Many car enthusiasts like to carry out tuning of various kinds. Recently, the installation of a crankcase gas oil separator has become widespread. It is especially popular among fans of fast driving. In stores, they will ask for 2000 rubles for such a device, if not more. However, why pay if you can make such a necessary device yourself?! But first you need to figure out why it is needed at all. Maybe the engine is fine without it? But there are some peculiarities that this article is devoted to.

Purpose of the crankcase ventilation system (CVG)

Crankcase ventilation is necessary to continuously remove the toxic mixture of unburned hydrocarbons, exhaust gases and oil mist. Before the tightening of environmental standards, the breather, a piece of hose connecting the engine block and the atmosphere, did an excellent job of this task.

In modern realities, crankcase ventilation is a closed system. Exhaust gases are fed into the intake manifold, where they are mixed with a fresh charge and safely burned in the engine.

Is it possible to install an additional oil separating filter?

As you can see, this is a useful thing, especially when there is no time or desire to clean the throttle, change spark plugs and clean the intake manifold. However, not many automakers install such filters on their cars.

photo: www.drive2.ru

If there is no oil trap, you can install it additionally by first purchasing a ready-made one in the store (experienced users claim that they are ineffective) or make it yourself.

For an example of how this can be done, see here:

Video taken from the YouTube channel “Denis MECHANIC”

And more on the topic:

Video taken from the YouTube channel “Yuri K”

Operating principle of the oil trap

An oil separator is a device that is capable of separating and trapping oil particles in a gas or liquid stream. In a car, it is installed directly in the internal combustion engine to prevent engine oil from entering the intake manifold.

The device is an elongated flask, which is divided into 2 parts by a cone. It is along the walls of the cone that oil particles flow down. This occurs due to centrifugal force, which, from the flow of air mixture entering the apparatus through its upper part, carries oil particles into a separate cavity for collection through the lower part of the inertial cyclone filter.

Thread separation

The standard crankcase ventilation system has two pipes for supplying gases to the intake tract. This is due to the difference in pressure in front of the throttle and in the space behind the throttle. In minimum load mode, when the throttle valve is barely open, the flow area is minimal, so the greatest vacuum is in the throttle space. In heavy and full load modes, an open throttle valve does not create significant resistance to the flow of air, so the vacuum in the intake tract is minimal. Separation of entry points allows flexible dosing of crankcase gases.

PCV valve

The crankcase ventilation system valve is necessary to limit the vacuum. High vacuum, as well as excess pressure, can damage the seals. Therefore, the PCV valve allows crankcase gases to enter as the vacuum in the intake manifold drops.

In normal condition, the valve is held open by a return spring. When the engine is idling, the vacuum overcomes the spring force and closes the channel connecting the engine crankcase and the intake manifold. Accordingly, as the throttle valve opens and the vacuum decreases, the return spring slightly opens the channel for gas access.

On many VAG vehicles with a two-stage filtration system, the PCV valve's job is to interrupt the flow from the coarse stage to the fine stage.

A wise decision

The increased pressure that is constantly applied to the oil worsens the properties of the lubricant over time. Without a crankcase gas oil separator on the Polo, for example, the lubricant itself ages faster and its service life is significantly reduced, which entails frequent replacement of consumables. To avoid unnecessary pressure in the engine crankcase, a special exhaust gas ventilation system is provided. However, the standard separator, which is installed by many manufacturers on cars, does not completely clean the crankcase gases from oil particles. Therefore, some car enthusiasts install an additional device.

Most drivers of domestic and foreign cars with impressive mileage have often encountered sticky oil deposits on various parts of the engine. Often this is:

- intake tract;

- throttle valve;

- intake manifold;

- idle control valve;

- air filter - oil can get here through the mass air flow sensor (MAF).

By interacting with the mass air flow sensor, the oil can cause its failure, and replacing it costs 2500-3000 rubles. Isn't this a reason to take care of an additional measure in the form of a crankcase oil separator on a Citroen-Picasso or any other car?

Why is the PCV valve important?

Faulty PCVs can cause engine oil contamination, sludge buildup, oil leaks, high fuel consumption, and other engine damage problems, depending on the type of fault.

