Nichrome from a soldering iron

Disassemble the soldering iron and find the same nichrome wire.

We actually found one, but it was very thin. You can find out the cross-section of the wire by winding 10 turns of thread tightly pressed together around a pencil. Our turns took 1 mm. This means that the cross-section of our thread is 0.1 mm. You can buy a lot of such cheap soldering irons, but the nichrome spiral in them may differ in length. Disassembling a household soldering iron to obtain nichrome is a really working scheme. But what to do if you don’t have a soldering iron?

A similar spiral is found in hair dryers. Different models have nichrome threads of different diameters, but they are definitely there. Nichrome can be found in a heater built on the principle of a fan. This option will be slightly more expensive than the previous one.

And finally, the most difficult way is to get this metal out of an electric stove with an open spiral. Today we told you that nichrome winding is not such an expensive undertaking. If you decide to find a thread in a soldering iron, then it can reach 2.5 m. This will turn out to be far from 1 winding.

Operating requirements

To ensure a long service life of nichrome products, it is important to follow certain rules:

- to prevent overheating, winding the heating cable on the frame in several layers is not allowed;

- the bend of the current-carrying core in the cable should not exceed five of its diameters.

The integrity of the conductor can be restored by mechanical twisting, threaded clamps or couplings, soldering or welding.

When you turn on a device with a nichrome heating cable for the first time, a small amount of smoke may be released due to the burning out of residual oil.

Nichrome spiral

Refractory Tungsten Production Process

This material is classified as a rare metal.

It is characterized by relatively small volumes of consumption and production, as well as low prevalence in the earth’s crust. None of the rare metals are obtained by recovery from raw materials. Initially, it is processed into a chemical compound. And any rare metal ore undergoes additional enrichment before processing. There are three main stages for obtaining rare metal:

- Ore decomposition. The recovered metal is separated from the bulk of the processed raw materials. It concentrates in a precipitate or solution.

- Obtaining a pure chemical compound. Its isolation and purification.

- The metal is isolated from the resulting compound. This is how pure materials without impurities are obtained.

There are also several stages in the process of obtaining tungsten. The starting materials are scheelite and wolframite. Typically they contain from 0.2 to 2% tungsten.

- Ore beneficiation is carried out using electrostatic or magnetic separation, flotation, and gravity. As a result, a tungsten concentrate is obtained, which contains approximately 55–65% tungsten anhydride. The presence of impurities in them is also controlled: bismuth, antimony, copper, tin, arsenic, sulfur, phosphorus.

- Preparation of tungsten anhydride. It is the raw material for the production of metal tungsten or its carbide. To achieve this, a number of procedures are carried out, such as: leaching of cake and alloy, decomposition of concentrates, production of technical tungsten acid and others. As a result of these actions, a product should be obtained that will contain 99.9% tungsten trioxide.

- Obtaining powder. In powder form, pure metal can be obtained from anhydride. This is achieved by reduction with carbon or hydrogen. Carbon reduction is carried out less frequently because the anhydride is saturated with carbides and this leads to brittleness of the metal and poor processing. When obtaining powder, special methods are used that make it possible to control the shape and size of grains, granulometric and chemical compositions.

- Production of compact tungsten. Basically, it is in the form of ingots or bars and is a blank for the manufacture of semi-finished products: tape, rods, wire and others.

Conditions for receiving tungsten

It is important to note that different companies have different approaches to accepting recyclable materials. However, despite this, there are a number of general rules that enterprises of all types try to adhere to.

Both individuals and legal entities have the right to hand over tungsten scrap when registering scrap metal at the enterprise. When receiving it, an analysis is carried out and the exact content of pure metal and impurities is determined. This procedure is carried out using special instruments - metal and alloy analyzers.

The final price may vary depending on the composition of the tungsten alloy and the presence of various additives in it.

However, the cost in any case remains very high, since rare non-ferrous metals are used as impurities.

Recyclable materials with varying contents of the main element from 5 to 99% are accepted.

Large enterprises that provide secure and documented transactions place increased demands on the quality of scrap and on individuals or legal entities handing over the metal, namely:

- Acceptance of scrap is carried out in accordance with state standards, and the transaction must not contradict regulations.

- Metal can be accepted from an individual only upon presentation of an identification document.

- Recyclable materials are accepted only in their pure form without any dirt or impurities.

