Chrome plating is the application of a thin layer of chromium to a metal or plastic surface in order to give it a more attractive appearance, enhance the strength of the metal and increase its resistance to corrosion. However, with use, physical wear of the chrome coating occurs, which is why it loses its aesthetics, so many people think about how to remove chrome from plastic at home. Today, there are several main ways to do this, each of which involves the use of certain equipment, special solutions or other available means. Regardless of which method of removing chrome plating you choose, you must follow certain rules and precautions.

Use of chemicals

Chemicals include:

- hydrochloric acid;

- sulfuric acid

- sodium hydroxide.

How to remove chrome from plastic using hydrochloric acid? You will need to make a 40 percent acid solution. To do this, dilute hydrochloric acid in water in a ratio of 1 to 3. Ready-made solutions are also available for sale, the instructions for which tell you how to remove chrome from plastic. "Mole" is one of such means.

The chrome-plated part is placed in a solution of hydrochloric acid until the chrome coating is completely removed, after which it is thoroughly washed under running water and soap and sent for drying.

The principle of using sulfuric acid to remove chrome plating is completely identical to that with hydrochloric acid.

“How to remove (remove) chromium from plastic using sodium hydroxide?” - you ask. In the same way as described above. However, there is one important nuance here. When working with this substance, contact with water and aluminum should be avoided, since when it reacts with them, sodium hydroxide releases toxic and flammable gas.

Chrome plating of plastic: stages of work

At the first stage, the part is prepared. It is treated with a degreasing solution, which is prepared from the following components:

- soda ash;

- sodium hydroxide;

- silicate glue.

The ingredients are mixed in equal parts and diluted with water, then put on fire and brought to a boil. When the solution is ready, the part to be chromed is lowered into it.

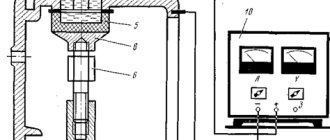

After the part is degreased, proceed to the next stage - chrome plating. This can be done using a galvanic bath or a special brush. Everyone chooses the method that they consider most convenient.

Chrome plating with a brush

You can make a brush yourself. You will need a hollow tube made of plexiglass. A bristle is fixed to one end of it, which can be made from a bundle of bare copper wire. The brush is wrapped with a thin lead wire. The brush and the part are connected to the battery. A transformer can act as a power source, then the hand is connected to it with a diode, while the anode goes to the transformer winding, and the cathode is connected to the part. The diode is not useful for the battery.

Which method is not recommended?

Some experts recommend one piece of advice on how to quickly and efficiently remove chrome. It involves reversing the galvanization process. This method is very effective, but it is not recommended to use it yourself at home, since it is based on the use of electric current, and in the process of removing the binding of chromium elements to the metal, some very dangerous and toxic substances are released. Therefore, if you are looking for a way to remove chrome from plastic, then you should not experiment with this, but rather choose another method described above, or seek help from a qualified specialist.

Reasons for the formation of defects

How to wash a car at home. how to wash a car without streaks at home

The procedure for chemical chrome plating of plastic parts is quite labor-intensive and does not always give an ideal result. In order to eliminate possible errors in the future, you need to know the reasons that can lead to coating defects.

The electrolyte is not warmed up enough or the current significantly exceeds the norm for chrome plating. As a result, an uneven shine will form on the surfaces, reducing the aesthetics of the overall appearance of the processed product.

Incorrectly calculated proportion of chromic anhydride CrO3 in the electrolyte (lower or higher than required) or relatively low concentration of sulfuric acid. Such a defect can lead to a complete lack of shine or the appearance of brown spots on the metallized coating.

An overheated electrolytic solution can result in an overly soft chrome plating.

Removing chrome plating using brake fluid

The last method of removing a layer of chrome is perfect for car enthusiasts. Because it is based on the use of brake fluid. The thing is that it has a similar effect on light chrome plating as a solvent on paint, so brake fluid can help remove the chrome coating from a plastic part. However, it is immediately worth noting that this method cannot be called fast, since the process lasts several days.

All chrome on our parts appears due to galvanic chrome plating.

Galvanic chrome plating

- is an electrochemical method of applying metal coatings to plastic. The bottom line is that three layers of metal are applied: copper + nickel + chromium. Chromium reacts and settles evenly on the surface of the product. This type of chrome plating is used for car emblems, radiator grilles, souvenirs, etc. and so on.

How did I get rid of this chrome?

There is an option to actively work with sandpaper, but very often the parts are never even, with many small elements. Sanding something like this will make your hands dry. That is why chemistry, which we love to skip at school, will help us! The easiest way is to put our plastic part in a ferric chloride solution for a while and etch it, like a printed circuit board.

What is ferric chloride?

Ferric chloride FeCl3 is an average salt of ferric iron and hydrochloric acid. In appearance, this chemical raw material is a soft crystalline mass of rusty-brownish-black color. Used for etching printed circuit boards in the electronics and instrument making industries.

