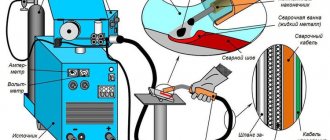

To ensure that the process of joining parts into a single whole is not difficult and everything works out the first time, before practical work you need to understand the theory of how semi-automatic welding is carried out in a carbon dioxide environment for beginners. Let's consider the main aspects and essence of this method.

Relevance of the issue

Shielding gas prevents hydrogen, oxygen, and other harmful substances from entering the weld pool from the air, which deteriorate the quality of the weld. In some cases, gas removes such elements from the weld pool.

Gas is supplied to enterprises by the oxygen shops of factories; a home welder can buy a cylinder of it in a retail chain. For example, a 10-liter cylinder of carbon dioxide costs a little more than 500 rubles, but after using up the gas supply, the container can be filled with a new portion of dioxide.

Every welder tries to increase the operating time of a cylinder with a controlled gas environment, and simply reducing its consumption by simply tightening the valve will not work.

Any welding, at home or in production, strives not only to reduce carbon dioxide consumption, but also to improve the quality of the parts being joined, which for a beginner often occurs in inverse proportion.

However, the output of CO 2 - carbon dioxide, when working with semi-automatic welding, can be pre-calculated so as not to run to the store for a new cylinder just before the end of the working day.

What should the consumer do?

If a company uses carbon dioxide in its work, it needs to find those who will organize the supply. The receiving procedure looks like this:

- The supply company leaves a request to receive a certain amount of the product.

- At the appointed time, receive cylinders filled with gas.

- Return those tanks from which carbon dioxide has already been used.

Various types of cylinders are used for refilling:

- A 40-liter container holds 24 kilograms of gas. The cylinder has a diameter of 21.9 cm and a height of 140 cm.

- The 20-liter has a diameter of 21.9 cm and a height of 85 cm. It holds half as much gas - 12 kilograms.

- The 10-liter container is smaller. The diameter is 14 cm and the height is 86.5 cm. The buyer is provided with 6 kg of carbon dioxide.

There are several other types of cylinders that can be refilled.

Appearance of carbon dioxide cylindersSource nord-gaz.com

Consumption factors

The most significant conditions for the consumption of the welding mixture - a controlled atmosphere - are the following mediators:

- Type and thickness of metal being connected.

- Welding rod diameter.

- Current strength of the welding machine.

Taking into account each of the above factors, the consumption of the protective medium can be derived. The data below determines the amount of welding mixture output when operating semi-automatically, taking into account the wire diameter and current strength:

- wire 0.8-1.0 mm, device current 60-160 amp. — 8 liters of gas per minute;

- 1.2 mm, 100-200 A - 9.5-12 l/min;

- 1.4 millimeters, 120-320 apm. — 12-15 l;

- 1.6 mm, 240-380 - from 15 to 18 liters;

- 2.0 mm, 280-450 A - up to 20 l/min.

These are average mathematical conclusions that, in addition to the diameter and thickness of the parts, do not take into account environmental factors. The process in an enclosed space will require less consumption of the controlled gas medium, while in an open area some volatilization of carbon dioxide occurs, which is reflected by its greater outflow from the cylinder.

When working outside on a windy day, evaporation, and therefore carbon dioxide consumption, will increase even more.

Last but not least is the quality of the controlled atmosphere. Using unpurified gas, the welder will inevitably face increased production costs.

Voltage setting

Changes in voltage are determined by the energy costs of melting the metal and burning the arc. An increase in energy consumption causes an increase in the thickness of the consumable material and the penetration depth of the workpieces. Household semi-automatic devices are configured using a stepwise method.

There is a reference table for selecting voltage values on the inside of the casing cover. This is important information from the manufacturer, which allows you to select optimal power values for each model, taking into account specific operating conditions.

Carbon dioxide consumption

In order not to be unfounded in assessing the yield of carbon dioxide for production needs, a specific example should be given. A standard gas container is a 40-liter cylinder, containing 24 kg of pure carbon dioxide, which at the outlet forms 12 cubic meters of a protective environment.

