The quality of the work it produces directly depends on the sharpness of the blade. A dull or deformed tip does not perform its functions and can not only ruin the cutting process, but also injure the operator. Throughout the development of all bladed weapons, sharpeners were invented that could restore the original quality of the cutting edge. The further progress developed, the more high-tech sharpening stones became, and the amount of time that needed to be spent on work was reduced. Models with a motor at the heart of the design are considered the most powerful and efficient. Their range of functions includes straightening a bent edge, removing chips and nicks, grinding, cleaning, and restoring the original sharpness. However, the turning process requires practical or at least theoretical preparation. Unlike manual abrasive bars, where a sharp change in the angle of the blade will not have a critical effect on it, on automated models any mistake can lead to damage to the product. We will explain how a knife sharpening machine works, how to properly sharpen knives on a machine, how to achieve maximum efficiency and avoid the most common mistakes.

How to sharpen knives on a machine correctly

Before you learn how to properly sharpen knives on a machine, you need to become more familiar with its design. Since all motor models are divided into automatic and semi-automatic, instructions for their use will vary.

Figure 1. Wheels for sharpening knives: abrasive and felt

However, the operating principle remains the same:

- The electric motor rotates the axis on which a circle with a special coating is installed. For turning it is crystalline abrasive grains of various sizes, for grinding it is felt (Figure 1). The coarser the crystals on the wheel, the more severe dullness they can handle. It is prohibited to use coarse grain for thin, soft or partially dull blades - complete deformation will follow. The use of small crystals for a completely dull tip will also be ineffective;

- The rotation speed of the axis is selected by the operator himself, depending on the type of steel and the degree of dullness. If you choose the wrong mode, you can overheat the product and inevitably damage it under the influence of temperature;

This is where the similarities between automatic and semi-automatic devices end.

Figure 2. Options for professional knife sharpening machines

A professional automatic knife sharpening machine (Figure 2) operates according to the following algorithm:

- A motor and abrasive wheels of different grain sizes are built into a maximally closed casing with an opening (or several openings) for the blade. The system is designed in such a way that the inclination of the grinding wheel can change depending on the impact on the guides themselves. The operator inserts the product into the opening, and the guides automatically adjust the required angle;

- Since the turning inclination is individual for each tip, such devices imply the ability to adjust down to the millimeter;

- Most devices have several speed or time modes, so you need to know the characteristics of the gun in advance. By choosing too intense a mode, you can also deform the tip.

Figure 3. Typical “Epaper”

A manual machine (Figure 3) for sharpening knives (aka “emery”) requires an integrated approach to the entire process:

- Turning is carried out by applying the edge to a rotating wheel; precise inclination must be maintained. Otherwise, you can either grind off a significant layer of metal, or completely change the slope of the processing, which will ruin the blade;

- The attachment with grain is also selected according to the characteristics of the implement. For kitchen or travel models, fine sandpaper is sufficient, for working tools (for example, shoemakers) – medium sandpaper. Axes and other household and garden tools are sharpened using the coarse fraction;

- To ensure that the process proceeds smoothly, at first it is recommended to work with a partner who will monitor the uniformity and accuracy of the operator’s movements. Even an untrained person can act as an assistant: he only needs to concentrate on the work. At a more professional level, the operator copes independently;

- It is recommended to work in plastic safety glasses and closed clothing to prevent crumbs or sparks from touching soft or mucous tissues. Neglecting safety precautions when working with the machine is strictly prohibited.

Grinding

During processing, a sharpened knife develops microprotrusions and fractures—burrs. These defects are eliminated at the final stage for kitchen knives - grinding.

The grinding function is usually already built into the machines. It is done manually using a fine-grained abrasive. More professional products are polished at the end of processing.

When polishing yourself, you can use stretched leather - a special paste is applied to it. You should move the blade along the skin with movements toward you (towards the handle).

If sharpened correctly, the product will be razor sharp and will last a long time. Universal sharpeners allow you to bring not only knives to this state, but also, for example, scissors.

Sharpening or straightening knives?

Before moving on to the instructions on how to sharpen knives on a sharpening machine correctly, you need to determine what kind of care the blade of your tool needs - sharpening or sharpening. What is it for? The fact is that for different types of deformation, the principles of care will also differ. For example, when bending an edge, one nozzle and one speed are used, when removing chips, a completely different disk and different settings are used. Using standard bent edge turning techniques, you can cut off too much metal. Therefore, it is recommended to edit the gun first. Among the mechanical analogues, musat is used to eliminate wavy irregularities and curves - a round oblong file with a handle (Figure 4). However, if you have a machine, processing with hand tools is too energy-intensive.

