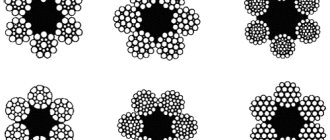

Currently manufactured ropes are classified according to GOST 7372-79 “Steel ropes. Technical specifications” according to the following characteristics: BY DESIGN:

- single lay (spiral) - consisting of one, two or three concentric layers of wire twisted in a spiral;

- double lay - consisting of six strands twisted into one concentric layer;

- triple lay - consisting of twisted double lay ropes.

BY MECHANICAL PROPERTIES OF THE WIRE:

- VK – high quality;

- B – improved quality;

- 1 – normal quality.

BY TYPE OF WIRE SURFACE COATING:

- without cover;

- with zinc coating for various environments - coolant, liquid and wet.

BY PURPOSE:

- cargo-human (GL);

- cargo (G).

BY CORE MATERIAL:

- with an organic core made of natural or synthetic materials - OS;

- with a metal core - MS.

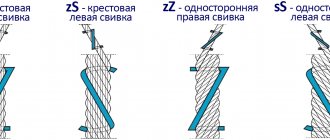

IN THE DIRECTION OF LAYING THE ROPE ELEMENTS:

- right lay;

- left lay (L).

BY COMBINATION OF LAY DIRECTIONS OF THE ROPE AND ITS ELEMENTS:

- cross lay, in which the direction of lay of the strands in the rope is opposite;

- the direction of laying of wires in strands;

- one-sided lay, in which the direction of lay of the wires in the strands and the strands in the rope is the same (right or left).

BY DEGREE OF STRONGNESS:

- twisting - with the same direction of lay of all strands along the layers of the rope, these are, as a rule, six- and eight-strand ropes with an organic or metal core;

- low-twist (MC) - with the opposite direction of lay of rope strands in layers in multi-layer, multi-strand and single lay ropes.

BY ROLLING METHOD:

- non-unwinding (N) - rope elements retain their position after removing the ties from the ends of the rope and removing the end welding;

- unwinding.

BY DEGREE OF BALANCE:

- unstraightened;

- straightened (R).

BY TYPE OF LAYING STRANS AND ROPES OF ORDINARY LAYING:

- with point contact of wires between layers (TC);

- with linear contact of wires between layers (LC);

- with a combined point-linear contact of wires between layers (TLC).

BY MANUFACTURING PRECISION:

- normal accuracy;

- increased accuracy (T);

- with stricter maximum deviations for the rope diameter.

BY STRENGTH CHARACTERISTICS:

The classification is based on the value of tensile strength:

- 1370 N/mm2 (140 kgf/mm2);

- 1470 N/mm2 (150 kgf/mm2);

- and then after 100N to 2160N/mm.

| Double lay rope type LK-RO Design 6x36(1+7+7/7+14)+1 o.s. GOST 7668-80 |

| Double lay rope type LK-R Design 6x19x(1+6+6/6)+1 o.s. GOST 2688-80 (DIN 3059-72, JIS G 2525-88, PR-W-410D-84, UNI 7265-7) |

| Double lay rope type LK-PO Designs 6x36(1+7+7/7+14)+7x7(1+6) GOST 7669-80 (DIN 3064-72, ISO 2408-85, BS 302-8742, JIS G 3525-88, NFA 47-200-83, UNI 7297-74) |

| Double lay rope type LK-3 Design 6x25(1+6; 6+12)+7x7(1+6) GOST 7667-80 (DIN 3057-72, ISO 2408-85, GIS G 3525-88, NFA 47-200 -83, UNI 7295-74) |

| Double lay rope type LK-O, design 6x19(1+9+9)+1 o.s. GOST 3077-80 (DIN 3051-72, ISO 2408-85, BS 302-8742, PR-W-410D-84) |

| Double lay rope type TLK-O design 6x37(1+6+15+15)+1 o.s. GOST 3079-80 |

| Double lay rope type LK-3, design 6x25(1+6; 6+12)+1 o.s. GOST 7665-80 |

| Double lay rope type LK-O, design 6x7(1+6)+1 o.s. GOST 3069-80 (DIN 3055-72, ISO 2408-85, BS 302-87 4.2, NFA 47-200-83) |

| Double lay rope type LK-O design 6x19(1+6)+1x7(1+6) GOST 3066-80 (DIN 3055-72, ISO 2408-85, BS 302-87, NFA 47-200-83, UNI 7293-74) |

| Single lay rope type TK design 1x37(1+6+12+18) GOST 3064-80 |

Characteristics of steel ropes. Double lay rope type TK, LK-R.

Purpose of steel ropes.

A steel rope (cable) is designed for lifting and towing various heavy loads.

Most often, steel cable is used in metallurgy, construction, agriculture, mechanical engineering, shipbuilding, the oil industry and other industries where safe transportation of goods is necessary. Very often, steel ropes are used in lifting machines and mechanisms during installation work, therefore, for their full operation, it is necessary to use ropes (cables) with the most suitable diameter, design breaking force and GOST of the rope; these parameters can be found in the technical documentation for each lifting device. The tables below show the calculated breaking forces of the rope, the calculated cross-sectional area of all wires and the weight of 1000 m of lubricated rope for different rope diameters, depending on the type and design of the steel (cable) rope.

Steel rope manufacturing. GOST

Steel rope (cable) is made according to GOST, from spring wire grades, and can be coated or uncoated. The tables below show the technical characteristics for three types of steel ropes (cables) according to GOST: GOST 2688-80 , GOST 3070-88 , GOST 3071-88 .

Fig.1. Steel ropes GOST.

Types of steel ropes.

There are three main types of steel ropes (cables): single (single-layer), double (two-layer) and triple (three-layer) lay. All these types are shown below in Figure 2.

Fig.2. Types of laying of steel ropes (cables).

Types of laying of steel ropes.

Also, according to the type of laying of steel ropes (cables), they are distinguished:

— ropes with linear contact of wires, type LK;

— ropes with point contact of wires, type TK;

— ropes with linear contact of wires, with different diameters of wires in the outer layer of the strand, type LK-R;

— ropes with linear contact of wires, with identical wire diameters, type LK-O;

— ropes with linear contact of wires, with filling wires, type LK-Z;

— ropes with linear contact of wires, with identical and different diameters of wires in rope strands, type LK-RO;

- combined, TLC type.

Fig.3. Types of laying of steel ropes (cables).