While some of these problems can be caught before they escalate with simple checks, failure of the PCV valve or related components often results in costly repairs. This is because most car owners do not include the PCV system in their maintenance routines. Even though some car manufacturers suggest replacing this part regularly, car owners still forget to replace it. Additionally, not all manufacturers emphasize the importance of regular system checks.

Device installation

The crankcase gas oil separator is installed depending on the engine type:

- carburetor;

- injector.

In carburetor engines, the device is mounted directly in front of the air filter, which regulates crankcase gases. If it is an injector, the device is connected to the inlet pipe located close to the throttle valve and cylinder block cover.

The system is now ready for use. However, for its high-quality and productive functioning, installation alone is not enough; it is necessary to inspect the device from time to time and carry out regular maintenance. To do this, the device must be disconnected from the system and rinsed thoroughly, completely getting rid of any remaining accumulated oil. In this case, treatment with a solvent will not interfere.

After the maintenance procedure, the crankcase gas oil separator device is put into place and can be used for further operation. There is no need for frequent inspection and maintenance; the frequency can be at least once every two months.

As is already known, oil leakage not only has a negative impact on the efficiency of the engine, but also significantly reduces its service life. A homemade device allows you to eliminate this problem to some extent. However, the lubricant itself also plays a key role. Therefore, you should not save on purchases; it is better to purchase only high-quality products. No engine will put up with cheap oils whose quality is questionable.

Symptoms of a Stuck PCV

- Engine misfires at idle

- Lean air-fuel mixture

- Presence of engine oil in PCV valve or hose

- Increased oil consumption

- Hard engine start

- Rough, unstable engine operation at idle

Additionally, a stuck PCV valve can cause a check engine light due to increased air flow. And the diagnostic computer may mistakenly show this error due to the mass air flow sensor or oxygen sensor, making it difficult for you to identify the real source of the problem.

Main characteristics

| Make: BMW | Gearbox: automatic / manual |

| Model: X1 | Body: sedan, coupe, station wagon |

| Year of issue: 2009 | Power: petrol/diesel |

| Engine capacity: 1985 cm³ | Drive: rear |

–> Good afternoon, Friends!

I would like to share with you my experience in making an oil trap and crankcase gas filter with my own hands, using the example of a VAZ 21102 produced in 2000.

First, a small digression, for those who do not know why this modification is needed.

Many car owners, both domestic and foreign cars with high mileage, have more than once paid attention to oil deposits in the form of a plasticine-sticky mass (which appears when crankcase gases with droplets of oil escape, due to wear of the oil scraper rings, from the “breather”) in the intake path, as well as on the throttle valve, intake manifold, idle air valve, oil also flows into the air filter through the mass air flow sensor (MAF), which can lead to failure of the mass air flow sensor (replacement cost is about 2500-3000 rubles) . And so, if you are tired of suffering from idle problems and constantly carrying out preventive work on cleaning the intake manifold, throttle assembly and changing various sensors, which, firstly, not everyone can do due to lack of knowledge, and secondly, it is necessary a lot of time, tools and of course money

In general, to avoid all of the above, you can install a crankcase gas filter or an oil trap, which can also be bought at a tuning store at a fairly decent price, or you can make it yourself. We will dwell on the latter, that is, the manufacture of an oil trap (crankcase gas oil trap), in detail.

So, to make a crankcase gas filter we will need:

– a hose with a diameter approximately similar to the hose of the interior heating system and a length of about 25-30 centimeters;

– fine fuel filter without settling tank for carburetor cars,

– plastic clamp for the filter.

First, we disconnect the hose from the valve cover and from the intake tract, you need to make any plug for the hole remaining in the intake tract (I took a technological plug from the new VUT), then we take a hose of the required length (depending on the location of the filter), I took about 30 centimeters, so that the filter is at the level of the air filter housing, we put it on the valve cover fitting and fix it with a clamp, then from the fine fuel filter housing, you need to take out the filter element and put it on the hose, securing it with a plastic clamp.

