Gas sauna stoves are selected depending on the performance and volume of the steam room.

When the question arises of which stove to use in a bathhouse, they start from the communications that are connected to the site. Access to gas will solve many problems, including installing a gas furnace. Gas furnaces are smaller in size, and their efficiency is higher than that of their hard and liquid fuel counterparts. Not everyone knows how to make a gas burner for a bathhouse with your own hands, without making mistakes that can be life-threatening. Let's look at some of the design features of gas stoves and tell you how to make gas correctly in a bathhouse.

Do-it-yourself gas burner for a bath: photo and diagram

When the question arises of which stove to use in a bathhouse, they start from the communications that are connected to the site. Access to gas will solve many problems, including installing a gas furnace. Gas furnaces are smaller in size, and their efficiency is higher than that of their hard and liquid fuel counterparts. Not everyone knows how to make a gas burner for a bathhouse with your own hands, without making mistakes that can be life-threatening. Let's look at some of the design features of gas stoves and tell you how to make gas correctly in a bathhouse.

Device

In the vast majority of cases, household gas burners for stoves are designed to be connected to an air heating main. Even less frequently, connections to water circuits are provided. In some cases, a system is provided that removes heat to adjacent rooms.

Certain models of burners for stove heating can also be designed to burn solid or diesel fuel. The standard temperature of the system itself is usually 130 degrees.

Do-it-yourself circular gas burner from a piece of profile

A burner device for home or bathhouse consists of:

- valve assembly that regulates the fuel supply;

- metal pipe (usually with a wall width of 0.2 Washing machine and a length of up to 10 Washing machine);

- fuel metering cap;

- control knob or button.

Automatic burners are widely used for the heating system in any room. They are even more convenient than designs that do not have automation equipment. Any model is equipped with automation of a strictly defined standard. There is virtually no comparability between these types. Installation of modern burner technology is painfully simple and does not require a call to specialists, which is also due to the simplicity of the device.

Features of a gas oven

Craftsmen have come up with homemade designs for gas stoves for baths, but without experience, it is difficult to make a gas burner with your own hands. Models from well-known manufacturers meet all fire safety requirements, and you can install them correctly yourself. The main thing is to coordinate the project with the gas and fire authorities of the city.

Types of gas generators

Gas heat generators are divided into types according to their purpose:

Heating generators are used in bath structures. In rare cases, heating systems are additionally used, for example a gas boiler, when it is necessary to provide heating and hot water supply in the bathhouse. It is impossible to heat a bathhouse with their help.

Household appliances include appliances, for example, for cooking. In terms of maintenance, they are simple, so you can often find, for example, a gas stove in the country. But maintaining a high temperature in a room with humidity above normal can only be done using heating systems.

Based on their design features, gas furnaces are divided according to the following criteria:

Methods of heating water.

What material was used for manufacturing.

Take a closer look at some of them.

The material from which the oven is made

A gas generator can be made of metal or made of brick. Each material has its own characteristics.

Only a specialist can build gas stoves from bricks. Moreover, metal elements are still used inside the structure. It is more difficult to heat a brick stove, since it takes a long time to heat up, but it retains heat for up to 48 hours. The design is outwardly little distinguishable from a wood-burning one, but instead of firewood there is a gas burner. And the stones are placed in a special sealed container that will not allow moisture to reach the fire. To do this, the pallet must have sides and a solid bottom.

The advantages include:

You can choose a large-volume heater.

You can use hot water for another 1–2 days after heating.

The heat from a brick structure is more uniform.

You need to start heating the stove 4 – 6 hours before the bath procedures.

Installing a brick stove is expensive.

It is necessary to make a massive foundation for the stove, since the structure is heavy.

Metal gas stoves are light and small. Their walls are made of metal with a thickness of 5 mm. The heater is small and you can warm up the sauna in 2 - 3 hours. Its compactness allows the generator to be used in a bathhouse of any size, starting from 2 x 2 m.

