A well-equipped locksmith workplace by default implies the presence of a workbench. There are many different models and among them you need to choose the most suitable option for your specific conditions. So, how do the models on the market differ and what are their advantages?

An equipped workplace is necessary for everyone who is engaged in metal processing at an amateur level or professionally. Regardless of the frequency of use, the equipment must be functional, reliable and durable. A metalworking workbench best suits the stated requirements. It is indispensable in all cases where metal processing is planned.

A metal workbench is a specialized table designed for performing metal work. An experienced specialist, of course, has a clear idea of what a locksmith’s workbench should ideally be like. Next, we will consider the equipment options produced today, their features and advantages. Let's figure out which of the existing models is more suitable for professional use and which one is more suitable for amateur use.

Do-it-yourself carpentry workbench: how to organize a comfortable workplace

To organize a convenient corner for woodworking, it is not necessary to buy a specialized table. Having basic skills in working with this material, you can make a carpentry workbench with your own hands . The article contains information that will help you easily and quickly cope with this task: optimal dimensions of structures and drawings, useful recommendations and step-by-step technology with a detailed description of all actions, as well as visual photographs. Workbench in the garage: options for workbenches, how to make them yourself (read more) Having minimal skills, you can make a carpentry workbench with your own hands.

Selection criteria: wood or metal

For many car enthusiasts, the garage is a second home, so they approach its arrangement with due attention. A particularly important point is the purchase of a workbench; the selection criterion may be the purpose for which it is intended. In most cases, such equipment is installed to perform the following work:

For regular inspection and maintenance

car.

For small plumbing work

, minor repairs, correction of defects associated with the maintenance of the house and garden area.

If plumbing or carpentry is part of your hobby

.

The first question that arises when choosing is the material of manufacture. There are wooden (most often homemade) and metal workbenches offered by various manufacturers, both domestic and foreign.

Workplace for the soul

Wooden workbenches

A wooden workbench for the garage, made entirely or partially from wood, is suitable for periodic and short-term work with simple parts; it is not well suited for machining complex metal components. The frame of such models is made of strong wood (beech or oak) and secured with self-tapping screws. The stability of the table is ensured by additional spacers, transverse or x-shaped. Wooden models are usually equipped with shelves or drawers for storage. The wooden tabletop is trimmed with metal along the edge.

A common model is a design of two massive cabinets connected by a tabletop. This option looks quite practical, since it solves most of the problems associated with the placement of tools. Despite the relative cheapness and good (albeit somewhat limited) functionality, many believe that a workbench in a wooden garage has significant disadvantages:

The wooden bench is not designed for heavy loads

.

With intensive use

The service life of the frame is significantly

reduced

.

On our website you can find contacts of construction companies that offer metal structure installation services. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

The table area does not allow for placing

several types of equipment at the same time.

becomes unusable over time under the influence of chemical agents (paints, solvents) and metal dust.

, and traces of oils remain forever.

Wood is a fire hazardous material

; in combination with the collection of chemical substances located nearby, this property increases many times over.

Metal workbenches

To assemble a functional metal bench, you will need special equipment and skills in working with metal (the fragments are connected by welding). Metal models, assembled in workshop conditions, have a durable construction and modern design. Despite the higher price due to the cost of metal and a more complex assembly process, metal equipment has many advantages, including:

Long service life

. Stainless steel models boast an impeccable service life of 50 years.

Large selection of models

and their configurations. Manufacturers offer both universal and highly specialized options.

Multifunctionality

. You can perform any type of work, including turning, cutting, grinding.

Mobility and compactness

. Many models can be disassembled (in whole or in part), and, if necessary, new tools (vises, clamps) can be added.

Light weight

while maintaining strength. The tabletop is resistant to deformation and damage (scratches).

Minimal care

. The design is characterized by increased resistance to corrosion processes and does not require painting. Cleaning metal dust and shavings from the surface of the countertop does not take much time.

Workbench: this is the main element of the woodworker's workshop

In any workshop where they work with wood, there is always a carpentry workbench. Regardless of how the material is processed (manually or using a power tool), the presence of this element allows not only to properly organize the workspace, but also to make it more convenient and comfortable. All this ultimately affects the result. In such conditions, the productivity of the master and the quality of his work increase.

Any carpenter cannot do his work without a workbench.

A workbench is a work table that is used for processing wooden products manually or mechanically. Its design and ergonomic capabilities are designed in such a way that it is convenient for the master to fix parts in different positions to perform various tasks.

