Steel tempering is the final stage of heat treatment and is used to reduce excess hardness, reduce brittleness and eliminate internal stresses of the metal. It is most often applied to carbon steels that have been hardened to martensite, that is, heated slightly above 727 ºC and cooled at a high rate in an aqueous environment.

Typically, steel products are tempered at temperatures that are several times lower than the quenching temperature, while maintaining the martensitic structure, which ensures the hardness of the metal. Cutting tools and other products made from tool steels are mainly subjected to this heat treatment.

However, there are types of tempering with heating close to quenching (on troostite and perlite), after which the metal acquires the required elasticity and its impact strength increases. Alloying additives slow down the process of formation of the required structure, so parts made of alloy steels are tempered at higher temperatures.

Traditional tempering technology involves heating the product to a standard value and cooling it in the open air, although some types of steel products are tempered in oil or molten media. You can release the entire product or part of it. For example, only the butt and handle of knives are tempered, while maintaining the full hardening of the blade.

What is steel tempering?

Tempering of a metal is one of the types of heat treatment in which its phase state is preserved, but at the same time a number of hardening characteristics are corrected. First of all, during tempering, the stress of the internal structure, which arises as a result of deformations of the crystal lattice during quenching, sharply decreases.

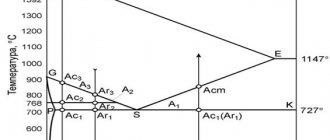

In addition, rigidity and brittleness are reduced, which is a consequence of the saturation of the needle-shaped elements of martensite with ferrite and the formation of pearlite grains (see figure below). This structure retains the properties of hardened metal, but at the same time becomes more ductile and tough.

In alloyed steels, all these processes occur with some differences, which are associated with the fact that alloying elements under certain conditions become centers of crystallization and thus change the physical and chemical characteristics of the metal.

Steel products are tempered by heating them to a given value, followed by slow cooling in the open air or in a special environment. The phase state and structure of the metal formed after tempering, and, consequently, its physical characteristics, directly depend on the heating temperature.

In general, the rule is observed: the higher the temperature, the lower the brittleness and hardness and the higher the flexibility and toughness. Depending on the temperature ranges used, there are three main types of steel tempering: low, medium and high, the heating limits of which are, respectively, 300 ºC, 450 ºC and 650 ºC. The first type is characterized by the highest hardness, and the latter by the highest impact strength.

The heating temperatures during tempering of steels directly depend on their chemical composition, since alloying additives have a significant impact on the process of formation of structural elements. This is usually due to a slowdown in the decomposition of martensite, which requires an increase in temperature conditions.

In addition, when high-alloy steels are tempered, phenomena such as an increase in rigidity associated with the formation of troostite and the occurrence of temper brittleness may be present.

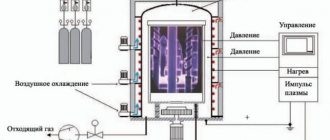

Equipment for hardening

The equipment is divided into two main groups - heating units and cooling baths. At modern enterprises, the following are used to obtain quenching temperatures:

- thermal muffle furnaces;

- induction heating equipment;

- installations for heating in melts;

- laser heating devices;

- gas plasma devices.

The first three types of installations are in demand for volumetric hardening, the last three - for the surface process.

Quenching equipment is steel containers, graphite crucibles, furnaces that contain molten metals or salts. Quenching baths for liquid media are equipped with heating and cooling systems. Their design may include special mixers for mixing liquid media and eliminating the steam jacket.

Low Vacation

Low tempering is carried out in the temperature range of 120÷300 ºC.

The choice of a specific temperature regime depends on the grade of metal and the desired result. Most often, this method reduces internal stresses and slightly increases the toughness of tool steels, which require increased hardness and wear resistance. At 120÷150 ºC there is no change in hardness, but only residual stresses decrease. To reduce it, the product must be heated to at least 200 ºC and kept under these conditions for at least one hour. In the range from 200 ºC to 300 ºC, the formation of tempered martensite begins and the hardness decreases with a simultaneous increase in the toughness of the steel.