You can assemble a metal gas stove with your own hands; all you need is to have the necessary drawings and some tools and materials:

Gas cylinder. You can buy a new one, but it's cheaper to use a used one. This one is easy to get at scrap metal collection points.

Wheels from a Kamaz truck or a used car. The size depends on how powerful the stove will be.

Metal pipes: diameter 2 and 4 cm. The smaller one is for gas and air supply, the larger one is for the chimney.

Gas burner (atmospheric).

DIY diagram of a gas stove for a bath.

Assembling a gas stove with your own hands is carried out in the following steps:

The top of the cylinder is sawed with a grinder so that the hole is inserted into the wheel rim. The seam is welded using a welding machine. If there is no welding, then you can use bolts.

The next step is preparing a pipe for the air supply. To do this, take a diameter of 2 cm and drill 9 - 11 holes with a diameter of 5 mm in it. A hole with a diameter of 50 mm is also drilled in the lower part of the cylinder. The pipe is inserted into the cylinder so that on one side it sticks out 15 - 20 cm. The seam is welded.

The gas pipe is welded in the same way; you can see it in detail in the figure. An adapter is mounted at the free end for attachment to a gas generator (cylinder, pipe).

A chimney pipe is mounted on top of the cylinder by welding. On the side, as shown in the figure, a hole is cut along the bottom of the door. It is cut out of a piece of steel and welded onto hinges.

Type of fuel

Based on the type of fuel, bathhouse generators are divided into combined and gas-only. The first option is more expensive, but it is more convenient. The sauna can be heated with either gas or wood. This method is convenient because if the gas suddenly runs out, you do not need to stop the procedure, but continue heating with hard fuel.

Gas stoves are cheaper, but you need to take care, for example, of an additional gas cylinder. The use of propane and butane will be more economical if you replace the injector with another one with smaller holes.

Whatever gas stove you choose, you need to properly supply gas to it.

How to calculate the consumption of natural and liquefied gas

The main indicator on which the calculation depends is the area of the room and the power consumption of the equipment. Outdoor temperature readings taken during the coldest time are also taken into account.

The calculated figure is ideally always 35-50% higher than actually consumed, since the air temperature always changes up or down. When choosing ready-made equipment, this fact should be taken into account and instead of, for example, 100 W of energy, you can take 50.

The amount of natural gas is calculated using the formula: L = Q / (qH x 0.92), where:

- L – calculated volume of fuel (1 cubic meter per hour);

- Q – heating power, kW;

- qН – maximum fuel combustion power, for natural gas 10.175 kW/m3;

- 0.92 – efficiency of a gas boiler/furnace.

On average, for heating a room with an area of 100 sq.m. the calculation will look like this: 5 / (10.175 x 0.92) = 0.53 m3 / h, which corresponds to the consumption of natural gas per unit of time (hour).

Based on such indicators, it is possible to determine the nominal gas consumption in any room for a certain period of time. Since the bathhouse is not used daily or around the clock, this consumption will be less.

Bottled (liquefied) gas is more expensive and its consumption will have to be calculated not by liters, like natural gas, but by kilograms. The heat of combustion of gas remains the same - 10.175 kW/m3 = 12.8 kW/kg, heating power - 5. We get: 5 / (12.8 x 0.92) = 0.42 kg/h, which corresponds to 0.78 liters per hour. Considering that 1 liter of bottled gas weighs 540 mg. Based on the approximate number of days and hours of operation of the bath, you can calculate the required volume.

In order to make a stove for a gas bath with your own hands, you need to decide on three main parameters:

- Material;

- What kind of gas burner will it be?

- Placement of the container – built-in or remote tank.

Now about each of them in more detail.

Methods of supplying gas to the stove

There are two ways to gasify a bathhouse:

From the citywide system.

Individually using a balloon.

