Metal bending prices

Prices for steel bending

| Thickness, mm | Bending length, mm | |||||

| up to 100 | up to 500 | up to 1000 | up to 2000 | up to 2500 | up to 3000 | |

| 0,5 — 2,5 | 10 rub. | 15 rub. | 20 rub. | 30 rub. | 40 rub. | 55 rub. |

| 3,0 — 5,0 | 15 rub. | 20 rub. | 25 rub. | 40 rub. | 50 rub. | 105 rub. |

| 6,0 — 8,0 | 30 rub. | 45 rub. | 55 rub. | 75 rub. | 110 rub. | 220 rub. |

Stainless steel bending prices

| Thickness, mm | Bending length, mm | |||||

| up to 100 | up to 500 | up to 1000 | up to 2000 | up to 2500 | up to 3000 | |

| 0,5 — 2,5 | 20 rub. | 30 rub. | 40 rub. | 60 rub. | 80 rub. | 110 rub. |

| 3,0 — 5,0 | 30 rub. | 40 rub. | 50 rub. | 80 rub. | 100 rub. | 210 rub. |

| 6,0 — 8,0 | 60 rub. | 90 rub. | 110 rub. | 150 rub. | 220 rub. | 440 rub. |

Prices for aluminum bending

| Thickness, mm | Bending length, mm | |||||

| up to 100 | up to 500 | up to 1000 | up to 2000 | up to 2500 | up to 3000 | |

| 0,5 — 2,5 | 15 rub. | 25 rub. | 30 rub. | 45 rub. | 60 rub. | 85 rub. |

| 3,0 — 5,0 | 25 rub. | 30 rub. | 45 rub. | 60 rub. | 75 rub. | 160 rub. |

| 6,0 — 8,0 | 45 rub. | 70 rub. | 85 rub. | 120 rub. | 165 rub. | 330 rub. |

Types of bending of metal products

Metal bending is done manually and using automatic devices. In the first case, the process will be quite labor-intensive, requiring the use of pliers and a hammer, as a result of which this procedure will take a lot of time.

It will be much easier and better to mechanize the process with the help of machines and corresponding devices. The cylinder shape is given to the product by special rollers. With their help, chimneys, gutters, and pipe products are created.

The development of machine tool production has made it possible to achieve bending of material for the manufacture of the most complex products. And the quick replacement of the working tool allows you to reconfigure the machine device as efficiently and quickly as possible.

Sheet metal bending: scope of application

This professional manipulation is used in many industries.

In particular, sheet metal bending is necessary for the following areas of the national economy:

- construction;

- design;

- production of metal structures;

- manufacturing of metal furniture;

- advertising designs;

- housing and communal services sector.

In addition, metal bending is used not only in industry. In private households, it can also provide an invaluable service in landscaping the area adjacent to the house.

Thanks to the elements obtained by bending, it is possible to create exclusive decorative compositions. Perhaps they will become the most creative moment of landscape design. Using sheet metal bending, you can make original courtyard structures, fencing structures around green spaces or gazebos.

Among other things, various household containers for storing equipment and household items are also made of sheet metal.

How to bend a metal strip into a ring?

In the process of building a house or cottage, there is often a need to equip drains, sewers, and metal frames.

When manufacturing such products, it is necessary to give the flat workpiece the necessary spatial shape. Advice from experienced craftsmen on how to bend a sheet of metal at home will allow you to produce good quality structures that will last a long time.

Bending technology - basic information

Metal bending is performed without welding seams, which avoids corrosion in the future and produces a product of increased strength. Deformation does not require significant effort and is usually performed in a cold state.

The exception is hard materials such as duralumin or carbon steels. Sheet metal bending technology is developed according to the assigned tasks in such options as:

- radius,

- multi-angle,

- single-angle,

- U-shaped.

A special case is flexion with stretching. This technology is used in the manufacture of parts with large bending radii and small diameters. When making parts with your own hands, the process is combined with operations such as cutting or punching.

Soft types of metals and alloys, such as brass, copper, and aluminum, are well suited for home processing. The production of products by bending is carried out on rolling or rolling machines, or manually.

The last procedure is quite labor-intensive. Bending is done using pliers and a rubber hammer. If the sheet is thin, use a mallet.