Double lay ropes: a) TK6x19 [1+6+12] +1.0.S, GOST 3070-88; b) LK-06x19 [1+9+9]+7x7 [1+6], GOST 3081-80; c) LK-R6x19[1+6+6/6]+1.0.S, GOST 2688-80; d) LK-R06xZb [1+7+7/7+14]+7x7 [1+6], GOST 7669-80; e) LK-Z6×25 [1+ 6+12/6]+1.0.C, GOST 7665-80; f) TLK-06×27 [1+6+10+10]+1.0.S, GOST 3079-80.

The tables below show the technical characteristics for three types of steel rope construction: double lay rope type LK-R 6x19 (1+6+6/6)+1.0.S., double lay rope type TK 6x19 (1+6+12 )+1.0.S., double lay rope type TK 6×37 (1+6+12+18)+1.0.S.

Steel rope weight. Weight of steel ropes.

Double lay rope type LK-R 6×19.

Table 1. Double lay rope type LK-R design 6 ×19 (1+6+6/6)+1.0.S. according to GOST 2688-80.

| Rope diameter, mm | Estimated cross-sectional area of all wires, mm2 | Estimated weight of 1000 m of lubricated rope, kg | Estimated breaking force of the rope as a whole in kgf (not less) for the marking group for temporary tensile strength, kgf/mm2 | ||

| 140 | 160 | 180 | |||

| 4,1 | 6,55 | 64,1 | 1000 | ||

| 4,8 | 8,61 | 84,2 | — | — | 1 315 |

| 5,1 | 9,76 | 95,5 | — | — | 1 490 |

| 5,6 | 11,9 | 116,5 | — | — | 1 820 |

| 6,9 | 18,05 | 176,6 | — | 2 450 | 2 685 |

| 8,3 | 26,15 | 253 | — | 3 555 | 3 895 |

| 9,1 | 31,18 | 305 | — | 4 235 | 4 640 |

| 9,9 | 36,66 | 358,6 | — | 4 985 | 5 455 |

| 11 | 47,19 | 461,6 | — | 6 415 | 7 025 |

| 12 | 53,87 | 527 | — | 7 325 | 8 020 |

| 13 | 61 | 596,6 | 7 255 | 8 295 | 9 085 |

| 14 | 74,4 | 728 | 8 850 | 10 100 | 11 050 |

| 15 | 86,28 | 844 | 10 250 | 11 700 | 12 850 |

| 16,5 | 104,61 | 1025 | 12 400 | 14 200 | 15 550 |

| 18 | 124,73 | 1220 | 14 800 | 16 950 | 18 550 |

| 19,5 | 143,61 | 1405 | 17 050 | 19 500 | 21 350 |

Double lay rope type tk design 6x19.

Table 2. Double lay rope type TK design 6 ×19 (1+6+12)+1.0.S. according to GOST 3070-88.

| Rope diameter, mm | Estimated cross-sectional area of all wires, mm2 | Estimated weight of 1000 m of lubricated rope, kg | Estimated breaking force of the rope as a whole in kgf (not less) for the marking group for temporary tensile strength, kgf/mm2 | ||

| 140 | 160 | 180 | |||

| 3,3 | 3,62 | 35,5 | — | — | 553 |

| 3,6 | 4,38 | 42,9 | — | — | 669 |

| 3,9 | 5,2 | 51 | — | — | 795 |

| 4,2 | 6,1 | 59,8 | — | — | 930 |

| 4,5 | 7,07 | 69,3 | — | — | 1 075 |

| 4,8 | 8,12 | 79,6 | — | — | 1 240 |

| 5,5 | 10,42 | 102,5 | — | 1 415 | 1 590 |

| 5,8 | 11,67 | 114,5 | — | 1 585 | 1 785 |

| 6,5 | 14,53 | 142,5 | — | 1 970 | 2 220 |

| 8,1 | 22,64 | 222 | — | 3 075 | 3 370 |

| 9,7 | 32,52 | 319 | — | 4 420 | 4 840 |

| 11 | 44,21 | 433,5 | 5 255 | 6 005 | 6 580 |

| 13 | 57,7 | 565,5 | 6 860 | 7 845 | 8 560 |

| 14,5 | 72,96 | 715 | 8 670 | 9 900 | 10 800 |

| 16 | 90,02 | 882,5 | 10 700 | 12 200 | 13 400 |

| 17,5 | 108,86 | 1070 | 12 900 | 14 750 | 16 150 |

| 19,5 | 130,11 | 1275 | 15 450 | 17 650 | 19 350 |

Rope type TK 6×37.

Table 3. Double lay rope type TK design 6 × 37 (1+6+12+18)+1.0.S. according to GOST 3071-88.

| Rope diameter, mm | Estimated cross-sectional area of all wires, mm2 | Estimated weight of 1000 m of lubricated rope, kg | Estimated breaking force of the rope as a whole in kgf (not less) for the marking group for temporary tensile strength, kgf/mm2 | ||

| 140 | 160 | 180 | |||

| 5 | 8,48 | 82,5 | — | — | 1 250 |

| 5,4 | 10,08 | 98,1 | — | — | 1 480 |

| 5,8 | 11,84 | 115,5 | — | — | 1 740 |

| 6,3 | 13,73 | 134 | — | — | 2 025 |

| 6,7 | 15,75 | 153,5 | — | — | 2 320 |

| 7,6 | 20,22 | 197 | — | 2 650 | 2 980 |

| 8,5 | 25,25 | 246 | — | 3 310 | 3 725 |

| 9 | 28,1 | 273,5 | — | 3 685 | 4 145 |

| 11,5 | 43,85 | 427 | — | 5 750 | 6 255 |

| 13,5 | 63,05 | 613,5 | — | 8 240 | 8 960 |

| 15 | 85,77 | 834,5 | 9840 | 11 200 | 12 200 |

Classification and labeling

The range of products with an organic core and a steel wire sheath is determined by GOST 2688–80. Steel ropes are divided according to mechanical properties, purpose, type of wire material, laying method and direction, manufacturing accuracy and degree of balance.

Classification differences

Cables are divided into types according to their intended purpose:

- GL - cargo-carrying vehicles, which are used for ascent, descent, and movement of people and cargo.

- G - cargo, they are used for transporting and securing cargo.

The following grades are distinguished based on their mechanical properties:

- 1 – quality is normal.

- VK - high quality.

- B - increased quality.

By type of wire used:

- without external covering;

- with a galvanized layer.

