Characteristics of steel grade 10

Steel 10 is a structural high-quality carbon steel, weldable without restrictions.

Welding is carried out without heating and without subsequent heat treatment, methods: manual arc welding, automatic submerged arc welding and gas protection, CTS, ESW. The plasticity of the metal allows them to be used for the manufacture of stamped parts and components. To produce industrial quantities of goods, cold stamping technology is used. Not prone to flake sensitivity, no tendency to temper brittleness. Hardness of steel 10: HB 10 -1 = 143 MPa. Cutting machinability In the hot-rolled state at HB 99-107 and σB = 450 MPa, Kυ hard alloy. = 2.1, Kυ b.st. = 1.6. It has found its application in the production of pipes and fasteners for boilers and pipelines of thermal power plants; pipe fasteners for nuclear power plants, fasteners for steam and gas turbines are made from steel 10. When using chemical-thermal treatment, the range of applications expands sharply; bushings, spring ears, diaphragms, washers, screws, parts operating up to 350 ° C are made from it, which are subject to the requirements of high surface hardness and wear resistance with low core strength. A high endurance limit determines the use of the material in the manufacture of critical parts that are designed for long-term operation. Forging is carried out at temperatures from 1300 to 700 0C, cooling in air.

Purpose

Steel 10 - carbon, high-quality, structural steel - these definitions indicate its purpose.

Carbon - means unalloyed, with a minimum amount of additives in the composition. The disadvantage of such steels is their susceptibility to corrosion and the undesirability of operation at very high or very low temperatures. The advantages include ease of manufacture, low cost due to the absence of expensive additives in the composition, and high performance characteristics under normal conditions. This is the best steel for mass-use products - structures, pipes, fasteners, fittings, fences, cladding, beams, channels, etc.

Structural - means that the steel is intended for the manufacture of structures (welded and non-welded) and mechanical parts. Such steels are very popular in mechanical engineering and construction. Depending on their characteristics, rigid load-bearing structures, frames, trusses, critical and non-critical parts, fasteners, fittings, etc. are made from them.

Decoding steel grade 10

Interpretation of steel: Structural high-quality carbon steels are produced in converters or in open-hearth furnaces. The designation of these steel grades begins with the word “Steel”. The next two numbers indicate the average carbon content in hundredths of a percent; numbers 10 indicate a content of about 0.1 percent.

| Long and shaped rolled products | GOST 8510-86; GOST 8239-89; GOST 10551-75; GOST 8240-97; GOST 2879-2006; GOST 2591-2006; GOST 2590-2006; GOST 8509-93; GOST 1133-71; GOST 11474-76; GOST 9234-74; |

| Sheets and strips | GOST 6765-75; GOST 14918-80; GOST 19903-74; GOST 82-70; GOST 16523-97; GOST 103-2006; |

| Ribbons | GOST 3560-73; |

| Long and shaped rolled products | GOST 7417-75; GOST 8560-78; GOST 8559-75; GOST 1050-88; GOST 1051-73; GOST 14955-77; GOST 10702-78; |

| Sheets and strips | GOST 4405-75; GOST 10885-85; GOST 1577-93; GOST 4041-71; |

| Ribbons | GOST 19851-74; GOST 10234-77; GOST 503-81; |

| Steel pipes and connecting parts for them | GOST 22786-77; GOST 8638-57; GOST 8645-68; GOST 53383-2009; GOST 24950-81; GOST 6856-54; GOST 30564-98; GOST 30563-98; GOST 8646-68; GOST 23270-89; GOST 8644-68; GOST 11249-80; GOST 20295-85; GOST 5005-82; GOST 8642-68; GOST 10707-80; GOST 1060-83; GOST 550-75; GOST 8639-82; GOST 8731-87; GOST 8732-78; GOST 8733-74; GOST 8734-75; GOST 12132-66; GOST 9567-75; GOST 3262-75; GOST 14162-79; GOST 13663-86; GOST 10705-80; GOST 10704-91; GOST 5654-76; |

| Low carbon steel wire | GOST 5663-79; GOST 1526-81; GOST 792-67; GOST 5437-85; |

| Medium and high carbon steel wire | GOST 17305-91; GOST 9389-75; GOST 7372-79; GOST 26366-84; GOST 3920-70; GOST 9850-72; |

| Metal mesh | GOST 9074-85; |

Application

Rolled steel sheets 10 are used for cold stamping of parts; the strength/ductility ratio makes it most suitable for this processing method. Steel 10 is used to make parts that require high ductility and wear resistance. Steel 10 is an improved alloy; parts can be subjected to chemical-thermal treatment to improve performance characteristics. Popular are hot-deformed, cold-deformed, welded pipes made of steel 10, as well as elements of boilers, thermal power plants, and hydraulic systems.

