Metal bending

is a technological operation that gives a metal sheet or profile a bend along the selected direction. The main advantage of bending is that this operation eliminates the use of welding and the metal structure remains monolithic. Bending is carried out on straightening presses and roll forming machines. A type of bending is rolling.

Rolling

is a technological operation of radial deformation of rolled sheets or profiles. Rolling is carried out on sheet bending and profile bending machines using special rollers (rollers).

We offer bending and rolling services for sheet metal, pipe, section and profile metal: reinforcement, circle, square, angle, I-beam, channel. All work is performed with high quality in a short time.

Metal bending and rolling

Flexible and rolling are often equated.

This is not entirely true, although the second technology is, in fact, a more complex version of the first. And the simplest bending and rolling are performed on fundamentally different equipment. Let’s take, for example, the most popular rolled product in processing—sheet metal. To bend it in the usual way, you will need a sheet bending machine, and this operation will be directly performed by its two leading elements - the matrix and the punch. In the case of rolling, the sheet is bent on rollers (rollers) - special rollers. Sometimes, in order to acquire the desired shape, the workpiece passes through a whole system of these mechanisms.

Our equipment

Our production uses the following sheet bending and roll forming equipment:

- sheet bending machine Sahinler 4R HSS 25-320

- roll forming machine Durma PBH 100

- press brake I1422

- press brake I-134

Sheet bending machine Sahinler 4R HSS 25-320

The 4-roll hydraulic sheet bending machine Sahinler 4R HSS 25-320 is designed for rolling metal sheets up to 20 mm thick. This machine is used for the production of cylindrical parts with constant and variable radius.

Technical characteristics of the sheet bending machine Sahinler 4R HSS 25-32

| Number of rolls, pcs | 4 |

| Roll length, mm | 2550 |

| Maximum sheet thickness, mm | 20 |

Roll forming machine Durma PBH 100

The 3-roll hydraulic roll forming machine Durma PBH 100 belongs to the class of roller rotary machines with rotational-translational movement of the working body and translational movement of the workpiece. The machine allows you to perform radius bending operations of various types of profiles: rectangular profile, strip, T-beam, I-beam, angle, rod, channel, pipe of round, rectangular and square sections.

Technical characteristics of the Durma PBH 100 roll forming machine

| Number of rollers, pcs | 3 |

| Roller diameter, mm | 315 |

| Maximum profile height, mm | 100 |

Press brake I1422

The I1422 hydraulic press brake is designed for bending sheet and strip metal products. Using a universal V-shaped die, the metal is bent at a certain angle, and the part is given the required configuration.

Technical characteristics of press brake I1422

| Nominal force, tons | 16 |

| Maximum length of bendable surface, mm | 1350 |

| Maximum sheet thickness, mm | 10 |

Press brake I-134

The I-134 crank press brake is designed for bending sheet and strip metal products.

Technical characteristics of the I-134 press brake

| Nominal force, tons | 100 |

| Maximum length of bendable surface, mm | 2550 |

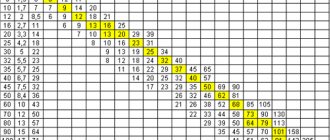

Metal rolling price

When indicating prices for rolling in price lists, many manufacturers clarify that this information is not a public offer and requires clarification. And there is no guile here, because the final cost of the project will depend on several factors:

- metal from which the blanks are produced;

- section thickness,

- complexity of the workpiece: passing a sheet through rolls is much easier than rolling a circle;

- bending radius;

- number of workpieces for processing.

By the way, the last factor can affect the formation of a discount: the larger the order volume, the greater the percentage the price can be reduced.

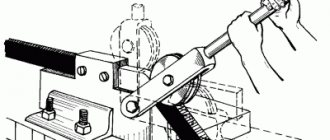

Making sheet-bending equipment yourself

To assemble a machine for sheet metal processing , you must have certain skills, consumables and tools.