Using a filler thread with a diameter of 1.0 mm, we set the lowest current strength - 100 A. If you refer to the data in the reference books, a continuous mode similar to welding will last exactly one day - 24 hours.

However, work shifts with such a work duration are almost never found; let’s take a regular shift - 8 hours. Dividing the gas volume by one working day, we get 8 liters of controlled atmosphere.

The reference book indicates that 1 kg of surfacing will require 1100 g of carbon and 1300 g of filler material. Using simple calculations, we can come to the following conclusion: 1200 g of additive will be taken from a cylinder of 1000 g of gas.

Based on this, it can be stated that a 40-liter gas container is enough to melt almost 29 kg of welding material.

Of course, this is approximate information, but it often coincides with actual data. For novice welders, a table of carbon dioxide consumption is provided, depending on the diameter of the thread and the current rating.

Technical requirements

Steel pressure vessels with a volume of 0.4–50 l are used almost forever . Domestic GOST 949-73 applies to containers for transportation of intermediate storage and technological distribution to consumers.

Solid-drawn seamless cylinders of small and medium volume made of structural steel 45D and alloyed 40KhGSA are designed for a working pressure of 15 and 20 MPa for vessels of 50–20 l and 15 MPa for smaller ones, which can be produced with a flat bottom.

Distinctive marking is a yellow enamel inscription “carbon dioxide”, “CO2”, “carbon dioxide” on a black field . The main physical parameters and standard sizes are presented in the table:

| Pressure, MPa | 50 l, | ||

Steel 45D/30HGSA

Vessels of smaller volumes are made of steel 45D, operating pressure 15 MPa

| 40l Steel 45D/30HGSA | 20 l Steel 45D | ||||||||

| Ø, mm | L, mm | M, kg | Ø, mm | L, mm | M, kg | Ø, mm | L, mm | M, kg | |

| 15 | 219 | 1685/1660 | 71,3/62,5 | 219 | 1370/1350 | 58,5/51,5 | 219 | 740 | 32,3 |

| 20 | 1755/1650 | 93,0/62,5 | 1430/1350 | 76,5/51,5 | 770 | 42,0 | |||

| Ø, mm | 12 l | 10 l | 8 l | 5 l | 4 l | 2 l | ||||||

| L, mm | M, kg | L, mm | M, kg | L, mm | M, kg | L, mm | M, kg | L, mm | M, kg | Ø, L, mm | M, kg | |

| 140 | 1020 | 17,6 | 865 | 13,0 | 710 | 12,4 | 475 | 8,5 | 400 | 7,3 | 108/330 | 3,7 |

The package includes:

- oxygen shut-off valve with right-hand thread, brass;

- rubber safety rings for the cylindrical part;

- rectangular support shoe for stability;

- safety cap made of steel or molded from non-metals.

Cylinders in use undergo periodic re-certification after 5 years , including technical inspection and testing with excess pressure exceeding the working pressure by 50%. Information with the date of inspection is applied with impact stamps to the cleaned neck, framed by a yellow stripe around the perimeter.

This is a “carbon dioxide cylinder passport” with a complete list of information:

- date of issue, recertification;

- Cylinder number assigned by the manufacturer;

- filling capacity;

- process hydraulic pressure;

- steel grade and physical quantities of weight and dimensions.

Saving mixture

Based on the foregoing, we can conclude that the consumption of a controlled carbon dioxide medium depends not only on direct factors - the diameter of the rod, the current strength and the thickness of the metal elements being connected. Indirect factors affecting carbon dioxide consumption are weather conditions - wind, open area.

However, taking into account the latter, it is possible to minimize the costs of the welding process.

An optimized option would be to carry out the work in a closed, artificially ventilated room, with the involvement of an experienced welder. You can also entrust the process to a beginner, but the expense will still be slightly or significantly higher. An inexperienced employee has the right to suggest achieving savings by screwing on the valve on a carbon dioxide cylinder during semi-automatic welding.

Such an operation will reduce the flow of the mixture to the weld pool, but will increase the flow of oxygen from the atmosphere, which will affect the quality of the weld. However, there is a way out of this situation.