Gasification from the city system

If a gas pipe runs through the area, then it is more profitable to power the bathhouse from it. Let’s say right away that this is a labor-intensive task and requires knowledge and permissions. The price for the services of specialized companies is high, but once you supply gas to the bathhouse, you won’t have to worry about it for many years. And paying gas bills will be less expensive than purchasing bottled fuel each time.

For urban gasification it is necessary to carry out a number of measures:

Receive and approve a number of documents: gas supply project, agree on technical conditions and draw up an estimate.

Purchase equipment and pipes and carry out installation.

Prepare test and technical documentation and submit the work to the local gas service.

Enter the system, install and register the meter, start it up and receive documents for maintenance and fuel supply.

It’s difficult to do all of the above points on your own; it’s easier to call a specialist. Moreover, the city gas company itself will provide and conduct pipes to the heating device.

Individual gasification

Individual gasification is suitable for areas where there is no city line. A gas cylinder can be purchased at any specialty store. But such gas supply is quite unsafe.

Safety comes first, the cylinder should not be installed in a bathhouse, its place is outside. The place chosen is easily accessible and ventilated, that is, the cylinder cannot be filled with various objects or covered with things. A fire extinguisher is hung nearby or a small box of sand is installed.

What are the features of installing gas equipment in baths?

When supplying gas to the bathhouse, you must not forget about possible leaks. Therefore, there are special requirements for bath equipment:

A special sensor must be installed in the stove, which will prevent the supply of gas if the burner goes out.

Natural gas is supplied through the city main pipe; cylinders are filled with propane and buton at simple gas stations.

When installing gas stoves, it is necessary to comply with all fire safety rules, as when heating with wood or liquid fuel.

In the bathhouse, it is necessary to properly install the exhaust system and chimney.

Service details

Maintenance of a gas burner

Maintenance of gas burners of any homemade version only involves cleaning it. This process must be annual. Doing it yourself is not recommended. After all, you will have to disassemble and reassemble the boiler. As a rule, people turn to service centers for service. Accumulated contaminants are eliminated by air blowing. The air here is compressed.

The pressure to the burners must be adjusted carefully. For example, for some current versions of burners, parameters of 8-10 atm can be detrimental

The need for cleaning the burner can be reduced significantly if a filter is installed on the gas supply pipe. This work is performed by a gas service employee, who should be contacted with a special request.

How to properly install a chimney with a gas generator

For a gas stove and boiler, a chimney is needed in the same way as for wood burning. Carbon monoxide will form in the stove and, in the absence of a chimney and good exhaust hood, will accumulate in the steam room. The main danger is that it has neither color nor smell and it is very easy to get poisoned by it.

Modern gas furnaces are equipped with special sensors that, if the exhaust is poor, are triggered and shut off the gas supply. But in order to save money, they buy the cheapest generators for their dacha or garden plot.

A properly organized chimney should have the following components:

Passage hole in the ceiling.

Flash hole in the roof.

An umbrella that prevents sparks from hitting the roof of the bathhouse.

For a brick oven, you can assemble a gas pipe. But it will be more difficult to care for it, and installation work will not be cheap. It is easier to install a sandwich pipe.

The structure is easy to install; even a beginner with no prior training can handle it. The joints will be located at the outlet of the furnace, at the joints between the ceiling and the roof.

The sandwich pipe design has a heat-insulating lining, but since the temperature in the bathhouse is always high, the roof and ceiling can still burn out. To avoid this, it is necessary to insulate the ceiling and roof from asbestos fiber or metal sheets.

An umbrella is mounted on top of the pipe. You can do it yourself from an old tin can: cut out the bottom and lid, cut the walls in one place to form a rectangle, and roll it into a cone. It will prevent precipitation from getting inside.

With proper installation of the chimney and equipment, gas in the bathhouse will become a convenient and safe fuel. You can make an iron stove with your own hands. But you need to understand that any little thing can lead to dire consequences. If you are not confident in your knowledge, then it is better to seek the help of specialists.