It is customary to prepare a ferric chloride solution based on a ratio of 1 to 3 (1 part iron to 3 parts water) by weight. The solution should be prepared in a heat-resistant non-metallic container into which water is poured at a temperature of about 60-80 degrees. It is advisable, of course, to use boiled water, but ordinary tap water also copes well with this task. According to science, you need to use distilled water, but in practice no one bothers with this - we are not a chemical laboratory! Ferric chloride must be poured into water (! not the other way around!) in small portions, continuously stirring the solution. When dissolved, the water will heat up and a fairly violent reaction will be visible (bubbling, hissing, releasing steam, which is highly not recommended to inhale). It will take about 20 minutes to dissolve (it all depends on the volume), but the iron will dissolve completely and will not settle to the bottom of the container, nor will the solution boil or melt the container. There is only one piece of advice - don’t rush! After dissolution, the solution must be allowed to settle. After 20 minutes, it will be possible to observe the settling of iron hydroxide (rust) at the bottom, which is always contained in ferric chloride powder and which prevents etching. It is better to let the solution sit for 10-12 hours so that any debris that is often present in ferric chloride settles to the bottom of the container. After the solution has settled, it must be filtered into a clean container in which it will actually be stored. The solution can easily be used repeatedly, and it can be stored for as long as desired. As a result, we received a clean, transparent, brown solution of ferric chloride.

Methods and types of restoration of chrome parts

Chrome-plated body elements add special elegance and style to the car. Every car manufacturer uses such auto styling elements. However, beauty requires sacrifice. This is due to the fact that chrome plating is susceptible to corrosion, but with the right approach to cleaning chrome elements, you can maintain its perfect appearance. Therefore, it is necessary to follow the recommendations for cleaning and restoring chrome plating.

Polishing chrome parts: general rules

Firstly, if you have a new car, you should clean the chrome plating in a timely manner. This will help you maintain the shine of chrome elements for a long time.

To clean and restore chrome plating, you will need a special product, which is sold in a car store or home remedies, which are listed below. As a rule, the store-bought product is called chrome restorer or car shampoo with coating restorer. There may be other names, so check with the seller for information. Also purchase a coarse and soft sponge for washing. For final polishing, you can use microfiber or a woolen cloth with a large pile.

Stock up on sponges and cleaning product and go ahead. The process is quite long. For example, one chrome rear bumper molding will require about 80 grams of cleaning agent and 2 sponges.

Once you have roughly cleaned the chrome finish, you can begin polishing the part. The polished part must be completely dry. For the best effect, it is recommended to use a hair dryer, microfiber or woolen cloth with a large pile. When polishing, you can use a special polish for chrome. It will help avoid deposits on the coating and create a protective layer. Polishing is done in a circular motion, covering the entire surface. After polishing, you need to leave the car for 30–40 minutes, and then go over the polished part again with microfiber to remove excess polish.

To maintain the ideal condition of chrome elements, it is necessary to carry out these operations 2-3 times a year. The effect that will be achieved will meet all your expectations.

How to remove rust from chrome car parts

In this case, it all depends on the size and depth of the corrosion spots on the chrome part. If the corrosion centers look like small rusty spots or scratches, this is half the battle, but if the corrosion center has already grown sufficiently and has an impressive depth, or the chrome has generally bulged, then it is practically impossible to save the coating or will not succeed at all.

1. Corrosion in the form of dots and scratches.

If a chrome-plated part has corrosion damage in the form of rusty spots with a shallow depth or scratches, then simple means are suitable for cleaning the surface and removing this rust: these are polishes, acetic or citric acid, soda, etc. The ideal option after this would be to coat the cleaned part with a protective polish to prevent the growth of former foci of corrosion.

2

. Corrosion in the form of severe lesions or swelling.

How to polish a car body correctly?

If the chrome-plated part has significant corrosion damage, it will be necessary to first clean it with almost the finest sandpaper, and then proceed to the method described above in the first case

It is worth paying attention, if the chrome coating is completely swollen, then nothing can be done. You can only resort to special services that deal with chrome plating of parts

Or you can cover this part with a chrome film yourself. This, of course, will not take much time, but still the effect will not be what you would like.

How to clean plaque on chrome car parts

Currently, there are quite a lot of products that can be used to clean and remove plaque from chrome car parts.

Moreover, it is important to mention that for this there is no need to run to a car store and spend money. And by the way, not every product for cleaning chrome elements will always cope with this.

To some extent it will cope, but the cleaning process may take a long time. Therefore, below we will list the means that are probably in every home. And this: At least one of the above list is definitely in every home. Therefore, there is no need to spend money on cleaning products at the auto store.

Interesting video on cleaning chrome parts

This video shows how, oddly enough, cleaning a chrome surface occurs with water and ordinary foil.

What is chromium and how is it applied?