Experts advise using multi-component controlled gas compositions in your work, which can reduce carbon dioxide consumption while simultaneously improving the quality of the seam. For example, an argon mixture consists of 20% carbon dioxide and 80% argon. Its main advantages are:

- reduction in the amount of wire used up to 80%;

- reducing the amount of stuck metal splashes;

- increased penetration depth of elements;

- fewer pores in the weld.

The total cost of the operation is reduced to 20%.

Semi-automatic welding technique in carbon dioxide environment

- Content:

- Where is carbon dioxide welding used?

- Carbon dioxide welding technique

- What is the carbon dioxide pressure during welding?

- Carbon dioxide consumption for a semi-automatic machine

Semi-automatic welding in a carbon dioxide environment is used to repair car body parts and work with thin sheet steel. Thanks to the automation of the process, even a novice welder can achieve an even weld.

When performing work, the surface being processed heats up less, resulting in only minor deformation or warping of the part.

Types of products

Carbon dioxide is produced in the following form:

- Liquefied gas, which is stored under a pressure of 50 kg/sq.cm. To do this, it is necessary to ensure an air temperature not exceeding 31 degrees.

- Liquid carbon dioxide for storage in special thermoses.

- In the form of dry ice.

The product is then placed in black tanks with yellow warning labels and delivered to consumers for use.

Gas flow reducerSource donmet.com.ua

Carbon dioxide welding technique

The implementation of welding work and the technology of semi-automatic welding in a carbon dioxide environment is quite simple; in fact, the master is required to withstand the required wire extension and move the machine’s torch at the same speed.

The result is a uniform seam without beads, ensuring sufficient penetration of the steel and mechanical strength of the resulting joint.

When performing work, the master is required to comply with the following recommendations:

- Before starting welding, make sure that the shielding gas is escaping from the torch. The working pressure of carbon dioxide during semi-automatic welding is 0.02 kPa. But this indicator is not absolute; the presence of a draft or wind slightly increases the consumption of material. Accordingly, the pressure to create a normal seam will increase.

- The burner angle should be between 65-75°. The seam must be drawn from right to left, this way the welded edges are better visible.

- Current strength. Welding modes in carbon dioxide are regulated by changing the wire feed speed and arc voltage.

What is the carbon dioxide pressure during welding?

GOST for semi-automatic welding in carbon dioxide is regulated by guideline document 26-17-051-85. According to the document, a standard cylinder filled with CO² is enough to provide 15-20 hours of continuous operation. To increase productivity, be sure to use a dehumidifier.

The supply of carbon dioxide can be changed upward in the presence of drafts, wind and other negative factors. The quality of the resulting seam plays a decisive role when choosing a suitable operating mode.

The essence of welding in a carbon dioxide environment is that CO² protects the surface being processed from overheating. As a rule, the quality of the weld directly depends on the consumption of carbon dioxide during semi-automatic welding. At the same time, the master is required to ensure optimal costs between the use of gas and the consumption of welding wire.

Carbon dioxide consumption for semi-automatic welding machine

Although carbon dioxide consumption rates depend on many factors, on average, the following consumable costs are provided for a semi-automatic device:

- Wire feed speed – depends on the width of the consumable material, ranges from 35-250 mm/sec.

- Gas consumption is determined by the quality of the flux and weather conditions. Can vary from 3 to 60 l/min.

Calculation of carbon dioxide consumption during semi-automatic welding can be done independently, knowing the following parameters:

- The costs of preparatory work account for about 10% of the total CO² consumption.

- Specific gas consumption required to pass a seam.

Also, when calculating, the thickness of the wire and the metal being processed is taken into account.

About 25 kg of carbon dioxide is poured into the cylinder. As a result of the chemical reaction, about 509 liters of gas are produced from each kilogram. Accordingly, one standard cylinder is more than enough for continuous operation for 12-15 hours.

It is possible to do without the use of shielding gas. Instead of CO², cored wire is used. When heated, the powder-coated wire releases gas, which protects the treated surface from overheating.