The first thing you need is to draw it up yourself or find a drawing on the Internet. Next, you can begin preparing materials and assembling structural units, which include:

- roller frame;

- side racks;

- steel rollers (their diameter and number depend on the power of the device);

- a handle that sets the lower rollers in motion;

- drive unit (gear or chain), which ensures synchronous rotation of the lower rolls;

- spring type pressure unit.

The assembly of the rollers begins with the manufacture of the frame. It can be welded from thick steel blanks according to the dimensions indicated in the drawings. For the side racks, powerful channels made of low-carbon steel are suitable, which are attached to the frame by welding.

The elements of the drive unit are fixed on one of the racks, for which special holes are provided. After mounting the side posts, rollers are installed in the bearing units. They must be set in parallel and the remaining nodes must be finally fixed.

Rolling is widely in demand due to its undeniable advantages. Since this is a cold forming method , the material is not exposed to high temperatures during processing. This feature leaves the properties of the materials unchanged. The rolling operation makes it possible to obtain an accurate workpiece, a full-fledged part or a decorative element.

Sheet rolling

The main task of sheet rolling is to obtain a spatial product, from which a cylindrical blank (pipe), cone, oval, and other products can subsequently be formed. This technology differs from cylinder rolling by greater simplicity, since it is not volumetric, but flat rolled products that have to be bent. Compared to pressing and drawing work, this technology is considered:

- economical: the costs of equipment and equipment are minimal, and the process itself takes little time;

- effective. It can be used for both piece and mass production of blanks;

- gentle on the equipment - its wear is insignificant, and repair work in case of problems is simple and inexpensive;

- accurate and accurate: in the process of work, the likelihood of defects is reduced to a minimum.

Rolling process

Thanks to easy processing, products of any shape can be made from sheet material: in the form of a cone, cylinder, gutter, pipe, semi-ring or individual segments. The rolling technology itself is quite simple: the workpiece is passed between special shafts (rollers), after which it is deformed and takes the shape of a cylinder.

The process takes place in several stages:

- preparation of rollers;

- rolled sheet or bar;

- treatment of burrs and cracks;

Sheet rolling machines

Depending on the structure (number of work rolls), rolling equipment is divided into:

- two-roll,

- three-roll,

- four-roll.

The less equipment a machine has, the less functionality it has.

But even the simplest two-roll machines can bend metal on rollers for the manufacture of elements of chimneys, ventilation systems, air ducts, drainage networks, etc. The capabilities of the equipment are also determined by the size of the rollers: the bending radius directly depends on their size. The length of the roll is no less important: it affects the throughput across the width of the sheet. Finally, the power of the drive system indicates the machine’s potential for processing thick workpieces.

Roller components

There are two types of rolling equipment:

- machines with a pressure roller, most often located in the middle;

- installations with tools placed eccentrically.

The first type is used for rolling thick metal. The second option is used when workpieces are deformed by no more than 2.5 mm.

In the equipment under consideration, a significant difference is the relative arrangement of the rolls: symmetrical or asymmetrical. Asymmetric machines are more versatile. They are used not only for rolling cylinders, but also for a variety of edge designs.

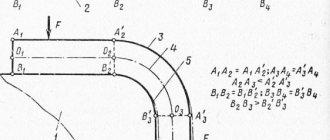

In practice, a scheme with three symmetrically located rolls is more often used, since it is more technologically advanced during maintenance. This type of rolling machine with external drive has the following components:

- electric motor;

- clinometer transmission or gearbox;

- a shaft with a main roll placed on it;

- side stands with bearing assemblies: rolling bearings are used in high-speed rollers, and sliding bearings are used for equipment power;

- two driven bottom rolls;

- bed with two support posts;

- protective casing for receiving semi-finished products during machine operation;

- roller control system.

The technological parameters of the equipment are adjusted by changing the gap between the rolls. In manual models this is done using a screw or ratchet mechanism, in automatic machines - programmatically.

Metal rolling technology

The feed of the workpiece during sheet bending on rollers can be longitudinal, transverse or helical (also called spiral).