The workbench allows you to perform the following operations:

- assembly of wooden structures;

- production of wood parts;

- processing of workpieces with varnishing compounds and other means.

A carpenter's workbench is a table on which a craftsman processes wood products.

On a note! A traditional carpenter's workbench is designed for working with lumber whose length does not exceed 3-3.5 m. To work with longer workpieces, you will have to use a carpenter's workbench.

Workbench requirements

A master professionally engaged in metalworking does his work only in a specially equipped place. Comfortable conditions and safety will be ensured only if there is a workbench. And, according to practicing experts, it must meet a number of requirements:

- large margin of safety and reliability. It is important that you can work in intensive mode or with large, heavy workpieces;

- maximum functionality and thoughtful ergonomics. A well-organized workplace, where everything necessary for work is always at hand, is a prerequisite for production efficiency;

- sustainability. When you have to work with heavy components, this requirement is mandatory for safety. Without a stable table it is impossible to ensure high accuracy of work;

- immunity to aggressive compounds and other influences. A bench made from high-quality materials lasts for several decades.

Construction of a carpentry workbench: design features

The simplest carpentry workbench consists of two elements: a workbench board (tabletop) and a workbench (a frame that performs a load-bearing function). A traditional workbench must be equipped with a vice. Depending on their placement, they can be front or end. Using a vice, wooden blanks are fixed in the required position.

Construction of a carpentry workbench: 1 – front clamp; 2 – rear clamp; 3 – screw; 4 – twists; 5 – tray; 6 – emphasis; 7 – sockets for wedges; 8 – wedges; 9 – front legs; 10 – hind legs; 11 – connections (2 pcs.); 12 – wedges (4 pcs.).

There are holes in the cover of the workshop table, as well as in the jaws of the vice, made of wood. They are used to install stops and clamps, which can have different heights and cross-sectional sizes.

Before work, the stops are set in a certain configuration so that the part can be placed between them in the required position. After the workpiece is installed, it is pressed using a screw mechanism that is equipped with a vice. This design allows you to securely fix the wooden part in a horizontal position.

The vice can be used to work with workpieces of different thicknesses. Specially for this purpose, stops of different heights are provided. The size of this element is selected so that during the processing of the part it does not protrude beyond the edge and does not interfere with the master.

The required components of the simplest workbench are a table top and a supporting frame.

Safety requirements for a homemade workbench design

- If the garage area is not too large, then you can make a smaller table for plumbing work with your own hands. But it is worth knowing that the entire structure must be stable, not sway or budge with little effort.

- The workplace should be organized so that nothing disturbs a person. When working with a vice, all unnecessary tools should be removed from the tabletop.

- Corners and protruding parts of the table should not be too sharp or have cutting edges.

- After repair work at the workbench, you need to clean the workplace from metal shavings, drops of oil and other materials.

- If a homemade workbench is made correctly, it can easily withstand a load of 200 kg.

Plywood for board

Tool shield

Tool shield

Tool shield

Materials for making the frame and cover of a carpentry table

In the process of processing wooden workpieces, the working surface is subjected to serious loads, so increased demands are placed on it. Regardless of whether a regular or folding carpentry workbench is made with your own hands, its structure must be strong and rigid.

The workbench must be made of rigid and durable materials.

A high-quality frame must withstand all types of loads:

- Static. They occur under the influence of heavy weight if a massive workpiece is processed on the table.

- Dynamic. They are a side effect of processes such as drilling, sawing, impacts, etc.

The strength characteristics of the frame depend on factors such as the reliability of the fastening elements (nails, bolts, nuts, screws) and the type of material from which it is made. The underframe is made from softwood, such as pine. Although linden or maple are also suitable for these purposes.

Most often, the workbench top is made of wood.

The workbench tabletop is made of wood with a high strength index:

- beech;

- oak;

- maple;

- ash, etc.

To create a carpentry table cover with your own hands, experts recommend using a glued board. In this case, you will not have to spend a lot of time and effort on adjusting the wood. A complete blank in the form of a laminated board will eliminate the need to cut the material, process its edge part, and then glue and level it. The finished shield will cost a little more, but it's worth it.

On a note! When working with wooden workpieces, you can accidentally damage the cover with a power tool. To prevent this, additional flooring can be made for the workbench top made of plywood or fiberboard. It is cut according to the shape and dimensions of the lid. It is better if the protective flooring is made together with the workbench.