It is important to understand that many companies that accept tungsten scrap set a minimum weight of one kilogram, while large ones set it at 50 or more. Of course, it is possible to find small buyers through advertisements, but the price may be much lower

Compound

Nichrome contains about 20% nickel and up to 80% chromium.

In addition, the alloy may contain additives in the form of manganese, aluminum, iron, silicon, etc.

The introduction of alloys into the nichrome composition increases the performance indicators and technical parameters of the metal:

- nickel and iron improve machinability;

- iron, titanium, aluminum and manganese reduce resistance to elevated temperatures;

- In the presence of iron in the alloy, nichrome acquires magnetic properties.

Increasing additives can degrade the characteristics of the metal.

The amount of nickel determines the temperature that the heating elements can withstand.

The chromium content in the alloy should be no more than 20%. An increase in the amount of chromium increases the brittleness and impairs the machinability of the metal. When its content in the alloy is more than 30%, cold rolling and drawing of the material becomes impossible.

The strength of the protective film and oxidation resistance depend on the amount of chromium.

Application area

Due to its unique properties, tungsten is widely used. In industry it is used in pure form and in alloys.

The main areas of application are:

They became special. In the production of high-speed steels and tool steels, this material is used as an alloying element or a main component. Dies, punches, cutters, drills and others are produced from such steels. The letter “P” in the name of the alloy means that it is high-speed steel, and the letters “K” or “M” mean steel alloyed with cobalt or molybdenum. Tungsten is also included in magnetic steels, which are divided into cobalt tungsten and tungsten. Hard alloys based on tungsten carbide. It is a compound of carbon and tungsten. It is refractory, wear-resistant and has high hardness. Working parts of drilling and cutting tools are made from it. Wear-resistant and heat-resistant alloys. They use the refractoriness of tungsten. The most common are chromium and cobalt compounds - stellites. They are usually applied by surfacing to heavily worn machine parts. Heavy and contact connections. These include alloys of tungsten with silver and copper. These are quite effective contact materials for the production of working parts for switches, switches, electrodes for spot welding and other equipment.

Electric lighting and electric vacuum technology. Tungsten in the form of various forged parts, strips or wires is used in the production of X-ray equipment, radio electronics and electric lamps. This is the best material for coils and filaments. Tungsten rods and wires serve as electric heaters for high-temperature furnaces. These electric heaters can operate in an atmosphere of inert gas, hydrogen or vacuum. Welding electrodes

Welding is an important area for the use of this metal. Electrodes for arc welding are made from it, as they are infusible.

Where to find nichrome wire

So, let's look at what nichrome wire actually is:

- differs from kanthal in its lower resistivity;

- The box mod delivers high performance power;

- does not contain iron, therefore it does not corrode and lasts much longer;

- conducts heat well. Thus, the coil heats up faster and cools down faster.

Obviously, nichrome is sold in vape shops. 1 meter of such wire is very expensive. When this option does not suit you, you can find nichrome on radio markets. They still exist, but the likelihood that you will be able to find it there is very small.

However, this issue can be solved, you just need to know where to go. Also in this matter, a regular soldering iron or a faulty device that you can stumble upon in a closet or garage will help you out. If you were unable to find a soldering iron, then you can buy it at the Fix Price store, where everything is sold at the same price. The price of a soldering iron there will be only $1.

Temperature coefficient of resistance

The resistivity of an alloy changes when the material is heated or cooled.

The temperature coefficient of resistance (TCR) of nichrome is defined as the ratio of the change in electrical resistance to the change in temperature in degrees Kelvin, taken to the minus of the first power (Kˉ¹).

TKS of nichrome is determined by the formula: α= (R1 - R2) / R1 X (T1 - T2), where:

- R1 is the resistance value at the initial temperature;

- R2 - at final temperature;

- T1—initial temperature;

- T2—changed temperature;

- (R1 - R2) - difference in electrical resistance;

- (T1 - T2) - temperature difference.

Heating by 100°C increases the electrical resistance of nichrome by 2%.

Single hook lures

Tungsten wire is very stiff and requires very strong finger pressure to place it neatly on the hook. And the force is such that a single hook, even made of relatively thick wire - about 0.65 mm - simply breaks on the second or third turn, or uneven turns are obtained. Therefore, it is better to abandon 0.5 mm wire and switch to 0.3 mm.