First, a few words about what it is and how it is done. Chrome-plated elements and parts are chrome-plated by applying a galvanic layer, which is a mirror chrome coating. Chromium plating refers to an electrochemical process in which metal particles are applied to plastic. It happens something like this: three metal layers are applied to the plastic: copper, nickel, and then chromium. The last layer interacts with nickel and lies evenly on the surface, completely covering it. This type of chrome plating is used to apply chrome to various decorative parts, such as emblems, radiator grilles, moldings and other inserts that emphasize the gloss and status of the car.

Specialized equipment

It is usually used when it is necessary to remove worn chrome directly from the metal of the body, its large parts, the same alloy wheels, etc. But it is not always possible to remove old chrome on your own due to the inaccessibility of the installations or their high cost. It is not advisable to purchase such systems for one-time use.

Equipment suitable for performing the assigned tasks is divided into 2 types:

- abrasive installations;

- ultrasonic devices.

Abrasive units are special equipment for which special powders are used. They are supplied under high air pressure, which allows the metal layer previously applied by galvanic method to be gradually removed. Gradual erasing occurs, keeping the metal intact.

Increased pressure and high abrasiveness may not be suitable for processing delicate and brittle plastics. It may become damaged and become unsuitable for further use.

Basically, abrasive units are used to clean metal parts from the chrome layer. Such equipment is sold in specialized construction stores; some auto repair shops use it to restore rims, etc.

Depending on the thickness of the layer provided on the part, a powder of the appropriate grain size is selected.

When working with such installations, personal protective equipment must be used. Otherwise, there is a risk that particles of chromium and the sand itself will penetrate the respiratory tract, get on the mucous membrane, etc. This is dangerous to health.

How and with what to remove chrome from plastic?

Anything that cannot be removed mechanically can be removed chemically. It is chemistry that allows you to remove chrome without a trace without causing harm to the product. To work, you will need ferric chloride, which will do all the dirty and hard work for us.

What is ferric chloride?

Ferric chloride or ferric chloride (designated FeCl3 ) is an average salt of ferric iron and hydrochloric acid - as it is written on Wikipedia. This chemical composition appears as a soft, crystalline mass of reddish-brown, reaching almost black in color in places. In industry it is mainly used for etching printed circuit boards.

How to prepare a solution for removing chromium from plastic?

Now let’s talk about how to prepare a miracle composition that will help you get rid of chromium once and for all.

To make the magic composition you need to take one part of ferric chloride and mix it in three parts of hot water. During cooking, a reaction releases heat and steam, so you should “boil” it in a heat-resistant container, but not in a metal one. Also take care to protect your hands and respiratory tract so that God forbid you do not harm yourself. Ferric chloride is poured into water in small portions, while the composition is constantly stirred. Stir gently until the mixture becomes homogeneous and there is no sediment in it. In general, many pros recommend using a purified composition, which has been well settled for 5-7 hours, after which it has been filtered.

How to remove chrome at home?

After you have made the correct solution (it is advisable that its temperature be above 60 C°, this significantly speeds up the process of chromium removal), the parts to be treated are immersed in the composition and left in it for some time. It’s difficult to say which one, it all depends on many factors, such as: chromium layer, temperature of the composition, quality of ferric chloride, etc.

The process can be monitored by periodic checking; it should be checked no earlier than after 2-3 hours. The effect will be as follows: the part will completely get rid of chrome and will look white or black depending on what color of plastic you have. If you are satisfied with the result, you can stop the process at any time.

After carrying out all the work related to removing chrome, I recommend washing the parts using water and detergent. Further processing, be it water-print painting or film, is carried out as usual, without any differences.

In conclusion, I would like to add that all work must be carried out in a well-ventilated area in compliance with all safety regulations using gloves and a respirator. Careless handling of chemical composition may cause harm to you or your health. If the solution gets on your skin or, God forbid, in your eyes, wash it off with plenty of soap and water. If irritation or itching occurs, consult a doctor immediately.

Useful tips

In order to get a high-quality result and maintain the effect for a long time, you need to take into account the following tips:

- if the procedure is being carried out for the first time, you can first practice on a prototype;

- if for some reason it is impossible to chrome plating at home, it is permissible to replace chrome with nickel;

- the chrome coating may fade over time; if this happens, the part must be rinsed well in warm water using household chemicals, then the product is dried and rubbed with a soft material;

- when exposed to low temperatures, chrome plating can quickly fade;

- At the final stage, do not neglect polishing the part.

Currently, you can purchase ready-made chrome-plated parts in the store. But in some cases you have to do this procedure yourself. You can coat both plastic and metal parts with the solution. The processing process is complex and requires preparation. However, if you know how to do chrome plating at home and take care of safety, you can get a perfect, shiny part without harming your own health.

Products with chrome coating have an aesthetic and attractive appearance, which is why they are so popular and are more expensive than their non-chrome counterparts.

But what if there are no chrome-plated options on the market, or you want to give the corresponding appearance to existing items without a chrome layer? In such a situation, chrome plating of plastic at home can help.