The use of steel 10 for pipelines depending on the parameters of the transported medium (GOST 32569-2013)

| Steel grade, strength class, standard or specifications | Technical requirements for pipes (standard or specifications) | Nominal diameter, mm | Types of tests and requirements (standard or specifications) | Transported medium (see GOST 32569-2013 designations in table 5.1) | Pipeline design parameters | ||||

| Maximum pressure, MPa | Maximum temperature, °C | Pipe wall thickness, mm | Minimum temperature depending on the thickness of the pipe wall when the wall is stressed from internal pressure [σ], °C | ||||||

| more than 0.35[σ] | no more than 0.35[σ] | ||||||||

| Seamless pipes | ||||||||||||||

| Steel 10 GOST 1050 | GOST 550 groups A, B | 10-300 | GOST 550 | All environments | ≤32 | 475 | ≤12 >12 | minus 40 minus 30 | minus 40 | |||||

| GOST 8731, GOST R 53383 group B, except for those made from ingot | 50-400 | GOST 8731, GOST R 53383 with hydrotest guarantee | ≤5 | ≤12 >12 | minus 40 minus 30 | |||||||||

| Group B media, except steam and hot water | ≤5 | ≤12 >12 | minus 40 minus 30 | |||||||||||

| GOST 8733, GOST R 54157 group B | 10-150 | GOST 8733, GOST R 54157 | All media with hydrotest guarantee | 32 | ≤6 | minus30 | ||||||||

| TU 14-3-826-79 | 20-50 | TU 14-3-826-79 | All environments | ≤12 | minus 30 | |||||||||

| TU 14-3-1486-87 | 300, 350, 400 | TU 14-3-1486-87 | — | minus 40 | ||||||||||

| TU 14-3-587-77 | 500 | TU 14-3-587-77 | ≤12 >12 | minus 40 minus 30 | ||||||||||

| TU 14-ZR-55-2001 | 50-400 | TU 14-ZR-55-2001 | — | minus 30 | ||||||||||

| TU 14-3-1577-88 | TU 14-3-1577-88 | — | minus 40 | |||||||||||

| TU 14-3-1128-2000 TU 14-ZR-1128-2007 | TU 14-3-1128-2000 TU 14-ZR-1128-2007 | ≤12 >12 | minus 40 minus 30 | minus 60 minus 40 | ||||||||||

| Spiral welded electric welded pipes | ||||||||||||||

| Steel 10 GOST 1050 | GOST 3262 | 6-150 | GOST 3262 | Group B media, except steam and hot water | ≤1,6 | 200 | ≤5 | minus 20 | minus 20 | |||||

Limits of application, types of mandatory testing and control of gaskets made of steel 10 for pressures above 10 MPa (100 kgf/cm2) (GOST 32569-2013)

| Steel grade, standard or specification | 10 GOST 1050 | |

| Technical requirements | OST 26-01-49-82 | |

| the name of detail | Metal gaskets | |

| Limit parameters | Wall temperature, °C, no more | -40 to +250 |

| Nominal pressure, MPa (kgf/cm2) no more | 32 (320) | |

| Mandatory tests | σ0.2 | + |

| σв | + | |

| σ | + | |

| f | — | |

| KCU | + | |

| HB | + | |

| Control | Flaw detection | + |

| Non-metallic inclusions | — | |

Use of steel 10 for the manufacture of fasteners (GOST 32569-2013)

| steel grade | Technical requirements | Acceptable operating parameters | Purpose | |

| Wall temperature, °C | Medium pressure, MPa (kgf/cm2), no more | |||

| Steel 10 GOST 1050 | STP 26.260.2043 | From 0 to +300 | 2,5 (25) | Nuts |

| -40 to +450 | 10 (100) | Washers | ||

Mechanical properties steel 10

| GOST | Type of delivery, heat treatment mode | σв(MPa) | δ5 (%) | ψ % | NV, no more |

| 1050-88 | Hot-rolled steel, forged calibrated steel and silver steel of the 2nd category after normalization | 335 | 31 | 55 | |