Types of gas burners for sauna stoves

You can install two types of gas burners in the sauna: atmospheric and forced. Atmospheric ones are cheaper and work autonomously without electricity. They are one or more hollow tubes into which gas is supplied under pressure. The air necessary for productive combustion of gas is taken directly from the room in which the stove is installed. It is mixed with gas, then the gas-air mixture is ignited using electric or piezo lighters.

The structure of an atmospheric gas burner

It is in the mechanism of operation that the main drawback of atmospheric models lies - good traction is required, as well as an effective ventilation system that ensures air flow. The dependence of this type of equipment on the state of the atmosphere in the room from which the bathhouse is heated causes a lot of trouble. With each more or less active movement of air, the proportions of the gas-air mixture change, which leads to a change in the amount of heat that is released. In general, such burners do not burn gas completely, and a significant part of it flies into the chimney. A minimum of automation, of course, monitors the presence of air and flame, ensures minimal safety, but it is necessary to monitor the operation of the equipment.

What is also important is that an atmospheric burner cannot be simply placed in a wood-burning sauna stove if this was not provided for during the design. If this is done in stoves with an internal heater, the flame will rest against the stone container. And the gas must burn in the air, without contact with metal. If you put an atmospheric burner in a stove without a heater, the gas burns normally, but only the upper part of the fuel compartment heats up - the flame is directed upward and the lower part remains almost without heating, which reduces the heating rate of the steam room.

One of the gas stoves for a bath - “Taimyr Inox BSE ZK anthracite”

One more point: experts advise installing only gas burners specially designed for them in sauna stoves. They are longer than usual, since they are designed for a remote firebox (when using gas, it is necessary to heat only from the room adjacent to the steam room). One problem: they are several times more expensive than conventional ones used for heating boilers. The price is almost the same as for forced-air burners, and the efficiency is almost two times lower. Therefore, more often they either install devices for heating stoves, or with forced air supply.

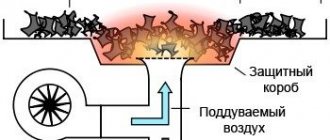

The second type of gas burners for sauna stoves is fan or forced-air, blown (these are all different names for the same design). In them, gas is mixed with air using a fan. Its rotation speed is adjusted during installation. Subsequently, the parameters of the atmosphere in the bathhouse have little effect on the intensity of gas combustion. Structurally, it looks like a block with attached sensors and a controller.

Scheme of operation of a burner with a fan

This type of equipment is on average two times more economical than atmospheric type installations. Their disadvantage is their volatility (they only work when there is a power supply) and their high price - 2-3 times higher than atmospheric ones. Nothing can be done about the price, but you can reduce the dependence on the availability of power if you create a backup source (battery or diesel generator).

The advantage of forced-air gas burners is that they can be installed in wood-burning stoves. You just need to select a model so that the flame does not rest against the back wall of the firebox (use short-flame models). Wood-burning sauna stoves are designed for the combustion temperature of wood - this is about 800°C. When gas burns, the temperature at the top of the flame can reach 1600°C. That is why it is so important not to allow the flame to touch parts of the furnace (in the case of an atmospheric installation the situation is the same). But even in this case, the metal will most likely burn out faster - the temperatures are higher.

The positive aspect of burners with fans is the ability to adjust to any power and switch to liquefied gas (and vice versa).

Pressurized gas burner from Termofor

Automatic protection system

Unburned fuel in a sauna stove sometimes leads to an explosion of the gas-air mixture. Therefore, it is necessary to monitor the flame of a working nozzle for your own safety. This can be done visually or using automation with modern photocells that are sensitive to light emission.

The burner protection system automatically performs the following functions:

- power regulation;

- refueling with fuel and air;

- completeness of gas combustion.

it is necessary to take into account the increase in the size of the modernized structure. Especially when the size of the bath is small. If the size of the device is an important criterion for you, then for compactness all the automation can be placed outside.