Serious damage to the engine

Burnt gases have a negative impact on the oil and reduce engine efficiency. In fact, crankcase gases are unburnt fuel residues and contain many harmful impurities that have a detrimental effect on the environment. The presence of water evaporation in gases leads to the formation of an emulsion, due to which foam is observed in the oil. Because of it, the rubbing elements do not receive a sufficient amount of lubrication, due to which they wear out faster and fail. And the vapors themselves that fall on the oil dilute it. Various impurities are formed, which have the most destructive effect, reducing the durability of almost all parts with which the oil comes into contact. As a result, the engine life is reduced several times.

What might you need?

There is no need to immediately run to the store in search of a miracle device, because you can make it yourself, unless you buy the necessary “ingredients”. So, for home production of a crankcase gas oil separator on a VAZ-2109 (for example), you cannot do without:

- repair coupling;

- plugs for the socket (2 pieces);

- plastic pipes (also 2 pieces);

- metal sponge.

A repair coupling is sold at any hardware store and is used when carrying out sewer work. It is a plastic cylinder, which at both ends has a small thickening on the outside with a rubber seal. The remaining components can also be purchased both at construction sites and in stores selling household goods. As for the cost, it is quite affordable and affordable for any family budget. The metal sponge will serve as the main element of the entire system.

What problems may arise

- Gases mix with oil. It changes its physical properties. This will negatively affect the life of the motor;

- Excessive pressure is created inside the engine. This leads to “squeezing out” of gaskets and seals. Where there are weak spots in the seals, there will be oil leaks and oil fogging.

Often on older cars you can notice leaks through the crankshaft oil seal and valve cover gasket. In worst cases, pressure raises the dipstick.

Therefore, we must remove these gases from the crankcase. If your stomach is bloated, you feel like you're going to burst. So is the motor. He needs to “fart his way through”, excuse the expression. If it doesn’t do this, then you will spend money on repairs and constantly adding oil.

Assembly technology

This process is not particularly difficult. First of all, you need to install a plug on one side of the coupling. You will get something resembling a very ordinary glass. For greater reliability, it is recommended to seal the plug with sealant - no one will remove it in the future.

We place a metal sponge on the bottom of the coupling, without completely filling the cylinder. We drill two holes in the top plug - the diameter is the same as that of the prepared pipes. We process their edges with silicone grease, and then install them in the holes so that when viewed from the inside, one of them is approximately 1 cm shorter than the second. The longer pipe will be used for inlet.

We seal the top cover with a rubber gasket. The assembly of the gas recovery device is complete.

If desired, you can paint the resulting unit and, after waiting for it to dry completely, proceed to installation.

How to make it yourself

There are many oil traps available on the market today. However, most of them are disposable and expensive. Therefore, many car owners prefer homemade devices that can be cleaned and used for many years.

To make a filter with your own hands you need:

- Take a container. You can use a metal power steering reservoir from Volga as it.

- Place several metal sponges for washing dishes in an empty tank. They should take up the space previously occupied by the filter and springs.

- Cover the container with a built-in mesh and casing.

- Connect the resulting device with hoses to the system on both sides.

A homemade oil catcher will protect turbines, spark plugs and other important car parts from soot.

To work you will need:

- Sealant;

- Transition coupling ∅110 (plumbing) and two plugs for it;

- Copper fitting and adapter 2 pcs;

- Gasket for fitting, 2 pcs;

- Nut for adapter, 2 pcs;

- Coolant drain tap, if you are going to make it possible to drain the oil from the oil trap;

- A piece of hose;

- Several metal “hedgehogs” for washing dishes.

Cheap and cheerful, but functional

Many drivers who have already managed to make a crankcase oil separator on their own are pleasantly surprised by the price. In some cases it is practically zero. Perhaps craftsmen make do with improvised means that they find in their own garage. But even if nothing suitable is available, the price of the crankcase gas oil separator is low, since all the parts from the instructions discussed above are cheap.

On the Internet you can find many ways to make a homemade device, for which different materials are used. However, everything is done according to the scheme described above. Differences may relate to the use of additional elements or the replacement of plastic pipes with metal fittings that are screwed into the oil separator cover.

At the same time, there is a positive trend in engine performance. Oil no longer accumulates, which means you can drive for a long time without problems. However, do not forget to look under the hood of the car and check the condition of the device.

How to make an oil trap with your own hands - step-by-step instructions

1. First, you need to unsolder two holes in one plug, after which you need to screw the corresponding adapters into them. To be safe, we seal everything with sealant.