| 10702-78 | Steel calibrated and calibrated with special finishing: | ||||

| after annealing or tempering | 335-450 | 55 | 143 | ||

| after spherodizing holiday | 315-410 | 55 | 143 | ||

| cold-worked without heat treatment | 390 | 8 | 50 | 187 | |

| 1577-93 | Normalized or hot rolled strips | 335 | 8 | 55 | |

| 16523-70 | Hot rolled sheet (transverse samples) | 295-410 | 24 | ||

| Cold rolled sheet (transverse samples) | 295-410 | 25 | |||

| 4041-71 | Heat-treated sheet of category 1-2 | 295-420 | 32 | 117 | |

| 8731-87 | Hot-deformed, heat-treated pipes | 355 | 24 | 137 | |

| 8733-87 | Cold- and heat-deformed heat-treated pipes | 345 | 24 | 137 | |

| Cementation 920-950 °C. Quenching 790-810 °C, water. Vacation 180-200 °C, air. | 390 | 25 | 55 | hearts 137 surface 57-63 |

Pros and cons of U10A steel

To weld surfaces made of alloy U10 and U10A, preliminary heat treatment of the metal is required. The material is difficult to weld. Steel has its positive and negative sides, let’s look at them in more detail:

pros

- knives made from the alloy are very sharp, such a blade can be sharpened to razor sharpness;

- the cutting edge of alloy knives remains sharp for a very long time, the products do not become dull for a very long time;

- metal products are resistant to chipping, bending of the edges of the cutting edge is not dangerous, even when cutting a small carcass while hunting;

- a knife can replace a screwdriver and can be used in aggressive environments;

- used for the production of exclusive products by private craftsmen;

- Thanks to the simple production technology, the cost of the finished product is not very high;

- the material meets all necessary hygienic standards;

- a knife made of this alloy can serve its owner for up to 50 years;

- ease of care for alloy products, it is enough to remove moisture from the surface of the blade and nothing else is required;

- the alloy is easily etched in a solution of ammonium persulfate and water;

- collectors like the appearance of alloy products.

Minuses

- steel products are shock-resistant;

- It will not be possible to sharpen a knife in the field, the hardness is too high;

- steel does not resist corrosion well.

Mechanical properties of steel 10 at elevated temperatures

| Test temperature, °C | σ0.2 (MPa) | σв(MPa) | δ5 (%) | ψ % | KCU (kJ/m2) |

| normalization 900-920 °C | |||||

| 20 | 260 | 420 | 32 | 69 | 221 |

| 200 | 220 | 485 | 20 | 55 | 176 |

| 300 | 175 | 515 | 23 | 55 | 142 |

| 400 | 170 | 355 | 24 | 70 | 98 |

| 500 | 160 | 255 | 19 | 63 | 78 |

The study of relaxation resistance by the free bending method showed that samples subjected to MMTO have lower relaxation resistance at 150°C than in the initial state (after annealing). Additional annealing of samples after MMTO at 300-500°C allows for a sharp increase in the relaxation resistance of steels 10 and 35. The stress drop in samples over 3000 hours after additional annealing at 400°C for steel 10 and at 500°C for steel 35 decreases by 10- 30 times in comparison with samples after MMTO without additional annealing. In this case, the maximum relaxation resistance was obtained at slightly higher temperatures of additional annealing after MMHT than the maximum values of the elastic limit.

The experimental data obtained suggest that the low relaxation resistance of the samples after MMTT is associated with insufficient stability of the fine structure of the metal. Additional pre-recrystallization annealing after MMTO makes it possible to more fully stabilize the structure and, thus, sharply increase the metal’s resistance to microplastic deformations under short-term and long-term loading.

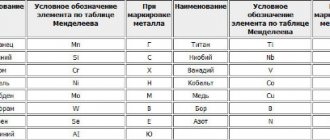

Chemical composition and its effect on the properties of steel

In addition to the chemical elements indicated in the labeling, steel contains a large number of impurities and additives. They are not indicated on the label due to their low concentration.

- Silicon. It is introduced into the composition as a deoxidizer, binds harmful impurities and remains in a small amount - up to 0.4%.

- Nickel. At high percentages, it makes the steel corrosion resistant, non-magnetic and heat resistant. Increases viscosity, elasticity and workability.

- Manganese. Deoxidizes steel, binds sulfur, improves the machinability of steel, in particular, hardenability.

- Sulfur. Forms a harmful compound with iron – iron sulfide. It negatively affects the structure of steel and makes the alloy red-brittle.

- Phosphorus. Gives steel cold brittleness - a tendency to become brittle at low temperatures.

- Chromium. One of the most common alloying elements, inexpensive and effective, in large quantities makes steel stainless, non-magnetic, and heat-resistant.

- Copper. Steel with a high copper content hardens better and is less susceptible to corrosion.