You can add automatic templates to work with simple elements. Compact placement will save usable space in a small bathroom

To control the combustion process, a factory automatic installation of the SABK-8-50S type can be used. It provides a high level of security thanks to four levels of protection. The operation of the gas stove equipment with such a device will automatically stop if a dangerous emergency mode occurs.

Permits and requirements for installing gas equipment in a bathhouse

Like any gas equipment, installing burners on a sauna stove requires permission from the gas supply organization. If we talk about the use of atmospheric models, they are very reluctant to issue them. When issuing, the following requirements apply:

- good ventilation system;

- excellent adjustable traction;

- a room with a volume of at least 12 m3;

- ensuring fire safety measures when installing the stove;

- insulation of the chimney as it passes through the ceiling and roof;

- the presence of a spark arrestor at the top of the pipe.

If these requirements are met and you have a Certificate of Compliance and a Rostechnadzor permit, you may be given a permit.

When installing pressurized gas burners, permission is also required, but some requirements for the premises are not imposed (ventilation, draft and volume are unimportant, all others remain in force). When following the installation rules, it is enough to have certificates of conformity and an operating permit from Rostechnidzor (included upon purchase).

Atmospheric gas burner for a bath: appearance

But this is only when using main gas. Liquefied gas must be stored somewhere. According to the requirements of the pozhnadkhor - in a separate room. And this is not a dressing room, canopy, etc. This must be a separate room. In principle, a free-standing metal cabinet or gas holder is suitable for storing liquefied gas cylinders - an underground container measuring 3 cubic meters or more (should be located no closer than 5 meters to the building).

A pipeline is laid from the gas storage site to the furnace. It must be made of non-flammable materials - copper or steel pipes. It must be completely sealed (be sure to check all connections).

Preparation

When sketching drawings of a gas furnace, it is necessary to indicate the exact parameters of each element.

- At the installation site, prepare a level base and cover it with a fire-resistant layer.

- Lay fireclay bricks on top in two rows.

- Walls located less than one meter from the stove and the ceiling must be protected with non-combustible material.

- Most stoves heated by gas have almost the same design, so their assembly and installation is also identical.

It is not difficult to assemble it yourself; the main thing is to properly prepare the room before doing so, following the recommendations of specialists and observing safety rules.

Popular gas burners for saunas

Most often, atmospheric burners of the UGOP type are installed in sauna stoves. They are available in different modifications - from 8 kW to 30 kW. There are models equipped with draft presence sensors, a gas shut-off valve, and flame control. All these options increase the safety of using gas equipment, but at the same time they raise the price and also make repairs more difficult (and expensive). There is also a temperature control function, but it is rarely found. The most popular gas burners are UGOP-16 and 12 - they are suitable for most steam rooms. Their technical characteristics are shown in the table below.

Technical characteristics of UGOP 12, 16, 30

Please note that there are dozens of manufacturers of this equipment, and some parameters may vary. Be sure to read the description and technical specifications of the specific equipment model. The description must indicate that the device can be used in sauna stoves. Before purchasing, be sure to find out the physical parameters of the burner (at least the length of the tubes) and decide whether this modification is suitable.

Burner UGOP-P 16 with micro-flare burners

Trouble-shooting

Having a boiler at home brings many advantages, but it also has a number of disadvantages, and the user does not always know what to do correctly. Boiler faults are common to many types

It is important to promptly determine the cause of these faults before calling emergency services. List of the most common and most likely faults

First of all, if the boiler does not start, you need to check the circuit components:

- network voltage;

- faulty boiler fan switch or motor;

- damaged boiler cables;

- false triggering contacts of automation or commissioning equipment;

- availability of water, whether the gas boiler is powered to the minimum required level specified by the equipment manufacturer.