The set of equipment for semi-automatic welding in carbon dioxide includes:

- Rectifier - can be transformer or inverter type. The first is optimal for thick wire, the second ensures a uniform voltage supply and a stable welding arc.

- Feeding mechanism – has restrictions on the thickness of the wire. When choosing, you should take into account that not every flux can be used when performing welding work.

- Holder with hoses.

All equipment together ensures optimal operating conditions and creates conditions for the formation of a high-quality weld.

Carbon dioxide welding

Welding metal in a protective carbon dioxide environment is considered by professionals to be one of the most effective. Especially when it comes to joining thin workpieces or parts. That is why carbon dioxide welding is used to repair car bodies, the minimum thickness of which is 0.5 mm. The main advantages of this type of metal welding include:

- fairly high performance;

- slight heating of the workpieces being welded, which leads to minimal warping;

- you can weld seams in any position, and this is not difficult and does not affect the quality of the final result;

- favorable conditions for the welding process;

- minimal costs, since carbon dioxide itself is very cheap.

Arc welding in a carbon dioxide environment can be carried out manually, using semi-automatic and automatic machines. In small car repair shops, semi-automatic welding is used in a carbon dioxide environment. This is convenient; it allows you to regulate the supply of filler wire to the welding zone, the speed of which varies between 148-600 m/h.

Welding mode and technique

What you need to pay attention to when carrying out semi-automatic welding in a carbon dioxide environment.

- Welding of metals is carried out using direct current with reverse polarity. This is when the minus is connected to the workpiece, and the plus to the electrode. In this case, with semi-automatic machines for filler wire.

- The current strength is adjusted depending on the thickness of the metals being welded, the speed at which the filler wire is fed into the welding zone, and the voltage of the electric arc.

- Arc voltage is a very important part of the welding process. The size of the weld depends on its value. For example, if the voltage is high, then the width of the seam during the welding process also becomes large.

- Wire extension also plays an important role. If the overhang is small, then the welder has difficulty seeing both the joining process and the welding zone. With a large wire extension, the welding arc is destabilized.

Adjustment

The tension of the main spring is adjusted using an adjusting screw, depending on the initial gas pressure in the cylinder. The control spring lowers with the diaphragm, opening an opening for carbon dioxide to pass under reduced pressure to the shut-off valve. From there, the gas flow moves through the hose to the burner. The membrane of the carbon dioxide reducer is made of oil-resistant rubber and ensures its precise positioning relative to the outlet. As the gas pressure in the cylinder decreases over time, the upper control spring can drop, changing the flow area of the inlet valve. The carbon dioxide reducer also allows manual control of the gas flow; to do this, simply unscrew/screw in the adjusting screw, depending on the current readings of the pressure gauges.

The constant pressure in the reducer chamber is ensured due to the fact that when the gas pressure coming from the cylinder decreases, the membrane moves upward, compressing the return (upper) spring, and when the pressure increases, it moves down. The outlet pressure remains stable due to a corresponding change in the flow area of the shut-off valve.

To ensure the resistance of the membrane against sudden excess of gas pressure (which can cause the membrane to rupture), carbon dioxide reducers are equipped with a safety valve. It is triggered when the inlet fitting for some reason loses its seal and begins to let an increased volume of carbon dioxide from the cylinder.

Features of the welding process

Semi-automatic carbon dioxide welding is practically the same process as submerged arc welding. The thing is that not all metals can be welded without a protective layer. But welding with carbon dioxide is, first of all, cheap, because other types of semi-automatic welding also have a high quality of the final result.

What is the essence of using carbon dioxide? It protects the welding area from ambient air, which contains moisture and oxygen. But under the influence of high temperatures, carbon dioxide breaks down into the same oxygen and carbon monoxide. So this oxygen begins to interact with the metal, oxidizing it. Which, of course, is not very good. This is why it is so important to neutralize the oxidizing chemical.

This can be done in one single way - by feeding metal containing deoxidizers into the welding zone. And this is silicon or manganese. Since these two metals are more active than iron, they are the first to react with oxygen. Therefore, for welding in carbon dioxide, steel wire is used, which contains these two elements. This is a very important point. It is believed that the optimal ratio of manganese to silicon in the filler wire should be 1.5-2.0. That is, there should be almost twice as much manganese.

