electric gas welder is a worker who has mastered gas, manual arc, plasma and non-consumable electrode (argon-arc) welding. The seams are subject to high requirements for resistance to mechanical and vibration loads. Welders have a great responsibility for the quality of connections; the differences between categories in this category are expressed very precisely.

Regardless of the category and category, the welder must have basic knowledge and skills

Categories of welders

They depend on the ability to use one or another welding technology.

- Welders who work on resistance spot welding equipment. There are no electrodes, and the process itself is quite simple.

- Workers who can work on diffusion-welding type installations. These are operations with a piece connection, which allows you to increase the characteristics of the weld.

- Ability to work on electron beam installations. Welding is carried out in a vacuum; workpieces made of special alloys are usually joined using this technology. Such an employee must know a lot; he usually has the highest qualifications.

- A welder who can perform thermite welding. The process itself is carried out on special presses, the welding molds of which are heated, and therefore the parts being joined are heated.

- Gas welding. Such a worker is called a gas welder. By the way, he can also cut metals using a gas cutter.

- And the last category is electric welder. The most popular profession in the welding category.

So, we’ve sorted out the categories, we can move on to the categories.

Average salary for a welder

The salary level depends on the rank, length of service, turnover of the enterprise and location of the company. In Moscow, salaries are the highest:

- 3rd category - 35,000-40,000 rubles.

- 4th category - 40,000-50,000 rubles.

- 5th category - 50,000-60,000 rubles.

- 6th category - 60,000-130,000 rubles.

Salaries vary across regions:

- 3rd category - 25,000-35,000 rubles.

- 4th category - 35,000-40,000 rubles.

- 5th category - 40,000-55,000 rubles.

- 6th category - 60,000-70,000 rubles.

It happens that salary depends on the number of hours worked. The rank then affects the hourly rate. In the case of piecework wages, the grade affects the cost of the joint and operation, so welders with a higher level receive more. They are trusted only with critical connections, and the rest are performed by welders with less qualifications.

How much does a welder earn in Russia?

Current realities are such that there is an acute shortage of skilled workers in the labor market

.

For this reason, the average salary of welders in Russia is quite high. According to employee search services, a technical school graduate with a first grade and little experience can easily find a job for 20,000 rubles

a month in the housing and communal services sector.

A highly qualified professional can count on a salary of 30,000 rubles

.

At the same time, the housing and communal services sector has the lowest salary level, and, for example, in the oil and gas industry, a qualified welder can earn about 90,000 rubles

.

The highest salary indicated on online job search services is more than 150 thousand rubles for professional welders with extensive work experience

.

Another factor influencing the level of a welder’s salary is additional payments and compensation for hazardous work. According to the Labor Code of the Russian Federation, it must be at least 4% of wages. At the same time, the employer, assessing the complexity and working conditions, can increase this percentage.

How to increase the rank of a welder

As the young specialist gains experience, he has the opportunity to increase his level, for example, from 3 to 4. If the enterprise where he is employed has a qualification commission with the appropriate powers, he just needs to submit an application. Once approved, a date will be set for the exam. After passing the test, the applicant is given an official document confirming that the welder’s rank has been increased.

At small enterprises there are no qualification commissions, but management can send an employee to courses or to a training center. This is the best option, since the training is paid for by the company.

If you apply for advanced training yourself, you will have to pay out of your own pocket.

It would be a good idea to find out first what document you can get after training. If this is a certificate of completion of the course, it is better to look for another place of study, since it does not have legal force. A certified training center issues an official certificate of higher qualifications. The document, after being presented to the management of the enterprise, will be the basis for a salary increase.

The popularity of the welding profession among young people is explained by its high demand and salary. Also attractive is the career growth system that is accessible to everyone. A graduate of a technical school or college will not have to look for a job for a long time. Many enterprises hire low-qualified specialists for further training of personnel in the required profile.

Welder's certificate

"Builder's School" offers students to obtain a welder's certificate certified by a representative of Rostechnadzor. It allows you to get the desired position. There is an opportunity to take advanced training courses and recertification, which is often required in production.

The received documents contribute to career growth and salary increases. You can obtain the certificate yourself at the office in Moscow. If necessary, it is sent by mail to any region of the country. For customer convenience, express delivery is available.

