Straightening, straightening and bending during metalwork work

Straightening is a metalworking operation to eliminate defects in workpieces in the form of concavity, convexity, warping, curvature, etc. The essence of straightening is to compress the convex layer of metal and expand the concave layer. Straightening is carried out in a cold or heated state of the workpiece (depending on its size and material). Straightening can be done manually or by machine using special rollers or presses. A distinction is made between straightening blanks made of sheet metal, profile metal and pipes.

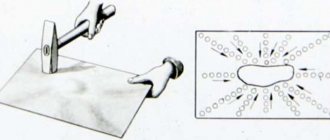

Manual straightening of sheet blanks is performed on a cast iron or steel plate using special hammers with a spherical striker; blanks made of thin sheets are adjusted with hammers with an inserted striker made of soft metal or with a wooden mallet.

Editing sheets is the most difficult. The sheet is laid on the slab, the places of the convexities are determined with a ruler, the boundaries of which are outlined with chalk. Striking patterns during editing are selected depending on the number of protuberances and their location. If there is one bulge in the middle of the sheet, blows are applied starting from the edge of the sheet towards the bulge, changing the force and location of the hammer blows. When editing a sheet with several convexities, blows begin to be applied from the gap between the convexities, gradually approaching their middle.

To straighten the sheet, place it on the plate with its convex side up, supporting it with your left hand; with the right hand they strike with a hammer. The blows should be frequent, but not strong.

Editing strips curved along an edge is carried out as follows: determine the curvature with a ruler or by eye, marking its boundaries with chalk. The wide surface of the strip is placed on the slab and blows are applied across the strip along the edge of the concave side. The strip is elongated on one side as a result of the “acceleration” of the metal, taking on a rectilinear shape. This method is used when straightening a corner with a slight curvature of the shelf.

Round blanks (rods) are straightened on a plate, in prisms or using a hand press. Hammer blows are applied to the convex part from the edge of the bend to its middle part. The editing is completed with light blows, turning the part around its axis. This straightening method is also used for straightening steel pipes.

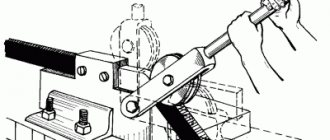

When the force of the hammer does not provide straightening, manual screw presses are used. Two prisms are installed on the press table, on which a curved shaft or pipe is placed so that the prismatic tip on the press rod is located above the place of greatest curvature. Smoothly rotating the flywheel, bring the tip of the screw to the bend. Then the screw is pressed onto the shaft to be corrected.

The profiled metal is heated with a gas-flame torch or cutter. In particular, crescent shape is straightened by forming a heating zone in the form of a triangle or trapezoid with the base facing the convexity; During the cooling process, the workpiece deforms, the magnitude of which is determined by the area and degree of heating.

Straightening is a type of straightening. Straightening is performed on heat-treated parts. The peculiarity of straightening is that the straightening of the part occurs as a result of striking the concave part of the part with the toe of a rounded and hardened hammer head. The latter is installed on a steel heat-treated straightening head. The working surface of the cylindrical straightening head must have a sphere with a radius of 150...200 mm.

Flat workpieces are straightened on a flat, straight steel plate. The strip is placed on the slab with the concave side up. Hammer blows are applied at the point of contact of the part with the slab from the edge of the concavity to its middle. The impact force is selected depending on the thickness and curvature of the part.

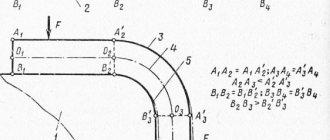

Bending is a metalworking operation in which a workpiece or part thereof is given a curved shape in accordance with the requirements of the drawing. Workpieces made of strip and sheet steel, rods, and pipes are subjected to bending. The sequence of the bending operation depends on the size and material of the workpiece. The length and width of the workpiece are calculated according to the drawing, taking into account the radii of all bends. The size of the minimum permissible bending radius depends on the mechanical properties of the workpiece material, the bending technology and the quality of the workpiece surface (Table 1).

When bending blanks made of strip and sheet material, their outer part is extended and the inner part is compressed. Therefore, when marking, it is necessary to take into account the allowance on the inside for each bend within 0.5...0.8 of the thickness of the workpiece. To bend at right angles, the workpiece after marking is clamped in a vice with jaws so that the bending line coincides with the upper plane of the jaw. Using a hammer, bend one side of the workpiece and, repeating the operation, bend the second side if necessary. When bending curves, various mandrels are used, which are clamped in a vice along with the workpiece. Using a hammer, the end of the workpiece is bent along the mandrel, achieving a tight fit to the surface of the mandrel. If necessary, the workpiece with the mandrel is rearranged and the operation is repeated.