With it, it turns out much easier, but not elementary, the wire is very springy, so all winding has to be done under tension, constantly squeezing with your fingers and not allowing it to unwind, so that the diameter of the winding does not increase. At the same time, in order to avoid kinks, the wire cannot be held rigidly; it must unwind around its center. For this reason, it will not be possible to wind wire onto a workpiece from a common reel.

You need to estimate the length of the piece needed for two layers and cut it from the reel with some margin. Particular precision cannot be achieved in this process; it is inconvenient to work with a short end, so you will have to put up with the fact that somewhere around 10-15, if not more, percent of the wire will go to waste. But the resulting products are quite aesthetically pleasing (photo 29). And with a relatively small size, they have good mass, which allows them to be used even in windy conditions.

We also make jigs on hooks Nos. 10 and 12 for fly fishing flies; the hooks themselves, depending on the size and model, are made of wire from 0.45 to 0.65 mm. If there are no problems when winding on thicker hooks, then you need to work very carefully with thin ones, and you get two layers of wire (photo 30). Depending on the size of the hook, you can make a jig from three layers of wire. We wind the third layer separately, on the jig in a screwdriver. And then, we fix everything with Moment-gel glue or Norpol-type polyester resin with the addition of dye.

To prevent the first layer of winding from dangling or rotating on the fore-end, you need to do the following. Saikyo hooks have a bent eye and we place the first layer of winding on the already bent part of the hook (photo 31), and from there we begin laying the second layer, we get a kind of lock. The coil does not rotate and cannot move anywhere, even when you apply significant force to the body of the jig when releasing it from the perch’s mouth.

It is recommended to bend the resulting body a little to bring the shape closer to the “Banana” shape. When testing both options: in the form of a nail and bends, no significant changes were noticed in the perch’s reaction to them. He willingly eats both. The main thing is to get into the theme with the color of the beads.

Tungsten wire and its features

Basic properties of tungsten

Tungsten is a refractory metal that is used in the manufacture of heat-resistant alloys. It has a high density, its density reaches 19.3 g/cm3. Tungsten begins to melt at 3395°C and boils at 5500°C, while its evaporation rate is low. As for the electrical conductivity of this metal, it is approximately 1/3 of the value of the same parameter for copper. Tungsten is brittle at low temperatures and also has low oxidation resistance. This metal can be processed by pre-heating it. Externally, tungsten is similar to steel.

Tungsten wire production

The most popular long products made from tungsten are wire. It is produced in accordance with GOST 25501-82. Tungsten wire is a semi-finished product, the cross-section of which remains constant along its entire length. It is made by pressing or drawing.

Since tungsten has low technological plasticity, to increase this property it is heated, which in no way affects the strength of the material, which still remains high. Only after such procedures can wire be obtained by any method of processing under pressure. Supplied in coils or coils.

Powder metallurgy methods are often used to produce tungsten blanks, which makes it possible to improve some of the quality and properties of tungsten. A shtabik is a semi-finished product from which wire is made. It is first heated, and then a special rotary forging machine is used to carry out the forging. This is how tungsten rods are obtained, the diameter of which is 2-3 mm. Wire is obtained from them by drawing in a heated state. The diameter of the resulting long rolled metal is represented by a number of standard values up to 0.3 mm.

Scope of application of tungsten wire

The electrical and electronics industries are the main consumers of pure tungsten. The metal is indispensable in cases where low vapor pressure is required at operating temperatures up to 2500 °C. Tungsten wire is a material for heating elements of furnaces operating in a hydrogen, neutral or vacuum environment, heating up to 3000 °C. Thermocouples are made from this grade of metal. For their manufacture, tungsten-rhenium wire with a rhenium content of 5 and 20% (VR 5/20, VR5/20, VR5/VR20) is used.

More information about the use of tungsten wire grades VA, VM, VRN, VT-7, VT-10, VT-15 can be found by reading GOST 18903-73.

How to make a nichrome jigsaw or cutter with your own hands

Wooden decorative elements are present in the homes of each of us. Sometimes we go to the store to buy a beautiful wooden frame or box for our home or as a gift to our loved ones, friends and relatives. However, the best gift is a gift made with your own hands, and to make a beautiful frame or box we will need a cutter or a nichrome jigsaw, which we will do right now.