How to bend at right angles

To bend a bracket from a metal sheet, you will need a set of tools and accessories, consisting of:

- vice,

- hammer,

- power saws,

- bar,

- frames

The length of the strip is made according to the scheme, with the calculation that there should be a margin of 0.5 mm for each bend, plus another millimeter for folds on both sides. The workpiece is placed in a vice with squares. Clamping it along the fold line, process it with a hammer.

After this, the future bracket is unfolded in a vice, clamped with a frame and a block, and the other side is formed. The workpiece is pulled out, the required length of the sides is measured, making bends along the bottom.

Use a triangle to check the correctness of the angle, correcting inaccuracies with a hammer. When performing both operations, the workpiece is pressed with a block and a frame. The finished staple is filed to the desired size.

:

How to make a sheet bending machine yourself

To give the metal the desired configuration, tinsmiths use a sheet bending machine. But what should a master do if he doesn’t have special equipment at hand?

In fact, the question of how to bend sheet metal at home is easily resolved. It is enough to use your own ingenuity and basic equipment to make a simple machine.

To make a bender for a metal profile, you will need:

- I-beam 80 mm,

- fasteners (bolts),

- loops,

- corner 80 mm,

- clamps,

- a pair of handles.

You will also need a welding machine and a stable table on which the finished machine is mounted.

The basis of the device is an I-beam, to which a corner is screwed with two bolts, holding the workpiece during the bending process. Three door hinges are attached under it by welding. Their second part is welded directly to the corner.

In order for the machine to easily turn while bending sheet metal, handles are attached to it on both sides. The finished machine is secured to the table with clamps. Before laying the workpiece, the corner is unscrewed or lifted. The sheet is pressed, aligned along the edge and folded, turning the machine by the handles. The homemade device is only suitable for processing workpieces of small thickness.

:

Bending a metal sheet with a hammer

In order to bend a sheet up to 1.2 mm thick at a right angle, use the simplest tools - pliers (clamps) and a rubber hammer.

The processing is carried out on a flat wooden block. The fold line is drawn using a pencil and ruler. Then the sheet is clamped with pliers so that their ends fall exactly on the marking line.

The edge is gradually bent upward, moving along the fold. Once the angle approaches 90 degrees, the sheet is placed on the block and finally leveled using a hammer.

Narrow parts, such as tin edges, are made in this way.

Tip: Use a rubber or wooden hammer to prevent dents from forming on the metal. If bending is performed with a conventional tool, you need to take a textolite plate as a gasket.

It is convenient to bend sheets up to 2 mm thick on a desktop. The metal is positioned so that the marking line falls on the edge. A steel corner is placed under the material being processed.

The sheet is clamped in a vice using two wooden blocks. Bending is done using a hammer, tapping the metal from one end to the other. At the same time, the edge of the sheet is directed downward so that it ultimately lies completely on the corner fixed along the edge of the table. This method can be used to make products of any width, including boxes or barbecues.

:

Making pipes without using a machine

Home craftsmen have invented a lot of ways to bend a metal sheet into a pipe without using a machine.

We propose to consider the simplest option using a blank of suitable size. It is made from an old pipe of suitable diameter.

A sheet of metal is laid out on the floor and a piece of the required length is cut from it. To determine the required size, the required pipe diameter is multiplied by 3.14 and added 30 mm for the seam.

A pair of tubes are welded to the blank on both sides, perpendicular to one another. The crowbar should be freely inserted into their holes.

Master's recommendation: by bending a metal sheet using a blank, it is convenient to make pipes no more than a meter in length.

To use the device, the effort of three people is required. The blank is placed on the edge of the sheet. One person stands on top, two others screw the metal onto the blank, turning the crowbar 90 degrees.

The entire length of the sheet is rolled in this way, the remaining edge is hammered. The seam is secured by welding.

:

It must be taken into account that the bend radius of sheet metal depends on its thickness and manufacturing method. Hot rolled steel is more suitable for pipes; profile products are made from cold rolled steel. (

15,00

Production features of the method

The advantage of this method of processing metal sheets is the ability to produce a variety of metal profiles. Our company’s specialists can perform bends not only at right angles upon customer orders. Our company's production capacity allows us to perform Z-bending of sheet metal. This requires specific equipment and extensive professional experience.