Depending on the density of zinc, the following types of galvanized wire are distinguished: Coolant, S, Zh. Cables made of wire coated with Coolant are suitable for use in particularly harsh conditions and aggressive environments. For standard operating conditions in air, wire ropes made from uncoated or coated Group C wire are suitable.

In the direction of twisting the wire:

- Left lay - denoted by the letter L.

- Right lay - no designation.

By combination of wire and strand directions:

- Single-sided lay: with the same direction of wires and strands in the rope.

- Cross: with the opposite position of the wire and strands.

- Combined: when strands of the right and left twisting directions are used simultaneously when laying the cable.

By laying method:

- Non-unwinding - denoted by the letter N.

- Unwinding - no symbol.

Based on manufacturing accuracy, designs are distinguished:

- increased accuracy - T;

- normal.

By balance:

- unstraightened;

- straightened - R.

The balance of a metal rope is determined by the fact whether straightening - straightening the strands - was used in the process of its production. This process removes tension from the cable so the product remains straight after twisting.

Symbol

All symbols specified in GOST are used when marking ropes. The first digit of the marking is the cross-sectional diameter of the cable, followed by the designation of the type of purpose, quality mark, coating group, direction of lay, curl characteristics, indication of straightening, accuracy and designation of the marking group.

For example: Rope 28 - G - 1 - L - 1670 GOST 2688–80. The designation of untwisted unstraightened cables of right-hand lay, normal precision manufacturing and made of uncoated wire will be shorter due to the lack of letters and numbers of the symbol. Only the diameter, purpose, quality group, left lay direction and marking group are indicated.

Straightened, non-unwinding cables of improved quality and manufacturing precision, made of coolant-coated wire, will have the following markings: Rope 21 - GL - V - coolant - N - R - T - 1470 GOST 2688–80.

Cable diameters available

- 5 mm

- 6 mm

- 7 mm

- 8 mm

- 9 mm

- 10 mm

- 11 mm

- 12 mm

- 13 mm

- 14 mm

- 15 mm

- 16 mm

- 17 mm

- 18 mm

- 19 mm

- 20 mm

- 21 mm

- 22 mm

- 23 mm

- 24 mm

- 25 mm

- 26 mm

- 27 mm

- 28 mm

- 29 mm

- 30 mm

- 31 mm

- 32 mm

- 33 mm

- 34 mm

- 35 mm

- 36 mm

- 37 mm

- 38 mm

- 39 mm

- 40 mm

- 41 mm

- 42 mm

- 44 mm

- 45 mm

- 46 mm

- 48 mm

- 49 mm

- 50 mm

- 52 mm

- 54 mm

- 56 mm

- 57 mm

- 58 mm

- 60 mm

- 61 mm

You can also see all the steel ropes of all diameters and manufacturers that we have in stock and steel rope GOST 2688-80.

If you have any questions about ordering any of the cables, you can leave a request or contact the contact numbers above.

| Brand | Series | Marking | A country | Approximate weight of 1 m of rope, kg | Minimum breaking force of rope, kN marking group: | Torsion resistance | |||

| 1770 N/mm2 | 1960 N/mm2 | 2160 N/mm2 | |||||||

| Teufelberger | EVOLUTION TK16 | Steel rope 10 mm TK 16 16ХК6 / 16ХК7 | Austria | 0,5 | 82 | 91 | 98 | average | |

| Teufelberger | EVOLUTION TK17 | Steel ropes 10 mm TK1716ХК7PIWRC | Austria | 0,48 | 82 | 91 | 98 | average | |

| Teufelberger | PERFECTION TK15 | Steel ropes 10 mm TK15 16 X7 | Austria | 0,45 | 74,4 | 82,4 | 87,4 | high | |

| Teufelberger | QS816V(G) | TK 16 16xK6 / 16xK7 | Austria | 0,46 | 81 | 89 | 98 | average | |

| Redailly | FlexPack | STEEL ROPE 10 mm IPERFLEX 34(W)ХK7 | Italy | 0,48 | 92 | 98 | high | ||

| Redailly | Iperflex | Steel rope 10 mm Iperflex 34(W)x7 | Italy | 0,43 | 79 | high | |||

| Redailly | A4ALC Pack133 | STEEL ROPE 10 mm A4ALC/PACK 13319ХК7 | Italy | 0,46 | 57,1 | 60,5 | high | ||

| BDJWGS | STEEL ROPE 10 mm GT34Z 34ХК7 | China | 0,72 | 97 | 101 | ||||

| BDJWGS | STEEL ROPE 10 mm GT34 34Х7 | China | 0,46 | 57,1 | 60,5 | ||||

| BDJWGS | STEEL ROPE 10 mm GT8Z8ХK36 | China | 0,47 | 93 | 97 | ||||

| BDJWGS | STEEL ROPE 10 mm GT18Z19ХК7 | China | 0,5 | 80 | 88 | ||||

| BDJWGS | STEEL ROPE 10 mm GT6Z6XK36 | China | 0,46 | 87 | 94 | ||||

Our company's catalog contains a wide range of cables from the world's leading manufacturers. We work directly with manufacturers, so our price for 10 mm steel rope is favorable. We also offer fastening equipment and provide services for preparing cables for operation. The products are widely used in many industrial fields.

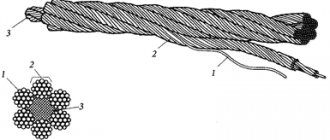

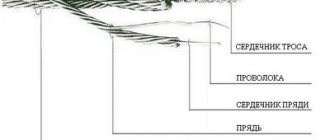

Features of design and materials

Steel rope GOST 2688–80 consists of six wire strands , which are twisted into one concentric surface around an organic core.

Natural and artificial materials are used as an organic core, such as:

- sisal;

- hemp;

- cotton yarn;

- nylon threads;

- nylon;

- polyethylene.

The core material is impregnated with a lubricant, which protects it from rotting and increases the life of the product. GOST 15037–69 lubricants are mineral oils containing solid hydrocarbons and copper salts. The organic core provides the necessary elasticity and flexibility of steel cables.

Each LK-R metal strand consists of 19 round wires twisted into three layers. The outer layer contains wires of different diameters, which ensures a linear type of contact in the strands, uniformity and strength of the rope surface. Cables with LK-R strands have high wear resistance and performance.

A design feature is the direction of twisting of the rope elements. The direction of twisting of the wire in the strands can be left or right. The combination of directions of elements during laying determines the properties of the cable. Single-laid ropes are flexible, wear-resistant, but easily unwind under load. Non-unwinding structures are made using cross or combined laying methods.