- Arsenic. It has a harmful effect similar to the effect of phosphorus, but of less intensity. Slightly increases anti-corrosion properties.

Chemical composition, % (GOST 1050-2013)

| steel grade | Mass fraction of elements, % | |||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | |

| no more | ||||||||

| 10 | 0,07-0,14 | 0,17-0,37 | 0,35-0,65 | 0,030 | 0,035 | 0,15 | 0,30 | 0,30 |

Physical properties of steel 10

| Temperature | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| 0C | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.1 | 7856 | 140 | |||

| 100 | 2.03 | 12.4 | 57 | 7832 | 494 | 190 |

| 200 | 1.99 | 13.2 | 53 | 7800 | 532 | 263 |

| 300 | 1.9 | 13.9 | 49.6 | 7765 | 565 | 352 |

| 400 | 1.82 | 14.5 | 45 | 7730 | 611 | 458 |

| 500 | 1.72 | 14.85 | 39.9 | 7692 | 682 | 584 |

| 600 | 1.6 | 15.1 | 35.7 | 7653 | 770 | 734 |

| 700 | 15.2 | 32 | 7613 | 857 | 905 | |

| 800 | 12.5 | 29 | 7582 | 875 | 1081 | |

| 900 | 14.8 | 27 | 7594 | 795 | 1130 | |

| 1000 | 12.6 | 666 | ||||

| 1100 | 14.4 | 668 |

At a temperature of +20 0C, the density of steel is 7856 kg/m3

Treatment

Pendulum temperature changes are carried out exclusively in chamber and shaft furnaces. Processing with constant heat removal and spheroidization are necessary for U10 steel. The temperature should be 760 degrees.

Exposure in such conditions is necessary for 2.5 hours. During continuous operation of the furnace, isothermal annealing is carried out.

Heating occurs taking into account the heating of steel at one millimeter per minute. A conveyor is used for proper processing.

During the annealing process, the steel acquires a fine-grained structure. Such indicators are better than the corresponding coarse-grained one. Spherodization gives the alloy a granular structure. With each passage of the temperature stage, the workpieces are kept for 45 minutes.

Forging of U10 steel begins at a temperature of 1180 degrees and ends at 800. Workpieces up to 100 mm2 are cooled openly. If the part is large in size, it is left in the hot furnace, and the cooling takes place along with it. Hardening is carried out at 800 degrees.

Hardness of steel grade 10

| Hardness steel 10, calibrated cold-worked steel according to GOST 1050-88 | HB 10 -1 = 187 MPa |

| Hardness steel 10, hot rolled steel according to GOST 1050-88 | HB 10 -1 = 143 MPa |

| Hardness steel 10, heat-treated sheet according to GOST 4041-71 | HB 10 -1 = 117 MPa |

| Hardness steel 10, Seamless pipes according to GOST 8731-87 | HB 10 -1 = 137 MPa |

| Hardness steel 10, hot-deformed pipes according to GOST 550-75 | HB 10 -1 = 137 MPa |

| Hardness steel 10, hot rolled rod according to GOST 10702-78 | HB 10 -1 = 115 MPa |

Knives made of steel U10/U10A

The blades of knives made of carbon tool steel U10 have high characteristics. The alloy holds an edge well and has high wear resistance, but does not resist corrosion well, so knives should be thoroughly wiped after use. Steel is considered an alloy of increased hardness and it ranges around 60-64HRC.

Kitchen knife – CoolToolme JP Gyuto

CoolToolme are designer kitchen knives of the premium segment of domestic production. Initially, CTm Knives were aimed at professional chefs, but over time they deserved a wider consumer. Many blades are made to order according to the personal wishes of the buyer. Knife characteristics:

- Total length: 346 mm;

- Blade length: 224 mm;

- Butt thickness: 3.8 mm;

- Blade material: U10;

- Handle material: Wood;

- Manufacturer: CTM Knives, Russia;

- Weight: 224 grams.

Designer kitchen knife CoolToolme JP Gyuto.

Cutting knife – Specialist

The handmade knife is made of forged carbon steel U10A with a blued blade. Handle made of printed leather and textolite. This knife is ideal for hunting and tourism. The leather handle is warm, pleasant to the touch and does not slip in the hand. Product characteristics:

- Manufacturer: ZlatProfit;

- Steel: U10A;

- Handle: Leather;

- Total length: 250 mm;

- Blade length: 140 mm;

- Blade width: 30 mm;

- Blade thickness: 4.0 mm;

- Blade hardness: 60-62 HRC.

