Welder is a prestigious profession. They get paid better than many others, because a high-quality welder is worth his weight in gold. But knowing how to cook using conventional methods is not a difficult task. As practice shows, after several attempts, even the most ordinary person can somehow weld one metal workpiece to another. That’s why people learn this profession, that’s why there is such a thing as the ranks of welders.

So, welders are assigned six categories, which depend on the qualifications of the worker. To improve your qualifications means to receive the next rank. And this is not only honor and respect, it is a substantial increase in wages. This is an opportunity to take part in more complex projects.

Before moving on to analyzing the categories of welders, it is necessary to understand the categories.

Electric gas welder - categories

Depending on the qualifications, experience and knowledge of the electric gas welder, categories are assigned according to several criteria. This determines the level of clearance to perform certain work. However, regardless of the category, electric gas welders must:

- be able to carry out work in accordance with welding technology suitable for specific types of metal;

- produce designs without defects;

- be able to plan future work;

- know and comply with certain safety requirements;

- carry out activities aimed at increasing the efficiency of welding work.

According to the generally accepted classification, the first rank of welder is assigned after the start of training at a specialized institution (mainly in vocational schools). In the future, as knowledge and experience accumulate, both the level of tolerance and the characteristics of the structures that the specialist must manufacture change.

Welder 1st category

All students of specialized vocational schools and other similar institutions are considered to be welders of the first category. Specialists at this level can perform simple tasks that do not have strict requirements.

Welder 2nd category

A welder receives promotion to grade 2 after graduating from a vocational school or another specialized institution. Specialists at this level can connect parts in a lower and vertical position. However, to obtain a sealed seam, the welder must increase the grade to third.

Welder 3rd category

This qualification is awarded to graduates of specialized educational institutions. Moreover, to receive this category you do not even need to visit a construction site.

Specialists at this level are able to:

- seal joints;

- weld corner, horizontal and vertical seams;

- understand the design features of main and auxiliary equipment;

- comply with safety requirements;

- assemble structures based on drawings.

At the same time, to perform more complex tasks it is necessary to increase the rank from 3 to 4.

4th category

Welders of the fourth category gain access to more complex tasks. In particular, specialists with such qualifications must be able to work with different types of structures in all spatial positions. However, the 4th grade welder also has a number of limitations.

A 4th category welder must be able to

The fourth category for welders gives the following skills:

- weld any structures of medium complexity;

- cut out shaped elements from metal;

- carry out plasma cutting;

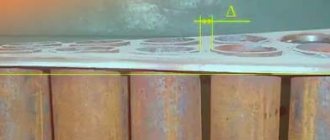

- create high-quality sealed seams on pipes with high internal pressure;

- read and draw drawings.

Useful article - Types and features of NAKS certification that every welder and welding production specialist needs to know

Welder 5th category

The 5th category is assigned to specialists who are capable of welding complex structures.

A 5th grade welder must be able to

Specialists with this qualification are able to:

- work in any direction;

- cut out parts of complex configurations;

- work with different types of materials;

- create sealed seams on high-pressure pipelines.

This qualification is awarded to experienced craftsmen.

6th category

The sixth category is the highest. That is, it is impossible to move to level 7, according to Russian standards.

A 6th grade welder must be able to

Specialists of the 6th category are able to perform experimental operations in which masters of previous levels are not involved. In particular, this may involve the production of parts from a new alloy.

A master with such qualifications independently determines the technology, type of consumables and working conditions. That is, regardless of the work experience of an electric gas welder, category 6 indicates that the specialist is capable of solving non-standard problems that require a creative approach.

Useful article - Everything you need to know about silumin - what it is and where it is used

III. Rights

A welder of manual arc welding with a consumable coated electrode has the right:

1. Request and receive the necessary information, as well as materials and documents related to issues of their activities.

2. Improve your qualifications, undergo retraining (retraining)

3. Take part in the discussion of issues included in his functional responsibilities.

4. Make suggestions and comments on how to improve activities in the assigned area of work.

5. Require the management of the organization to provide assistance, including ensuring organizational and technical conditions and execution of the established documents necessary for the performance of official duties.

6. Make independent decisions, guided by qualification requirements and job responsibilities

7. ___________________________________________________________

How to get a rank

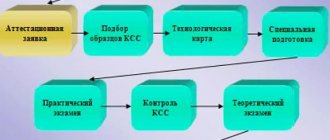

Welding categories are assigned according to different criteria. Moreover, the latter are clearly defined in the relevant standards regulated by the National Tax Code. To increase your access level you must complete training:

- at specialized courses;

- in vocational schools;

- in college;

- at the technical school.

Subsequent levels of clearance are assigned depending on the qualifications (skills) of the master. But in each case, the specialist must undergo the appropriate certification at NAKS.