Figure 4. Variant of the Musat file

Editing is carried out at minimum speed:

- The wave-bent metal is removed completely under the base. It will be impossible to bend it back. It is worth considering that cutting the deformed layer must be done with pinpoint precision, so as not to double the time of further processing and not accidentally shorten the length of the blade;

- Based on the initial edge angle, further work is carried out.

If you don't have any tools at hand

There are situations when there are no tools at hand at all, and sharpening a blade is a matter of life and death. For example, you find yourself without a sharp knife on a hike or you find yourself visiting a charming girl to whom you want to demonstrate your masculinity.

Here are some tips on how to “refresh” a knife blade using the simplest means at hand. This is not a thorough sharpening, but rather a finishing touch - but the tool will definitely cut better after it.

- Any stone. As you know, you can sharpen a knife with any stone, including a brick or cement block. The procedure here is the same as with a whetstone: move the blade in circles along its surface or edge, maintaining the correct angle.

- Ceramic plate. Ceramic is slightly harder than metal, so the back of ceramic cookware is also suitable for sharpening kitchen tools. This method helps to sharpen the blade no worse than using a block - although this procedure will take an order of magnitude longer.

- Sandpaper - “skin”. You won't be able to sharpen a dull blade well with sandpaper, but it will help sharpen a slightly dull blade.

How to sharpen knives on an emery machine

An electric sharpener, which is based on an emery disc, is used both at home for sharpening cutting edges and in production (Figure 5). The machine is used for sharpening jointing knives, countersinks, dies, drills, spatulas, hand scythes, household and travel blades, scissors and even screwdrivers.

The main requirement for the operator’s work is accuracy and adherence to the algorithm.

Figure 5. Electric grinder in production

How to sharpen knives on a sharpening machine:

- The standard set of sandpaper includes two abrasive discs of different grain sizes. At the first stage of processing, large grains should be used to give the primary shape and sharpness. Finishing is carried out on small crystals. If the blade is made of thin metal, then it is recommended not to use large crystals at all;

- The RPM for most tools should be up to 150 rpm. This value is the maximum, so you can reduce it if you have doubts about the speed;

- The point is made exclusively on the side of the abrasive nozzle. First, the blade is installed parallel to a special stand, then tilted at the required angle (Figure 6). For thin kitchen blades this value will be up to 20 degrees, for tourist and shoe blades - up to 35 or 40 degrees;

- The width of the approach (the transition from the “body” of the blade to the tip) should be 2-3 millimeters. A larger value of 4-5 millimeters is used for rough tools such as an ax or garden shears;

- During the entire process, it is necessary to make smooth and symmetrical movements, barely touching the disk and moving the blade from side to side with the same amplitude. This is necessary for uniform turning;

- To prevent the tool from overheating, if it is impossible to reduce the engine speed, it should be cooled regularly. A container of cold running water will suffice for cooling.

Figure 6. Sharpening a knife: parallel and at an angle

What's the end result?

As follows from the above article, the 21st century market is replete with a wide variety of sharpening machines that differ in purpose, which provokes users to make strict demands on them. However, in some cases the popularity of models depends on the cost of the device. In this situation, it will be more profitable to order online, including from the Ali Express website, after first reading the reviews of happy, or not so happy, owners. A large selection is presented on various platforms, including branded ones, where you can buy both simple electrical gadgets and those with a number of add-ons. This solution makes the systems suitable for any knife. And the above rating and recommendations will help you decide which one is better to buy.

Electric knife sharpeners

An automatic electric knife sharpening machine does not require special care. Previously, such models were used in public catering places - canteens, cafes and restaurants and were a bulky structure. Over time, their dimensions began to decrease, and now they are compact devices with connectors for different types of blades. The entire system is hidden under a plastic or metal casing, thereby increasing the safety factor.

Figure 7. Sharpening a knife on an automatic machine

Let's look at how to properly sharpen knives on an automatic machine (Figure 7):

- First, the point is inserted into the opening for rough processing, brought to the end and fixed between the plates. Since the device is equipped with guides, the disks will be positioned at the required angle as soon as the product is inserted into the slot;

- Then you should turn on the device, selecting standard or individual mode, depending on the provided functionality;

- Sharpening is done by lightly pressing the tip and moving it with the same movements in one direction. It is forbidden to drive first towards yourself, then away from yourself, since nicks will appear in the best case, and the edge will deteriorate in the worst case;

- After initial processing, the tool is inserted into a second slot with fine-grained discs, where it undergoes final grinding and finishing.

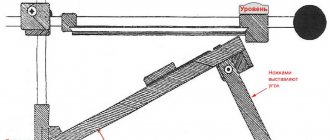

Homemade sharpening device

In order to make a knife sharpening machine with your own hands, the first thing you need to do is find a suitable drawing. There are many modifications for its production.