Round wire for steel cables is made from carbon steel without coating or with a galvanized outer layer.

Steel rope 10 mm: brands and characteristics

The Austrian manufacturer Teufelberger produces a wide range of rope products. The products meet the high requirements of international quality standards and have high technical characteristics. They are reliable, safe to use, and resistant to corrosion. The brand's cables are made from high-quality raw materials. Production technology is constantly being improved.

Redailli (Italy) is a manufacturer of steel ropes intended for use in construction, elevators, and equipping various lifting equipment. The manufacturer's ropes are highly durable.

The company's catalog also includes cables from a major Chinese manufacturer, BDJWGS. They serve for a long time, have high breaking characteristics, and are affordable.

The weight of 10 mm ropes ranges from 0.43 to 0.5 kg/meter. They can withstand between 5.8 tons (57 kN) and 10 tons (101 kN). The characteristics depend on the design and model of the cable.

Fill out the form on our website to buy 10 mm steel rope from our company. We offer wire ropes for all industrial areas. If necessary, our specialists will help you choose the optimal type of cable for your lifting equipment. We offer high quality products that are characterized by reliability and long service life.

Marking groups, dimensions and weight

The last digit in the rope designation is a marking group that indicates the strength characteristics of the rope. The higher the number, the stronger the cable and the greater the load it can withstand during operation.

According to GOST 2688–80, ropes are produced with a cross-sectional diameter from 3.6 to 56 mm with strength characteristics from 1370 to 1860 N/mm 2 (140–190 kgf/mm 2). The standard tables indicate the diameters of the ropes, all wire layers of strands, strength characteristics and the approximate weight of 1 thousand meters of cable. The weight of a steel rope GOST 2688–80 can be determined by multiplying the weight value of 1 thousand meters of cable taken from the table by the length of the rope and dividing the resulting value by 1000.

1 thousand meters of rope with a diameter of 12 mm weighs approximately 520 kg; with a diameter of 21 mm - 1630 kg. The weight of one meter of a product with a thickness of 37 mm will be approximately 5 kg, and one meter with a thickness of 56 mm will be 11.6 kg.

Tensile strength parameters of steel cables

To establish what load a steel cable can withstand, it is important to take into account that its choice is determined by two main parameters - breaking and working strength.

Tensile strength

Breaking strength refers to the minimum force on a rope at which it will break. If it is necessary to determine this value of a steel cable, the tensile characteristics are taken from GOST or determined using the formula:

R=Kd2, where

- K – safety factor;

- d – diameter, mm.

The coefficient K when calculating the breaking load of cables is unchanged and is selected depending on the type of specific product. So, if you need to find out the value of a single-strand type product, use the figure 70. For a rope with one organic core, take the number 40, with several cores - 34.

SK-Supply

Steel rope GOST 2688-80 crane round strand analogue DIN 3059 ISO 434,

It is used in mines, in hoisting and transport machines, for overhead roads and cable cranes, in earthmoving and road machines, for lifting installations in the metallurgical industry, on ships, timber rafting, forestry and woodworking industries.

Made from uncoated and galvanized wire. At the Customer's request, ropes are supplied lubricated or not.

According to European standards, the analogue of GOST 2688 is DIN 3059. The rope of this GOST has an organic core (hemp, polypropylene).

Steel rope GOST 2688 80

Breaking strength of rope 2688 in general, depending on its diameter and marking group:

- 1570 N/mm2 15800 - 676000 N

- 1670 N/mm2 16800 - 610500 N

- 1770 N/mm2 17800 - 629000 N

Steel rope GOST 2688-80 has proven itself to be excellent when working in aggressive environments, for unfavorable and stressful conditions, with intense alternating bending in the open air. High filling density, flexibility, large bearing surface, designed for high abrasive wear.

The high structural strength of GOST 2688-80 ropes allows them to be used in many very stressful working conditions.

The approximate weight of 1000 m of lubricated rope GOST 2688 55.1 is 5740 kg. GOST 2688 rope is supplied wound on a wooden drum.

The stock range includes steel ropes from leading manufacturers: steel rope GOST 2688-80 galvanized dry for cargo, cargo, lift, crane, lifting, metal, rope for gantry and cantilever cranes, beam crane, for hoists and winches.

Steel rope GOST 2688-80 is divided according to the following criteria:

by purpose: cargo rope - GL, cargo rope - G;

by mechanical properties of grades: VK, V, 1; by type of wire surface coating: from uncoated wire, from galvanized wire, depending on the surface density of zinc: S, ZH, OZH; in the direction of lay: right, left - L; by combination of directions of laying of rope elements: cross, one-sided - O; combined - K; by laying method: non-unwinding - N, unwinding; according to manufacturing accuracy: normal, increased - T; according to the degree of balance: straightened - R, unstraightened. Steel rope GOST 2688-80 cable. Specifications.

| Diameter, mm | Estimated cross-sectional area of all wires, mm2 | Weight of 1000 m of lubricated rope, kg | Marking group, N/mm2 (kgf/mm2) | |||||