How to improve the qualifications of a welder (increase the rank)

To increase the rank, a welder must undergo a special procedure by passing an aptitude exam. Certification is carried out once every few years.

The nature of the procedure is determined depending on the qualifications claimed by the electric and gas welder. Certification can be carried out both in the enterprise (the relevant commissions are assembled) and in specialized training centers.

To increase the level of admission, it is necessary to pass the appropriate exam, tasks for which are selected based on the level of preparation of the applicant. In particular, a novice electric gas welder who has recently completed his studies at a specialized institution will not be given the task of creating a sealed seam in high-pressure pipelines.

average salary

The salary amount is determined not only by the level of training, but also by the field in which the specialist works. This is also affected by:

- the level of education;

- current qualifications;

- region of residence;

- specialization and other factors.

On average, specialists in Russia are given 30-100 thousand rubles. But after increasing the rank, a welder who has been given the maximum level of clearance can receive a higher salary.

Useful article - How to check your NAKS certificate using the register of welders - find yourself by last name on the official website

IV. Responsibility

A manual arc welder with a consumable coated electrode is responsible for:

1. For improper performance or failure to fulfill one’s job duties provided for in this job description - within the limits determined by the current labor legislation of the Russian Federation.

2. For offenses committed in the course of carrying out their activities - within the limits determined by the current administrative, criminal and civil legislation of the Russian Federation.

3. For causing material damage - within the limits determined by the current labor and civil legislation of the Russian Federation.

4. ____________________________________________________________________

This job description has been developed in accordance with the provisions (requirements) of the Labor Code of the Russian Federation dated December 30, 2001 No. 197 FZ (Labor Code of the Russian Federation) (with amendments and additions), the professional standard “Welder” approved by order of the Ministry of Labor and Social Protection of the Russian Federation from November 28, 2013 No. 701n (as amended by order of the Ministry of Labor of Russia dated December 12, 2016 No. 727n) and other legal acts governing labor relations.

Categories of welders - by method

Categories of welders are assigned after completing appropriate training and obtaining qualifications. That is, this gradation criterion determines what technology a specialist can use in the manufacture of specific products. Electric and gas welders receive a new category, regardless of experience and age.

To do this, specialists undergo training at a retraining center or other similar institutions.

NAKS monitors the determination of category (level) and qualifications. Also, this organization constantly monitors the equipment used and the working conditions (nature) of electric and gas welders.

contact welding

Contact welding is considered one of the simplest methods of metal structures. In this case, the seam can be obtained by exposing the material to a high voltage electric current.

Provided the technology is followed, durable structures can be welded using this method. To obtain high-quality seams, a special pressing machine is often used. The latter, due to high pressure, also heats the material, thereby creating a strong connection.

There are minimum requirements for specialists authorized to use this technology. The welding process is fully automated. Therefore, operators are only required to comply with labor safety standards and follow the technical map according to which a specific product is manufactured.

Diffusion welding

Having acquired the skills to use this technology, specialists can weld metal structures of increased strength. Nitrogen is used to strengthen the seam during operation.

Specialists working using diffusion welding technology produce products according to piece orders. That is, this method is not used in mass production. To connect the parts, the latter are placed in honeycomb furnaces.

Induction

Induction welding is a type of thermite welding in which the workpiece is heated using magnetic induction to produce a weld. This technology has a number of advantages:

- welding speed does not depend on the thickness of the metal;

- suitable for various types of metals;

- welding takes a few seconds;

- economical consumption.

This technology is mainly used to connect steel pipes. Welding is carried out in a special installation in which the workpiece is placed.

Useful article - How to properly prepare welding documentation and submit work on time

Electron beam

For this type of welding, a vacuum chamber is used. The procedure is carried out under the control of automatic systems. This technology is used both for the manufacture of piece products and in mass production.

The vacuum chamber can be configured depending on the tasks facing the operator. In particular, this device is used for welding jewelry and thin-walled workpieces.

This camera requires special knowledge on the part of the operator. Therefore, specialists with the highest rank can work with electron beam welding.

Cold

Cold welding refers to a process during which workpieces are joined without exposure to temperature. This happens due to the filling of the voids with a special plastic mass that connects the individual components.

Electroslag

This type of welding is classified as arcless. The seam is obtained by heating individual workpieces with the heat of a slag bath into which an electric current is supplied. This process helps prevent the formation of cracks in the metal after it cools.

The following types of electrodes are used in electroslag welding:

- wire;

- lamellar;

- melting mouthpiece.

This technology is mainly used for connecting thick parts (from 15 to 600 mm). In this regard, to gain access to such work, the welder’s rank must be the highest.

Ultrasonic

Ultrasonic welding does not require a high level from a specialist. This technology has the following advantages:

- you can weld contaminated workpieces;

- there is no overheating of parts;

- can be welded in hard-to-reach places;

- there are no harmful secretions;

- heating the surface takes a fraction of a second.