The most important thing is that when oxygen interacts with manganese and silicon, oxides of these metals are formed. They do not dissolve in the liquid molten metal formed in the weld pool. But they interact well with each other, turning into slag, which is easily removed from the welding zone. Here are a few features of carbon dioxide welding.

Cylinder weight

When using, transporting and charging, it is necessary to monitor the presence of carbon dioxide in the cylinder. Weighing is used for this purpose. The mass of the following parts must be subtracted from the total weight:

- A vessel containing liquefied gas.

- The valve through which charging is carried out.

- Protective cap.

- Safety iron rings.

- If used, consideration must be given to how much the shoe weighs.

The entire structure is weighed, then the mass of the listed parts is subtracted. The remaining part tells how much carbon dioxide remains inside. The average weight of these nodes is:

- The weight of the ring is 300 g.

- The weight of the metal cap reaches 1.8 kg.

- The shoe typically weighs 5.2 kg.

Completeness of equipment

The welding station is equipped with the following equipment and accessories.

- DC source. This could be a welding transformer or an inverter. The second source maintains a stable arc.

- Gas cylinder with a capacity of 40 liters, which can accommodate carbon dioxide weighing 25 kg. It will easily be enough for continuous work for 15 hours.

- Feeder. Today, manufacturers offer a huge range of this device, so there is plenty to choose from. For example, the very popular model A-547-U. The feed mechanism is located in a small metal case that is easy to carry. Some models are equipped with a shoulder strap. The suitcase also contains a spool of wire. A gas valve is also installed here as a secondary protective element. The first, of course, is the reducer on the cylinder.

- The intermediate element from the cylinder to the burner is a gas dryer (electric heater).

- Burner with a set of hoses and cables.

Checking the cylinder

After the five-year period, carbon dioxide cylinders must be inspected. Without passing it, further use of the container is impossible. Inspection can only be carried out by an authorized organization.

The procedure involves checking the condition of the equipment. In doing so, pay attention to the following:

- A thorough inspection of the exterior is performed. There should be no damage or extensive or deep traces of rust.

- Carbon dioxide is completely removed from the container being tested. This is done using inert gases.

- Check the proper operation of the valve.

- The thickness of the cylinder walls is assessed. To do this, it is weighed. The result will show how much its weight has decreased and, accordingly, the walls have become thinner.

- Hydraulic tests show the proper operation of the equipment.

- After checking, drying is performed. This is done using heated air.

- If necessary, the valve can be replaced or the tank can be painted.

After the inspection is completed, a special stamp is used to put the date of the inspection and outline it with an oval line. The cylinder must have its technical passport. It contains the following information: serial number, capacity in liters of water, manufacturing weight, operating and test pressure in atmospheres, brand of the plant that carried out the recertification.

The capacity in liters of water has increased, which indicates the possibility of internal cracks forming or a change in the geometry of the container. If the increase exceeds 1.5%, then this is considered a sign of equipment malfunction.

Carbon dioxide cylinderSource chipmaker.ru

What you need to know about semi-automatic welding

Before you learn how to properly weld with carbon dioxide using a semi-automatic machine, you need to understand the technology itself in more detail.

The welding process using this equipment is quite simple. The wire is fed continuously at a certain speed, and carbon dioxide or another gas mixture enters the working area through the nozzle. Such units are very easy to use and allow even non-professionals to carry out work, which is why they are very popular in everyday life and in small private enterprises.

Image of the semi-automatic welding process

One of the main advantages of this technology is the ability to work with both thin products (up to 0.5 mm) and large thicknesses. In addition, the total cost of the work is relatively small.

What is the difference between an oxygen reducer and a carbon dioxide reducer?

The designs of carbon dioxide reducers are very similar to oxygen ones, and differ mainly in the methods of connection to the valves, and - sometimes - in the absence of a second pressure gauge. Therefore, the question often arises: are oxygen and carbon dioxide reducers interchangeable?