Watch the video to see how a nichrome cutter is made:

So, to make a cutter we will need a 12 volt 5-10A power supply (you can use a computer unit), nichrome wire with a cross-section of 0.4-0.8 mm (you can disassemble a wire-wound resistor or the same boiler that uses nichrome thread), two pieces of a cut branch , from which we will make handles, copper wire 1-1.5 m long, as well as two nails or two pieces of rigid wire.

The first thing you need to do is take care of the handles. To do this, you need to drive a nail into the pieces of the branch or insert a wire. For convenience, it is better to use a branch from a soft tree. When the wire or nail is inserted, you should take pliers and make rings from the protruding parts of the wire so that the wire itself, as well as the wires, do not slip off when twisted.

Where can I get nichrome wire?

There are several options for how and where you can purchase a nichrome product.

Today, in almost every locality there is a help desk for goods and services. By contacting it, you can obtain information from the operator about which organization sells nichrome and its contact numbers. This information can also be found on the Internet. However, in this situation, the chances of purchasing a normal product are almost zero.

, because if anyone undertakes to deliver the material, it will only be one and a half to two meters. Organizations mainly specialize in wholesale sales. But it’s still worth clarifying.

If such a product is sold in another city, then you can use it. However, this option requires an additional payment.

for shipping. You can purchase wire in specialized stores. These could be “Radio Components”, “Skillful Hands” and other similar pavilions. The sellers of such private stores, who sell various spare parts, know each other very well. Therefore, if such a “private trader” does not have nichrome wire in stock, he can tell you where to purchase it. By the way, you can find it in an ordinary hardware store. Spirals for electric stoves are made of nichrome.

Not a single locality can do without a bazaar where you can buy anything. The most important thing is to carefully go around the entire market and you can even ask the sellers. You may also come across such a product made of nichrome.

find an old device somewhere

, for example, a laboratory rheostat. In itself it is of no value, but it has a small amount of nichrome wound on it.

Nichrome wire is a high-quality plastic product due to its remarkable technical characteristics. Buying or getting it in any other way, although difficult, is possible. You just need to take the initiative and try all the above methods.

For this you will need nichrome wire. The resistivity of nichrome wire grade X20N80 is given in the table. For shaped cutting, a thermal cutter made from a piece of nichrome wire is used.

Nichrome wire X20H80 is used to make a spiral when independently rewinding the atomizer. Therefore, to obtain the same value, in the case of thin nichrome wire, fewer turns will need to be made. However, for use at higher power, it is recommended to use thicker nichrome wire or 2 thin threads braided.

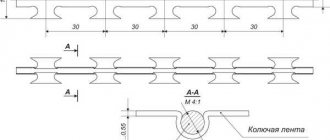

Nichrome wire is used for the manufacture of cutters, jigsaws, soldering irons, machines for cutting foam plastic, polystyrene, etc. Wire is obtained from them by drawing. Nichrome products are used in places that require high-quality metal. The ends of the nichrome wire are attached to springs mounted on M4 screws. The screws themselves are screwed into metal posts pressed into the base of the machine.

Before screwing the screw into the rack, a groove was machined at its head so that the nichrome wire could not move arbitrarily during adjustment, but would occupy the required position. To prevent nichrome wire from sagging due to elongation when heated, it is secured to the screws through springs. After preparing all the fasteners, you can fasten the nichrome wire. Nichrome wire is not much different in appearance from steel wire, but it is made from an alloy of chromium and nickel.

However, unlike steel or copper wire, nichrome wire has a higher resistivity and can withstand heating temperatures up to 1200˚C while maintaining high mechanical strength.

It should be noted that for heating the nichrome wire of a foam cutting machine, a power source of both alternating current and direct current is suitable. Remove the plug from the network and connect the wires coming from the nichrome thread to the “Load” terminals. Insert the power cord plug into the socket and use the phase indicator to check the absence of phase on the nichrome wire. Having dealt with the phase, you can slowly turn the LATR handle to apply voltage to the nichrome wire.

In this circuit, thanks to the isolating step-down transformer, the nichrome spiral is not galvanically connected to the electrical network and is therefore safe for operation. After all, when cutting foam plastic on a device, there is no need to regulate the heating temperature of the nichrome wire. The temperature is selected once when setting up the machine.

Nichrome insulation with silicone multi-core cable

Heat-resistant heating cable in silicone insulation based on X20N80 tape or wire is used in various heating systems and thermal treatment installations.