2. Step two - screw the fittings into them, do not forget about the seals.

3. A hose is installed on the back of the adapter; it can be attached to glue. The length of the hose is calculated based on the fact that it should not reach the opposite plug by approximately 10 mm.

4. Next, we assemble the plug with the coupling and place metal jaws in it.

5. In the other cover we install the previously prepared faucet. This modification will allow you to drain the “kaka” without disassembling the oil trap.

6. At the end we collect everything.

Assembly process

There is no particular difficulty in assembly. The first step is to put a plug on one end of the coupling. The result will be something like a glass, but not for tea drinking. During operation of the most effective design of the crankcase gas oil separator, the plug will not have to be removed, and therefore for better reliability it is worth sealing it with a sealant. The next step is to place the metal sponge on the bottom of the cylinder. Just don't fill it out completely. In the upper part of the second plug, you need to drill two holes for the prepared plastic pipes. The edges of the tubes should be treated with silicone grease and installed in the prepared holes.

Looking at the inside of the plug, one of the pipes should be 1 centimeter shorter than the other. The longer one will be the intake one. Now all that remains is to fix the resulting cover in the rubber gasket. That's all - the homemade automotive gadget for catching crankcase gases is ready. If the owner has a delicate taste, then the product can be painted in the desired color and then allowed to dry thoroughly. Only after this can you proceed to further installation.

Finalization of the finished device

Not every car enthusiast wants to assemble an oil filter from scratch, or pay a large sum of money for a quality device.

In such cases, you can take the easier route and simply modify a ready-made, but budget-friendly oil catcher. To do this, just put on the tube for the inlet hose, disassemble the device and fill it with metal brushes. In this case, the soot will settle on them, which will allow you to use the filter several times, since replacing the brushes with new ones is quite simple.

Why you should never fill the filter with oil before installation Most car enthusiasts install the filter by first filling it with oil. This can be explained by the fact that...

The oil catcher not only collects oil from crankcase gases, but also allows it to be reused, which has a beneficial effect on the condition of the internal combustion engine and the environment. However, built-in devices for the most part cannot be cleaned and quickly become dirty. Therefore, almost every car owner knows that a production inertia filter does not bring any benefit and must be replaced after 500 thousand km.

Manufacturing process

- We make a hole in the plug for a plastic pipe or fitting. We fix it on the plug and seal it. This will be the filter outlet.

- At the end of the sewer coupling, closer to the edge, a hole is made for the second pipe. We fix it on the coupling and seal it. This will be the inlet pipe from the crankcase.

- We stuff metal sponges inside the coupling as a filter element. They will trap dirt and oil capillaries. You should not tightly pack the jaws inside the coupling, as this will complicate the passage of air.

- We insert the plugs from both ends into the coupling; the joint can be additionally sealed.

How to check?

The first method is simple

– visual. If there are oil leaks or fogging at the oil seals, it’s time to check the crankcase ventilation system.

Second way

. Open the oil filler cap. We start the engine and place our palm on it. If you feel increased pressure with your hand, the system malfunctions. In sad cases, you can observe bluish smoke from the neck. If the ventilation valve is stuck in the open position, a hissing sound is heard or the palm is sucked in, that is, air is sucked through it into the engine crankcase. The same effect can be observed if you pull out the oil level dipstick.

Oil in the air filter VAZ 2112

In normal condition, the air filter should remain dry after any period of use of the machine. If, upon opening the lid, you see oil stains on the filter itself, in the groove of the housing or in the crankcase, then urgent action must be taken.

There are several reasons for the appearance of oil:

- poor compression;

- use of additives;

- high oil level;

- wear of oil seals;

- burnt and sunken oil scraper rings;

- poor quality repairs at service stations;

- crankcase ventilation failure;

- valve adjustment is impaired;

- oil pump is faulty;

- clogging of the tubes from the upper valve to the injector;

- absence and malfunction of the oil trap in the corrugation.

Considering that the Zhiguli hatchback models differ only in the number of valves and the height of the head, oil accumulates in the air filter of the VAZ 21124 for the same reasons as in the base version of the car.

