07.27.2019 Author: VT-METALL

A crack is called a discontinuity, which is caused by sudden cooling or exposure to loads. A type of this defect, which can only be detected with optical instruments with a magnification of at least fifty times, is called microcracks.

Longitudinal cracks are located along the welded joint and can be located:

- in the weld metal;

- in the main material;

- at the alloy boundary;

- in the area of temperature influence.

longitudinal crack

Cracks in the base metal caused by high stress are called hidden cracks. Outwardly, they resemble steps. This defect is inherent in welded joints of considerable thickness. High voltages are caused by joints that are too rigid or by incorrect selection of welding technology. Reducing welding stresses reduces the likelihood of hidden longitudinal cracks.

The configuration of longitudinal cracks is determined by the lines of the weld alloy and the base metal.

These cracks are divided into:

- hot, their cause is the high-temperature brittleness of the alloys;

- cold - occur during the slow destruction of metal.

Transverse cracks are oriented perpendicular to the axis of the weld. They can occur both in the base material and metal of the welded joint, and in the temperature-affected zone.

Radial cracks diverge from one point and are otherwise called star-shaped. Their locations are similar to those of transverse cracks. The reasons for the formation of transverse and radial cracks are the same as for longitudinal ones.

At the point where the arc is torn off, a depression is formed on the surface of the seam. Defects occurring at this location are called crater cracks. They are divided into longitudinal, transverse, star-shaped. The configuration of this defect is determined by: the microstructure of the welded joint zone, phase, thermal and mechanical stresses.

If a group of cracks not connected to each other occurs, then they are called separate. The places and causes of their occurrence are similar to these characteristics of transverse and radial cracks.

VT-metall offers services:

If a group of cracks is formed from one crack, then such a defect is called branched cracks. Their locations are the base material, the weld metal, and the area of thermal impact. The causes of occurrence are the same as in longitudinal cracks.

Pores: their shape, location and reasons for their appearance

Defects in welded joints and joints in the form of cavities in a welded joint are called pores. These cavities are filled with gas that has not had time to escape.

The following types of pores are distinguished:

- A gas cavity is a formation of arbitrary shape, has no corners, the cause of which was gases that did not have time to leave the molten material.

- A gas cavity is sometimes called a gas cavity and has a spherical shape.

- A group of gas pores located in the metal of a welded joint is called uniformly distributed porosity.

- A cluster of pores is three or more gas cavities located closely at a distance from each other, not exceeding triple the diameter of the maximum pore.

- A chain of pores is a series of gas cavities that are located in a line along the welded joint with a distance between them that does not exceed three diameters of the longest time.

- If the defect is not continuous, extends along the axis of the weld and has a height that is much less than the length, then it is called an oblong cavity.

- A fistula is a tubular cavity located in the weld metal. A fistula is caused by the release of gas. Its shape and position are determined by the gas source and the hardening regime. As a rule, fistulas form clusters in the shape of fir trees.

- A gas cavity that violates the integrity of the surface of the welded joint is called surface time.

- If a cavity forms during hardening due to shrinkage, it is called a shrinkage cavity. A shrinkage cavity located at the end of the roller and not welded during subsequent passes is called a crater.

Time - defects in welded joints, photos of which are given below, appear due to the presence of harmful impurities, both in the base metal and in the filler metal. Time stains can form due to rust and other contaminants that were not removed from the edges of the material before welding, high carbon content, high speed of the welding process, and violations of the weld pool protection. The most common cause of pores is a damp coating melting the electrode.

The presence of single pores does not pose a danger, but their chain can negatively affect the strength of the welded joint. section of the weld, shocked by these defects, is digested, having previously mechanically cleaned it.

Time and slag inclusions

How is the initial consultation with a coloproctologist?

When applying for an appointment, no complex special preparation is required, which can take you out of your normal daily routine.

The doctor will listen to you, ask you about your complaints, how long the disease has been, and then conduct an examination.

The examination in our consultation room is carried out in the supine position with the legs raised on supports (lithotomy position).