If the boiler failure is not caused by any of these problems, the following procedure:

Pay attention to the noises made by the boiler, because they are often the first witnesses of destruction. They can also be due to hot water trapped inside the firebox or due to the presence of air in the heating system due to clogged air ducts. Pipe rupture

It usually occurs due to problems with a jammed boiler feed valve, various scale-forming deposits in the boiler, or a malfunction of the condensate drainage systems. Failures due to exceeding the pressure and temperature readings, their corresponding sensors can trigger, for example, due to a broken thermometer or, conversely, which is especially dangerous as a result of real overheating of the boiler. The heating circuits are not working, possibly due to poor quality of feed water and scale formation in the boiler pipes. A problem occurs with the burner (flame breaks, gas accumulation causes detonation and explosion).

For some of these problems, mainly pressure or temperature, the boiler monitor displays an error message, then the system shuts down and automatically restarts. If the problem persists after restarting, it is best to call a professional to troubleshoot the problem. It should be noted, however, that most of these failures can be avoided.

The best prevention is to have your boiler inspected, maintained and cleaned annually, usually by a professional. This will prevent the pipes from clogging and bursting. Prevention is better than restoration, and a simple annual inspection will protect the equipment and the health of users from possible emergency situations.

Making gas burners yourself: to do or not

Doing something with your own hands is a pleasure, and often brings significant savings. But in the case of gas burners, it’s better not to take risks: you can’t be sure that you did everything right, and the cost of a mistake is too high. At the same time, the cost of an atmospheric burner is only about $20. It's not worth it. The only thing you can do is change the parameters of the distribution pipes. This part can be redone without much risk.

One more thing: you will never get permission to use a homemade burner. You can, of course, install equipment without permission, but the fines are too high.

Main stages

It is not difficult to make a burner or mini-burner according to the drawings, as already noted, without spontaneously changing the parameters.

Frame

The body is usually steel. A brass rod with a width of 2 cm is suitable for its manufacture. A divider can be made from the same rod. Then several holes are made that will help create oxygen circulation in the device. Fire, as you know, does not exist without oxygen. There should be 4 such holes: each about 1 mm in diameter. They are made in the burner divider rod. The next step is to press the divider into the device body. The internal flange is installed with a gap of 0.5 cm. This gap will subsequently slow down the powerful flow of gas that approaches the igniter.

Nozzle

This part of the device ensures the supply of fuel from the cylinder to the outside. It is made from a metal rod. At this point, the technician will need a two-millimeter drill to form a blind hole in the nozzle. And for the jumper you will need a four-millimeter drill.

Then a hose from the gearbox, made of fabric or rubber special material, is attached to the end of the tube. Fastening is carried out with a clamp using a regular screwdriver.

Gas burners for sauna stoves

The use of such economical and high-energy fuel as gas as a heat source for heating homes at one time made a real revolution in people's lives. There is no longer a need for labor-intensive preparation of firewood for the winter, and even for the bulky brick stoves themselves, which many got rid of by installing modern gas boilers instead.

At the same time, until recently, bathhouses continued to be built and heated in the old fashioned way - with wood, burning them in brick or metal stoves. In areas where there are no large forests, purchasing firewood for bathing procedures is a big problem, which also entails additional financial costs.

Manufacturers of stove accessories relatively recently offered consumers a worthy alternative to wood-burning and electric stoves and they were right - gas heater stoves and special gas burners for existing wood-burning stoves began to be in high demand among the population.

Advantages of using gas burners for a sauna

Gas burners for factory-made sauna stoves have become a real godsend for people living in steppe and forest-steppe regions. Despite the apparent complexity of converting wood-burning stoves to gas, it is very simple to do; you just need to comply with some safety conditions, which will be discussed a little later.

- it is more convenient to heat with gas than with wood - just open the valve, light the burner and after 60-80 minutes you can use the steam room;

- heating a sauna with gas is 20-30% more economical than using wood, and 100-120% more economical than using electricity;

- gas is an easier fuel to use than firewood - there is no ash after it, no additional space is needed for storing firewood;

- from a fire safety point of view, gas is preferable - the temperature of the exhaust gases is much lower than when heating with wood, so there is no need to additionally insulate the places where the chimney passes through the ceiling and roof.