To insulate nichrome wire or tape, two-layer silicone insulation is mainly used.

The basis of the insulating material is silicone rubber, obtained on the basis of high molecular weight organosilicon compounds. In appearance, the insulation is similar to ordinary rubber, but differs from it in higher technical indicators:

- resistance to high voltages - breakdown voltage is 5,000 Volts;

- resistance to aggressive environments and atmospheric influences;

- fire resistance - the material does not burn and does not emit toxic smoke when burned;

- operating temperatures from -60°С to +180°С;

- increased strength and durability.

Silicone insulation can withstand short-term temperature increases up to 220°C without changing the structure and quality of the coating. It is not destroyed by ultraviolet and radioactive radiation. Does not lose its qualities under the influence of ionizing radiation up to 20 Mrad (20 x 106 kJ/kg).

For the manufacture of heat-resistant heating cables, mainly two-layer silicone insulation is used.

Nichrome in isolation.

Prices at reception points

To form average prices, consider the cost of receiving tungsten scrap at three types of enterprises:

- those that accept scrap with a total weight of several tens of kilograms;

- enterprises purchasing metal from 0.5 kilograms;

- places where you can donate tungsten scrap up to 0.5 kilograms.

Large parties

Mosvtormetal

This Moscow enterprise accepts various types of scrap raw materials, including tungsten. The company’s website contains information that scrap is purchased from 50 kilograms, while the price for one kilogram of pure metal ranges from 900 to 950 rubles, depending on the condition in which the scrap was delivered to the enterprise.

The company also buys a number of tungsten alloys at the following prices:

- VN, residence permit – 550 rubles;

- VD, VND – 450 rubles;

- VMN – 500 rubles.

Tekhnolom

Moskovskaya also accepts almost all types of scrap metal, including purchasing tungsten.

Acceptance is carried out with a weight of 10 kilograms or more, and pick-up of scrap from anywhere in the Moscow region is possible only if the total weight of the scrap exceeds one ton.

The price of recyclable materials containing tungsten per kilogram is 700 rubles, and in large quantities from 100 kg the prices increase. The company also accepts tungsten alloys. The cost of hard alloys VK and TK is 500 rubles.

LLC "Resurs"

Resurs LLC is a Moscow enterprise that accepts tungsten scrap from 10 kg. The company buys scrap according to general rules:

- no pollution,

- impurities in scrap,

- normal radiation background.

Acceptance of alloys is characterized by the following prices:

- TK, VK – 500 rubles per kg;

- P18 – 60 rubles;

- R6M5 – 60 rubles.

From 0.5 kg

Vecomet

Vekomet is a company located in the Moscow region.

She is engaged in buying tungsten weighing from half a kilogram.

At the request of the seller, the company can independently remove recyclable materials and carry out analysis and weighing on site.

Cash payment is carried out after acceptance of the metal at the following prices:

- pure tungsten scrap – from 909 rubles/kg;

- VD, VND – 570 rubles;

- rolled tungsten – up to 2000 rubles.

PG Riten

This Novosibirsk company carries out independent removal of scrap of any weight.

Also, at the request of the seller, he can dismantle and weigh the goods, however, the price will be lower.

The company’s website does not indicate the price of pure tungsten scrap, but the company purchases the following tungsten alloys:

- hard alloys TK and VK – 820r/kg;

- Р6М5 – 118r/kg;

- Р18 – 173r/kg;

- P9, P12 – 75r/kg.

Metallych LLC

Metallych LLC is a Perm enterprise that purchases scrap of various metals, which includes tungsten. The company carries out independent dismantling and removal, and the price for pure tungsten scrap ranges from 900 to 950 rubles per kilogram.

Alloy prices:

- VN, residence permit – 550 rubles/kg;

- VD, VND – 450r/kg;

- VMN – 500 r/kg;

- VK, TK – 800 RUR/kg;

- Р18 – 150 r/kg;

- P9, P12 – 20 r/kg;

- Р6М5 – 100 r/kg.

MDM Vtormetal

The company is located in Moscow and accepts scrap from 0.5 kg with one very important condition: the mass of an individual scrap element must be at least 10g.

The only exceptions may be powder and dust, for which the minimum mass is set at 1.5-3g.

The company does not accept pure tungsten scrap.

Alloy prices:

- VN, residence permit – 700 rubles/kg;

- VD, VND – 600 r/kg;

- VMN – 600 RUR/kg.