The frame of a carpentry workbench is made of wood, less often of metal.

Material selection

The material is wood, steel, or a combination. In the composite version, the support frame is made of hard rock. For this they take oak, birch, plane tree, maple, acacia, and apple tree. It is not recommended to take spruce, fir, aspen, linden, chestnut.

Wooden posts and longitudinal elements can be fastened with iron corners or profile pipes for stability and reliability. There are single spacers or x-shaped structures. Screws and bolts are used for fixation. The iron walls of the bedside tables are equipped with drawers with sides, and shelves are made of thick OSB panels.

Compliance with assembly technology helps to increase the service life, despite the materials chosen for the manufacture of the desktop.

Choosing between wood and metal

Wood for making a workbench must be treated with antiseptics.

Wooden workbenches are often made with two pedestals. Two storage compartments serve as supports for the connecting tabletop.

This manufacturing option is cheap, but has some disadvantages:

- You can’t make great efforts;

- significant loads shorten the service life.

Wood requires preliminary and regular treatment with antiseptics and moisture impregnations. The surface gradually deteriorates from aggressive components, for example, car oil, gasoline drops.

Steel workbenches allow you to perform various types of work and can withstand heavy loads. Strength is ensured by metal supports, beams, and frame struts. A tabletop with a metal or galvanized coating does not deform from the action of aggressive substances. Wood and iron dust is quickly removed from the coating.

Main types of workbenches: photos of structures and vices for various purposes

Drawings of tables that can be found on the Internet are presented in a huge variety. To choose the best option for creating a workbench at home, it is better to decide in advance on the type of structure and its configuration. There are several types of tables used for working with wood.

The simplest design to manufacture is a stationary type workbench. To create it you will need a minimum set of tools and a little patience. Such structures are mainly used for processing large-sized wooden workpieces.

Carpentry workbenches differ in size and type of construction.

Folding carpentry workbenches have a more complex structure. These products are quite compact. Their weight does not exceed 30 kg. Such structures are considered mobile and, if desired, they can be easily moved from one place to another. In folding workbenches, the lower support part can be made of metal. This is done in order to increase the stability of the structure. Mobile tables are designed for working with small wooden workpieces.

Carpentry workbenches can also be composite. In this case, all structural elements are fixed using bolted connections. The advantage of such a table is that all its components are interchangeable. On the other hand, the drawings of composite type carpentry workbenches are quite complex, as is the technology for their manufacture. Only an experienced master can cope with this task.

Workbench vices come in universal, special, manual and chair types.

Before you start creating a workbench, you need to choose a suitable vice option. In this case, the specifics of future work must be taken into account.

There are several types of vices for a carpentry workbench:

- Chairs - these devices are used extremely rarely, since they are designed to perform heavy work.

- Universal – designed for working with small workpieces. Bolts are used to secure this fastener to the workbench cover.

- Special - allow you to adjust the position of the workpiece both vertically and horizontally, which greatly simplifies the work of the master.

- Manual - there are instrumental, rotary and non-rotary.

On a note! In non-rotary and rotary manual type vices, the width of the jaws is 8 cm.

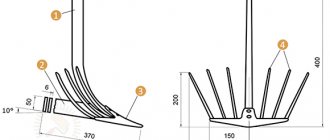

Drawings and dimensions

To assemble a high-quality workbench for the garage, you must first decide on its dimensions. When drawing up a drawing, special attention should be paid to the height of the table top . The optimal option for this indicator is the distance from the elbow of a standing person to the floor.

The width should not be too large. This is due to the limited size of the garage and the need to often work when a car is parked inside the room. Space will be required for people to pass through, so the optimal width of the structure varies from 50 to 80 cm.

How to calculate the dimensions of a workbench for a garage: recommended dimensions

The dimensions of the structure are selected individually depending on the preferences of the owner, as well as taking into account the expected types of work. The width of typical structures is in the range of 0.7-1.2 m, and the length is from 1.5 to 2 m. Workbenches are single and double. The differences between these designs are the length and number of nightstands with drawers. If the desktop is single, in this case the optimal dimensions of the tabletop will be 0.8 x 0.8 x 1.5 m. In double designs, the length is increased to 2.8 m.

Drawing of a simple carpentry workbench with dimensions for a garage.