Steel bending technology consists of simultaneous impact on a metal sheet from different sides. As a result, the linear size becomes larger on one side and smaller on the other. However, along the axis the metal completely retains its physical parameters. It is important that our clients can request bending according to customer drawings - for a specific project.

In different production conditions and depending on the task set by the client, the place of pressure and the force of pressure on the rolled product may be different. In order to fully meet the client’s requirements, bending is carried out according to a previously drawn up project.

Bending strips on edge

If bending is often done on strips of different widths, then you need to make several blocks with slots corresponding to the gauge that is being processed. But a homemade tool, for all its attractiveness and cheapness, is still inferior to an industrial one, the functionality of which is much higher.

Hand tools are produced in the form of universal devices, in which only the attachments and levers are changed, or in the form of entire sets, where each mechanism performs only one, maximum two functions. An example of such a kit is “Cold forging” of industrial production.

Moreover, their cost is not too high even for a home craftsman. Finding the necessary parts for a homemade machine, assembling, fitting and tuning will not cost much less, even with proper metalworking qualifications. If you do not buy the cheapest tools, then bending machines will work for decades.

Stages of work

The process is carried out in several stages. First of all, it is necessary to remember that bending is performed only in professional conditions. This procedure requires professional equipment and bending tools. Only in production workshops can the proper level of safety be ensured in meeting all technological requirements.

- At the preparatory stage, our specialists work on the product configuration. It is during this period that the locations of future bends are determined and the sizes of the corners are determined.

- The first stage of the procedure is cutting the workpiece. After this, it is sent to the bending machine. Bending and cutting of metal are carried out in conjunction. These manipulations are performed sequentially.

- The second stage is cutting according to the drawn up sketch. Depending on the complexity of the order, our specialists can choose laser cutting or a standard guillotine to perform this task. It should be noted that laser cutting ensures the most accurate compliance with the original plan.

- The next step is clamping the workpiece in the machine. For this, a hydraulic booster is used. Actually, the bending procedure is carried out using a hydraulic press.

- Finally, when the process is completed, our specialists verify all the specified parameters.

Strip metal bending

A series of articles devoted to metal processing continues on our website. We talked about how sheets and rolls from the delivery state are unraveled into strips (strips) in the article “Metal slitting lines.”

Metal bending is done using specialized equipment or manually. We described how this happens with imported equipment using the example of products from the Italian machine tool concern WARCOM. We talked about the use of domestic sheet bending machines for these purposes in an article about the Lipetsk sheet bending plant.

Today we will talk about manual bending of strip metal.

Manual bending of strip metal

Manual processing of metal strips is a labor-intensive operation, in most cases requiring special training of the worker and the appropriate tools. This operation is performed by a mechanic at a specially equipped workplace:

- a mechanic's workbench equipped with an appropriate vice;

- set of locksmith tools.

Let's look at a few simple operations with strip metal.

Right angle bending

We will bend the strip steel in a bench vice. Place the workpiece (clamp it) in a vice.

Bending in a vice.

We do this in such a way that the side with the bending point faces the stationary jaw of the vice (away from the worker). In this case, the mark should be approximately 0.5 mm higher than the jaw of the vice. Hammer blows should be applied in the direction of the stationary jaw of the vice. To avoid injury (if the workpiece springs back), the mechanic, when performing this operation, should not be positioned in the path of the hammer.

Bending at an acute angle

In this case, a mandrel having the required angle is used. It is installed in a vice along with the workpiece, as shown in the figure (with the high side facing the workpiece). The workpiece is deformed by hammer blows until it touches the bevel of the mandrel.

This is interesting: Why do they bend and weld sheet metal?

Manufacturing of staples and clamps

To make a bracket, you should use a frame block, the thickness of which will be equal to the opening of the bracket. Next, you should fasten the strip with the mandrel in a vice, as indicated in the figure, and bend first one side, and then the other.

Manufacturing of staples and clamps.

To make a clamp, fix the frame in a vice and bend a strip on it (see figure). Then, bend the ends of the clamp, release the equipment from the vice and use a hammer to give the part its final shape on the workbench table.

Hammer blows should not be applied to the clamp itself, so as not to leave scratches, nicks and dents on it. They should be carried out through a copper plate of small thickness, since it will well redistribute the impact force.