High speed:

- Р18 – 180 r/kg;

- Р6М5 – 120 r/kg;

- P9, P12 – 80 r/kg.

LLC "SnabResurs"

SnabResurs LLC purchases tungsten scrap in Moscow at the following prices:

- pure tungsten - 800 rubles/kg;

- VK, TK - 650 rubles/kg;

- P18 - 90 r/kg;

- Р6М5 - 150 rubles/kg.

Up to 0.5 kg

The purchase of tungsten scrap up to 0.5 kg is most often carried out by private resellers. On the Internet you can find many advertisements for the purchase of metal starting from just a few grams, but private traders do not indicate prices. They ask you to call the numbers provided and “make an agreement.”

Many of these businesses operate without a license, so be wary.

You can find out how much tungsten scrap of various types costs per 1 kg from the table:

| Type of tungsten scrap | Pure tungsten | VK, TK | P18 | R6M5 | P9, P12 | VN, residence permit | VD, VND | Tungsten wire |

| Price per kg | 801.5 R/kg | 654r/kg | 130r/kg | 109r/kg | 58r/kg | 600r/kg | 517r/kg | 1100r/kg |

You can learn some more interesting information about this metal from the video:

You can learn about the rules and features of accepting other non-ferrous metals from this article, and read the average prices for non-ferrous metals here.

Properties and grades of tungsten

Tungsten has its own mechanical and physical properties, as well as several types of grades.

Physical properties include:

- The coefficient of thermal linear expansion is 4.32*10 (-6) m/mK.

- Electrical resistance - 5.5 μOhm*cm.

- Thermal conductivity - 129 W/(m*K).

- Specific heat capacity - 0.147 J/(g*K).

- Boiling point - 5900 degrees.

- Melting point - 3380 degrees.

- Density - 19.3 g/cm3.

- Atomic diameter - 0.274 nm.

- Atomic mass - 183.84 g/mol.

- Atomic number - 74.

Mechanical properties:

- Relative elongation - 0%.

- Tensile strength - 800−1100 MPa.

- Poisson's ratio is 0.29.

- Shear modulus - 151.0 GPa.

- Elastic modulus - 415.0 GPa.

This metal is distinguished by its low evaporation rate even at 2 thousand degrees and a very high boiling point - 5900 degrees. Properties that limit the range of use of this material are low oxidation resistance, high brittleness and high density. It looks like steel. Used to produce high strength alloys. It can only be processed after heating. The heating temperature depends on what kind of processing method you are going to carry out.

Tungsten has the following grades:

- MV is an alloy of tungsten and molybdenum. The strength of molybdenum increases while maintaining ductility after firing.

- VRN - tungsten without additives. It contains a high level of impurities.

- VR is an alloy of rhenium and tungsten.

- VL, VI, VT - tungsten with lanthanum, yttrium and thorium oxide additives, respectively. Increase the emissive properties of tungsten.

- VM - tungsten with thorium and silicon-alkaline additives. Increases recrystallization temperature and strength at high temperatures.

- VA - tungsten with aluminum and silica-alkaline additives. Increases the temperature of primary recrystallization, dimensional stability at high temperatures, as well as strength after annealing.

- HF - pure without additives.

How to verify nichrome

You may have a thought while winding up your coil. What if the metal you got is not nichrome at all. How can you distinguish it from other metals? There is one simple and reliable way to determine. Take a magnet and use it to check your thread. For your information, kanthal will immediately be attracted to it, but nichrome will not care about the magnetic field. Good luck with your experiments.

Craftsmen, inventors and innovators have never been translated into our country. Many of these enthusiastic people would like to know where nichrome wire is sold, where to get this material at home? Why is it attractive to modern Kulibins and home-grown homemade ones? Nichrome wire is used for the manufacture of cutters, jigsaws, soldering irons, machines for cutting foam plastic, polystyrene, etc. The material is also widely used in industrial production.

Nichrome 60 vs Nichrome 80

The properties of nichrome are determined by the quantitative ratio of nickel and chromium in the alloy.

The more nickel in the alloy, the higher its maximum operating temperature:

- for nichrome X20N80 this figure is 1200°C;

- for alloy X15N60 - up to 1125°C.

The next important indicator is plasticity. It affects the machinability of the metal.