The main preparatory operation in the manufacture of pipelines is bending pipes at various angles, which is performed using special devices or on pipe bending machines. In the bending zone, the thickness of the pipe wall on the outside decreases, and on the inside it increases. The bending radius is set according to regulatory documents; it is usually prescribed at least 2Dn, where

Dн - outer diameter. The permissible ovality in the bending zone of pipes Dn up to 250 mm should not exceed 10%, and for Dn = 300...400 mm - 6...8%.

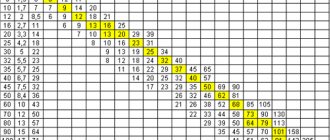

Table 1. Minimum permissible bending radii (mm) of sheet material blanks

| Workpiece thickness, mm | Workpiece material | ||||

| Steel | Duralumin | Aluminum | Copper | Brass | |

| 0,4 | 0,5 | 1,5 | 0,5 | 0,4 | 0,5 |

| 0,5 | 0,6 | 0,5 | |||

| 0,6 | 0,8 | 1,8 | 0,6 | ||

| 0,8 | 1,0 | 2,4 | 1,0 | 0,8 | |

| 1,0 | 1,2 | 3,0 | 1,0 | ||

| 1,2 | 1,5 | 3,6 | 1,2 | 1,0 | 1,2 |

| 1,5 | 1,8 | 4,5 | 1,5 | ||

| 2,0 | 2,5 | 6,5 | 2,0 | 1,5 | 2,0 |

| 2,5 | 3,5 | 9,0 | 2,5 | 2,0 | 2,5 |

| 3,0 | 5,5 | 11,0 | 3,0 | 2,5 | 3,5 |

| 4,0 | 9,0 | 16,0 | 4,0 | 3,5 | 4,5 |

| 5,0 | 13,0 | 19,5 | 5,5 | 4,0 | 5,5 |

| 6,0 | 15,5 | 22,0 | 6,5 | 5,0 | 6,5 |

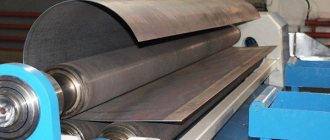

Cold bending of pipes is used in the manufacture of pipelines with Dn up to 150 mm. For cold bending of pipes, three main methods are used: on two supports, rolling with a roller and with an internal mandrel. Bending on two supports is carried out in special machines. It is used for pipes with a diameter of up to 125 mm. Cold bending of pipes by rolling a roller is recommended for pipes with a diameter of up to 32 mm. The pipe is rigidly attached with a bracket to a stationary bending disk, and the rolling roller is moved in an arc around the bending disk and bends the pipe. The radii of the grooves of the bending disk and rolling roller must exactly correspond to the outer diameter of the pipe being bent.

Cold bending with an internal mandrel is used for thin-walled pipes with an outer diameter of 32...219 mm. The bent pipe is put on a rod with an internal mandrel, which is placed at the bend. This protects the pipe from ovality and corrugation. The end of the pipe is clamped between a bending disk having a semi-circular groove (groove) and a liner with the same semi-circular groove. During the bending process, the disk, turning, carries the pipe along with it, pushing it off the internal mandrel. The pipe, pressed against the slider, moves forward as a result of friction. The shape of the internal mandrels can be spoon-shaped or spherical. During cold bending, pipes are blown with compressed air, and their inner surface is lubricated with machine oil or soap emulsion.

Hot bending of pipes is carried out in two ways: with heating with high frequency currents (HF) and with heating in fiery furnaces or furnaces with filler (filling with sand). Pipe bending with HDTV heating, which is most widely used, consists of continuous sequential bending of a small section of pipe heated in a ring inductor under the influence of an electromagnetic field that is created by HDTV. When bending pipes with high-frequency heating, three schemes are used: with a deflecting roller, with a carrier and a “add-on”.

Bending of pipes made of non-ferrous metals is carried out in a cold state: with a diameter of up to 38 mm with a bending radius of at least 2.5 Dn without a mandrel and filler, and with a diameter of more than 38 mm with a bending radius of at least 3 Dn with a mandrel or filler (sand).

078

1.6. Hole machining

Holes in the metal body for fasteners (bolts, studs, screws), as well as for subsequent processing (drilling, countersinking, reaming, threading and boring) are achieved by drilling. Standard drills made of high-speed steel with a diameter of 0.3 - 80 mm are used as a tool for drilling. According to the design and nature of the work performed, drills are divided into feather, spiral, centering, drills for deep holes, etc.

Feathers

-(flat) are easy to manufacture, durable, but do not provide high accuracy and cleanliness of the hole. Used for drilling shallow holes.

Spiral -

perfect in design, easily remove chips through screw channels, low friction force on the hole wall, do not require additional processing of the hole, allow a large number of regrinds.