In this process, the connection is obtained by applying ultrasonic vibrations. The method is used for spot, seam or contour welding.

Friction

This technology is a type of pressure welding. The method involves installing two blanks into a special apparatus that unwinds the parts. As a result, friction causes the metal to heat up. At the end of the process, a forging force is applied to the workpieces, which forms a seam.

Only the highest categories of welders can use this technology, since the procedure requires compliance with many important nuances.

Termite

A welder of the highest category also has access to this technology. According to the technical description, the equipment used for such welding consists of a melting crucible. The latter contains a hole through which thermite metal and special devices are supplied that heat the workpiece to a temperature of 500-900 degrees. Also, the design of this equipment includes presses that tighten the structural parts when the welding technology involves upsetting.

The reasons why welding ranks need to be upgraded to access this technology are as follows:

- the welder must accurately measure the amount of thermite mixture;

- it is important to properly prepare the crucible and other elements;

- It is important to heat the unit correctly.

In addition, once the process is complete, it is important to increase the strength of the joint by proper stripping.

Gas

One of the important skills acquired during training to become a gas welder is the ability to independently cut material. That is, a specialist of this level must not only connect the parts, but also prepare them.

Gas welders are able to create seams of any type and in different positions. Therefore, specialists of the maximum ranks have access to this type of work.

Dugovaya

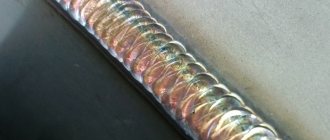

This technology can be used by electric and gas welders whose category corresponds to the highest level. Such specialists are able to create strong connections using the following welding methods:

- argon-arc (welding with tungsten electrodes);

- plasma;

- semi-automatic/mechanized in gases (inert or active);

- manual.

That is, from the number of categories that exist in the Russian Federation, access to arc welding is obtained only if in-depth and long-term training has been completed, and you also have the appropriate skills to work with other types of technologies. This is explained by the fact that high demands are placed on the seams that are formed during arc welding in terms of their ability to withstand mechanical and vibration loads. And electric and gas welders bear full responsibility for the quality of the connection.

II. Job responsibilities

The responsibilities of a manual arc welder with a consumable coated electrode (2-3 category) include:

1. Carrying out preparatory and assembly operations before welding and cleaning welds after welding:

— Familiarization with design and production-technological documentation for welding

— Cleaning structural elements (products, assemblies, parts) for welding with a hand or power tool

— Selection of the spatial position of the weld for welding structural elements (products, assemblies, parts)

— Assembly of structural elements (products, assemblies, parts) for welding using assembly devices

— Assembly of structural elements (products, assemblies, parts) for tack welding

— Inspection using a measuring tool of prepared and assembled structural elements (products, assemblies, parts) using assembly devices for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

— Inspection using a measuring tool of prepared and tack-assembled structural elements (products, assemblies, parts) for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

— Cleaning weld seams with hand or power tools after welding

— Removal of surface defects (pores, slag inclusions, undercuts, metal splashes, sagging, etc.) using manual or power tools

2. Manual arc welding (surfacing, cutting) with a consumable coated electrode (CD) of simple parts of non-critical structures:

— Checking the equipment of the welding station RD

— Checking the functionality and serviceability of taxiway post equipment

— Checking the presence of grounding of the welding station RD

— Preparation and testing of welding materials for welding work

— Setting up welding equipment for welding

— Performing preliminary and concomitant (interlayer) heating of the metal

— Performing design work on simple parts of non-critical structures

— Performing arc cutting of simple parts

— Control using a measuring tool of welded welded parts for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

3. Manual arc welding (surfacing, cutting) with a consumable coated electrode (CD) of complex and critical structures (equipment, products, assemblies, pipelines, parts) from various materials (steels, cast iron, non-ferrous metals and alloys) intended for work under pressure , under static, dynamic and vibration loads:

— Checking the functionality and serviceability of welding equipment for RD, setting up welding equipment for RD taking into account the features of its specialized functions (capabilities)

— Performing work on complex and critical structures using specialized functions (capabilities) of welding equipment

— Performing arc cutting

— Inspection using measuring tools of welded RDs of complex and critical structures for compliance of geometric dimensions with the requirements of design and production-technological documentation for welding

— Correction of RD defects by welding

Advantages and disadvantages

Representatives of this profession are constantly in demand on the Russian market. At the same time, specialists receive high salaries on average throughout the country. However, representatives of this profession work in difficult conditions with increased stress on the body (the eyes are considered the most vulnerable). There are also cases when electric and gas welders are forced to perform tasks at extremely low temperatures.

The following diseases are typical for this profession:

- asthma;

- silicosis;

- pneumoconiosis and other pathologies of the respiratory system.

But despite the above, an electric and gas welder is a profession in demand. The demand for such specialists is constantly at a high level.