We offer laser cutting on a wide range of materials wood, plywood, chipboard, MDF, HDF, and various laminated materials such as chipboard, LMDF. Who requires precision cutting, non-standard cutting and engraving on various materials. You can contact us and we will definitely help you.

The amazing qualities of MDF allow it to be used for architectural details, grilles, ventilation trims, furniture elements, stencils, props, interior decoration, moldings, etc.

From 10r/meter of cut.

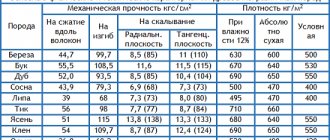

We process not only plywood, but also numerous wooden surfaces, such as oak, beech, ash, pine, etc. But plywood is an excellent material for processing with high flexibility parameters. Cutting wood and plywood with a laser involves a thermal effect on the material, as a result of which the cut is processed by combustion. Cutting plywood and wood with a milling cutter is carried out using a high-precision CNC milling and engraving machine. Both processing methods have a number of advantages. The choice depends on the idea of your final product and the layout. Figurative cutting of wood requires skill and excellent creative abilities, then the finished products acquire a finished aesthetic appearance.

Does wood burn during laser cutting?

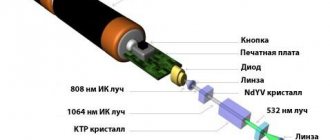

When laser cutting wood, a gap is formed; in this gap, the laser creates elevated temperatures, which are higher than the combustion temperature of the wood. In the laser cutting area, where elevated temperatures are created, the wood “suddenly evaporates” and produces smoke at a rapid rate. This smoke also removes heat from the wood. In this case, air is supplied to the cutting line under pressure, which significantly reduces the temperature. Therefore, there is only a relatively low thermal stress factor on the material near the cutting gap. By precise focusing and selection of appropriate optics and supplying compressed air , a high-quality cut is obtained. Cutting edges with their brownish color can often be used effectively in a variety of designs.

Shaped cutting of wooden and plywood surfaces

Shaped cutting of wooden and plywood surfaces has a number of features depending on the properties of the material, its thickness and size. Standard plywood sheet dimensions are 1525 x 1525 mm, 2440 x 1220 mm, 3000 x 1500 mm, thickness can vary in the range of 3-40 mm. We offer only high-quality raw materials for the manufacture of finished products - FK and FSF, grades 1\2, 2\2, Ш2. The materials used are free from knots and irregularities, and careful double-sided grinding guarantees the production of aesthetic and attractive products.

High-quality modern CNC cutting machines and a sufficient amount of material in stock allow us to fulfill orders of any volume and complexity. We carry out figure cutting of plywood in a short time; a small volume of the order is transferred to the buyer on the day of the request. At the customer's request, we paint finished products with any shade from the RAL CLASSIC palette.

Geometric carving technology

Geometric wood carving is considered the simplest and is perfect for beginners. To create the intended design, you need to have a small set of wood carving tools and clearly follow the design. In geometric wood carving, symmetry and repetition are of utmost importance. This achieves a wonderful play of light and shadow.

Cutting boards using this technique and wooden panels look wonderful in the kitchen.

Geometric carving consists of sequential cutting out of simple geometric shapes: rectangles, triangles, squares, rhombuses. But the result is a wonderful ornament that looks different in different lighting.

The sequence of performing any wood carving is as follows:

- First, a wooden blank is made (board, deck, blank).

- Next is rough leveling of the surface of the workpiece, during which all defects and roughness are removed.

- Then a decorative relief is formed using special cutters.

- After the main carving is completed, the finishing process is grinding, impregnation, painting, varnishing.

You cannot work with a workpiece on your knees! The master must have a table to work on.

Master class “Geometric wood carving on a cutting board”

Tools . You will need 2 knives for wood carving: a triangular jamb knife and a feather knife, a ruler, a compass, a pencil.

A triangle jamb knife is necessary for cutting triangular shapes of various configurations, as well as for cutting long straight lines. A pen knife is used to cut long lines such as a petal or groove. Carving knives should be sharp and comfortable.

First stage. We make a sketch of the pattern on the board. It can be applied using a compass and ruler. Or you can print out carving patterns taken from the Internet and use carbon paper to transfer them to a prepared cutting board.

Second phase . Cut out the petals. We use a pen knife.

While working, the thumb is pressed firmly against the board, and the index finger lightly touches the wood. This will help regulate the depth of the knife into the surface and the angle of inclination. And your thumb will help you move the blade smoothly. First, we cut in one direction at an angle, then we turn the board over and cut on the other side.

If the shavings curl like a rope, the knife is good and sharp. It must be periodically sharpened with a piece of leather with GOI paste.

Third stage . We cut out the triangles with a blunt knife. Using the heel, at an angle of 45 degrees, we cut the knife into the wood, not reaching the edges of the pattern on three sides. The slots should meet on all sides in the shape of a pyramid. The sliver falls out and forms a beautiful triangle.

Fourth stage. What we couldn’t cut, carefully clean it so that the edges are frequent and even. Using the same principle, we cut out grooves and triangles around the perimeter of the board.

Fifth stage . We sand everything with sandpaper and treat it with natural impregnation. All! The work is done. We decorate the kitchen with a useful and beautiful cutting board with wood carvings.

Original

Answers to questions about laser and milling cutting of wood and plywood

What types and brands of plywood can be used for laser processing?

What types and brands of plywood can be used to make interior decorative elements using laser cutting? And what options should you absolutely not use?