The easiest way

This option does not require special skill or the use of expensive components. To make it you will need:

- Wooden corners with a side of 20-30 centimeters: 2 pieces.

- Screws with nuts in the amount of 10 pieces.

- Protractor for precise angle setting.

- In addition, you will need a drill and drill bits.

To make it, you need to mark the corners and drill 3-4 holes at identical points. Place a block between them at the desired angle and secure with bolts.

To sharpen a knife or scissors, you simply need to run the blade along the surface of the block, holding it strictly vertically.

How to sharpen knives on a machine with an abrasive wheel

Another way to sharpen knives on a machine correctly is to use a grinder with a granular disk attachment (Figure 8). This method is popular among both professionals and amateurs, since there is no need to buy a separate device for turning.

Figure 8. Sharpening knives using a grinder

Turning on an angle grinder is carried out according to the same algorithm as on emery.

It is enough to fix the device vertically on the surface and install a medium or fine abrasive nozzle. Since the grinder produces over 11,000 rpm at its lowest power, it should be handled very carefully.

Tips on how to avoid mistakes when choosing

- You need to purchase a knife taking into account the composition of the cutting blade that is to be processed.

- The next equally important selection criterion is the ergonomics of the device. The tool must be extremely stable and easy to use.

- The power of the electric motor itself. These parameters affect only the sharpening speed, but not the quality. For a household appliance, a value of 20 W would be a good indicator, but devices with a power of 40 to 50 W are preferable.

- When buying a gadget, you should not rely only on the photo in the catalog and the seller’s promises. It is advisable to visit the mass market yourself and touch the item with your own hands. The highest quality models weigh more. Or read the comments of the owners if we are talking about purchasing from an online store.

- Solving the dilemma of what to prefer - power from an outlet or a device powered by a battery. It is better to pay attention to the option that operates from the network, since removable units can lose charge at the most inopportune moment.

- Manufacturer. Since there are quite a lot of such devices in 2022. It is worth choosing offers from well-known manufacturers with a large number of positive reviews and a long warranty on the device.

- Cost of goods. Often this aspect depends on the ergonomics and degree of sharpness of the object. Simple electric sharpeners without any additions can be found at prices ranging from 500 to 700 rubles. But their multifunctional subspecies are already more expensive.

Short

Battery or mains? The vast majority of electric cutters operate on mains power. Some have the ability to operate from other power sources, such as a car battery. Models with their own battery are not so common, and rarely does anyone use a knife outside the kitchen.

We sharpen the scissors. Not all scissor blades can straighten scissor blades. However, there are models that are designed for a wide range of household utensils. Such devices can not only sharpen knives and scissors, but also straighten drills, electric knives and other cutting objects.

Blade options

To sharpen a kitchen knife efficiently, you must not only have a regular whetstone on hand, but also know how to use it. It is also important to know what material the blade is made of in order to choose the right sharpening device for it.

Types of blades by material of manufacture:

- Carbon steel. This budget option for inexpensive products is made from an alloy of iron and carbon. Such blades are very easy to sharpen and retain their sharpness for a long period. The disadvantage of this material is oxidation when interacting with an acidic environment, as a result of which stains and rust form on the blade. Oxidation stops after some time when a coating forms on the metal.

- Stainless low carbon steel. The alloy of this material, in addition to iron and carbon, includes chromium. For some products, molybdenum or nickel is additionally added. In terms of strength, stainless steel blades are inferior to their carbon steel counterparts. They become dull faster and therefore require frequent sharpening. The advantage is high corrosion resistance.

- High carbon steel. These are knives of a higher category. A higher quality material with a high carbon content is used to make the blade. Vanadium or cobalt is additionally added to the alloy. Products made from this metal are resistant to corrosion and do not require frequent sharpening.

- Damascus steel. This material is intended for the production of edged weapons. But there are also models of kitchen knives. Such products have a multi-layer blade made from several high-quality alloys. The only negative is the high cost of the product.

- Ceramics. Blades made from this material are famous for their sharpness, which they retain for quite a long time. Due to this quality, they are very popular among consumers. But there is also a big disadvantage of such products - the high fragility of the material. The ceramic blade can be damaged by dropping the product on the floor from a height, or by significant bending.

When buying knives, it is not recommended to be fooled by advertising of self-sharpening products. Blades made of absolutely any material become dull; only those made of high-quality alloy last longer and, accordingly, cost more.

But you shouldn’t spend a lot of money on buying expensive blades; it’s better to buy a set of ordinary kitchen knives, several high-quality sharpening devices and learn how to sharpen knives yourself with a whetstone.