The height of the carpentry workbench is selected taking into account the height of the craftsman who will work at it. Typically this figure varies from 85 to 95 cm. It is quite easy to check the correctness of the calculations. If, standing at the table, the master can freely rest his palms on its lid, then the height is chosen correctly. It is very important not to make a mistake with this indicator, since frequent stretching and bending is harmful to a person’s back and can lead to rapid fatigue.

The same applies to metal structures, which can also be used for plumbing work. In any case, the desktop must be stable and very durable. The minimum thickness of the lid is 5 cm. Textolite or linoleum is used as upholstery, which will protect the tabletop from damage. In metalworking workbenches, the wooden surface of the workplace is covered with a steel lid. The minimum thickness of this coating is 5 mm.

About the types of workbenches

Car owners regularly face the need to perform a variety of repair work. For everyone involved in carpentry and plumbing (no matter at a professional or amateur level), proper equipment of the workplace helps to allocate energy and time more economically, and also ensures better results. A workbench is suitable for the role of universal equipment suitable for use in garage conditions.

Initially, the workbench arose as a carpenter's workplace intended for processing wood. With the advent of various (including electrical) equipment and the division of professions, the workbench began to specialize. Today, in addition to carpentry, there are carpentry and metalworking workbenches, as well as combined varieties.

Great-grandfather of modern models

The optimal place to install a homemade workbench

It is imperative to take into account the characteristics of the room before making a bench with your own hands.

It is recommended to install the workbench against the wall in one of the corners.

Drawings of the future structure, as well as its dimensions, are selected taking into account all the conditions:

- Type of design – stationary or mobile.

- Features of the tabletop: a fixed work area with constant dimensions or a folding lid.

- The functional content of the workbench is a simple design in the form of a table or a functional option with additional drawers, shelves or holders for storing tools.

- Table configuration - corner, straight or U-shaped.

- Installation option - a structure mounted near a wall or a free-standing table.

Most often, there is very little free space in the garage or workshop. According to the recommendation of experts, when making a workbench with your own hands, folding structures are given greater preference. They are mostly stationary and are usually installed near a wall. In this case, it is better to use the corner area of the room or its least used area.

If you plan to make a compact portable workbench with your own hands, you can install it anywhere. After use, the folding structure is simply removed to another place or retracted.

Note! If the room has windows or ventilation is provided, drafts may appear. It is not recommended to place a workbench in their area of effect, as this can cause problems with the neck and back, as well as with muscles heated during work.

Technology for creating a carpentry workbench with your own hands: drawings, dimensions and procedure

The most convenient option for a private home or garage is a design with a hinged lid. Unlike a folding workbench, its working surface rotates rather than unfolds. This design option has a completely different structure, although it is no less functional and compact.

Drawing of a wooden carpentry workbench with dimensions.

Mobility is achieved due to the presence of wheels installed on the bottom. To prevent arbitrary movement of the structure, it is advisable to use rollers with a locking function. As a last resort, you can install a wedge under the wheels, but this option is not so convenient and practical.

On the right side of the design there are pull-out drawers for convenient storage of small items. If the table will be used by a left-handed master, they should be placed on the other side so that everything you need is at hand. In addition, the workbench is equipped with a special holder. It is made of perforated plywood and mounted on the back of the cabinet. Thus, it becomes possible to make maximum use of the surface of the workbench and organize additional space for storing small tools for carpentry.

On the left or right (for left-handers) there is an open compartment in the design. It is suitable for placing narrow, tall equipment such as a drilling machine. Thanks to the roller mounted on the edge of the tabletop, the process of processing long lumber is greatly simplified, and due to the multi-socket outlet, you can simultaneously connect several tools to the network.

Types of metalworking workbenches

Mechanical workbenches differ in several ways. The following characteristics are used for classification:

- number of workplaces;

- availability of storage space;

- tabletop material;

- installation method.

When choosing equipment, you also need to pay attention to the dimensions and weight.

Availability of storage space

Another criterion for classification is the number of cabinets in the structure. Manufacturers offer the following types of workbenches:

- without pedestals;

- single-pedestal;

- double-pedestal;

The first type is represented by a simple tabletop on metal stands. They do not provide storage space for tools or workpieces. But such products are light in weight and can be moved, so they are used in home workshops or garages. As additional places for placing tools, you can use a protective screen on which everything necessary for work is hung.