What qualities should a welder have?

The specificity of this type of occupation is such that the welder needs to be aware not only of the concept of the operation of professional equipment, safety measures during operation of the welding machine, but also know physics and chemistry at least at the level of school knowledge.

The most important personal characteristics of a welder include accuracy, precision, diligence, and hard work.

At the same time, one should not overlook the fact that the welder works in heavy production, so he needs to carefully monitor his health. For example, it is necessary to regularly check your vision, cardiovascular system, and respiratory organs.

And according to the safety precautions of any heavy production, people with unstable mental health, osteochondrosis, radiculitis and allergies are strictly not allowed to work with a welding machine. Those who have problems with vision, heart and lungs may also be denied employment.

Welder training at the “Builder School”

By choosing our training center for education, a person is confident that in a short time he will master the skills necessary for the profession. The theoretical course on training welders contains the required information. Full-time students reinforce their lectures with practical exercises.

It is possible to undergo welder training in absentia, remotely. These forms are suitable for those who combine work and study and who do not have the opportunity to attend classes every day. The center provides the opportunity to undergo recertification, and there are advanced training courses. A person gains knowledge in various fields:

- features and subtleties of handling different types of welding machines;

- basic safety rules;

- specifics of working with metals of different properties and structure.

It is mandatory to study the rules of first aid in the event of an unexpected situation at work.

Where can I get training to become a welder?

You can become a certified specialist after the 9th or 11th grade of school. Training to become a welder is carried out in almost all vocational schools and colleges in the country. Also, those who want to master this profession can enter a higher educational institution. Studying at a university provides the student with the opportunity to later begin a career as a personnel manager or start their own business.

At the same time, in all educational institutions there is an annual shortage of budget places in this area, which indicates a clear shortage of qualified workers.

Also, a future welder can undergo training through courses. In a short period of time, which in most cases does not exceed three months, you can master a profession and become a specialist in this field. Some organizations offer to become a specialist remotely in an even shorter period of time.

The final stage of the training is obtaining a welder’s certificate of the established type, which allows you to perform welding work. But in order to perform complex welding work on large projects, obtaining NAKS certification is required.

NAKS is the National Welding Control Agency. An employee who has received a document from this organization is considered the most qualified specialist in this field.

Responsibilities

A 6th category welder performs the following duties:

- repair of light and heavy equipment, know the nuances of drivers’ work;

- welding of certain elements and parts of automobiles;

- welding of sealed tanks - boilers, pipes and other pressure vessels;

- fusing of holes;

- production of curved elements from sheet steel;

- fusing onto worn parts of parts and elements;

- welding repair of all types of engines;

- performing non-standard work, including experimental work;

- assembly according to the sample or instructions of metal structures.

Personal qualities of the gas welder profession

To perform the job, a specialist must have the following character traits: responsibility, attention to detail, accuracy, diligence, patience, hard work, perseverance in achieving the desired result.

In addition, persons with allergies, bad habits, poor stamina, and poor eyesight cannot be allowed to work. An employer may refuse to work for those who have problems with the heart and lungs, unstable psyche, osteochondrosis, or radiculitis.

Since a gas welder works in heavy production, he must monitor his health and undergo medical examinations.

What does being a welder require?

The most important responsibility of representatives of this profession is quality work.

Another equally significant responsibility is compliance with safety regulations and labor standards in hazardous production. The rest of the functionality depends on what company the welder works at and what category he has. Therefore, the list of employee responsibilities can also include: tracking the deadline for completing work, ordering the necessary materials or equipment, maintaining reporting documentation.

One of the distinctive features of workers in this profession is a welding mask.

, which allows you to more accurately connect parts. When welding, a lot of heat and light energy is released; without eye protection from bright light, vision loss is inevitable, so a worker in this profession must be sure to monitor the condition of his mask.

Pros and cons of the profession

The positive side is the constant demand for specialists in the labor market and high pay. But, like every profession, there are also negative aspects:

- welders often have to work in difficult, bordering on extreme, conditions;

- protective masks and special glasses cannot completely eliminate the negative effects of infrared and ultraviolet rays on the eyes;

- During welding of metals, harmful gases are released, which enter the human lungs and, over time, cause occupational diseases.