Bending connection

Strip bending is widely used for bending joints of parts. The connection can be completely bendable, as shown in the figure. Here, the fastening force is created by bending one part (often all connected parts are deformed).

In a number of cases, strip bending plays a supporting role. It can, for example, strengthen a threaded connection.

Examples of bending connections.

The figure shows examples of strip bending and strengthening of a nut-bolt threaded connection: a cotter pin and a lock washer.

Edge bending

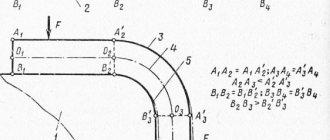

The operation is performed on the roller machine shown in the figure.

Bending steel strip “on edge”.

There are two features of this machine to consider:

- the upper guide of the base bar must have a groove that exactly matches the size of the deformed metal strip;

- The working roller and the top of the strip must be lubricated with grease.

These are the basic simple techniques for manually bending strip metal.

At the addresses indicated here you can select and purchase a metal bending machine.

Advantages of bending as a metal processing method

Automatic movement of the machine stops guarantees the quality of processing of individual elements in the total volume. That is, the human factor is eliminated when using sheet bending machines. Even the slightest inaccuracy is not allowed here.

Technically, the procedure consists of the knife pressing a workpiece of the required size into a v-shaped matrix, and this happens according to a preset algorithm. The machine does everything itself.

The advantages of automation also lie in the fact that the machine itself automatically calculates the position and trajectory of the bend. Accuracy is maintained across the entire width, so the final product complies with GOST.

Metal bending does not violate the physical and chemical properties of the material. The structure becomes stronger because the rib formed as a result of bending ensures stability and stability of the entire structure. This is a convenient, functional procedure that guarantees the durability of the entire metal composition.

Rules for bending metal in case of defects and processing difficulties

When working with low-plasticity steels (with a carbon content of more than 0.5%), difficulties arise due to springing, which leads to the fact that the configuration of the finished part does not correspond to the drawing. Springback is a major issue that must be considered when determining the bending process.

The essence of the phenomenon is the elastic aftereffect of the material, despite the removal of the working load. The result is a distortion of the shape of the workpiece (the actual springing angle can reach 12–150°); the defect negatively affects the accuracy of the mating of the finished part with the adjacent one.

Eliminating or reducing springback is possible using the following methods:

- Compensation of the spring angle due to a corresponding change in the settings of the working part of the punch and matrix. For the method to be effective, it is necessary to know the grade of the metal/alloy or its strength characteristics, including the tensile strength limit. In some cases, there is a need to carry out technological tests for bending. So, having found out that the spring angle is 100°, you should increase the working edge of the punch by a similar angle.

- By changing the working profile of the matrix, which leads to constant contact of the workpiece along the entire deformed length with the active working tool. This is achieved through technological undercuts or recesses (if possible) in the matrix.

- Increasing the ductility of the metal by annealing it before stamping. High-carbon steels are annealed at temperatures from +570 °C to +6,000 °C, low-carbon steels - at +180–2,000 °C.

- Flexible when hot, because as the temperature of the metal increases, its plastic characteristics improve. However, in this case, it is necessary to additionally clean both the workpiece surface and the working plane of the matrix from scale after each punch stroke.

By following the rules of metal bending, high-quality products are obtained, and the risk of harm to the health of the craftsman working with the workpieces is minimized.

What will a customer get from contacting our company?

Our specialists have a full set of modern tools to perform this service efficiently.

We perform bending for:

- case products;

- fences for portals in elevators;

- fastening strips;

- metal profiles;

- mounting plates;

- metal racks;

- metal parapets and railings.

To improve the quality of the work performed, upon agreement with the client, it is possible to apply silicone protection between the part and the matrix. This procedure is relevant for working with workpieces made of stainless material.

We will perform metal bending of any complexity, but first the managers will conduct a specialized consultation and offer to use standard projects developed by VT-Metall specialists.

So, the advantage of contacting our company is the availability of high-precision equipment, professional tools and extensive experience of craftsmen.

Defects that occur when metal bending rules are violated

The main flaws that arise when metal bending rules are not followed are:

- sink in the bending zone;

- cracks;

- folds;

- inaccuracies in the size and shape of parts.

- Utyazhina.

Due to this defect, the shape of the part is distorted and its strength is reduced. To eliminate the deficiency, metal is first collected at the bend site or a workpiece is planted during processing.