Single-pedestal designs have one place for storing tools, located at the edge of the table. These can be pull-out drawers or a cabinet with hinged doors. The remaining free space under the tabletop is used to organize shelves. Compact dimensions allow you to install single-pedestal workbenches in small spaces.

The third type of workbenches is equipped with two cabinets on the sides of the tabletop. Storage areas are equipped with drawers in which you can place a large number of tools or fasteners.

Drawers in bedside tables must slide out completely to provide access to parts and tools. Durable guides will allow maximum loading of storage spaces.

Tabletop material

Types of metal workbench differ in the material used to make the countertops, which can be:

- wooden;

- sheathed in metal.

In the first case, the countertops are made of durable wood or thick MDF. They are applicable when performing simple plumbing work. The surface is covered with a galvanized metal sheet, which prevents damage to the countertop by aggressive substances.

Structures with a metal tabletop are considered the most durable and stable. A workbench with a metal-covered table top is heavy, so it does not move under heavy loads, but it is more expensive.

Installation method

According to the method of installation, workbenches are:

- stationary;

- mobile.

Stationary ones are installed in a permanent place using fasteners. The equipment is used in industrial production. This is a full-scale design with storage areas and a protective screen.

Mobile models have appeared recently. They are small but durable workbenches with drawers equipped with wheels. Some products have a perforated screen for protection. The equipment is easy to move not only around the workshop, but also outside the room.

Drawing of a wooden workbench with your own hands and materials for work

Based on the design drawing, you need to make all the parts necessary for its assembly. The overall dimensions of the workbench in this case are 175 cm (length) and 76 cm (width). A distinctive feature of this table is its three-layer lid, which has an increased margin of rigidity and strength. The upper and lower levels are made of plywood sheet with a smooth surface. The middle layer of the table top is stacked, it is formed from boards.

Note! It is imperative to leave a gap between the boards in the middle layer of the tabletop. This space is necessary to allow the threaded rod to rotate freely.

A table containing a list of materials needed to create a wooden carpentry workbench:

| Material type | Quantity, pcs. | Dimensions, mm |

| plywood sheet | 1 | 1.2x1.2 (8 mm) |

| 2 | 0.2x2.5 (8 mm) | |

| 3 | 1.2x2.5 (18-20 mm) | |

| 4 | 0.9x2.5 (25 mm) | |

| 3 | 1.2x2.5 (25 mm) | |

| Perforated plywood | 1 | 1.2x1.2 (8 mm) |

| Threaded rod (stud) | 1 | M20 (180-200 mm) |

| Lock-nut | 2 | M20 |

| Washer | 4 | 20 mm |

| Latch with mate | 4 | — |

| Handle for drawers and folding tabletop | 8 | — |

| Furniture wheel with flat support for fixation | 4 | — |

| Self-tapping screws or wood screws | 0.5 kg | M8-M24 |

| Self-tapping screws or wood screws | 0.5 kg | M50 |

Do-it-yourself carpentry workbench: assembling the base

Before making a workbench from wood, it is better to estimate the amount of work in advance and outline the procedure. Most of the table parts are fixed using screw connections. To facilitate the assembly process, it is advisable to make holes for them in the plywood in advance in the appropriate places. For these purposes, you need to use a drill whose diameter is approximately 1/2 or 1/3 smaller than the diameter of the fastener itself.

Having prepared all the necessary tools and materials, as well as carefully studying the drawings of the carpentry workbench, you need to make all the structural parts. A circular saw is suitable for cutting wood and plywood. After this, the end part must be sanded so that the edges of all elements are smooth. This will not only simplify the assembly process, but will also avoid problems with joining parts.

To assemble the workbench base, you need to secure the frame and base plate.

First of all, the base is assembled. It consists of a base plate where a cabinet with drawers will be installed, an open area for equipment and stiffening ribs to strengthen the structure. To do this, you need to assemble the frame and fix the plate on it. For fixation, M50 fasteners should be used.

Note! Only dry lumber can be used for work. The optimal wood moisture content is 12%.

Purpose

The bench is used for processing parts made of metals and alloys. The design is designed to perform a wide range of operations:

- carving;

- engraving;

- trimming parts;

- riveting;

- drilling holes;

- bending and cutting;

- assembly of mechanisms.

To work on a workbench, special tools are required. One of the most necessary devices is a vice. Using a tool mounted on a table, parts or workpieces are fixed.

