Peculiarities

Non-consumable arc welding typically uses non-consumable consumables to produce high quality welds. However, it is worth considering that technology with coated electrodes has low productivity.

The main advantage of welding in inert gases with a non-consumable electrode is that it is possible to fuse ferrous metal with workpieces that may differ from it in structure, including products made of high-alloy and low-carbon steels. This method can be used for welding metals of dissimilar composition.

Welding, which uses non-consumable electrodes, has several characteristic features. One is to use special elements that cover the electrodes - tungsten, graphite and other types.

The second feature is the use of inert gases. They limit oxygen access to the welding area. They also protect the electrode and weld pool from oxidation.

Advantages and disadvantages

Many novice welders often ask the question - what is arc welding with a non-consumable electrode? This is a convenient technology that allows you to weld different metal workpieces. It is simple to carry out and does not require special skills or experience.

Non-consumable electrodes can be used when welding at home, but they are also often used in industry to fulfill the following conditions:

- They can carry out high-quality welding of thin metal sheets;

- They are excellent for welding work with steels of all classes, non-ferrous metals, as well as their alloys;

- Consumable electrodes make it possible to obtain high-quality welds when welding different types of metals.

In addition, it is worth paying attention to the fact that welding with a non-consumable electrode in an argon environment has some advantages and disadvantages. The positive features of this technology include:

- The arc has high stability, which does not depend in any way on the current polarity;

- It provides the opportunity to obtain welds with a base metal content from 0 to 100%;

- It is possible to regulate the chemical composition and geometry of the connection while changing the feed rate, inclination angle, profile, and brand of filler material.

But do not forget about the negative qualities:

- Has low efficiency indicators for the electricity used;

The use of special devices is required to ensure the initial initiation of the arc; A high cooling rate of the manufactured seams is observed.

What it is?

People started welding metals quite a long time ago. However, old and modern welding are very different. TIG welding is one of the most modern methods of joining metal workpieces. Its main principle is the use of a tungsten electrode introduced into the atmosphere of a chemically inactive gas. A rod of this kind itself is usually classified as a “non-melting” category.

The welder has to sharpen the electrode tool, otherwise it is impossible to achieve a constant stable existence of the electric arc. The official definition of the term TIG is argon arc welding using an infusible electrode tool. Of course, even tungsten can melt - but only at a temperature not lower than 3500 degrees. Sometimes the scheme involves supplying not argon, but another neutral gas. It is worth noting that in technical documentation this method may have other names. For example, in German-language literature the term WIG is used. There is also the name GTA, which does not indicate the chemical properties of the gas used.

Tungsten gas welding came into commercial use in the 1940s. It became a real salvation for the aviation industry, and later for rocketry, where other connection methods were no longer satisfactory. Quite soon, engineers from other industries also appreciated the advantages of TIG. The main characteristics of this method:

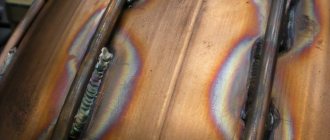

- maximum uniformity of the seam (the appearance of pores and abnormal cavities is excluded);

- reduction of internal mechanical stresses;

- no melting spatter;

- Suitable for virtually any pure metal or alloy;

- no need to further process the workpieces after joining;

- the opportunity to generally master the equipment and working methods in 2-3 sessions;

- low efficiency of work in the open air (without insulation from the wind);

- the need for careful surface preparation;

- complication of work due to the unacceptability of an acute angle of burner placement;

- the need to clean out marks left by the electric arc.

Crucible welding is suitable for working with almost all types of steel. When the electrode tool is located in the collet, it is rigidly fixed in the torch. Excess length is hidden by an additional cap, which eliminates the risk of short circuit. The final part of the burner is a special ceramic nozzle. In its middle there is an electrode surrounded by an insulating gas.

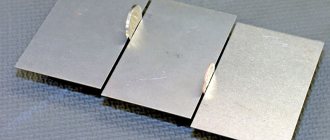

When the plates are separated by a gap, or the goal is to obtain a weld with high resistance to tearing and fracture, filler wire must be used. The cross-section of this wire is determined by the required thickness of the product and specifically the seam. In some cases, a pulsed version of TIG welding is used. This option implies that the current parameters change from maximum to minimum in a relatively short time. Both direct and alternating current can be used for operation. Both the type and thickness of metal blanks are taken into account. It is imperative to understand the differences between TIG and MMA.

The second option - MMA involves the use of a coated electrode. This approach eliminates the use of insulating gas. Melting electrodes leave a reinforced seam. You can work with steel confidently using MMA equipment. The TIG technique allows you to effectively manipulate aluminum and other non-ferrous metals.

Types of electrodes

When carrying out automatic or manual arc welding with a non-consumable electrode, consumables may be used, which may have different compositions. They help to obtain a high-quality and durable connection.

Typically, the following types of non-consumable electrodes are used during the welding process:

- From coal;

- Made from pure graphite;

- Made from tungsten base.

Moreover, each type of electrode may have important features and qualities that must be taken into account when carrying out the welding process.

Coal

Carbon consumables are often used during the air arc welding process. They can also be used to eliminate various defects and damage that exist on the surface of workpieces.

Manual argon arc welding with a non-consumable electrode, which has a carbon coating, can be carried out in modes with currents with voltage values of 500-600 Amperes. It is quite sufficient for connecting massive steel structures and for correcting defects in cast products.

The welding process itself can be carried out using filler wire, which is fed into the area where the weld is formed, and also without it.

Graphite

Pure graphite electrodes are often used when working with non-ferrous metals - aluminum or copper. They can also be used during welding of alloys and these metals. This type of non-melting material, in contrast to coal samples, is economical and beneficial to use in practice.