In some cases, a significant decrease in viscosity is observed in this temperature range, which is called temper embrittlement. The consequences of this phenomenon are eliminated by additional heat treatment. In addition to tool steel, low tempering with heating up to 250 ºC is also used for structural steels, the surface of which has been subjected to thermochemical treatment.

Steel composition

If steel is used to make such durable tools, then, consequently, it itself has, if not outstanding, then very significant characteristics. HVG steel acquired similar properties due to its rich composition, in which each individual element imparts certain properties to the alloy. Here is a complete list of these alloying elements and their percentages:

- Iron - about 94%. An element that constitutes the bulk of a steel alloy, as well as a binding element for all other alloying additives.

- Carbon - 1.25%. The most important additive, since it is carbon that gives iron, which is soft in nature, strength and hardness. Its content in the composition is more than 1%, which automatically classifies the steel as high-carbon.

- Manganese - 0.95%. Increases the wear resistance of the alloy, load resistance, strength, hardenability and reduces the risk of deformation during hardening.

- Chromium - 1.5%. Oddly enough, this alloying element is designed to improve the strength characteristics of HVG steel, as well as its hardenability and reduce the growth of carbide grains after heat treatment.

- Tungsten - 1.4%. Increases the strength characteristics of the metal and significantly increases heat resistance.

- Silicon - 0.25%. It adds plasticity to the finished product, but slightly reduces hardness.

- Copper, nickel, molybdenum, sulfur and phosphorus - in the region of 0.3% of the total mass of the alloy. With such a small content, no pronounced positive or negative properties are added to the alloy.

Average holiday

Medium tempering is intended for heat treatment of steel products, which must combine increased strength and elasticity with specified toughness parameters. As a rule, spring and spring steels operating under variable dynamic loads are tempered in this way.

The temperature range in this case is from 300 ºC to 450 ºC, and the hardness is reduced to 45÷50 HRC versus 60÷63 with low-temperature tempering. After such heat treatment, the steel acquires a troostite structure. The heating time during an average tempering can be up to several hours, and cooling is carried out naturally in calm air.

Heat treatment of tool alloys

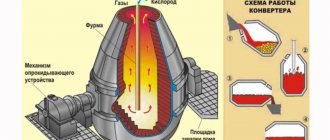

The following statement is true for almost all metals: with increasing tempering temperature, strength decreases and ductility increases. The only exceptions are high-speed steels used in the production of tools. To ensure better heat resistance and wear resistance characteristics, they are alloyed with carbide-forming elements: molybdenum, cobalt, tungsten and vanadium. And for hardening, heating to temperatures above 1200 °C is used, which allows the formed carbides to be most completely dissolved.

The thermal conductivity of iron itself and its alloying elements varies significantly, therefore, to prevent deformation and cracking during heating, temperature pauses should be performed. This occurs when temperatures reach 800 °C and 1050 °C, and for large objects the first interval is assigned at a temperature of 600 °C. The duration of the stop ranges from 5 to 20 minutes, which allows for the best conditions for dissolving carbides. Cooling is most often carried out in oil.

Deformation can be significantly reduced by stepwise heat treatment of steel in molten salts, where hardening is performed at a temperature of about 500 °C. To increase the hardness of the products, this is followed by double tempering at 570 °C. The duration of the process is 1 hour, and its mode is influenced by the chemical properties of alloying elements and temperature, which determines the rate of carbide release.

High holiday

High tempering is carried out in a temperature range close to the critical point: from 450 ºC to 650 ºC.

After such heat treatment, the steel becomes ductile, its relative elongation and contraction, as well as impact strength, increase. This is due to the fact that the metal acquires the structure of tempered sorbitol and its internal stresses are reduced by 95%. In this way, products operating under shock loads are released: shafts, axles, connecting rods, parts of presses and forging hammers.

If steel is tempered at 690 ºC, then granular pearlite will prevail in its structure, and it will have maximum ductility and minimum strength. In some vanadium, chrome and tungsten steels, when tempered with heating up to 560 ºC, troostite may form, which leads to an increase in hardness (the so-called secondary hardness).