- Cracks.

They appear in the bending area on the outside of the workpiece, most often when processing low-ductility metal (in a cold or frozen state). When bending, for example, a cold duralumin blank, not only cracks form, but also complete destruction of the metal is possible.

Compliance with the requirements is important for workpieces made of high-carbon, alloy steels and alloys. The rules for bending metal require the selection of a suitable processing mode, i.e., optimal temperature, processing pattern, minimum bending radius, sequence of transitions, etc.

Price list for sheet metal bending

Unlike many other sites that work only at negotiated prices and do not indicate exact amounts in their price lists, we publish specific prices for this service.

However, let us clarify that these are average amounts. If you entrust us with an order of increased complexity or very urgent work, the cost of the project may increase. When completing large volumes within a comfortable time frame, we can please you with a discount. Features of sheet metal bending

The most difficult task, even for a specialist bending a 6-meter sheet, is to “feel” the balance of stress and deformation in a specific sheet of a specific thickness, made of a specific metal. In the process of bending - no matter whether manually or machine-made - two influences are alternately exerted on the sheet: first elastic, and then plastic. Thus, the inner layers are compressed in the sheet and the outer layers are stretched. The border, or neutral, layer becomes the “golden mean between them. The ability to find it is a “pass” to bending that is harmless to metal.

Determination of workpiece dimensions

An accurate calculation of metal bending helps a lot in determining the final cost of the work. You need to focus on the neutral line, that is, the axial layers of the workpiece, the dimensions of which do not change during the bending process. The calculation is carried out by determining the length of straight sections, counting curved fragments and summing up the results obtained. To calculate the total length, it is necessary to take into account the length of straight sections, as well as bend angles and curvature radii. If there should be no roundings, the calculation of metal bending and the length of the workpiece is determined taking into account the length of straight sections, the number of bends without rounding and the thickness of the workpiece material.

How popular is metal sheet bending?

The technology under consideration is actively used, since it allows production to abandon the use of stamps. The result is a one-piece, seamless structure with precise consideration of the angles and linear dimensions of the product. For production, the absence of a weld seam is an important advantage, since this is the area that is always considered the most problematic.

We carry out bending of thin sheet metal, with the only exception being fragile workpieces. The use of such technology is advisable for the manufacture of corners, channels, brackets and boxes, racks and shelves, facade cassettes and cathedral elements, window sills and building profiles with a complex design.

Advantages of sheet metal bending machines

- modern equipment;

- exceptional precision;

- high speed.

Nowadays, CNC sheet bending machines are used in industry. Having in its arsenal controllers with visualization in 2D and 3D space, bending equipment instantly copes with complex tasks.

The press brake, using hydraulic cylinders synchronized by electromagnetic valves, bends sheet metal quickly and with high precision. This operation is controlled by a program control system (CNC). All this allows you to bend sheets efficiently and accurately. The use of automated manipulators with a press allows you to put production on stream.

Air

Air bending of metal , or free bending, is a particularly complex technique. The result is influenced by many factors: type, thickness of the material, rolling direction, thermal influences, tool wear, width of the die groove, shape of the upper knife, reamer shortening values, angles, internal radius, influence of holes.

We are equipped with the necessary equipment and are ready to solve the most difficult tasks. Whether it concerns simple, high-volume processes or tight tolerances, we have a solution that works for you.

Step-by-step technological process

Our production allows us to produce a wide range of different rolled metal elements, and the bending technology itself is represented by the following stages.

- The preparatory stage requires deciding on the angles and bend points, dimensions of the final product and configuration.

- Before bending the metal, the sheet is cut by laser cutting.

- The sheet is clamped on a special bending machine with hydraulic cylinders, due to which the product is pressed.

- Metal bending with a press is carried out using hydraulic force.

- At each stage, we check the quality of the work performed and take control measurements before the subsequent submission of a full batch of workpieces.

Cost calculation

Calculating the price is quite complex; it includes many parameters that need attention. Accurate calculations are required, as well as an understanding of the properties of specific materials.

Metal bending often follows other metalworking operations, such as jig punching or laser cutting. To eliminate possible procedural errors that will lead to defects or the appearance of hidden design defects, and to achieve a high-quality result, engineering calculations are required.