On the eve of the consultation, it is necessary to make a microenema and perform hygiene of the perineal area.

After the examination, a specialist doctor will tell you about your disease, prescribe additional examinations if necessary and suggest the most optimal treatment method.

Types of solid inclusions in a weld

Solid foreign inclusions, both metallic and non-metallic in nature, having at least one acute angle in their configuration, are unacceptable defects in the welded joint, since they play the role of stress concentrators. An additional danger of these defects is that they are not visible from the outside. They can only be identified using non-destructive testing methods.

Slag inclusions in a welded joint

Solid inclusions are divided into the following types:

- Slag inclusions are slag trapped in the weld. Depending on the conditions under which they were formed, they can be linear, disconnected, or other. The reasons for their formation are high speeds of the welding process, contaminated edges, multi-layer welding, if the seams between the layers are poorly cleaned. The shape of these defective inclusions is very diverse, so they can be much more dangerous than round pores.

- Fluxes, which serve to protect the metal from oxidation, cause the formation of flux inclusions. Just like slag fluxes, flux inclusions are divided into linear, disconnected and others.

- The reasons for the formation of oxide inclusions can be: an insufficiently clean surface of the base or filler metal, pulling the hot welding wire out of the protection area, improper preparation of the edges - they are too dull.

- Particles of foreign metals - tungsten, copper or others form metallic inclusions. The reason for their formation can be erosion of the tungsten electrode or accidental ingress of metal particles from the outside, as well as when copper shavings are used to ignite.

Elimination of cracks

Regulatory documents contain information on the most effective measures to prevent and eliminate defects in welding work, including various types of cracks. The main way to fix cracks is to weld them. Before eliminating the defect, preparatory work should be performed.

First you need to examine the flaw to accurately determine its beginning and end. The edges of the cracks are drilled out, and if this is not possible, then they are cauterized. First, the area to be restored can be slightly warmed up. If the crack is too large and its length is 30 centimeters or more, then it should be welded using the reverse-step method.

Lack of fusion and lack of penetration: causes

Lack of penetration and lack of fusion

Defects - lack of fusion and lack of fusion - are the lack of connection between the base material and the metal of the welded joint.

Non-fusion occurs at high speeds of the welding process and current strengths of more than 15000C. To prevent non-fusion, it is necessary to reduce the welding speed, reduce the time gap between the formation and filling of the groove, and thoroughly clean the welding area from oils and contaminants. Non-fusion can be located:

- at the root of the weld;

- on the side;

- between the rollers.

Lack of penetration occurs due to the inability of the molten metal to reach the root of the weld. There may be several reasons for lack of penetration:

- insufficient welding current;

- electrode movement speed is too high;

- arc length increased;

- the bevel angle is too small;

- distortion of welded edges;

- insufficient gap between edges;

- incorrectly selected—increased—electrode diameter.

- slag getting into the gaps between the edges;

- inadequate choice of polarity for this type of electrodes.

Lack of penetration is a very dangerous and unacceptable welding defect.

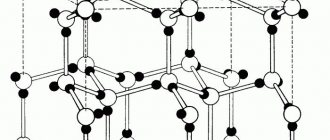

Crystallization

Crystals form during the cooling process of a metal, that is, during the period when it passes from a liquid state to a solid state. This is exactly the process that takes place after welding the workpieces. At this time, there is a high probability of metal deformation and crack formation.

During the crystallization process of the weld, hot cracks are formed. They are also called crystallization ones. They become noticeable already at the last stage of crystallization, when the temperature is close to solidus and the last drops of liquid metal disappear.

Types of deviations of the shape of the outer surface of the seam from the specified values

The following defects are considered to be defects in the shape of the weld:

- Continuous undercuts are continuous indentations located on the outer part of the seam bead. If undercuts are located on the root side of a single-sided weld and are formed due to shrinkage along the boundary, they are called shrinkage grooves. Undercuts are common surface defects that are caused by too high an arc voltage when welding fillet welds or by inaccurate electrode guidance. In this case, one of the edges melts more deeply, which leads to metal flowing onto the part in a horizontal position. There is not enough metal to fill the groove. When welding butt seams, undercuts are rarely formed. If the welding speed and arc voltage are too high, double-sided undercuts usually occur. The same type of defect occurs in automatic welding if the processing angle is increased.