Alternative solutions for crankcase gas filter

There are several options. The first is to simply bring the hose with crankcase gases outside, but here you will need to install a filter so that when air is drawn in from the external environment, dust does not get into the crankcase. The hose going to the intake manifold inlet will need to be plugged in this case.

The second option is to use a filter, which should be installed between the crankcase pipe and the intake pipe. This filter is used on some machines as standard, but not on all.

(standard oil trap with Ford Focus 2)

Apparently the ubiquitous savings are making themselves felt. And if this is so, then you have the opportunity to improve your car a little. By limiting the entry of crankcase gases with oil vapor into the throttle assembly, without associated cleaning.

Relevance

Why do you need to install such a clever device? Due to high crankshaft speeds, oil flies through the crankcase ventilation breather and can end up on the carburetor assembly, and in the case of injection engines, on the throttle unit. And to prevent this from happening, just such a device is installed. Moreover, it is advisable to install it not only for those drivers who do not mind pressing the accelerator pedal to the floor. Those owners who have been using their car for quite a long time should also think about it. After all, during this period, the rings have most likely already worn out and do not provide proper sealing of the combustion chamber.

What is the device and what is it used for?

Water separators differ in their design and operating principle. The cost of the factory model is considerable, it depends on the power of the device and its performance. There are also several homemade schemes that will help you make a reliable and effective dehumidifier at home.

To remove moisture from the compressor, you can use low temperature, centrifugal force or special filters. The main task is to remove excess moisture before the air mixture enters the compressor. To create such a device, it is necessary to strictly follow the instructions of experienced mechanics and assemble the parts in accordance with the instructions.

Advantages and importance of using the device

Using a moisture separator when painting a car with a compressor unit significantly increases the service life of the coating and protects the body from corrosion. The air must be dry - this is achieved through the use of refrigeration equipment, centrifugal force or silica gel. You can assemble a homemade device from an old cylinder, fire extinguisher, oil or water filter.

Some compressor units supply high pressure air and require factory filters and dehumidifiers. Before connecting the dehumidifier, carefully read the manufacturer's instructions and make sure that all requirements for the air mixture will be met.

In order for the compressor unit to apply a layer of paint more efficiently, experts recommend supplying dry air into it. You can remove excess moisture using homemade moisture separators. They will cost less than factory ones and, if manufactured well, will work reliably and efficiently for a long time.

Cyclone oil separators (oil separators)

To get rid of the shortcomings of synthetic fiber filter fabric, cyclonic oil separators .

Rice. Operating principle of the engine crankcase ventilation system with a cyclone oil separator: 1 – cyclone oil separator; 2 – pressure regulation valve; 3 – charge air cooler; 4 – turbocharger; 5 – gases breaking through the piston rings

Crankcase gases are supplied through a channel inside the engine into a cyclone oil separator. The cyclone oil separator causes the air to rotate. Due to the resulting centrifugal force, the oil mist hits the wall of the oil separator. Drops of oil form there, which flow through a channel in the crankcase into the oil pan. The air, cleared of oil mist, is supplied to the air intake duct through the pressure control valve.

We recommend: Tire load index - meaning of symbols

The cyclone oil separator is equipped with a special valve that limits the vacuum in the engine crankcase, since a strong vacuum can damage the engine oil seals and other rubber seals.

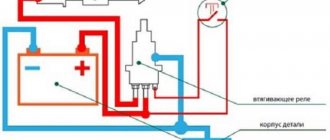

Rice. Diagram of operation of the cyclone oil separator pressure control valve: 1 – crankcase gas supply pipeline; 2 – air intake pipeline; 3 – membrane; 4 – compression spring; a – open position of the valve; b – valve closed position

The pressure control valve is located in the cover of the cyclone oil separator. It consists of a diaphragm and a compression spring and regulates the pressure when air is removed from the crankcase. The pressure control valve closes when there is a strong vacuum in the intake channel. When there is a slight vacuum in the intake channel, it opens by the force of a compression spring.

Oil separator operation

The oil separator, which is an important element of the crankcase gas recirculation system, can operate according to one of two basic principles:

- labyrinthine;

- cyclical.

Using the labyrinth method, the speed of crankcase gases decreases. Due to this, larger drops of oil remain on the walls of the device, and then fall back into the engine crankcase.