| rope | wire | 1370(140) | ||||||

| central | first layer (inner) | second layer | (external) | |||||

| Breaking force N, not less | ||||||||

| sum of all the wires in the rope | the rope as a whole | |||||||

| 6 wires | 36 wires | 36 wires | 36 wires | |||||

| 3,6 | 0,26 | 0,24 | 0,20 | 0,26 | 4,98 | 48,8 | — | — |

| 3,8 | 0,28 | 0,26 | 0,20 | 0,28 | 5,63 | 55,1 | — | — |

| 4,1 | 0,30 | 0,28 | 0,22 | 030 | 6,55 | 64,1 | — | — |

| 4,5 | 0,32 | 0,30 | 0,24 | 0,32 | 7,55 | 73,9 | — | — |

| 4,8 | 0,34 | 0,32 | 0,26 | 0,34 | 8,62 | 84,4 | — | — |

| 5,1 | 0,36 | 0,34 | 0,28 | 0,36 | 9,76 | 95,5 | — | — |

| 5,6 | 0,40 | 0,38 | 0,30 | 0,40 | 11,90 | 116,5 | — | — |

| 6,2 | 0,45 | 0,40 | 0,34 | 0,45 | 14,47 | 141,6 | — | — |

| 6,9 | 0,50 | 0,45 | 0,38 | 0,50 | 18,05 | 176,6 | — | — |

| 7,6 | 0,55 | 0,50 | 0,40 | 0,55 | 21,57 | 211,0 | — | — |

| 8,3 | 0,650 | 0,55 | 0,45 | 0,60 | 26,15 | 256,0 | — | — |

| 9,1 | 0,65 | 0,60 | 0,50 | 0,65 | 31,18 | 305,0 | — | — |

| 9,6 | 0,70 | 0,65 | 0,55 | 0,70 | 36,66 | 358,6 | — | — |

| 11,0 | 0,80 | 0,75 | 0,60 | 0,80 | 47,19 | 461,6 | — | — |

| 12,0 | 0,85 | 0,80 | 0,65 | 0,85 | 53,87 | 527,0 | — | — |

| 13,0 | 0,90 | 0,85 | 0,70 | 0,90 | 61,00 | 596,6 | 83650 | 71050 |

| 14,0 | 1,00 | 0,95 | 0,75 | 1,00 | 74,40 | 728,0 | 102000 | 86700 |

| 15,0 | 1,10 | 1,00 | 0,80 | 1,10 | 86,28 | 844,0 | 118000 | 1000000 |

| 16,5 | 1,20 | 1,10 | 0,90 | 1,20 | 104,61 | 1025,0 | 143500 | 1215100 |

| 18,0 | 1,30 | 1,20 | 1,00 | 1,30 | 124,73 | 1220,0 | 171000 | 145000 |

| 19,5 | 1,40 | 1,30 | 1,05 | 1,40 | 143,61 | 1405,0 | 197000 | 167000 |

| 21,0 | 1,50 | 1,40 | 1,15 | 1,50 | 167,03 | 1635,0 | 229000 | 194500 |

| 22,5 | 1,60 | 1,50 | 1,20 | 1,60 | 188,78 | 1850,1 | 259000 | 220000 |

| 24,0 | 1,70 | 1,60 | 1,30 | 1,70 | 215,49 | 2110,0 | 295500 | 250000 |

| 25,5 | 1,80 | 1,70 | 1,40 | 1,80 | 244,00 | 2390,0 | 334500 | 284000 |

| 27,0 | 1,90 | 1,80 | 1,50 | 1,90 | 274,31 | 2685,0 | 376000 | 319000 |

| 28,0 | 2,00 | 1,90 | 1,50 | 2,00 | 297,63 | 2910,0 | 408000 | 346500 |

| 30,5 | 2,20 | 2,10 | 1,60 | 2,20 | 356,72 | 3490,0 | 489000 | 415500 |

| 32,0 | 2,30 | 2,20 | 1,70 | 2,30 | 393,06 | 384,5,0 | 539000 | 4581000 |

| 33,5 | 2,40 | 2,30 | 1,80 | 2,40 | 431,18 | 4220,0 | 591500 | 502500 |

| 37,0 | 2,60 | 2,50 | 2,00 | 2,60 | 512,79 | 5015,0 | 703500 | 597500 |

| 39,5 | 2,80 | 2,60 | 2,20 | 2,80 | 586,59 | 5740,0 | 804500 | 684000 |

| 42,0 | 3,00 | 2,80 | 2,30 | 3,00 | 668,12 | 6535,0 | 916500 | 779000 |

| 44,5 | 3,20 | 3,00 | 2,40 | 3,20 | 755,11 | 7385,0 | 1035000 | 880500 |

| 47,5 | 3,40 | 3,20 | 2,60 | 3,40 | 861,98 | 8430,0 | 1180000 | 1000000 |

| 51,0 | 3,60 | 3,40 | 2,80 | 3,60 | 976,03 | 9545,0 | 1335000 | 1135000 |

| 56,0 | 4,00 | 3,80 | 3,00 | 4,00 | 1190,53 | 116550,0 | 1630000 | 1385000 |

Specifications. Steel rope GOST 2688-80 double lay cargo rope type LK-R, design 6x19 with an organic core.

| Diameter, mm | Cross-sectional area of all pr-ok, mm2 | Weight of 1000 m of grease rope, kg | Marking group, N/mm2 (kgf/mm2) | |||||||||||

| ka-ta | wire | 1470(150) | 1570(160) | 1670(170) | ||||||||||

| central | first layer (internal) | second layer (outer) | ||||||||||||

| Breaking force, N, not less | ||||||||||||||

| sum of all pr-ok in the rope | the rope as a whole | sum of all pr-ok in the rope | the rope as a whole | sum of all pr-ok in the rope | the rope as a whole | |||||||||

| 6 wires | 36 wires | 36 wires | 36 wires | |||||||||||

| 3,6 | 0,26 | 0,24 | 0,20 | 0,26 | 4,98 | 48,8 | — | — | — | — | — | — | ||

| 3,8 | 01,28 | 0,26 | 0,20 | 0,28 | 5,63 | 55,1 | — | — | — | — | — | — | ||

| 4,1 | 030 | 0,28 | 0,22 | 0,30 | 6,55 | 64,1 | — | — | — | — | — | — | ||

| 4,5 | 0,32 | 0,30 | 0,24 | 0,32 | 7,55 | 73,9 | — | — | — | — | — | — | ||

| 4,8 | 0,34 | 0,32 | 0,26 | 0,34 | 8,62 | 84,4 | — | — | — | — | — | — | ||

| 5,1 | 0,36 | 0,34 | 0,28 | 0,36 | 9,76 | 95,5 | — | — | — | — | — | — | ||

| 5,6 | 0,40 | 0,38 | 0,30 | 0,40 | 11,90 | 116,5 | — | — | 18650 | 15800 | 19800 | 16800 | ||

| 6,2 | 0,45 | 0,40 | 0,34 | 0,45 | 14,47 | 141,6 | — | — | 22650 | 19250 | 24100 | 20100 | ||

| 6,9 | 0,50 | 0,45 | 0,38 | 0,50 | 18,05 | 176,6 | — | — | 28300 | 24000 | 30050 | 25500 | ||

| 7,6 | 0,55 | 0,50 | 0,40 | 0,55 | 21,57 | 211,0 | — | — | 33860 | 28700 | 35900 | 30500 | ||

| 8,3 | 0,60 | 0,55 | 0,45 | 0,60 | 26,15 | 256,0 | — | — | 41000 | 34800 | 43550 | 3,6950 | ||

| 9,1 | 0,65 | 0,60 | 0,50 | 0,65 | 31,18 | 305,0 | — | — | 48850 | 41500 | 51900 | 44100 | ||