- Excess of convexity in a butt or fillet weld is an excess of deposited metal on the face of the welds in excess of the required value.

- If an excess of deposited metal in excess of the established value is located on the reverse side of the butt weld, then such a defect is called excess penetration. A variation is local excess melting.

- If excess deposited metal flows onto the base metal, but does not fuse with it, then such a defect is called overlay.

- Linear displacement occurs if the surfaces being welded are parallel, but not at the same level.

- Angular is the displacement between two surfaces when they are located at an angle that differs from the required one.

- Natik is formed from weld metal that settles under the influence of gravity. Natik is formed in horizontal, overhead, bottom welding positions, in corner joints and lap joints.

- When burns occur, the metal of the weld pool follows, forming a through hole. The causes of burn-through may be contamination of the surface of the base metal or electrode.

- Incomplete filling of the edge groove occurs due to a lack of filler material.

- If in a corner joint one leg is significantly larger than the other, then a defect of excessive asymmetry occurs.

- Uneven weld width.

- An uneven surface is the uneven shape of the seam reinforcement along its length.

- A root weld concavity is a shallow groove on the root side of a weld that is formed due to shrinkage.

- Due to the occurrence of bubbles during the solidification of the metal, porosity is formed at the root of the weld.

- Recovery. This defect is a local surface roughness in the recovery zone of the welding process.

Overlap and undercut

Other weld defects

All defects in welds and joints that are not listed above are classified as “other”. These include the following types of defects:

- Random arc. As a result of accidental arcing, local damage occurs to the surface layer of the base metal adjacent to the weld area.

- Metal splashes are drops formed from welded or filler metal during the welding process. They stick to the surface of the cooled weld metal or base metal located in the heat-affected area.

- Tungsten Spatter - Created by tungsten particles thrown from the molten electrode onto the base metal or weld.

- Surface scoring is a defect that occurs due to the removal of a temporarily welded fixture.

- Thinning of the metal occurs during machining. In this case, the thickness of the metal matters, less than the permissible value.

Permissible defects in welded joints are deviations, the presence of which does not reduce the operational properties of the welded joint and their presence is permitted by regulatory documentation. All other defects, as a rule, can be corrected by welding. It is not allowed to correct the quality of welding more than twice, as overheating or excessive consumption of metal may occur.

External defects include: sagging; undercuts; unfilled craters; pores extending to the surface of the weld; gone; external cracks, etc. Sagging is formed as a result of the flow of the molten metal of the electrode onto the unmolten base metal or a previously made roller without an alloy with it (Fig. 4).

The surges can be local, in the form of separate zones, and also significant in length.

Rice. 4. Sagging in seams: a - horizontal; b - overlap; in - T-bar; g - butt welding or when surfacing beads.

Sagging occurs due to: excessive current with a long arc and high welding speed; increased inclination of the plane on which the welds are applied; incorrect guidance of the electrode or incorrect displacement of the electrode wire when welding circumferential submerged seams; inconvenient spatial position (vertical, ceiling), as well as insufficient experience of the welder.

undercuts

They are depressions (grooves) in the base metal, running along the edges of the weld (Fig. 5). The depth of the cut can vary from tenths of a millimeter to several millimeters. The reasons why these defects in welded joints are formed are: significant current strength and increased arc voltage; inconvenient spatial position when welding; welder's negligence.

Rice. 5. Undercuts: a - in the butt seam; b - in a horizontal seam located on a vertical plane; c - in the fillet weld of a T-joint.