Graphite rods have some important advantages:

- They are resistant to high temperatures;

- Have good wear resistance;

- They have simple preparation for the work process.

Tungsten

Non-consumable tungsten rods are often used when carrying out the welding process in production and at home. They allow welding with a non-consumable electrode in protective gases of aluminum and other types of metals and alloys.

This consumable is manufactured in the form of a long coated rod with a diameter of 1 to 4 mm. They have a refractory structure. The melting temperature of tungsten-based electrodes is much higher than that of a working arc. This is what makes the rods universal and they can even be used for welding stainless steel, which has complex processing.

Often, during the manufacture of tungsten electrodes, various components are added to their composition - thorium, lanthanum oxide, yttrium. Each rod with the addition of one of these substances is intended for a specific type of welding.

Modes

Welding under argon will be of the highest quality if the optimal mode is correctly selected. The choice of mode is based on the following components:

- properties of welded metals . They determine the choice of current supply direction and polarity. For example, for welding steel structures, direct current of direct polarity is used, for welding aluminum and beryllium - direct current with reverse polarity;

- current strength . It is selected based on the diameter of the electrode that the welder uses; based on the type of metal to be welded, the thickness of the metals and the polarity. For example, for welding titanium, the operating mode is determined by the following parameters, from which it follows that the thicker the metal being joined, the larger the diameter of the tungsten electrodes should be:

| Material thickness | Electrode diameter, mm | Current strength, A |

| from 0.3 to 0.7 | 1,6 | 40 |

| from 0.8 to 1.2 | 1,6 | from 60 to 80 |

| from 1.5 to 2.0 | 2 | from 80 to 120 |

| from 2.5 to 3.5 | 3 | from 150 to 200 |

- welding arc length . The tension depends on it (as noted, the length of the arc directly affects the quality of the seam);

- gas consumption depends on the strength and uniformity of its supply by the burner . Experts recommend avoiding pulsations.

Equipment used

What equipment is used when carrying out manual, automatic and argon-arc welding with a non-consumable electrode? It all depends on the volume of welding work and the size of the assembled structures. Typically, welders use two types of equipment - universal and special.

The first class of devices is often used, because the second is most suitable for large volumes and often mechanized ones. Versatile manual and automated welding machines are easy to use and easy to maintain. For this reason, they are often used for welding in small workshops and large production facilities.

Devices for manual arc welding with a non-consumable electrode in shielding gases have the following components:

- They contain a source of direct or alternating current. Sometimes there are devices that can produce two different types of current;

- Burners of various sizes. They can be used for different current indicators;

- An oscillator that ignites the primary arc;

- Components that provide argon gas supply;

- Elements that control the welding process.

Requirements for argon arc welding with non-consumable electrode

Argon arc welding with a non-consumable electrode is often used for welding workpieces made of different types of metal. With its help you can obtain strong seams with high wear resistance. But in order for the workpieces to melt normally under the influence of a consumable electrode and argon during the welding process, it is imperative to fulfill the important requirements of the argon arc welding process.

The main requirements of argon arc welding include:

- When welding, the non-consumable tungsten rod can penetrate deeply into the gap area between the workpieces. A short arc should be used for the process. This will allow for deep melting, which may affect the quality of the connection. It will turn out small and durable;

- When mechanized argon arc welding with a consumable electrode, the movement of the rod should be carried out along the central part of the gap and in the middle. Even small violations can lead to a decrease in the strength of the connection, they can negatively affect its appearance;

- The filler element must always remain in the area with argon; it must not go beyond the welded zone. This is what protects the weld pool from the negative effects of oxygen and nitrogen that are present in the air. The influence of these substances can lead to increased brittleness of the joint. These requirements also apply to a non-consumable electrode;

- Under no circumstances should you sharply feed the filler wire into the weld pool area. This will cause severe spattering of the metal and, as a result, there will be excessive waste;

- When performing manual welding, the filler material must be fed at an angle. There should be no transverse irregularities;

- At the end of the welding process, you should not break the connection by removing the electrode from the welding area. It is enough to extinguish the arc with a rheostat;

- The supply and shutdown of shielding gas after the end of welding should be carried out within or within 10 seconds. This will protect the uncooled melting metal base, which upon contact with air is quickly covered with an oxide film;

- Before starting automatic argon arc welding with a non-consumable electrode, you need to prepare the workpieces to be joined from a metal base. All joining areas must be cleaned of dirt, rust and other contaminants. For cleaning, it is recommended to use an iron brush or an angle grinder with a metal brush attachment. It is necessary to clean until a metallic shine appears. If there are stains of oil or grease, then additional treatment with a solvent should be carried out;

- It is imperative to compare the modes of argon arc welding with a non-consumable electrode with the thickness of the workpieces being joined. In this case, it is necessary to take into account the diameter of the non-consumable electrode.

How to cook aluminum correctly

The welding process begins with preliminary preparation of the working edges. The main goal is surface cleaning, which is carried out in several stages:

- workpieces must be thoroughly cleaned using chemical compounds;

- after drying, the surface must be degreased with any solvent: acetone, aviation gasoline, white spirit or other liquid;

- if products with a thickness of more than 4 mm are subject to welding, then the edges should be cut;

- the final procedure is to clean the edges from the oxide layer; For this, the following tools are used: a file, sandpaper, a brush with steel bristles.

Results

Welding work with a non-consumable electrode must be carried out correctly; the quality of the resulting welded joint depends on this. First of all, it is worth understanding what gas shielded arc welding with a non-consumable electrode is and why it is carried out.

This method is considered popular among professionals and novice welders. It can be used to weld large structures made of different types of metals. This method is used in domestic and industrial settings.