| 9,6 | 0,70 | 0,65 | 0,55 | 0,70 | 36,66 | 358,6 | — | — | 57450 | 48850 | 61050 | 51850 | ||

| 11,0 | 0,80 | 0,75 | 0,60 | 0,80 | 47,19 | 461,6 | — | — | 73950 | 62860 | 78600 | 66750 | ||

| 12,0 | 0,85 | 0,80 | 0,65 | 0,85 | 53,87 | 527,0 | — | — | 84450 | 71750 | 89700 | 76200 | ||

| 13,0 | 0,90 | 0,85 | 0,70 | 0,90 | 61,00 | 696,6 | 89650 | 76190 | 95600 | 81250 | 101500 | 86800 | ||

| 14,0 | 1,00 | 0,95 | 0,75 | 1,00 | 74,40 | 728,0 | 109000 | 92850 | 116500 | 98950 | 123500 | 105000 | ||

| 15,0 | 1,10 | 1,00 | 0,80 | 1,10 | 86,28 | 844,0 | 126500 | 107000 | 135000 | 114500 | 143500 | 122000 | ||

| 16,5 | 1,20 | 1,10 | 0,90 | 1,20 | 104,61 | 1025,0 | 153500 | 130000 | 164000 | 139000 | 174000 | 147500 | ||

| 18,0 | 1,30 | 1,20 | 1,00 | 1,30 | 124,73 | 1220,0 | 183000 | 155000 | 195500 | 166000 | 207500 | 176000 | ||

| 19,5 | 1,40 | 1,30 | 1,05 | 1,40 | 143,61 | 1405,0 | 211000 | 178500 | 225000 | 191000 | 2319000 | 203000 | ||

| 21,0, | 1,50 | 1,40 | 1,15 | 1,50 | 167,03 | 1635,0 | 245500 | 208000 | 261500 | 222000 | 278000 | 236000 | ||

| 22,5 | 1,60 | 1,50 | 1,20, | 1,60 | 188,78 | 1850,0 | 277500 | 235500 | 296000 | 251000 | 314500 | 267000 | ||

| 24,0 | 1,70 | 1,60 | 1,30 | 1,70 | 2,15,49 | 2110,0 | 316500 | 269000 | 337500 | 2187000 | 359000 | 304500 | ||

| 25,5 | 1,80 | 1,70 | 1,40 | 1,80 | 2,44,00 | 2390,0 | 358500 | 304500 | 382500 | 324500 | 406500 | 345000 | ||

| 27,0 | 1,90 | 1,80 | 1,50 | 1,90 | 274,31 | 2685,0 | 403000 | 342000 | 430000 | 365000 | 457000 | 388000 | ||

| 28,0 | 2,00 | 1,90 | 1,50 | 2,00 | 297,63 | 2910,0 | 437500 | 371000 | 466500 | 396000 | 495500 | 421000 | ||

| 30,5 | 2,20 | 2,10 | 1,60 | 2,20 | 256,72 | 3490,0 | 524000 | 445500 | 559000 | 475000 | 594000 | 504500 | ||

| 32,0 | 2,30 | 2,20 | 1,70 | 2,30 | 393,06 | 3845,0 | 577500 | 490500 | 616000 | 523500 | 654500 | 556000 | ||

| 33,5 | 2,40 | 2,30 | 1,80 | 2,40 | 431,18 | 4220,0 | 633500 | 538500 | 676000 | 574000 | 718000 | 610500 | ||

| 37,0 | 2,60 | 2,50 | 2,00 | 2,60 | 512,79 | 5015,0 | 753500 | 640000 | 804000 | 683000 | 854000 | 725000 | ||

| 39,5 | 2,80 | 2,60 | 2,20 | 2,80 | 586,59 | 5740,0 | 862000 | 732500 | 919500 | 781500 | 977000 | 828000 | ||

| 42,0 | 3,00 | 2,80 | 2,30 | 3,00 | 668,12 | 6535,0 | 98200 | 833000 | 1045000 | 890000 | 1110000 | 945000 | ||

| 44,5 | 3,20 | 3,00 | 2,40 | 3,20 | 755,11 | 738,5,0 | 1110000 | 941000 | 1180000 | 1000000 | 1255000 | 1035000 | ||

| 47,5 | 3,40 | 3,20 | 2,60 | 3,40 | 861,98 | 8430,0 | 1265000 | 1070000 | 1350000 | 1145000 | 1435000 | 1185000 | ||

| 51,0 | 3,60 | 3,40 | 2,80 | 3,60 | 976,03 | 9545,0 | 11430000 | 1215000 | 1530000 | 1295000 | 1625000 | 1340000 | ||

| 56,0 | 4,00 | 3,80 | 3,00 | 4,00 | 1190,53 | 11650,0 | 1750000 | 14800010 | 1865000 | 1580000 | 1980000 | 1635000 | ||

Specifications. Steel rope GOST 2688 cargo cable type LK-R with an organic core.

| Diameter, mm | Estimated cross-sectional area of all wires, mm2 | Weight of 1000 m of grease rope, kg | Marking group, N/mm2 (kgf/mm2) | |||||||

| ka-ta | wire | 1770(180) | 1860(190) | |||||||

| center-oh | first layer (inner) | second layer (outer) | ||||||||

| Breaking force, N, not less | ||||||||||

| 6 pro-ok | 36 pro-ok | 36 pro-ok | 36 pro-ok | total of all pro-ok in the rope | the rope as a whole | total of all pro-ok in the rope | the rope as a whole | |||

| 3,6 | 0,26 | 0,24 | 0,20 | 0,26 | 4,98 | 48,8 | 8780 | 7465 | 9270 | 7880 |

| 3,8 | 0,28 | 0,26 | 0,20 | 0,28 | 5,63 | 55,1 | 9930 | 8400 | 10450 | 8750 |

| 4,1 | 0,30 | 0,28 | 0,22 | 0,30 | 6,55 | 64,1 | 11550 | 9750 | 12150 | 11C150 |

| 4,5 | 0,32 | 0,30 | 0,24 | 0,32 | 7,55 | 73,9 | 13300 | 11250 | 14090 | 11790 |

| 4,8 | 0,34 | 0,32 | 0,26 | 0,34 | 8,62 | 84,4 | 15200 | 12850 | 16050 | 13400 |

| 5,1 | 0,36 | 0,34 | 0,28 | 0,36 | 9,76 | 95,5 | 17200 | 14600 | 18150 | 15150 |