Undercuts in the seam reduce the working thickness of the metal, cause local concentration of stresses from work loads and can cause destruction of the seams during operation. Undercuts in butt and fillet welds located across the forces acting on them lead to a sharp decrease in vibration strength; even fairly large undercuts running along the acting force affect the strength to a much lesser extent than undercuts located transversely.

crater

- a depression formed in the event of a sharp break in the arc at the end of welding (Fig. 6). Craters occur especially often when making short seams. The dimensions of the crater depend on the value of the welding current. during manual welding, its diameter ranges from 3 to 20 mm; during automatic welding, it has an elongated shape in the form of a groove. Unwelded craters reduce the strength of the welded joint because they concentrate stress. In addition, they reduce the cross-section of the seam and can become hotspots for crack formation.

Rice. 6. Craters: a, b - top view; c - in a longitudinal section of the weld.

If there is a crater in the weld, the reduction in joint strength under vibration load for products made of low-carbon steel reaches 25%, and for products made of low-alloy steels - 50%.

headlong

— a defect in the form of penetration or deposited metal with the possible formation of through holes (Fig. 7). Missing occurs due to insufficient blunting of the edges, a large gap between them, excessive welding current or torch power at low welding speeds. Disappearances are especially often observed during the welding process of thin metal and when performing the first pass of a multilayer weld. In addition, losses can occur as a result of poor compression of the flux pad or copper substrate (automatic welding), as well as with increased welding duration, low compression force and the presence of contamination on the surfaces of the parts being welded or electrodes (spot and seam resistance welding). In all cases, the hole that appears when the hole disappears, although it is welded,

The quality of welded joints can only be ensured by constant production control, and all elements must be subject to control, starting from the material being welded, wire and electrodes, flux, and ending with control of the process itself and the quality of the finished product.

Preparing for your first meeting with the doctor

If you have an anal fissure, you should seek medical help from a coloproctologist.

Our Clinic is open 6 days a week from Monday to Saturday from 8:30 to 20:00 (opening hours are subject to change).

Below is information that will help you prepare for your meeting with a specialist.

When you make an appointment, ask if you need to do anything in advance, for example, special preparation for the examination, how long before the appointment you need to come to the Clinic, because it will also take time to prepare a medical record for an inpatient.

To make the outcome of your visit to the doctor more effective, so that there are no unanswered questions, make a list:

- Your complaints.

- Your medical history (surgeries, chronic diseases, etc., even not related to the problem that is bothering you now).

- All medications, vitamins or other supplements you take.

- If you have a person whom you completely trust, then you can take him with you. So that it reminds you of the questions you wanted to ask.

Prepare questions for your doctor

Here are some basic questions to ask your doctor at your appointment if you do not get answers to them during the conversation:

- What could be the reason for my complaints?

- Are there other possible reasons for my complaints?

- Is there a need for tests and additional examinations?

- Is my condition temporary (acute) or chronic?

- Are there any dietary restrictions?

- Are there any restrictions that I must follow?

Feel free to ask any questions you have about your disease during your meeting with the doctor.

Classification of defects.

For various reasons, defects in welded joints can occur, which have a significant impact on the quality and strength of welded structures. All defects today are usually divided into several groups, namely:

- External defects: external defects include various cracks, undercuts and craters, which significantly reduce the strength of the structure.

- Internal: internal defects are usually classified as various inclusions, weld porosity, and lack of penetration.

- Through: cracks and various missing.

Very often, defects arise due to a direct violation of welding technology or low qualifications of the welder himself or incorrect selection of materials. I would also like to note that often the cause may be equipment malfunction or poor quality of the materials themselves. Therefore, the causes of the defect need to be understood in detail, this will help eliminate the possibility of their occurrence in the future.

What is required for differential diagnosis of this disease?

A fissure can occur with inflammatory diseases of the colon, such as Crohn's disease or ulcerative colitis. Infectious diseases (syphilis, HIV, herpetic infection, etc.) can also contribute to the development of anal fissure. Tumor diseases such as cancer, melanoma, leukemia can manifest themselves in the same way as an anal fissure. The patient will experience pain in the anus and bleeding from the anus.

Rice. 8. Cancer of the anal canal with transition to the perianal skin