The longitudinal method is used to produce long-length pipes; the transverse method produces short ones. Spiral feeding produces pipes that do not need to be sealed by welding. For sheets of small thickness, up to 6 mm, roller bending is performed using the cold method. For thicker and non-plastic workpieces (for example, on a titanium base), heating in an oven to a maximum of 300 degrees is used.

Main characteristics of the process

Sheet rolling can be performed in the following options:

- In the longitudinal direction of the workpiece feed.

- In the transverse direction of the workpiece feed.

- With screw (spiral) feed.

Accordingly, in the first case, metal rolling is used to produce long, open pipes, and in the second, short ones. The result of helical rolling is the coiling of pipes that do not subsequently require welded sealing of the joint.

Rolling sequence

Rolling of steel products with an initial thickness of up to 4...6 mm is usually carried out without heating the original metal. However, when forming parts from thick sheet material, as well as alloys with low ductility (in particular, titanium-based), preheating to temperatures of 250...3000C is used. In such cases, the rolling machine is installed next to the heating furnace. The heating atmosphere in such furnaces is non-oxidizing, which reduces the formation of surface scale. However, with small rolling radii, the scale partially falls off during the deformation process on the rolling equipment.

A typical sheet metal rolling process includes the following transitions:

- Feeding the sheet into the gripping zone of the working tool.

- Setting the working gap between the rolls.

- Rolling a flat workpiece between a tool in a given direction of deformation.

- Removing the semi-finished product from the work rolls and rolling one of the edges of the workpiece (this is done so that the value of the radius of curvature of the part is the same along its entire diameter).

When hot-rolled sheets are deformed, the sheet is straightened before rolling.

This is due to the increased tolerance values for the non-flatness of the surface of such rolled metal, which is specifically stipulated by the technical requirements of GOST 16523. Straightening is also required for cold-rolled steel if its thickness exceeds 4 mm. The power characteristics of the sheet rolling process are determined by the following features:

- Deformation is carried out not by force, but by torque, the values of which depend on the physical and mechanical characteristics of the material being processed, the diameter of the work rolls and the conditions of contact friction;

- Rolling speed has virtually no effect on energy costs during the operation; Moreover, increasing the rotation speed of the rolls even slightly reduces the working force of the process.;

- The friction between the rolls depends on the condition of their surface: as the roughness decreases, it also decreases. Therefore, with the constant operation of rolling machines, periodic grinding of the surface of the equipment is required (especially if hot-rolled steel or thick sheet products are rolled);

- Rolling of high-carbon steels, as well as aluminum and manganese alloys, is often accompanied by the phenomenon of elastic springing of the material. Regarding rolling, it is not as noticeable as during bending, but in many cases it requires repeated deformation.

The range of technological capabilities of sheet rolling is as follows:

- Length of rolled products, mm - up to 12000.

- Thickness, mm - up to 60.

- Rotation speed of work rolls (for drive equipment), min-1 - up to 40.

- The practically achievable speed of continuous rolling, m/min, is up to 8…10.

- Diameter of work rolls, mm - up to 500.

The capabilities of manually driven rolling machines are more modest, but are also sufficient for single production of sheet folding operations according to the required radius values of finished parts.

Scope of application of metal rolling

Roller bending of metal is used in various industries. These include:

- assembly of mechanisms,

- production of advertising structures,

- construction,

- utilities,

- creation of original jewelry,

- Interior design.

And also much more. Depending on the purpose, the materials for deformable workpieces can be steel, aluminum, copper, brass, titanium and other metals and alloys.

High-quality rolling of stainless steel sheets to order

Our metalworking shop works with workpieces made from all of the above materials, including stainless steel sheets. By offering to order metal bending on rollers from us, we guarantee:

- high-quality and uniform deformation of rolled products,

- processing of products of large lengths and thicknesses;

- absence of cracks, creases and other unpleasant consequences of improper rolling,

- fulfillment of your order exactly on time.

Sheet processing

We provide professional services in the field of sheet metal working

.