Passing through the cyclic oil separator, the gases begin to rotate. Thanks to the centrifugal force generated in the device, oil drops settle on the walls of the oil trap, after which they flow by gravity into the crankcase. And to eliminate gas turbulence, a labyrinth crankcase oil separator is used, in which the oil becomes completely separable from the gases.

Signs of malfunction

- Excessive oil fogging in places of rubber seals. It is pointless to change the cylinder head gasket, pan or oil seals without eliminating the cause of the increased pressure of crankcase gases. The reason may be either insufficient crankcase ventilation performance or critical wear of the cylinder-piston group (hereinafter referred to as the CPG). In the latter case, more crankcase gases leak into the pan than the crankcase ventilation system can pass through. On cars with a synthetic filter element, we first recommend checking the condition of the filter.

- Excessive oil consumption. Increased pressure in the crankcase prevents the oil scraper rings from working effectively, causing oil to burn in the cylinders.

- Floating idle speed. The reason is a leak in the system. Cracks in hoses, PCV valve body, loose clamps - all these factors lead to the leakage of unaccounted air.

- Persistent smell of exhaust gases when driving at low speeds and while parked with the engine running. The closed crankcase ventilation system is leaky in the section up to the VCV valve, which is why gases break into the engine compartment, from where they are drawn inside the car by the cabin fan.

- A large amount of oil in the intake manifold, pipes and even on the air filter. The reason is a faulty oil trap.

Main characteristics

| Make: BMW | Gearbox: automatic / manual |

| Model: X1 | Body: sedan, coupe, station wagon |

| Year of issue: 2009 | Power: petrol/diesel |

| Engine capacity: 1985 cm³ | Drive: rear |

–> Good afternoon, Friends!

I would like to share with you my experience in making an oil trap and crankcase gas filter with my own hands, using the example of a VAZ 21102 produced in 2000.

First, a small digression, for those who do not know why this modification is needed.

Many car owners, both domestic and foreign cars with high mileage, have more than once paid attention to oil deposits in the form of a plasticine-sticky mass (which appears when crankcase gases with droplets of oil escape, due to wear of the oil scraper rings, from the “breather”) in the intake path, as well as on the throttle valve, intake manifold, idle air valve, oil also flows into the air filter through the mass air flow sensor (MAF), which can lead to failure of the mass air flow sensor (replacement cost is about 2500-3000 rubles) . And so, if you are tired of suffering from idle problems and constantly carrying out preventive work on cleaning the intake manifold, throttle assembly and changing various sensors, which, firstly, not everyone can do due to lack of knowledge, and secondly, it is necessary a lot of time, tools and of course money

In general, to avoid all of the above, you can install a crankcase gas filter or an oil trap, which can also be bought at a tuning store at a fairly decent price, or you can make it yourself. We will dwell on the latter, that is, the manufacture of an oil trap (crankcase gas oil trap), in detail.

So, to make a crankcase gas filter we will need:

– a hose with a diameter approximately similar to the hose of the interior heating system and a length of about 25-30 centimeters;

– fine fuel filter without settling tank for carburetor cars,

– plastic clamp for the filter.

First, we disconnect the hose from the valve cover and from the intake tract, you need to make any plug for the hole remaining in the intake tract (I took a technological plug from the new VUT), then we take a hose of the required length (depending on the location of the filter), I took about 30 centimeters, so that the filter is at the level of the air filter housing, we put it on the valve cover fitting and fix it with a clamp, then from the fine fuel filter housing, you need to take out the filter element and put it on the hose, securing it with a plastic clamp.

Now, when crankcase gases escape, the oil will remain inside the filter.

Consequences of faulty crankcase ventilation

Consequences of high pressure in the crankcase:

- Damage to the rubber seals of the crankshaft and camshaft. The engine will lose oil through squeezed out oil seals. If a sharp decrease in level is not noticed in time, oil starvation can lead to wear of the rubbing pairs and rotation of the liners.

- Turbine failure. After lubricating and cooling the turbocharger parts, the oil should drain by gravity into the pan. If there is a backlash of gases in the crankcase space (a kind of plug), the volume of engine oil pumped through the turbine will sharply decrease. Due to deterioration of heat dissipation, the oil will begin to coke inside the channels and on hot rubbing vapors. The consequence is scuffing on the liners and turbine shaft, which is equivalent to a deep restoration or replacement of the cartridge/turbocharger assembly.