Every year, protective equipment and working conditions for welders are improved. Therefore, the popularity of the profession is only growing. Business owners and plant managers implement various incentive systems for welders to motivate them to work in their organization. On-the-job training is provided to “grow” your workforce. Due to objective circumstances, the welding profession remains quite popular among young people.

Salary level

Like representatives of other professions, welders have their own remuneration system, regulated at the legislative level. This is highly skilled work that is harmful to health, therefore, when calculating payment, harmfulness and difficult conditions are taken into account . Damage to health is calculated and compensated by legislative acts.

It is logical that the fee for the work of specialists is determined by the region where the master is located. When a master is sent to another region to work on a shift or on a short-term business trip, he will also receive additional travel allowances.

It is also necessary to take into account the welding method, because the qualifications of a manual welding specialist must be improved in order to engage in argon arc welding. After training, the master receives documents of the established form, without which, permission to perform work will not be obtained.

Despite the nuances and differences, it is possible to find out the approximate average salary by considering large organizations that provide vacancies for the position of welder . One of the criteria by which salaries are calculated is the rank on which the minimum hourly wage depends. Payments made at our own rates are also paid depending on its volume, percentage of completion of the norm, and complexity.

Andrey Stepanov, electric and gas welder, 18 years of work experience: “The salary that the craftsmen receive plays a significant role in the popularity of the welding profession. But there will always be work for welders with small discharges. Organizations even apply for unqualified personnel, since some managers prefer to “grow” specialists for the enterprise themselves.”

Advanced training procedure

To increase the rank, an application is submitted to the certification commission working at the enterprise. In other cases, you should contact the training center. The decision to upgrade qualifications is made after passing the exam.

Confirmation is a hand-issued certificate, on the basis of which the salary will be paid in an increased amount.

Welding is a profession that requires full dedication from the worker.

Compliance with the grade standards described above is mandatory for each employee. A master who has mastered them increases his professional level and strives to obtain the sixth rank.

Areas of professional training for welders

You can obtain certificates for retraining and advanced training of welders in the following specialties:

- Gas cutter

- Gas welder

- Welding supervisor

- Welder on resistance (press) welding machines

- Electric and gas welder

- Electric welder on automatic and semi-automatic machines

- Electric welder performing manual welding

- Thermist

Now at the Builder's School you can undergo certification and recertification as a NAKS welder. More details here

Licenses:

Responsibilities of a welder

When starting work in production, a specialist gets acquainted with the job description, which outlines the range of his immediate responsibilities. During work, the welder must:

- produce quality products;

- observe the welding regime;

- plan deadlines, expenses, volumes;

- order the required materials;

- maintain reporting documentation;

- comply with safety and labor protection standards;

- increase productivity (if possible);

- improve and modernize existing technologies.

Knowledge and Responsibilities

Regardless of qualifications, the job responsibilities of a welder include:

- carrying out work in accordance with the selected welding technology;

- manufacturing products without defects;

- planning the volume and duration of work;

- compliance with labor safety rules;

- participation in research to improve the efficiency of technology;

- submitting reasonable requests for materials for work;

- process analysis.

In addition, the welder must know:

- basics of chemistry, physics, electrical engineering;

- welding technology;

- safety regulations;

- operating principle of main and auxiliary equipment.

Classification Features

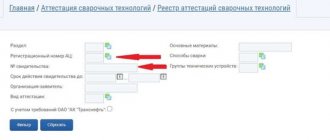

Not every welder is allowed to perform all the work. So, if you want to participate in the assembly of complex structures, then you need to pass the appropriate certification. This process is carried out entirely by the National Welding Control Agency (or NAKS). It is this agency that can assign the employee the qualifications necessary to perform work of high complexity and functions associated with a high level of responsibility.

A welder can have 4 skill levels;

- level No. 1 – welder who can participate in the assembly of structures;

- level No. 2 – master welder, who performs control functions and a number of other management tasks (for example, issue instructions for work);

- level No. 3 – technologist who monitors welding work within the enterprise;

- level No. 4 – engineer who approves the documentation.

In addition to the fact that NAKS is involved in testing the knowledge and skills of workers, the agency also pays great attention to the equipment with which welding is carried out.