In particular, we accept orders for bending, cutting, and laser cutting

of metal products according to individual customer drawings.

We produce sheet metal cutting and bending

exactly according to customers' drawings. If necessary, our specialists are always ready to offer the best option for acceptable standards and parameters of metalworking.

Our company produces metal chopping and cutting, both from our own warehouse stocks and from customer-supplied raw materials.

Having our own fleet of modern equipment for sheet metal processing, as well as an experienced staff, allows us to complete orders on time and in the best quality. What sets our company apart from our competitors is our ability to work with decorative stainless steel.

Guillotine metal cutting

Guillotine cutting

is a straight-line cutting of metal using guillotine shears. Metal cutting ensures a smooth cut without crumpled edges, nicks or burrs.

Cutting metal with guillotine shears

used in cases where subsequent processing of workpieces is expected.

As a rule, parts with a simple geometric shape are manufactured in this way.

Metal cutting allows, in some cases, to reduce the costs of intermediate metal processing, and, accordingly, reduce the cost of finished products.

Our company has the necessary capacity to fulfill orders of any level of complexity and in any volume. We offer services such as metal cutting: stainless and steel sheets, galvanized steel and aluminum.

Compared to curved cutting, such as laser, plasma or waterjet cutting, guillotine cutting is inferior in its capabilities, but significantly benefits in price and often in speed.

CNC hydraulic guillotine shear SB-K-6/3200

Maximum thickness:

- ordinary steel—6mm

- aluminum—8mm

- stainless steel – 5mm

Maximum cutting length 3200 mm.

Angle notching press

For some sheet metal cutting

Metal cutting is carried out on

a corner cutting press

, which allows you to

cut corners, grooves, channels in metal sheets with changing the cutting angle

, as well as cut the metal into pieces.

Laser cutting of metal

Laser cutting of metal

- This is one of the most economical, fast and high-tech methods of metal processing. The focused light beam, which is a laser, has phenomenal power capacity and accuracy.

After laser cutting, the resulting metal product can be used immediately, since it does not require additional processing.

The laser beam is capable of producing complex pattern cutting and high-precision metal cutting.

Sheet metal can be cut directly in the protective film (this feature is often necessary when cutting thin sheet steel or decorative steel, which is usually in a protective film).

To obtain the so-called “white cut”, it is possible to laser cut metal in a nitrogen environment.

Among the undeniable advantages of metal laser cutting are:

- high quality

- cutting of increased complexity and precision

- cutting waste reduction

- no deformation

- wide range of metals

Maximum thickness:

- ordinary steel - from 0.8 to 10 mm

- stainless steel - up to 8 mm

Maximum workpiece size 1500 x 3000 mm.

Sheet metal bending

Giving a certain shape to a metal sheet is called metal bending

. Metal bending is used in the manufacture of metal structures and metal parts. Metal bending, in some cases, can replace welding, increasing the quality of the product and reducing the cost of the product by saving labor costs.

Our equipment provides the capabilities of the most complex types of metal bending, requiring a special approach and high precision.

We accept orders for bending of various metals: stainless steel sheet, steel sheet, aluminum, brass, copper. The only exceptions are fragile materials that cannot be bent.

Hydraulic press brake with CNC, force 100 kN, length - 3200

Maximum thickness:

- ordinary steel - 6 mm

- aluminum - 8 mm

- stainless steel - 4 mm

Maximum bending length 3200 mm.

Press

bends sheet steel

at a given angle from 10 to 180 degrees

.

Allows you to produce profiles of various sections and shapes: profiles, channels, corners, additional elements

, etc. The bending radius is equal to two metal thicknesses.

There is a wide range of sheet bending tools (punches) for the production of profiles of various sections, including “irregular” shapes. There is also equipment for making a flattened profile (angle 180 degrees)

Sheet metal bending along the radius (rolling)

Radius bending of metal

(sheet steel) - a technological operation of deforming sheet material along a certain direction.