A carving knife is special.

Folding knife – Achilles

Folding knife Achilles is a handmade knife from craftsmen from the city of Zlatoust, the blade of the knife is made of carbon steel U10A with blued finish and decorated with engraving in the style of Zlatoust engraving on steel. The reliable mechanism of the Achilles folding knife will ensure long and safe use in any harsh conditions. Blade characteristics:

- Steel: U10A;

- Handle handle: Walnut;

- Total length: 220.0mm;

- Blade length: 110.0 mm;

- Blade width: 25 mm;

- Blade thickness: 3.0 mm;

- Blade hardness: 62 HRC.

Handmade Achilles folding knife.

Impact strength of steel 10

| Temperature +20 °C | Temperature -20(-30) °С | Temperature -40(-50) °С | Temperature -60 °C | Heat treatment (35 mm rod) |

| 235 | 196 | 157 | 78 | Absent |

| 73-265 | 203-216 | 179 | Normalization | |

| 59-245 | 49-174 | 45-83 | 19-42 | Annealing |

Heat treatment of taps

Heating is done in salt baths. In this way, the heat treatment of steel is carried out so that the surface layers receive additional hardness, and the core remains viscous. This adds extra durability to the tap.

As a result, the service life of the tool increases. Taps made of U10A alloy, with a diameter of up to 8 mm, are cooled in oil. If the workpiece is large, it is cooled in water. Both types of workpieces are tempered in an oil bath at temperatures up to 180 degrees.

The hardness of the product after tempering reaches 57-63 HRC. When choosing a cutting tool, a technologist must understand that the U10 alloy and its analogues lose their properties at 190-200 °C. Any person who has been involved in plumbing work has paid attention to the long service life of products made from U10.

Steel is a product of increased hardness; it makes excellent files and needle files.

But these qualities are not very good for knives. Yes, the blades hold an edge for a long time, this is undoubtedly a plus. But the material is highly fragile.

A product made of pure U10A alloy can crack at any second. For the production of knives, a package of U10A and 7ХНМ alloys is used. This combination allows you to achieve high-quality blades. They are used in tourism, hunting, fishing and even extreme sports.

Foreign analogues of grade 10 steel

| USA | 1010, 1012, 1110, C1010, Gr.A, M1010, M1012 |

| Germany | 1.0301, 1.0305, 1.0308, 1.1121, C10, C10E, Ck10, St35, ST35-8 |

| Japan | S10C, S12C, S9CK, SASM1, STB340, STKM12A, SWMR |

| France | AF34, AF34C10, C10, C10RR, XC10 |

| England | 040A10, 040A12, 045M10, 10CS, 10HS, 1449-10CS, CFS3, CS10 |

| European Union | 1.1121, 2C10, C10, C10D, C10E |

| Italy | 1C10, 2C10, C10, C14, Fe360 |

| Spain | F.1511 |

| China | 10 |

| Sweden | 1233, 1265 |

| Bulgaria | 10 |

| Hungary | C10 |

| Poland | 10, K10, R35 |

| Romania | OLC10 |

| Czech | 11353, 12010, 12021 |

| Switzerland | C10 |

Modulus of elasticity - what is it?

The elastic modulus of a material is a set of physical quantities that characterize the ability of a solid body to elastically deform under conditions of force applied to it. It is expressed by the letter E. So it will be mentioned in all the tables that will go further in the article.

It is impossible to say that there is only one way to determine the value of elasticity. Different approaches to the study of this quantity have led to the fact that there are several different approaches at once. Below are three main ways to calculate the indicators of this characteristic for different materials:

- Young's modulus (E) describes the resistance of a material to any tension or compression during elastic deformation. Young's version is determined by the ratio of stress to compressive strain. Usually it is simply called the modulus of elasticity.

- Shear modulus (G) , also called stiffness modulus . This method reveals the ability of a material to resist any change in shape, but while maintaining its norm. Shear modulus is expressed as the ratio of shear stress to shear strain, which is defined as the change in the right angle between existing planes subjected to shear stresses. The shear modulus, by the way, is one of the components of such a phenomenon as viscosity.

- Bulk modulus (K) , which is also called bulk modulus . This option denotes the ability of an object made of any material to change its volume if it is exposed to a comprehensive normal stress, which is the same in all its directions. This option is expressed by the ratio of the magnitude of volumetric stress to the magnitude of relative volumetric compression.

- There are also other indicators of elasticity, which are measured in other quantities and expressed in other ratios. Other very well-known and popular options for elasticity indicators are Lamé parameters or Poisson's ratio .