How to make a workbench out of wood with your own hands: installing a cabinet and tabletop

The next step is to install the side tables. In the process of assembling these elements, it is necessary to take into account that the plywood, which is attached to the back of the structure, must be fixed precisely to the frame.

Installation of the workbench tabletop must be done on a finished frame.

It is also worth paying attention to the fact that the outer plane for the left cabinet, used as a support, is longer than its inner part. To make a workbench made by yourself more rigid, this element must be fixed not to the base plate, but fixed to the frame. The cabinets themselves are installed on a base plate. For this, two types of fasteners are used. The lower plane is fixed with screws size M20-M24. For the inner sides, corners should be used.

After the cabinets are installed, you need to accurately determine the middle on their inner sides. This marking is necessary in order to cut U-shaped holes for the turning rod. This must be done so that the center of these holes is located at a distance of 2.2 cm from the bottom plane of the top cover on the cabinet.

Once everything is ready, you can thread the threaded rod through the holes in the four uprights. In this case, its ends should protrude beyond the workbench by about 4-5 cm. They are fixed (without tightening) with locknuts and washers.

Using clamps or screws, you need to install the support strips for the tabletop. They will be placed here temporarily - only so that the position of the tabletop and its horizontal plane can be aligned. Next, three layers of the cover are assembled, which are fixed with screws and adhesive. After this, the bars are removed and the result is checked. The table top should rotate freely.

Then the side surface of the lid (both rotary and stationary) is reinforced with slats. Finally, you need to install the turning handles and locking latches.

The final stage of assembling a workbench for carpentry work

When all the elements of the frame have been assembled, you can begin installing the drawers and fittings. First of all, you need to install the guides in the cabinet located on the right. To make work more convenient, it is better to use temporary inserts in the form of wood panels.

At the final stage, the product is polished.

Instead of homemade wooden guides, you can use ready-made factory-made retractable systems. Such fittings (provided they are of high quality) operate silently and trouble-free. These guides can be designed for either full or partial extension. Next, the storage boxes are assembled. For this, screws and adhesive intended for wood are used. The size of the facades is selected taking into account the dimensions of the cabinet.

Note! It is imperative to leave a small gap (about 1-3 mm) between the facades, otherwise the drawers will not slide out well.

As a functional addition, a movable bar can be installed on the spacer, along which one or more guide rollers will move. Their number depends on what work will be carried out in the workshop. So that the roller can move freely up and down, a slot is made in the movable bar for it, and then a wing nut is installed, which will serve as a clamping screw.

A roller is installed in the upper part of the movable bar. To do this, use a U-shaped holder. It must have slots or holes on the sides intended for the roller axis.

Sometimes craftsmen resort to other carpentry tricks, and homemade devices made with their own hands become an excellent addition to a workbench and other equipment:

- compact stands and holders for cutters;

- sliding stops for miter saw;

- magnetic pads on the jaws of clamps (pipe);

- devices for creating precise corner holes with a drill;

- guide bars for circular saw;

- MDF benchtop machines for eccentric sander, etc.

Ready-made carpentry workbench with swivel top and drawers.

Next, you need to install carpentry tools on the workbench with your own hands. When installing electrical equipment on a hinged cover, it is imperative to maintain balance. Do not load only one side or one corner of the workbench. The set screws are buried at least 2/3 of the thickness in the turning part of the tabletop. This allows you to achieve reliable fixation, because electrical carpentry equipment has considerable weight. In the side areas, where the working area remains stationary, this fastener can pass through the entire thickness of the cover.

In its finished form, a homemade workbench with a rotating tabletop and equipment installed on it is very convenient and functional. To protect wood from the negative effects of moisture, it is advisable to coat it with a primer or even paint. All parts are processed before assembling the workbench and must be thoroughly dried. Painting will also improve the appearance of your workshop bench.

How do vices work?

The design of the vice is quite simple. The most common mechanism is two flat jaws with an adjustment knob that moves a clamping screw. With its help, the sponges diverge and contract. By placing the workpiece between them, you can ensure its reliable fixation.

Interesting materials:

Print screen how to take a screenshot? How to print a screen on a computer? How to print a screen? OBEP came, what should I do? They sent me a reconciliation report, what should I do with it? I’m selling a car, what should I do with the documents? Neighbors spilled, what should I do? The panel at the bottom of the screen has disappeared, what should I do? The taskbar at the bottom of the screen has disappeared, what should I do? I was prescribed without the owner’s consent, what should I do?