| 5,6 | 0,40 | 0,38 | 0,30 | 0,40 | 11,90 | 116,5 | 20950 | 17800 | 22150 | 1,8,550 |

| 6,2 | 0,45 | 0,40 | 0,34 | 0,45 | 14,47 | 141,6 | 25500 | 21100 | 26900 | 22250 |

| 6,9 | 0,50 | 0,45 | 0,38 | 0,50 | 18,05 | 176,6 | 31800 | 26300 | 33600 | 27450 |

| 7,6 | 0,55 | 0,50 | 0,40 | 0,55 | 21,57 | 211,0 | 38000 | 32300 | 40150 | 32900 |

| 8,3 | 0,60 | 0,55 | 0,45 | 0,60 | 26,15 | 256,0 | 46100 | 38150 | 48650 | 39850 |

| 9,1 | 0,65 | 0,60 | 0,50 | 0,65 | 31,18 | 305,0 | 55000 | 45450 | 58050 | 47500 |

| 9,6 | 0,70 | 0,65 | 0,55 | 0,70 | 36,66 | 358,6 | 64650 | 53450 | 68250 | 55950 |

| 11,0 | 0,80 | 0,75 | 0,60 | 0,80 | 47,19 | 461,6 | 83200 | 68800 | 87850 | 72000 |

| 12,0 | 0,85 | 0,80 | 0,65 | 0,86 | 53,87 | 527,0 | 95000 | 78550 | 100000 | 81900 |

| 13,0 | 0,90 | 0,85 | 0,70 | 0,90 | 61,00 | 596,6 | 107500 | 89000 | 113500 | 92800 |

| 14,0 | 1,00 | 0,95 | 0,75 | 1,00 | 74,40 | 728,0 | 131000 | 108000 | 138500 | 112500 |

| 15,0 | 1,10 | 1,00 | 0,80 | 1,10 | 86,28 | 844,0 | 152000 | 125500 | 160500 | 131000 |

| 16,5 | 1,20 | 1,10 | 0,90 | 1,20 | 104,61 | 1025,0 | 184500 | 152000 | 194500 | 159000 |

| 18,0 | 1,30 | 1,20 | 1,00 | 1,30 | 124,73 | 1220,0 | 220000 | 181500 | 232000 | 189500 |

| 19,5 | 1,40 | 1,30 | 1,05 | 1,40 | 143,61 | 1405,0 | 253000 | 209000 | 267000 | 218500 |

| 21,0 | 1,50 | 1,40 | 1,15 | 1,50 | 167,03 | 1635,0 | 294500 | 243500 | 311000 | 254000 |

| 22,5 | 1,60 | 1,50 | 1,20 | 1,60 | 188,78 | 1850,0 | 333000 | 275000 | 351500 | 287500 |

| 24,0 | 1,70 | 1,60 | 1,30 | 1,70 | 215,49 | 2110,0 | 316500 | 314000 | 401000 | 328000 |

| 25,5 | 1,80 | 1,70 | 1,40 | 1,80 | 244,00 | 2390,0 | 380000 | 356000 | 454000 | 372000 |

| 2,7,0 | 1,90 | 1,80 | 1,50 | 1,90 | 274,31 | 2685,0 | 430000 | 399500 | 510500 | 418000 |

| 28,00 | 2,00 | 1,90 | 1,50 | 2,00 | 297,63 | 2910,0 | 525000 | 434000 | 554000 | 453500 |

| 30,5 | 2,20 | 2,10 | 1,60 | 2,20 | 356,72 | 3490,0 | 629000 | 520000 | 661000 | 544000 |

| 32,0 | 2,30 | 2,20 | 1,70 | 2,30 | 393,06 | 3815,0 | 693000 | 573000 | 731500 | 599500 |

| 33,5 | 2,40 | 2,30 | 1,80 | 2,40 | 431,18 | 4220,0 | 760500 | 629000 | 802500 | 658000 |

| 37,0 | 2,60 | 2,50 | 2,00 | 2,60 | 512,79 | 5015,0 | 904500 | 748000 | 954500 | 782500 |

| 39,5 | 2,80 | 2,60 | 2,20 | 2,80 | 586,59 | 5740,0 | 1030000 | 856000 | 1090000 | 891500 |

| 42,0 | 3,00 | 2,80 | 2,30 | 3,00 | 668,12 | 6535,0 | 1175000 | 975000 | 1240000 | 101000 |

| 44,5 | 3,20 | 3,00 | 2,40 | 3,20 | 755,11 | 7385,0 | 11330000 | 1075000 | — | — |

| 47,5 | 3,40 | 3,20 | 2,60 | 3,40 | 861,98 | 8430,0 | 1520000 | 1230000 | — | — |

| 51,0 | 3,60 | 3,40 | 2,80 | 3,60 | 976,03 | 9545,0 | 1920000 | 1395000 | — | — |

| 56,0 | 4,00 | 3,80 | 3,00 | 4,00 | 1190,53 | 11650,0 | 2100000 | 1705000 | — | — |

Double lay steel rope GOST 2688-80 type LK-R.

| Diameter, mm | Estimated cross-sectional area of all wires, mm2 | Approximate weight of 1000 m of lubricated rope, kg | Marking group, N/mm2 (kgf/mm2) | |||||

| rope | wire | 2160(220) | ||||||

| central | first layer (inner) | second layer (outer) | ||||||

| Breaking force, H, not less | ||||||||

| 6 wires | 36 wires | 36 wires | 36 wires | total of all wires in the rope | the rope as a whole | |||