What materials are optimal for laser cutting?

The optimal material for processing using laser cutting is aircraft plywood, which combines two excellent characteristics - high strength and ease of processing. For laser cutting of plywood, as a rule, special types of indoor plywood (FK brand) are used. It is not recommended to use moisture-resistant plywood (MPP) for laser processing of materials; cutting such material presents some difficulties for laser machines. It is not allowed to use laser equipment to process bakilite plywood, for cutting which milling machines are used.

How to choose wood material to make a quality product?

How to choose a wood material from which, when processed by laser, you can obtain high-quality decorative elements?

It is important to choose the right wood material for laser processing

In order to obtain high-quality decorative elements using laser or milling cutting methods, you need to choose the wood material wisely. Namely: if possible, purchase wood without knots, take dry and clean material. Avoid using lasers or milling machines to process warped plywood sheets.

Is it possible to process thick sheets of plywood on a laser machine?

Tell me, is it possible to process thick sheets of plywood on a laser machine, for example, whose thickness is more than 10 mm?

It is not advisable to use sheets whose thickness is more than 10 mm

For laser cutting of plywood, it is not advisable to use sheets whose thickness is more than 10 mm, since in the manufacture of plywood sheets a special adhesive composition is used, which impedes the operation of the laser beam. If the thickness of the sheet is non-uniform, when processing a decorative element on a laser machine, it is possible to obtain a product with a wavy structure. This result may not have the best effect on the quality of the final product for interior decoration.

How to achieve a good effect when burning a pattern with a laser?

What can you recommend for decorative interior elements made using the burning technique?

The burning effect will be clearly visible

To achieve the most effective results when burning a pattern for decorative interior elements with a laser, when choosing a material for laser processing, choose plywood sheets made from hardwood. This material is lighter and the burning effect will be clearly visible.

About wood carving for beginners

To decorate the internal and external space, various types of carvings and techniques for realizing the plan can be used. If you are interested in this type of needlework, then you must understand that you need to master the methods and techniques of wood processing, acquire the necessary tools and improve carving skills.

In the modern world of smartphones and tablets, a wooden stand decorated with wood carvings looks very original.

Skillfully executed carvings in the form of simple and ornate patterns and ornaments seem to enliven the world and endow it with sophistication, charm, emphasizing the taste of the owner of luxury items and the talent of the craftsman.

Panel

Cutting boards

Wooden icons

The works of the best carvers decorate the temples. Pay attention to the photo of the iconostasis of the upper Church of the Holy Image of the Savior, which is located in Moscow, in the Church of the Intercession of the Blessed Virgin Mary in Fili.

Modern masters with delicate taste create real masterpieces.

And thanks to finishing technologies and protection of the finished product from the destructive effects of mold and insects, these wood carvings have served people for hundreds of years.

Pay attention to the magnificent carved pieces of furniture:

Stylish doors:

Delightful handmade figurines:

Very often, connoisseurs collect handmade carved items. Wonderful chess that is worthy of any collection.

Perhaps, over time, your wood carving masterpieces will be carefully preserved by collectors or decorate temples.

Types of wood carving

Of all the types of wood carving, openwork or through wood carving is very interesting, which is characterized by some transparency, in which only the image remains, without a background. An example is an applied carving - this is an ornament that is attached to a finished background after production by a craftsman.

Geometric wood is a type of carving in which a pattern is formed using a variety of simple geometric shapes (a rhombus is often used).

Oriental wood carving is distinguished by its whimsical forms. Egypt is the cradle of the oriental type of wood carving.

Relief wood carving. In this technique, the image is located above the background or at the same level with it. These are carved panels of various shapes with three-dimensional images.

Carving in the Baroque style is a flat-relief carving, but distinguished by an abundance of carved and molded decorations, various colors, curls, leaves, figures of people in unnatural poses, and fabulous fantastic animals.

Kudrinskaya carving originated in the village of Kudrino. Well-known products in this type of carving are boxes, vases, dishes, ladles, and home decor items. The main element is a floral ornament: rosettes, curls and twigs.

Three-dimensional (sculptural) carving is excellent for making sculptures, animal and human figures, and toys. Bogorodskaya carving is a subtype of three-dimensional carving. This is the main industry of the village of Bogorodskoye in the Moscow region. The famous Bogorodsk toys are figurines of animals and people made of linden and alder.

Scandinavian carvings were most often used to decorate wooden Scandinavian churches. Wood carvers decorated the inside and outside of church buildings with images of Gods and various animals.

Contour carving is the simplest and most unique type of carving. On a flat background, the master cuts out grooves - grooves, forming a pattern. Carved landscapes - images of landscapes on wood.

All these types of carvings are quite conventional. Each master chooses the most suitable one, taking into account work experience, quality of wood and creative inspiration.

What can be decorated with carvings?

The simplest staircase is transformed, decorated with carved balusters. Balusters are curly posts in the form of columns, a stylish and noble decoration of the staircase. Wooden balusters look organically with a spiral wooden staircase.

Bas-relief. Another name is "low relief". This is a sculptural image on a plane. Most often these are figures of people and animals .

Wood carving designs

To perform wood carving, photographs, drawings and sketches are simply necessary. A large pattern for wood carving is used for large-scale products: for the facades of houses, interior decoration with carvings of churches, windows.

For interior items and furniture, carvers use small patterns that are carefully worked out by the craftsman.

YOU WILL NEED IT

We offer you an archive of 80 wood carving designs. Choose, print, create.