Gas burners for sauna stoves can be divided into two large groups , which are fundamentally different from each other. Each type of burner has its own advantages and disadvantages, as well as design features that determine their scope of application.

Criterias of choice

When choosing a gas injector, take into account the following points:

- The specifics of the model - power, efficiency level, efficiency, economy, safety;

- Features of operation. When arranging a small bathhouse, preference is most often given to atmospheric models. Powerful automatic burners for blow-type sauna stoves are recommended for use in large rooms.

- Type of heating equipment.

- Features of fuel supply - from the main line, gas tank or cylinder.

- Purpose of the product.

Models of nozzles of certain categories provide for installation in certain types of heat generators. For example, some proposals from domestic manufacturers are designed for use exclusively in boilers with a long channel for the fuel mixture.

Atmospheric burners

These are the cheapest, easiest to manufacture and use burners, with which you can quickly and cost-effectively convert your wood-burning stove to gas (see photo below).

Atmospheric burners do not depend on the availability of electricity; their operation does not stop when the gas pressure in the main line changes. The mixing and combustion of the gas mixture in the firebox occurs due to the pressure difference, i.e. in a natural way, hence the main drawback - the bathhouse will need to be additionally equipped with a high-quality air flow, as well as monitor the condition of the chimney. Otherwise, gas will be consumed inefficiently, and there may also be problems with high-quality, uniform heating of the fuel chamber and, accordingly, the entire steam room.

Installing atmospheric burners in existing wood stoves usually requires additional modifications and improvements, both to the fuel chamber itself and to the dimensions of the burner. The fact is that the fireboxes of a conventional sauna stove have more or less standard sizes; By placing a burner there, we get a situation where the flame from it, when burning, touches the bottom of the heater, or the metal parts of the stove, i.e. the burner is too high. This is unacceptable, since for proper heating of the fuel chamber and the entire furnace, it is necessary that the flame heats the air, and the source must be as close as possible to the bottom and exactly in the center. According to reviews from people who have already converted their wood-burning sauna stoves to gas, this is quite possible, although it requires some effort.

Pressurized burners

Pressurized or blown burners are a higher quality, fully automatic analogue of atmospheric burners, which are sold complete with a fan that forces air into the fuel chamber. When installing a forced-air burner in a wood-burning stove, it is not necessary to place it exactly in the center of the firebox - the fan creates forced circulation of hot air in it, which promotes uniform heating of the chamber.

Such burners, as a rule, have many settings - depending on the average gas pressure, the size of the steam room, the mode of use of the oven, etc. Multi-stage safety systems and high-quality automation make the use of stoves with forced-air burners quite convenient and comfortable, while they can be adjusted to almost any power in a wide range.

Perhaps the only drawback of such burners is their dependence on power supply, so in places where the power supply is unstable, it makes sense to provide alternative power sources. Also, when purchasing a forced-air burner, it is necessary to correlate its length with the depth of the fuel chamber - the flame should not touch its rear wall.

Which one is better to choose?

Any buyer thinking about converting their wood stove to gas fuel must carefully weigh the many parameters and factors that will ultimately influence the choice of a specific solution. Atmospheric burners are cheaper - they can be purchased for as little as $100 and do not rely on electricity - but you will likely need some modifications to the fuel chamber. Blast (pressurized) burners are more advanced, easy to use, but expensive - their average price is about 250-300 dollars. The operation of such burners will require a minimum of attention and personal participation from the bathhouse owner.

However, in any case - if you are just planning to build your own bathhouse and are thinking about purchasing a heater stove - it is better to buy a ready-made gas stove with a built-in burner. The design of such a stove and the configuration of its fuel chamber will be adapted to the type of burner you have chosen, and it will be equipped with all the necessary automation and safety systems. And believe me, after you try a gas oven, you will not regret your choice.