Knife manufacturing technology

Work should begin with the selection of suitable material. The blade blade must meet some mandatory requirements:

- Be convenient to use for certain purposes (a mushroom picker’s knife and a hunter’s knife are completely different tools);

- Be durable, withstand possible shock loads without destroying the blade;

- Be sharp and maintain an edge for as long as possible;

- Be as resistant to corrosion as possible.

There are a lot of options for blanks for the home craftsman. One of the most accessible is the flat file. Even a tool with a knurled cut can easily be turned into a convenient, practical, durable knife.

Tempering brittleness

For almost all steels, a standard relationship applies: the higher the heating temperature during tempering, the greater the ductility and toughness of the tempered product.

However, for some brands, as the temperature increases, these physical characteristics decrease and hardness and brittleness increase. This phenomenon is called temper brittleness and occurs during heat treatment of both carbon and alloy steels. It manifests itself in two temperature ranges: 250÷400 ºC and 500÷550 ºC and, accordingly, is called type I and II temper brittleness (see figure below).

The first is typical for carbon steels, and you can get rid of it by heating the part again a little above 400 ºC. As a rule, it does not appear again, but at the same time the metal exhibits a slight decrease in hardness. Type II temper brittleness can occur in alloy steels, which, after heating to the specified range, are subjected to slow cooling.

To counteract this problem, the cooling rate is usually increased, but reheating the product may again cause such brittleness to occur. Another way to get rid of this phenomenon is to introduce small amounts of molybdenum or tungsten into the steel composition.

It is preferable for tempering large-sized parts, since a high cooling rate can cause their deformation and the occurrence of excessive internal stresses.

Possible defects after hardening

Heating, holding, cooling and tempering of steel are carried out in accordance with technological maps developed by specialists. Violation of the developed and approved technical process and/or heterogeneity of the workpiece structure can cause various defects. Among them:

- Uneven heating and/or cooling. They lead to deformations and the formation of cracks, non-uniform composition and non-uniform mechanical characteristics.

- Burnout. Occurs due to the penetration of oxygen molecules into the metal surface. As a result, oxides are formed that change the performance characteristics of the surface layer. This defect occurs due to the burning of carbon from the steel caused by excess oxygen in the furnace.

- Water entering the oil cooling bath. This violation of the technical process leads to the appearance of cracks in the product.

All of the above defects are irreparable.

How to release steel yourself

In order to temper steel at home in order to relieve internal stress, it is not necessary to know its grade - it is enough to heat it to a temperature no higher than 200 ºC and hold it in these conditions for at least an hour.

If you plan to temper a steel product to reduce hardness and increase toughness, then knowledge of the steel grade is necessary to determine the tempering temperature conditions. This is actually not as difficult a task as it might seem. In textbooks on heat treatment and on Internet sites there are enough tables with lists of products and the grades of steel from which they are made, and often even with the temperature conditions for their quenching and tempering (see table above).

To heat your part, you can use almost any heat source: from the oven to a gas burner or a homemade forge. An important point is the heating temperature. In principle, it can be determined by color tables of tarnish appearing on hot metal, which are also easy to find on the Internet.

This is an old proven method, known since ancient times, but it requires some experience, since its main disadvantages are the subjectivity of color perception and its dependence on external lighting. For a beginner, the best solution would be to use a stove thermostat or a regular multimeter with a thermocouple.

Has anyone ever used a multimeter with a thermocouple to measure the tempering temperature? How accurate is this device and how do its readings correspond to the color of the tarnish? If anyone has such experience, please write your opinion in the comments.

Assembling a homemade knife

Having completed all the above operations and bringing the knife steel to the required hardness, we proceed to assembly. We adjust the shape of the pads to the shank of the knife and cut out two additional leather inserts.

Then we lubricate the parts with glue, install brass inserts on the glue and leave to dry for several hours.

It is better to make the extreme insert not from a rod, but from a tube of the required diameter. This will help attach the finished product to a leather strap during use, which will prevent its loss while hiking, fishing or hunting.

After the glue has dried, carefully sand the handle and blade with sandpaper. To protect the blade from corrosion, it is enough to polish it well after final sharpening and finishing.

Dear readers, if you have any questions, please ask them using the form below. We will be glad to communicate with you