| 3,6 | 0,26 | 0,24 | 0,20 | 0,26 | 4,98 | 48,8 | 10700 | 8910 |

| 3,8 | 0,2,8 | 0,26 | 0,20 | 0,28 | 5,63 | 55,1 | 12100 | 10000 |

| 4,1 | 0,30 | 0,28 | 0,22 | 0,30 | 6,55 | 64,1 | 14100 | 11650 |

| 4,5 | 0,32 | 0,30 | 0,24 | 0,32 | 7,55 | 73,9 | 16250 | 13100 |

| 4,8 | 0,34 | 0,32 | 0,26 | 0,34 | 8,62 | 84,4 | 18550 | 14950 |

| 5,1 | 0,36 | 0,34 | 0,28 | 0,36 | 9,76 | 95,5 | 21000 | 17050 |

| 5,6 | 0,40 | 0,38 | 0,30 | 0,40 | 11,90 | 116,5 | 25650 | 20700 |

| 6,2 | 0,45 | 0,40 | 0,34 | 0,45 | 14,47 | 141,6 | 31150 | 25200 |

| 6,9 | 0,50 | 0,45 | 0,38 | 0,50 | 18,05 | 176,6 | — | — |

| 7,6 | 0,55 | 0,50 | 0,40 | 0,55 | 21,57 | 211,0 | — | — |

| 8,3 | 0,60 | 0,55 | 0,45 | 0,60 | 26,15 | 256,0 | — | — |

| 9,1 | 0,65 | 0,60 | 0,50 | 0,65 | 31,18 | 305,0 | — | — |

| 9,6 | 0,70 | 0,65 | 0,55 | 0,70 | 36,66 | 353,6 | — | — |

| 11,0 | 0,80 | 0,75 | 0,60 | 0,80 | 47,19 | 461,6 | — | — |

| 12,0 | 0,85 | 0,80 | 0,65 | 0,85 | 53,87 | 527,0 | — | — |

| 13,0 | 0,90 | 0,85 | 0,70 | 0,90 | 61,00 | 596,0 | — | — |

| 14,0 | 1,00 | 0,95 | 0,75 | 1,00 | 74,40 | 728,0 | — | — |

| 15,0 | 1,10 | 1,00 | 0,80 | 1,10 | 86,28 | 844,0 | — | — |

| 16,5 | 1,20 | 1,10 | 0,90 | 1,20 | 104,61 | 1025,0 | — | — |

| 18,0 | 1,30 | 1,20 | 1,00 | 1,30 | 124,73 | 1220,0 | — | — |

| 19,5 | 1,40 | 1,30 | 1,05 | 1,40 | 143,61 | 1405,0 | — | — |

| 21,0 | 1,50 | 1,40 | 1,15 | 1,50 | 167,03 | 1635,0 | — | — |

| 22,5 | 1,60 | 1,50 | 1,20 | 1,60 | 188,78 | 1850,0 | — | — |

| 24,0 | 1,70 | 1,60 | 1,30 | 1,70 | 215,49 | 2110,0 | — | — |

| 25,5 | 1,80 | 1,70 | 1,40 | 1,80 | 244,00 | 2390,0 | — | — |

| 27,0 | 1,90 | 1,80 | 1,50 | 1,90 | 274,31 | 2685,0 | — | — |

| 28,5 | 2,00 | 1,90 | 1,50 | 2,00 | 297,63 | 2910,0 | — | — |

| 30,5 | 2,20 | 2,10 | 1,60 | 2,20 | 356,72 | 3490,0 | — | — |

| 32,0 | 2,30 | 2,20 | 1,70 | 2,30 | 393,06 | 3845,0 | — | — |

| 33,5 | 2,40 | 2,30 | 1,80 | 2,40 | 431,18 | 4220,0 | — | — |

| 37,0 | 2,60 | 2,50 | 2,00 | 2,60 | 512,79 | 5015,0 | — | — |

| 39,5 | 2,80 | 2,60 | 2,20 | 2,80 | 586,59 | 5740,0 | — | — |

| 42,0 | 3,00 | 2,80 | 2,30 | 3,00 | 668,12 | 6535,0 | — | — |

| 44,5 | 3,20 | 3,00 | 2,40 | 3,20 | 755,11 | 7385,0 | — | — |

| 47,5 | 3,40 | 3,20 | 2,60 | 3,40 | 861,98 | 8430,0 | — | — |

| 51,0 | 3,60 | 3,40 | 2,80 | 3,60 | 976,03 | 9545,0 | — | — |

| 56,0 | 4,00 | 3,80 | 3,00 | 4,00 | 1190,53 | 11650,0 | — | — |

Notes:

1. Rope GOST 2688-80, the breaking force of which is given to the left of the bold line, is made from uncoated and galvanized wire. ropes made of galvanized wire of groups Zh and OZh with diameters of 51.0 and 56.0 mm of marking group 1370 N/mm2 (140 kgf/mm2), 42.0-47.5 mm of marking group 1470 N/mm2 (150 kgf/mm2) , 30.5-47.5 mm marking group 1570 N/mm2 (160 kgf/mm2), 30.5-39.5 mm marking group 1670 N/mm2 (170 kgf/mm2), 31.0-33.5 mm marking group 1770 N/mm2 (160 kgf/mm2), 11.0-16.5 mm marking group 1960 N/mm2 (200 kgf/mm2) are manufactured by agreement between the manufacturer and the consumer.

2. Steel cable GOST 2688-80 , the breaking force of which is given to the right of the bold line, is made from uncoated wire. It is allowed, by agreement between the manufacturer and the consumer, to manufacture ropes from galvanized wire.

Rope diameters greater than 10 mm are rounded to whole numbers or to the nearest 0.5 mm.

At the customer's request, it is possible to ship GOST 2688 steel ropes of unmeasured length (with unwinding).

Examples of symbols.

Steel rope GOST 2688-80 with a diameter of 12.0 mm, for cargo purposes, made of uncoated wire, grade B, left one-sided lay, non-unwinding, non-straightened, increased precision marking group 1770 N/mm2 (180 kgf/mm2):

Rope 12-GL-V-L-0-N-T-1770 GOST 2688-80

Cargo rope GOST 2688-80 with a diameter of 19.5 mm, grade VK, non-unwinding, straightened, high-precision marking group 1670 N/mm2 (170 kgf/mm2):

Rope 19.5-G-VK-N-R-T-1670 GOST 2688-80

Cargo cable GOST 2688-80 with a diameter of 16.5 mm, grade B, galvanized according to group “C”, non-unwinding, straightened, with increased precision of marking group 1770 N/mm2 (180 kgf/mm2):.

Cable 16.5-G-V-S-N-R-T-1770 GOST 2688-80

Rope GOST 2688-80 with a diameter of 32.0 mm, for cargo purposes, grade 1, galvanized according to the coolant group, right-hand cross lay, non-unwinding, non-straightened, normal accuracy of marking group 1370 N/mm2 (140 kgf/mm2):

Rope 32-G-1-OZH-N-1370 GOST 2688-80

Technical requirements, acceptance rules, test methods, labeling, packaging, transportation and storage in accordance with GOST 3241-91.

Steel

rope GOST 2688-80 is a cargo double lay rope (cable) of type LK-R with linear contact of wires between layers at different diameters in the outer layer of a strand of structure 6x19 (1+6+6/6)+1 organic core.