Nichrome 60 alloy was created by reducing the amount of nickel in the alloy and increasing modifying additives to reduce the cost of heaters.

The use of the more expensive X20N80 alloy is justified when operating devices at extremely high temperatures.

Why is nichrome wire valuable?

Nichrome wire has the following valuable qualities:

Such wire is used in places where the highest quality characteristics, reliability and high strength are required from the metal.

Due to the combination of plasticity with a high yield strength, as well as resistance to strong aggressive substances, nichrome is in great demand

in industrial production. It is he who occupies one of the first places in the modern market of household and industrial electrical equipment.

In addition, nichrome wire is used in a number of industrial sectors that use electric heating furnaces. It is also used in electric ovens

, which are heated to very high temperatures in various thermal apparatus and ovens used for firing and drying. It is also used as a heating and resistor element.

Basically, such a nichrome product is used everywhere

, where resistance to high temperatures, heat and chemicals is required, that is, in aggressive environments.

It is also used in devices that require a high degree of reliability, such as resistors, resistance units and rheostats.

Nichrome wire has found its application not only in industry, but also in everyday life, and is used:

- for machines that cut foam plastic;

- in a device for wood burning;

- in the heating system of car windows and rear-view mirrors;

- in simple household heaters;

- in homemade welding machines.

Resistivity of nichrome and other alloys for heaters

Electrical resistivity determines the ability of a metal to prevent the passage of current. It is calculated as the ratio of the electric field to the current density and is measured in Ohm mm²/m.

Table 2. Resistivity of main alloys suitable for heating elements.

| Alloy | Resistivity | |

| ||

| 80 – Nickel, 20 – Chrome | 1.0803 Ohm mm2/m | |

| 80 – Nickel, 20 – Chrome | 1.18002 Ohm mm2/m | |

| 35 – Nickel, 20 – Chrome, 45 – Iron | 1.01382 Ohm mm2/m | |

| ||

| 73 – Iron, 22 – Chrome, 5 – Aluminum | 1.45425 Ohm mm2/m | |

| 74 – Iron, 22 – Chrome, 4 – Aluminum | 1.35453 Ohm mm2/m | |

| 81 – Iron, 15 – Chrome, 4 – Aluminum | 1.35453 Ohm mm2/m | |

| ||

| 55 – Copper, 45 – Nickel | 0.4986 Ohm mm2/m | |

| 89 – Copper, 11 – Nickel | 0.1495 Ohm mm2/m | |

| 98 – Copper, 2 – Nickel | 0.0498 Ohm mm2/m | |

The main factors in choosing an alloy for the manufacture of heaters are the combination of high electrical resistance and the ability to withstand extremely high temperatures for a long time.

Main sources of scrap

The paradox of this rare metal is that it can be found even in an ordinary residential building.

It is found in incandescent light bulbs and in the windings of electric furnaces. These are the main sources of tungsten for ordinary citizens and individuals.

However, it is very, very difficult to accumulate a sufficient amount to sell this non-ferrous metal from these sources.

Therefore, those who want to make a profit from several dozen light bulbs usually turn to resellers.

Tungsten is also contained in pobedite tips of concrete drills, which are also found in everyday life. It contains more of the main element, but it is not pure metal, but one of its alloys - “pobedit” or VK with cobalt.

Recyclable materials are sold by state and private enterprises that specialize in metal processing. They accept used tools made from high-speed steels:

- incisors;

- cutters;

- borax;

- cutting discs and so on.

Do not forget that tungsten is common in the form of a finished product:

- wires;

- rods;

- circles;

- headquarters.

And also in the form of production waste:

- various scraps;

- shavings;

- dust;

- powder.

What is a nichrome cutter?

Greetings to all subscribers and guests of the Podelkin channel. Today I want to introduce you to a homemade and very useful tool called a nichrome cutter.

A nichrome cutter is a device for cutting shapes from wood (plywood), which consists of two main elements: a power source (12V) and a cutting part (nichrome wire).

This tool is easy to make yourself and has a number of advantages over a conventional hand jigsaw. Unlike a manual jigsaw, a nichrome cutter does not have a metal arc-shaped frame that limits the length of the cut (with a manual jigsaw it is impossible to cut at a great distance from the edges of the part), so it can be used to make very voluminous products. A nichrome cutter has a much higher cutting speed, during which you will make virtually no effort. This device will not only simplify your work, but also save your time. And the last thing is the price. To assemble a nichrome cutter, you will spend approximately the same amount of money as a manual jigsaw costs.