- Squeezing out the dipstick and splashing oil into the engine compartment. In some cases, the dipstick flies out with such force that it leaves a noticeable dent in the hood. In this case, you won’t be able to get rid of it just by washing the engine compartment.

Diagnostic methods

The easiest way to check the PCV valve is by yourself. To do this, just blow into the valve from the side of the valve cover. If the air pressure from the reverse side is weak or does not come out at all, the valve is not working properly. Cleaning the crankcase ventilation system with carburetor cleaner should correct the situation. If the valve is blown in both directions, most likely it is stuck in a half-open state, or the rubber membrane is torn.

The degree of contamination and the overall efficiency of the crankcase ventilation is measured in two main ways:

- The crankcase gas pressure is measured at different engine operating modes.

- The volume of gases that the system can pass through itself is measured.

In order not to encounter the consequences of malfunctions of the VKG system, it is worth periodically changing the PCV valve, filter element, and cleaning the centrifugal/labyrinth oil trap.

A little theory

First, a little theoretical part. In any car engine, even a modern model, each system performs its duties, and there is nothing superfluous. Here we can draw a parallel with a person whose all organs are important and necessary. The main thing is to maintain a healthy lifestyle. Any car in this regard also needs regular maintenance.

The functions of all engine components and assemblies are constantly dependent on each other. And if a part breaks down in any system, the efficiency of the power plant is significantly reduced. The same applies to the crankcase ventilation system, in which a crankcase oil separator is simply necessary.

How to repair

In old domestic cars, the factory installed a so-called “breather” to solve the problem. It was direct-flow, constant action. You just had to monitor its frequency. Periodically disassemble the structure and wash it from oil deposits.

Engine crankcase ventilation system on domestic cars with breather

Modern cars have not come far in terms of system maintenance. It is necessary to periodically check its operation as described above. In case of problems or failures, we clean all elements. They are, in most cases, removable, can be washed with gasoline, dried and reinstalled.

The crankcase ventilation valve on many models is repairable. Let's take it apart and check why it jams. If it is “overgrown” with oil deposits, then wash it. If there is mechanical damage, we replace it.

Sources

- https://AvtoMotoProf.ru/obsluzhivanie-i-uhod-za-avtomobilem/ventilyatsiya-kartera-dvigatelya/

- https://lada-xray2.ru/sovet/kak-sdelat-masloulovitel

- https://autolirika.ru/teoriya/ventilyaciya-kartera.html

- https://santavod.ru/kak-proverit-klapan-ventilyaczii-karternyh-gazov-pcv/

- https://FB.ru/article/341878/maslootdelitel-karternyih-gazov-svoimi-rukami-opisanie-shema

- https://zen.yandex.ru/media/id/59ab872ae86a9e96d63241ad/ventiliaciia-kartera-dvigatelia—chto-eto-takoe-i-pochemu-ona-tak-vajna-dlia-motora-5e8b1a2482d52277064cd412

- https://www.autoposobie.ru/kak-sdelat-masloulovitel-svoimi-rukami/

- https://avto-idea.ru/remont/kak-sdelat-maslootdelitel-svoimi-rukami-materialy-i/

Operating procedure

You don't need any special tools for assembly. Everything you need is available in every garage. The work is carried out in the following order:

- The tank is disassembled

. Contents are extracted from it. The filter and 2 springs (large and small) can be put aside; they will not be needed; - We insert a tube with a diameter of 14 mm into the body; it should go down to the very bottom. So the gases will pass through the entire jar without exception;

- We take sponges and, after fluffing them, fill the jar with them. After that, we put a washer and a cotter pin, in the end we get this kind of filter;

- We take the mesh that was in the tank and make a hole for the tube. Then we install it in place;

- The next step is optional. You can paint the jar any color (at your discretion). But this will not affect performance;

- While the reservoir is drying out, it makes sense to clean the throttle valve from dirt; for this you can use any available method;

- We install it under the hood. We connect the hose from the breather to the terminal with a long tube, and attach the hose going to the throttle to the main one.