In order to prove the level of their qualifications, welders undergo several stages of certification - primary, repeated and extraordinary.

Qualification of masters

Workers are periodically certified by NAKS (National Welding Control Agency). Based on the test results, qualifications of 4 degrees are assigned.

- A specialist with this qualification takes part in the assembly of various structures.

- The foreman carries out control functions and performs tasks to distribute instructions regarding work to other participants.

- level is responsible for monitoring the progress of welding work at the enterprise.

- the level is assigned to engineers who approve documentation.

We recommend reading: How to treat an eye burn from welding

In addition to levels, masters have categories depending on their knowledge and ability to use welding technologies. One of them is working with devices for point joining of parts. There are no electrodes here, the process is not difficult.

It is more difficult to control diffuse welding units. They produce a high-quality seam. There are welders whose classes and categories allow them to work in a vacuum, connecting workpieces made of special-purpose alloys. This is done by highly qualified craftsmen.

There is thermite welding, gas welding, which allows cutting metal workpieces. The most common category is electric welder. If he performs work with gas equipment, he is called an electric gas welder.

NAKS is engaged not only in testing the knowledge of personnel, but also inspecting welding equipment.

Qualification categories

Assigning a rank to a welder is an important event. The existing rank indicates the qualifications of a specialist, his professional skills, knowledge and skills. The higher the rank, the more complex work the welder can perform.

Let's look at a detailed description of each category.

- 1. This category is assigned not to professional workers, but to pupils and students (for example, those who receive appropriate education in technical schools and colleges). If a welder has the 1st category, then he can perform only the simplest work.

- 2. After completing specialized education and receiving a welding diploma, the young man receives the 2nd category. At this stage of his professional development, a specialist can perform welding work in a lower and vertical position.

- 3. Graduates of educational institutions who have demonstrated special abilities are assigned the 3rd category, which indicates that the specialist can perform not only vertical and horizontal welding work, but also work on corner joints. In addition, a 3rd category welder must have the skills to create sealed seams on pipes. Increased demands are also placed on theoretical knowledge - for example, a welder must understand the structure and operating principle of equipment, be able to read drawings and reproduce products based on them.

- 4. A welder of this category works with parts of medium complexity; he must be able to cut shaped elements from sheets. One of the key skills at this stage of professional development is the ability to perform plasma welding. In addition, the worker must be able to make high-quality sealed seams in all positions (except for the ceiling).

- 5. This category is assigned to specialists with extensive experience and honed professional skills. So, a welder of this category must be able to carry out welding work in all positions, he must have the skill of creating high-quality sealed joints. In addition, materials of any thickness and composition (metals and their alloys) must be available to him.

- 6. The rank is considered the highest. This is the highest qualification a welder can achieve during their career. The specialist must have all the possible skills described above. In addition, he must be able to work with various experimental compounds.

The increase in rank occurs gradually as appropriate experience is gained, as well as professional skills and abilities are improved. Welders of the highest ranks can apply for management positions.

Number of ranks for welders

An important moment in the life of workers is the assignment of qualifications. The higher it is, the more difficult the work the welder performs. In Russia there are 6 levels of bit depth. The initial one is the first, the maximum is the sixth.

The first category is assigned to college students and students of welding training courses. The specialist performs simple metal cutting and welding tasks that do not require qualifications.

The second category is for graduates of educational institutions after receiving a certificate or diploma. They can perform work with workpieces located in a vertical or horizontal position.

The third category is awarded to graduates who have demonstrated higher abilities. They perform actions to form fillet welds, as well as sealed joints on pipes. Their theoretical training should also be higher than that of other graduates: they need to be able to reproduce products according to drawings. No production experience available.

A 4th category welder works on tasks of medium complexity: he cuts out elements of various configurations from sheets of metal, uses plasma methods, and makes sealed seams in different positions, except for the ceiling. Knowledge and ability to read blueprints is a must.

The fifth category is received by high-class craftsmen with extensive production experience. They work in any position, are able to create hermetically sealed joints, and weld metals and alloys of small and large thickness.

Sixth is the highest rank. Awarded to welders of the highest qualifications that can be achieved. In addition to the listed skills, they are able to perform work with metals and alloys belonging to the group of experimental materials. Such a welder can be appointed to management positions in an enterprise.

We recommend reading: How to weld exhaust manifolds

How to get a rank

To obtain a qualification document you must submit:

- for short-term courses;

- in a vocational school;

- to technical school;

- to college.

After completing the courses, you can obtain a qualification by passing the NAKS exam. When entering other educational institutions, the first rank is assigned at the beginning of training. The person who received it knows how to cut and weld simple workpieces. Together with the issuance of documents on graduation from vocational school, the graduate is assigned a second category.

The third is given if the student has the skills:

- welding vertical and horizontal seams;

- sealing of pipelines;

- knowledge of the operating principle and design of equipment;

- safety precautions;

- reading drawings.

The rest are assigned after mastering production skills and experience during the annual passing of qualifying exams. To do this, you need to improve your skills every day.

In 1-2 years you can reach the fourth category. Upon certification, the best applicants gain access to work in the gas and oil industry, where salaries are higher than in other enterprises.

What are the responsibilities of an Electrical Gas Welder?

Welding of cast iron structures. Surfacing of defects in complex machine parts, mechanisms, structures and castings for machining and test pressure. Hot straightening of complex structures. Reading drawings of various complex welded metal structures.

Interesting materials:

What is the penalty for failure to file a 2022 return? What is the penalty for submitting a declaration late? What is the penalty for late registration at the place of residence? What socket does the i5 9400f have? What sport is most popular in Russia? What is the average height of a guy? What is the average height at 14 years old? What is the average age of men in Russia? What is the loan write-off period? What length of service counts towards your pension?

Accelerated courses for welders 1-6 categories

Completing accelerated courses allows a person to master a profession in a short time. After graduation, he is assigned the first rank, with the possibility of promotion in the production process. The specialty has a gradation of 6 categories; you can receive the rank of welder with a certificate certified by an inspector of Rostechnadzor, one by one.

- 1st category - a specialist works with plastic products, performs simple welding work on parts and bags.

- 2nd category - the worker reads diagrams and has plasma and arc welding skills.

- 3rd category - a person performs all types of tasks, the emphasis is on manual and arc welding.

- 4th category - in addition to arc and manual welding, oxygen cutting of parts of increased complexity is performed.

- 5th category - welding work is carried out on parts and vacuum units.

- 6th category - the welder performs all work without exception, being considered a general specialist.

In short-term welding courses, it is possible to gain basic knowledge to start in the profession and improve your level. Mastering a sought-after specialty allows you to take the desired position, receive a competitive salary, and build a career.

The welding profession is divided into several subtypes, these include: gas welders and electric welders, thermite welding and manual welding, welders involved in the field of electron beam welding installations and welders of diffuse welding type installations, as well as welders working on press welding equipment.

A welder's certificate is required regardless of the chosen profession. The activity requires compliance with proper safety regulations, which applies to the processes of welding pipelines and containers, assemblies and structures, various types of products and parts. Also, this is determined by their type, purpose and level of complexity. Each welder must have an appropriate level of professional knowledge related to the scope of qualification training in combination with theory and practice. This confirms not only the presence of specific skills, but also the corresponding welder’s certificate.

| № | Course name | Number of hours (Duration of training) | Cost, rub. |

| NAKS welder certificate | from 30 days | from 35 000 | |

| Electric welder courses for manual welding | 2 - 3 days | 4 000 |

What do you need to know and be able to do?

According to the job description, a 6th grade welder must be able to and know:

- structure of the weld scar;

- methods for correct selection of electrode rods;

- structure and design of devices;

- methods and technologies for manual welding of metals, features of surfacing;

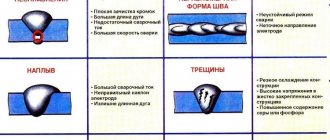

- causes of defects, their types and existing methods of avoidance;

- types of electrode coatings, the difference between them;

- norms and rules of labor protection;

- methods of preparatory work for metals under various conditions;

- types of cutting and selection of modes.

Advanced training for electric and gas welders

Periodic training of an electric gas welder and his constant practice is one of the most necessary things to improve his rank and increase his salary. Welding advanced training courses are designed for just such opportunities.

One of the most popular specialties is the specialty of a welder. Universal welders are needed in industry, in enterprises, in any production. A welder is especially needed in construction and the automotive industry.

Advanced training courses for welders allow you to significantly improve professional skills and use new technological approaches in the welding industry from your own experience. After completing the courses, professional performance improves and the potential for rising through the ranks appears.

Increasing the welder's rank

Every year, an increasing number of not only young welders are studying courses to improve their skills, but also seasoned professionals are coming to courses to raise their level.

Courses to improve the qualifications of electric and gas welders are formed in many training centers, schools and technical schools, where welding masters give candidates knowledge and share experience in working with welding equipment. During the training period, trainees use the latest welding machines.

Courses that improve the grade of a welder consist of two stages. The first stage, theoretical, studies the characteristics and parameters of welding equipment. Safety precautions, work techniques, working documentation, and so on are also studied. The second stage, practical, consists of “cementing” knowledge in practice.

The courses themselves can still be divided into a basic system, which trains welders up to the 4th category, and a specialized one, which allows increasing the categories from 4th to 6th. Each system has its own approach to presenting knowledge and its own cost.

Advanced training course program for welders

The training program includes the following knowledge and practices:

- familiarization with the equipment;

- study of welding processes;

- setting up equipment and welding mode;

- correct selection of welding material for specific purposes;

- learn the skills of making various seams and acquire the ability to weld metal in different positions;

- critical approach to the quality of work performed;

- techniques for safe use of a welding machine;

The knowledge that is acquired in the course of training is necessary to improve the qualifications of a welder: the ability to read drawings, properly handle welding equipment, the ability to use different modes and welding methods, and so on.

Where to increase the rank of a welder?

Establishments specializing in improving the qualifications of electric and gas welders require different payments for their services. The price depends on the method of presenting knowledge, the quality of the material taught, the use of the latest technology, etc. The average price of training starts from 13 thousand rubles and up to 30 thousand rubles or more.

When choosing such courses, pay attention to the recommendations of people who have completed these courses. You also need to find out about the qualifications of teachers. Upon successful completion of training, a certified welder certificate is issued.

Some may ask: “Why waste time and money, and often nerves, on advanced training?” The answer is quite simple and lies in the welder’s desire not only to improve the quality of his work, but also to start earning a higher salary, because his income depends on the welder’s qualifications and category.

How to increase the rank?

Many welders who are looking to increase their income and also advance their careers want to get a higher rank. Moreover, its assignment is carried out strictly in accordance with the officially accepted procedure. So, to begin with, you must be absolutely sure that you have the necessary amount of professional knowledge, skills, and abilities, since you will have to pass a professional exam. That is why you cannot increase the rank every month. Typically, advanced training occurs once every few years.

The procedure itself may vary depending on where you work. So, large enterprises have special qualification commissions, but small companies do not, so employees of such organizations need to contact a special training center. To improve your qualifications, you need to pass the appropriate exam, after which you will receive a certificate, which you must give to your employer.

Thus, a welder is a profession that requires maximum dedication from a person. The specialist must be responsible and attentive. In addition, to be successful in your career, you must constantly develop and improve yourself, improve your professional skills, and also expand your knowledge.

Sources

- https://kedu.ru/press-center/profgid/svarshchik-vostrebovannaya-no-nepopulyarnaya-professiya/

- https://www.svarbi.ru/articles/razryady-svarshchikov-kategorii-zarplata-plyusy-i-minusy-professii/

- https://svarkaved.ru/o-svarke/skolko-razryadov-sushhestvuet-u-svarshhikov

- https://svarkaprosto.ru/attestatsiya/skolko-razryadov-u-svarshhika

- https://TechnoRama.ru/vidy-stali/razryady-svarshchikov.html

- https://pressadv.ru/stali/razryady-svarshchikov-opisanie.html

- https://vplate.ru/svarshchik/razryady/

How to pass certification of specialists at the Builder School?

| 1. You send a request for execution from the website or call by phone | 2. Your personal manager advises you, identifies all training/certification requirements, and tells you the final cost and deadlines |

| 3. You make payment via bank account, in cash upon receipt or in any convenient way | 4. When ready, the manager contacts you and notifies you about it. At your request, we will send a scan and original of the certificate and protocol |