Rolling is carried out in hydraulic rollers, hence the name of this operation. It is possible to expose any ductile metals, including decorative stainless steel sheets.

Hydraulic plate bending rollers

Technical specifications:

- Length of parts – up to 3 m

- Thickness – up to 4 mm (for stainless steel)

- Minimum hauling radius – 300 mm

- Rolling of sheets with flanging is possible

If it is necessary to manufacture parts with large dimensions, it is possible to use partner equipment with a permissible length of up to 6 m

.

Types of rolling

One of the most difficult processes is rolling stainless metal. The sheets are dense and refractory. Therefore, for rolling it is necessary to heat the metal to the highest possible temperature. It is almost impossible to do this without special equipment. But with our company it’s easy. The use of industrial rolling machines will help to quickly heat even very strong steel without unnecessary problems.

Metal processing can be done in the following ways:

- manual;

- hydraulic;

- electric.

Another difficult material to roll is aluminum. Despite its plasticity, when rolling it is necessary to maintain maximum processing accuracy. Otherwise, deformation of the finished product cannot be avoided. But the experts of our company will easily cope with the task.

Additionally, our company offers the following services:

- design of metal structures;

- production of metal structures;

- installation of metal structures;

- metal cutting and other related services.

The development of innovations and new modern technologies and the introduction of modernization in existing devices creates an ever-growing demand for metal rolling services offered by companies capable of producing parts according to original drawings, in a short time and in batches of different sizes: from single copies to mass production.

Corner bending methods

Several basic methods are used to obtain structures of a given shape and profile from a metal corner, namely:

- cold bending,

- hot bending,

- shaping by cutting, bending and welding the finished product.

Cold bending of a metal corner, in turn, is divided into:

- free bending is when the corner is bent without the use of special equipment;

- bending using a rolling mechanism on a specialized profile bending machine.

The use of cold bending of a metal corner, unlike other methods, has certain advantages, namely:

- this is the least expensive method of giving metal a given shape, and does not require the use of additional equipment for heating, cutting, welding and subsequent processing of the metal;

- the resulting frame has greater strength, since it eliminates possible defects characteristic of heating, cutting and welding;

- finished structures are guaranteed to last longer due to the fact that the integrity of the metal profile structure is preserved during processing;

- the likelihood of metal corrosion occurring over time is reduced.

What do we offer

The Metallocentre production enterprise provides sheet metal and profile pipe rolling services in Moscow and throughout Russia at competitive prices. The procedure is characterized by minimal consumption of electricity and materials. Due to the successive movements of cylindrical shafts, rolled metal acquires the required shape, uniform thickness and aesthetic appearance. Modern technologies and equipment make it possible to produce non-standard products with large diameters. We guarantee the quality of the result and compliance with deadlines.

Stages of work

We work with your drawings or draw them up ourselves, taking into account your requirements. You only need to provide a sketch, photo of the product, technical specifications or describe the scope of application of the finished element. We will perform all calculations and design ourselves. We present the results of our work to the customer, approve all the nuances and only after that we proceed directly to rolling.

After agreeing on the project, we enter into an agreement, which will indicate the final cost of all rolling work and the deadline for their completion. The final cost of services is announced immediately and does not change during the process. It is calculated individually and depends on many factors: the complexity of the project, the complexity and volume of work, the timing of the order.

The next stage is the direct work of our specialists in processing the workpiece.

The final stage is the transfer of the completed work to the customer. We strictly comply with all approved product parameters and requirements of state standards.

Where is rolling used?

Using the metal rolling process, you can obtain a variety of designs and parts that are indispensable in construction, for decorating premises and external structures (for example, fences), and for other needs of various industries. Most often, sheet rolling is used to produce non-standard shapes, for example, pipes of unusual diameter.

Among the most famous rolling products:

- profiles;

- pipes;

- channel;

- fittings;

- profile pipes and the like.

All these products and many others are used in construction, the chemical industry, mechanical engineering and many others. Metal rolling can be ordered online on our website or by calling the numbers provided.