Much higher performance requirements are placed on the oxygen reducer. They are due to the fact that, unlike CO2, oxygen is not liquefied, and therefore is in the cylinder under much higher pressure (up to 200 atm versus 70...80 atm for liquefied carbon dioxide). Therefore, when oxygen enters the carbon dioxide reducer, the sealing membranes will gradually destroy. Therefore, the carbon dioxide reducer is not used to supply oxygen (reverse replacement is acceptable).

The gearboxes also differ in the possibilities of connection options to the cylinder. The carbon dioxide reducer can be connected using a clamp rather than a union nut, since CO2 does not have fire or explosion properties in case of leaks.

To improve the purity of the gas entering the reducer, cleaning filters are often included in the inlet valve design. The presence of a filter reduces the risk of gas venting back into the cylinder, where it can form a surface cushion over the liquefied gas.

Benefits of using carbon dioxide

When working with a semi-automatic machine, it is advisable to use a protective gas, due to which the result is of higher quality. Information about it can be found in the article: welding mixture or carbon dioxide - choosing a shielding gas for welding.

The use of CO2 has undeniable advantages:

- a narrow heat-affected zone allows you to weld even ultra-thin parts;

- The productivity of the device increases several times;

- the arc becomes more stable (compared to welding without shielding gases), and metal spattering is reduced;

- the seam is of high quality, even without additional adjustment of parts;

- carbon dioxide is a more accessible gas than modern welding mixtures.

But CO2 also has a number of disadvantages:

- the arc is not stable enough compared to the use of reliable protective gas mixtures;

- metal splashing still remains large compared to protective gas mixtures;

- the time for the cleaning process increases;

- consumption of filler materials increases.

Quality of seams obtained using carbon dioxide and welding mixture

Sometimes there is no point in using expensive protective mixtures if the work does not require special precision and excellent seam quality. But you won’t be able to make perfect seams, or it will require a lot of effort.

Learning how to properly weld semi-automatically with carbon dioxide is actually not that difficult. Moreover, the use of gas somewhat simplifies the work process, adding stability to it and reducing labor intensity. Of course, refilling a gas cylinder requires additional financial investments, however, in the end, the welder receives a number of advantages that quickly pay for the costs. You can read more about other technical gases in this section.

How to properly weld with carbon dioxide using a semi-automatic machine with your own hands

To ensure a high-quality seam even on a complex part, you must have certain skills and also follow the instructions.

Follow instructions for a safe and correct welding process

At the initial stage, the main task is to set up the device. Make sure that the source is configured correctly and that the output current characteristic corresponds to the rating data.

For each metal thickness, its own current strength is selected. We should not forget about the electrode feed speed, which is regulated electrically (variable resistance) or mechanically (by replacing gears).

The holder is positioned so that the tip is in the working area. Simultaneously with pressing the “Start” button, it is necessary to “strike” the electrode on the metal to ignite the arc. During the welding process, the tip is moved at the optimal speed without sudden movements, while the welder must constantly monitor its position and tilt.

Fast, slow and normal wire feed and welding speed

In order to thoroughly understand how to properly weld with carbon dioxide using a semi-automatic machine, it is better to first practice on a prototype. Thus, you can select the correct operating mode of the device, select the required electrode supply speed, and determine the optimal gas flow. When the arc becomes stable and the amount of flux is produced according to the norm, you can begin the main process.

Tips for choosing a semi-automatic machine

The quality and efficiency of work largely depends on the choice of machine for semi-automatic welding. Below are the main features that you should pay attention to when purchasing this equipment:

- the higher the power, the thicker parts can be welded;

- inverter devices are much easier to operate;

- It is advisable to choose devices with removable holders;

- the instructions should be convenient and understandable even to a layman.

If you plan to use shielding gas, you should take care to refill the cylinders. For complete information about this process, read the article: carbon dioxide: where to refuel is not an idle question.

You can also watch a video about semi-automatic welding:

You can fill the cylinders with a high-quality protective mixture. A wide range of products will allow you to choose the right gas for different purposes and materials.