Scope of application in industry and at home

Nichrome products are used in places that require high-quality metal. Particularly in demand in industrial production.

In industrial production

Metal products occupy one of the first places in the market of industrial and household electrical equipment. It has found wide application in industrial sectors using electric heating furnaces, roasting and drying furnaces, furnaces heated to high temperatures, and devices with thermal effects. It is used in welding machines, household heaters and heating systems for car windows and rear-view mirrors, in resistors, resistance units and rheostats as a heating or resistor element. As noted above, the material is widely used among home craftsmen.

In the household

In the domestic sphere it is used for cutting foam and polystyrene. Cutting these materials at home is quite problematic. There are several ways. Often a knife is used for these purposes, from which the material begins to crumble.

Home craftsmen know how to cut polystyrene foam at home so that it does not crumble. For this you will need nichrome wire. It is needed in order to make a machine whose cutting tool is a heated string. With its help, you can cut foam plastic and make products from it with your own hands.

To cut polystyrene foam at home, you can design a simple machine with a vertical or horizontal arrangement of the cutting tool

How to make a foam cutter with your own hands

Making a machine is not difficult. To do this you will need:

- a step-down transformer;

- lining made of pipe (pipe at least 20 mm thick, foam thickness at least 2 cm);

- springs for string tension;

- metal string.

To make a tabletop you will need a table, a board and a sheet of corrugated sheeting.

The simplest version of a foam cutting machine that you can make yourself

You can make a step-down transformer yourself from transformer iron. You will need to make a rheostat to select the current value. To do this, you can take a spiral from an electric stove, first stretching it into a string. The winding frame is constructed from an asbestos-cement or ceramic pipe 15-20 mm thick and about 80 mm long.

For shaped cutting, a thermal cutter made from a piece of nichrome wire is used. It is secured to a handle made of insulating material. A homemade cutter for foam plastic copes well with the task, including shaped cutting of material. The device allows you to make indentations, cut out cavities, and work with foam plastic the way a sculptor works with clay.

A foam cutter can be compared to a sculptor's tool when working with clay.

With the help of homemade devices in which nichrome wire is used, you can not only cut foam plastic, but also burn wood. It can also be used in homemade household heaters, welding machines, and heating systems for car windows and rear-view mirrors.

Selection of parts

The first step is to find a network step-down transformer with a power of 60-100 Watts; the output of the transformer will be an alternating voltage of 12V, safe for humans, with a current of 5-10A sufficient to heat the filament.

For assembly you will need the following parts:

- Step-down network transformer 12V;

- Two switches for a current of at least 10A;

- Nichrome wire.

We select the length of the nichrome thread as follows: cut and select a piece of nichrome wire so that it glows red (thread A), then connect another piece of nichrome wire (thread B) to the same thread in series and select its length so that thread A heats up half or to the desired value.

Let’s assume that the working length of the thread for cutting is 13 cm, we twist the rest of thread A into a spiral, and we also twist the entire thread B into a spiral.

We fasten the twisted spirals in a convenient place on the cutter so that they do not interfere, and we cut only with a stretched piece of thread 13 cm long.

Let's summarize how to profitably sell tungsten

In order to get as much profit as possible from the delivery of tungsten scrap, you need to prepare the goods for delivery in advance.

The highest price can be obtained if:

- clean the raw materials (make sure that there are no other metals, earth or dirt in it);

- sort recyclables by type and material;

- compress the product using any suitable press;

- collect as much metal as possible, because in most companies the fundamental factor in increasing the price is the amount of scrap delivered;

- consider at least five large companies involved in scrap collection and choose the most favorable price.

Thus, by donating tungsten, you not only receive significant benefits, but also help the industry, which is experiencing a shortage of this rare but necessary metal.

conclusions

The collection of scrap non-ferrous metals is gaining popularity, because metal recyclables have been valued at all times. According to people who have been collecting for several years, such an activity is addictive and captivating, and digging for non-ferrous metals becomes an original hobby for many.

In order to maximize the benefits from digging and delivering scrap non-ferrous metals, you need appropriate equipment (metal detector, magnet) and knowledge of the properties of non-ferrous metal, plus the desire and desire to earn money.

Learn more about how to search for non-ferrous metals in this video: