02/04/2022 Author: VT-METALL

From this material you will learn

:

- Pros and cons of the profession

- Necessary qualities for a welder

- Various welding categories

- Welding categories

- Skill Levels

- Upgrading procedure

The categories of welders are determined by the qualifications of specialists, that is, the knowledge and work experience they have. A person who is able to cope with the most complex tasks is always in high demand and receives more than his less advanced colleagues.

Each category implies that the welder has certain skills, and the skill is honed over the years. You cannot take an advanced training exam every month in order to become a top-level specialist in six months.

This is quite a long path, but those who take it receive certain preferences.

Pros and cons of the profession

The welding profession, like any other, has its advantages and disadvantages. It is worth dwelling on this issue in a little more detail. The obvious advantages are decent wages and constant demand.

There are also disadvantages. The first thing you should pay attention to is that the conditions in which welders work are usually very close to extreme. Second: there is a high risk that a specialist’s vision will deteriorate throughout his entire working life. And that, alas, is not all.

These specialists may develop diseases such as silicosis, asthma, pneumoconiosis, since welding produces dust, some of which is inevitably inhaled by the worker.

VT-metall offers services:

Nevertheless, despite the high harmfulness, the welding profession has always been at the peak of popularity. Guys who have recently graduated from a secondary specialized educational institution find work very quickly and are not afraid of losing it, because there are always enough offers on the market.

We said above that the main advantage of the profession is high wages. This indicator is formed based on the following factors:

- Employee education.

- Experience.

- Specialist rank.

- Region.

- The organization itself and the policy of wage formation in it.

On average, across the country, a welder’s salary varies from 30 to 100 thousand rubles per month.

In some organizations, welders work on a time-based wage system. In this case, the specialist’s rank has an impact on the hourly rate. If the form of remuneration is piecework, then the rank affects each operation performed. Obviously, the level of wages is mainly influenced by the rank of welder.

Necessary qualities for a welder

Let us immediately note that the work of a welder is not easy work, which indicates the need to have additional knowledge and skills. It is quite predictable that a specialist must perfectly know the technique with which he works, in addition, he must understand chemistry and physics. As for personal qualities: a welder must be careful, responsible and hardworking.

Let's not forget that the work of a welder is quite difficult, so a specialist must listen to his body and be sure to monitor his health. First of all, he needs to check those organs that are at risk: the lungs and organs of vision.

The welder must have a strong nervous system; if the specialist’s psyche is unstable, he should not be allowed to work.

Specialists with the following diseases are not suitable for welding work:

- Osteochondrosis.

- Radiculitis.

- Chronic allergic reactions.

If a specialist has eye or cardiovascular diseases, he may be denied employment.

Various welding categories

Before we move on to describing the categories of welders, it makes sense to focus on the categories.

Welding has its own classification. Belonging to one group or another directly depends on what technology is used in the work:

- Press room

. The specialist's job is to use a pressing machine. The connection occurs due to a combination of extremely high temperature and high pressure on the elements. This category allows you to weld all types of metals. - Diffuse welding

. This category is characterized by the presence of piece orders. As a rule, with this type of work, specialists use only experimental materials. In order to connect the elements, honeycomb furnaces are used. To make the material as strong as possible, nitrogen is used in the welding process. - Electron beam

. Here, a vacuum chamber is used to join metals. The equipment can be configured for both piece production and batch production. Welding jewelry occurs in this way. Electron beam welding is also suitable for products with thin walls that cannot be heated too much. In order to end up with high-quality products, it is necessary to correctly configure the system, and this can only be done by an experienced welder.

- Termite

. A special welding press is used for the work. The parts are heated by burning the thermite mixture. An employee in this category must know how to correctly install a welding press, be able to prepare the surfaces of working elements for welding, understand how the thermite mixture is prepared and its required amount is calculated. - Gas welding

. This category is characterized by the assembly of the most complex models and pipes, regardless of their position. A gas welder can work with any metal and has the skills to work with a gas cutter. - Electric gas welding

. The broadest category of welders. Such a specialist is fluent in gas, arc, argon-arc and plasma welding techniques. Specialists bear great responsibility, since quite high demands are placed on their work.

IV. Responsibility

The welder is responsible:

1. For improper performance or failure to fulfill one’s job duties provided for in this job description - within the limits determined by the current labor legislation of the Russian Federation.

2. For offenses committed in the course of carrying out their activities - within the limits determined by the current administrative, criminal and civil legislation of the Russian Federation.

3. For causing material damage - within the limits determined by the current labor and civil legislation of the Russian Federation.

4. ____________________________________________________________________

This job description has been developed in accordance with the provisions (requirements) of the Labor Code of the Russian Federation dated December 30, 2001 No. 197 FZ (Labor Code of the Russian Federation) (with amendments and additions), the professional standard “Welder” approved by order of the Ministry of Labor and Social Protection of the Russian Federation from November 28, 2013 No. 701n (as amended by order of the Ministry of Labor of Russia dated December 12, 2016 No. 727n) and other legal acts governing labor relations.

Welding categories

As trivial as it may sound, a welder needs to get an education before he starts work. Upon graduation from the educational institution and passing all regulated exams, the young specialist is issued a diploma, which indicates his position and rank. Based on this data, the management of the organization in which the welder is employed makes a decision about what types of work can be entrusted to a specialist.

Also, the rank of a welder affects the amount of his remuneration.

As a rule, a specialist who has just graduated from a secondary vocational educational institution has a 3rd category. Those who master the curriculum better than other students graduate as 4th grade welders. After completing his studies, a specialist, of course, has a chance to improve his rank in various advanced training courses for welders.

In total, there are 6 qualification categories of welders in Russia, and each of them deserves special attention.

1st category

To become a 1st category welder, you must successfully complete the first year of a secondary vocational educational institution. Here is a list of necessary skills to be awarded the first rank of welder:

- ability to hold an electric arc;

- ability to perform tacks.

2nd category

Welders receive the 2nd category on the same day when they are issued a diploma of secondary vocational education. This qualification is awarded to those former students who did not try hard enough to study. Such specialists are able to perform welding in the lower as well as in the vertical position, and surfacing metal layers.

In the second category, the worker is not allowed to weld pipes through which steam and water pass. Most often, such specialists weld craters, cracks and prepare the metal for welding.

3rd category

Obviously, the skills that a 3rd category welder must possess are already somewhat greater than in previous cases. Such a specialist uses electric arc and gas welding in his work, through which he welds corner, vertical and T-welds. The welder must understand the principle by which the equipment operates, and must also be able to configure it.

Professional 3rd category allows the welder to work with carbon steel and parts of average complexity.

Alas, if you graduated from college with the third category, the likelihood that you will immediately find a well-paid job is small. Enterprise management prefers to provide financial incentives to those employees who have significant experience in welding. But after a couple of years of work, you can start earning more than good money.

4th category

A welder of the 4th category has the following skills: assembles structures of medium complexity, welds parts with high quality regardless of the spatial position in which they lie, welds pipes hermetically even in cases where there is no possibility of rotation. The specialist works with materials such as cast iron, high-carbon steel, and non-ferrous metals. A 4th category welder can read drawings of average complexity.

5th category

A 5th category welder will do an excellent job of welding various carbon steels and non-ferrous metals. For these specialists, their spatial location does not matter. The presence of the 5th category indicates that the employee can work with complex parts and critical structures. You can trust him with those elements that endure high loads.

The 5th category allows you to weld pipelines, even those through which high pressure will later be directed. Able to work with complex shaped parts.

6th category

This is the highest level of welding. Obviously, he must have the ability to do everything that representatives of lower ranks can do. Only this specialist is trusted to work with experimental materials. They can choose their own methods and technologies of work.

It is welders of the 6th category who can be allowed to repair pipelines and ships that perform work in difficult, sometimes extreme, conditions.

Upon graduating from an educational institution, many novice specialists immediately ask themselves the question of how to improve their welding rank. Such activities are carried out gradually, as experience is gained.

It should be noted that the specialty provides an opportunity for career growth. Increasing your rank as a welder may serve as a reason for appointing him to a leadership position.

II. Job responsibilities

The responsibilities of a welder (2-3 category) include:

1. Carrying out preparatory and assembly operations before welding and cleaning welds after welding:

— Familiarization with design and production-technological documentation for welding

— Checking the functionality and serviceability of welding equipment

— Cleaning structural elements (products, assemblies, parts) for welding with a hand or power tool

— Selection of the spatial position of the weld for welding structural elements (products, assemblies, parts)

— Assembly of structural elements (products, assemblies, parts) for welding using assembly devices

— Assembly of structural elements (products, assemblies, parts) for tack welding

— Inspection using a measuring tool of prepared and assembled structural elements (products, assemblies, parts) using assembly devices for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

— Inspection using a measuring tool of prepared and tack-assembled structural elements (products, assemblies, parts) for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

— Cleaning weld seams with hand or power tools after welding

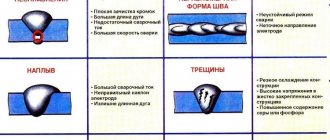

— Removal of surface defects (pores, slag inclusions, undercuts, metal splashes, sagging, etc.) using manual or power tools

Skill Levels

The work performed by a welder directly depends on his category. It is clear that not every specialist can be allowed to perform all types of welding. For example, if you want to participate in the assembly of highly complex structures, you must undergo appropriate training or certification. Certification of welders and improvement of qualification levels is carried out by the National Welding Control Agency (or NAKS).

There are four skill levels in total

:

- Level 1 – a specialist qualified to assemble structures.

- Level 2 – a specialist who has the right to issue recommendations and instructions during welding work.

- Level 3 – technologist who controls welding work within the organization.

- Level 4 – engineer who has the right to approve documents.

Upgrading procedure

We have already said that the qualification level of a welder has a direct impact on the level of wages. Therefore, most specialists want to improve their skills. Note that the assignment of a higher status is an official event that is carried out according to a certain procedure.

To increase the grade, the welder first needs to be confident in his abilities and knowledge. It’s easy to guess: without the appropriate knowledge, you won’t be able to pass the exam. As a rule, a specialist improves his qualifications no more often than once every few years.

If you work at a large enterprise, most likely there is a special qualification commission. By contacting her, you will find out what date the exam will be scheduled for you. After passing it, you will have a document in your hands confirming the fact of the increase in rank.

Smaller companies usually do not have such commissions. In this case, management will send you to specialized advanced training courses. Most often, tuition fees are paid by the company itself, but it also happens the other way around.

Before studying, check which document you will be given after completing the course. Remember, a certificate stating that you have listened to the entire volume of information does not increase your rank; such a document has no legal force at all.

Summarize

: welder is a profession that has been and will be in demand. To succeed in your career, you need to constantly develop and gain new knowledge.

III. Rights

The welder has the right:

1. Request and receive the necessary information, as well as materials and documents related to issues of their activities.

2. Improve your qualifications, undergo retraining (retraining)

3. Take part in the discussion of issues included in his functional responsibilities.

4. Make suggestions and comments on how to improve activities in the assigned area of work.

5. Require the management of the organization to provide assistance, including ensuring organizational and technical conditions and execution of the established documents necessary for the performance of official duties.

6. Make independent decisions, guided by qualification requirements and job responsibilities

7. ___________________________________________________________