Drills are made with cylindrical (up to d=12 mm), conical (6 - 60 mm) shanks. Drills are made of high-speed steel grades P18, P9, U10-U12 (small drills) and with hard surfacing of carbide plates.

Reaming

designed to increase the diameter of the hole in workpieces and is used when processing holes with a diameter of over 30 mm. First, drill a hole with a diameter of (0.2 - 0.3) D, and then drill this hole to a given diameter D.

Countersinking -

used for chamfering holes, producing cylindrical and conical recesses for screw heads and rivets.

Countersinking -

used for boring a hole and preparing it for reaming. Standard high-speed steel countersinks machine holes with a diameter of 3 - 100 mm. A countersink has a larger number of cutting teeth than a drill, so processing with it is more productive than drilling, and the quality of countersinking is higher than with drilling.

Deployment -

used for finishing a pre-drilled hole and obtaining precise geometric shape, dimensions and high purity

surfaces using cylindrical or conical reamers. Standard reamers are used for machining holes with a diameter of 1 - 300 mm in workpieces made of various materials.

For mechanical processing of holes by drilling and countersinking, pneumatic-electric machines and machines are used.

Safety precautions for manual bending

Manual bending and straightening are used for single or small-scale production. To perform operations, hammers, mallets, vices, hand pipe benders, mandrels, and other tools and devices are used.

Basic Rules:

- All instruments must be in good working order;

- A mitten should be worn on the hand holding the workpiece;

- The workpiece must be securely fastened in a vice;

- The left hand should not be held close to the bend of the workpiece;

- You cannot stand behind someone working.

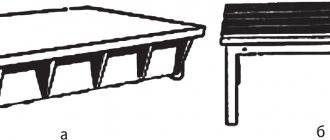

One of the conditions for ensuring safety during bending is the organization of the workplace. Before starting work you must:

- Make sure that the workbench is suitable for your height, and also check the strength and stability of the workbench.

- Remove all foreign objects from the workbench.

- Adjust local lighting so that the light does not dazzle and the work area is clearly visible.

- Prepare the necessary tools and accessories, arrange them in an order convenient for work.

- Inspect the tools. If cracks, chips, or other defects are detected, replace the faulty devices. The working part of hammers and mallets must be firmly attached to the handles, the surface must not have hardening, unevenness, or cracks. The vice must be in good working order and securely fixed on the workbench. The handle and screw should rotate easily, and the jaw cut should not be damaged.

Not only safety, but also labor productivity depends on the proper organization of the workplace. Following instructions allows you to avoid unnecessary pauses in work and reduce the number of defective parts.

When bending, you must:

- Adjust the clamping force in the vice so as to ensure reliable fixation and not damage the workpiece.

- Avoid bending the workpiece close to your face and avoid placing your left hand near the bend when working with wire.

- Be careful when working with impact tools to avoid injury to your fingers.

- Work in a hat, glasses and overalls with buttoned cuffs.

It is prohibited to use stands that do not ensure a reliable position of the part, or to use tools and devices for purposes other than their intended purpose. At the end of the work, you need to remove dirt with a special brush and wipe with a clean rag. Rags need to be collected in special metal boxes.

General safety rules when bending metal

The main condition for ensuring safety when bending metal is the use of serviceable tools, devices and equipment, proper organization of the workplace, and compliance with safety instructions.

The rules for bending metal include:

- Ensuring access to work only if you have the necessary qualifications, theoretical knowledge and practical skills. Only workers who have completed a training course and successfully passed a qualification exam and who have no medical contraindications are allowed to perform manual and mechanized metal bending. To gain admission, you must also undergo an introductory, primary or scheduled (unscheduled) safety briefing. When working on new equipment, you need to study it and, if necessary, seek clarification.

- Compliance with the work and rest regime. When performing work, you must take breaks at designated times, smoke and dine in specially designated areas.

- Checking the serviceability of the tool. Bending requires equipment and devices without cracks, hardening, or other defects. Tools must be used only for their intended purpose; the use of devices and equipment not intended for specific technological operations is prohibited.

- Use of personal protective equipment. Metal bending work must be performed in gloves, overalls, and safety glasses. PPE must be stored in specially designated areas.

- Knowledge and implementation of procedures in the event of an accident or emergency. In this case, you should stop work, turn off the equipment, and inform your supervisor. In the event of an accident, it is necessary to provide first aid to the victim, call an ambulance or ensure delivery to a medical facility.

Knowledge and implementation of safety instructions and guidelines when bending metal is a mandatory requirement of labor discipline. For non-compliance, various penalties are provided - from oral reprimands to dismissal and criminal prosecution.