What is a die and what is it used for?

A die is a common tool used for cutting external threads and calibrating them. These devices are used to produce pipes, rods, bolts, studs, as well as other parts and products.

Read also: DIY powder, recipes

Photo #1: Die

Die design

The design of the die resembles a large round nut. There is a hole with cutting edges in the center. It has coils (8–10 pcs.). They differ in sharpness of sharpening.

Rules for cutting threads using dies

Only if the established rules of work are observed, it is possible to obtain a surface with high precision and quality. A die for cutting external threads must be used in conjunction with a special driver, through which force is transmitted.

Options for cutting with round and sliding dies

When considering how to cut a thread with a die, you should pay attention to the following points:

Read also: How to apply black eye shadow to your eyes

- To determine the exact parameters of the tool, you should pay attention to the markings that are applied to the body. Labeling is carried out in accordance with established standards. Some experts can determine the parameters of a product “by eye”.

- The whole process begins with preparing the workpiece. You can ensure an easy start by chamfering, for which you can use a file. The chamfer is made at an angle of 45 degrees and should not be large. It is necessary to ensure that the metal is removed evenly.

- Cutting turns should not be carried out on a dry surface, as this leads to rapid wear of the cutting edge. A special lubricant is added to the cutting zone, which significantly simplifies the operation by reducing friction. Lubrication can be represented by motor oil or grease.

- The cutting process involves making two turns, followed by one turn in the opposite direction. Due to the movement of the tool in the opposite direction, chips are removed from the cutting zone, which leads to a simplified stroke and an increase in the quality of the work performed. For the first few turns, you need to ensure that the tool is in a strictly vertical position, otherwise the quality of the resulting surface will be poor.

- In the future, every two revolutions during cutting should be about a half-turn. This ensures a smoother ride. If the housing heats up during processing, you should take breaks. Too high a temperature causes plasticity of the metal, which leads to a decrease in wear resistance.

The quality of the resulting turns is checked when using a nut with the required diameter and thread parameters. The first pass may occur with slight difficulties, but within normal limits. The second and subsequent checks should be carried out effortlessly.

Tools for manual thread cutting

When cutting threads manually, the workpiece (rod, pipe) is stationary, and the tool itself rotates. In this case, there is no peripheral sliding speed, so the thread cutting tools practically do not heat up to high temperatures. To reduce mechanical wear of the thread-forming profile and reduce the effort, the area of the workpiece required for cutting is lubricated. If there are large differences between the diameter of the original workpiece and the diameter of the thread, it is also necessary to lubricate the inner surface of the hole.

It is believed that in order to form a full-fledged threaded profile, the diameter of the initial workpiece (for the most popular diameters) must correspond to the following values:

Diameter of cut thread M6 M8 M10 M12 M16 M20

Diameter of the original rod (or tubular blank), mm 5.80…5.95 7.75…7.90 9.70…9.95 11.80…11.95 15.80…15.95 19.80…19 .95

Note. The data given in the table can also be used to determine the diameter of the initial workpiece for subsequent thread shaping on machines with flat dies.

An important element for choosing the right lecher is the material from which it is made. The peculiarity of the thread cutting process - a gradual increase in force, with a sharp decrease towards the end of the process - determines the increased viscosity of the threading material, otherwise the thread profile will intensively chip. Therefore, the optimal choice would be levers made of alloy tool steel X12F1 or 9ХС, with a hardness of 59…61HRC. For cutting threads on heat-resistant and alloy steels, a tool made of high-speed steel grades R6M5 or R9K6, with a hardness of 60...63 HRC, is suitable. The price of such blades will be high, so their use is justified only for large volumes of production of threaded parts. For domestic purposes, it is quite acceptable to use lerks made from carbon tool steels U10 or U12.

Among the enterprises that produce such tooling, the highest ratings are those of Izhevsk, Chelyabinsk, Vladivostok, Samara, Bryansk, Nizhny Novgorod (Russia), Orsha, Minsk (Belarus), and Lvov (Ukraine). Foreign-made lechers from UFC (Italy) and CM Tools (Finland) have proven themselves to be excellent in operation.

https://youtube.com/watch?v=lsww6icPhaE%3F

Some technical characteristics and certain types of dies

It must be said right away that all such tools are used only in conjunction with special holders.

Such clamping tools, as a rule, can function normally with several hole diameters at once. For example, one holder is used with all lerks with a diameter of up to 1 cm, the same one holder is used with all lerks with a diameter from 12 mm to 24 mm, and the same situation with tools with diameters from 27 mm to 42.

Thread cutting tool

As mentioned earlier, there are tools that are capable of cutting pipe threads in metric and inch systems. The above dimensions are based on the metric system. There will always be a marking in the form of the letter “M” on the case. The full designation will also contain the thread pitch, that is, 8.10 and so on.

Some technical characteristics

To begin with, we note that the type of tool in question can only be used in conjunction with special holders. This is due to the fact that a lot of force must be transferred to the die during machining. One holder can be used to work simultaneously with different types of lechers.

The following information should also be taken into account:

- Left-handed dies are used to produce left-handed threads. Today they are used extremely rarely. To identify the tool, the designation “LH” is applied. Such a thread is required when the element is constantly in rotation during operation.

- Pipe versions differ from metric ones; for identification, the symbol “G” is applied to the surface of the body.

- To obtain a cone thread, a conical pipe tool is used. Most often used on production lines for the production of machine tools or fuel pipelines. Indicated by applying the letter “K” to the surface of the body.

When choosing a tool, you should pay attention to the concept of pitch - the distance formed between two adjacent turns. It is worth considering that the die has a main and an additional step.

Rules of procedure

When working with pipes, it is important to stock up on dies with a pipe clamp and a wrench. The die is selected taking into account the type of thread required

This can be determined by checking the stamp or inspection. The dies must be marked. The data on them will give an idea of what brand the tool is made from.

Most pipes require straight threads. Also, before working, you need to determine its direction: right or left. To do this, a letter indicator is depicted on the dies: “L” is left, and “P” is right. The die also indicates what grade of steel it belongs to, this makes it possible to choose the right tool for cutting stainless steel pipes.

The cutting rules are quite simple:

1). Prepare the pipe for cutting. To do this, the chamfer is removed with a file, and the area is treated with an oil solution.

2). Insert the die into the holder, securing it with screws.

3). Bring the die to the product and make several circular rotations in the required direction of the thread.

4). Lightly press down the die to embed it into the material.

Scrolling algorithm:

- 2-3 turns in one direction;

- half a turn to the other.

And so on until the end of cutting

In this case, it is very important to keep the pipe and die strictly perpendicular. Otherwise, the thread will “walk”, which will affect the quality of the connection.

The arrangement of elements, as well as thread cutting, is demonstrated on video and photo materials for better results. Checking thread quality is easy. To do this, it is enough to screw the nut if it is screwed along the outer diameter of the pipe. The most accurate cut is obtained with a sliding die. It will help out if you urgently need to replace a piece of pipe that has a threaded connection.

Also, when choosing dies, it is important to consider what kind of thread will be made, external or internal. High-quality work will allow you to make a sealed threaded connection even in pressure water pipes

Let's sum it up

As you can see, making your own carving using dies is not at all difficult. To do this, it is enough to choose the right tool, put in a little effort and accuracy. Probably, many representatives of the male half of humanity remember how similar problems were solved in labor lessons at school. Therefore, for the majority, it will only be necessary to remember the acquired skills and apply them in adulthood. It’s like riding a bicycle: you only need to learn once to feel confident in the saddle even after a long break.

Pipe dies

The thread on a water pipe differs slightly from the usual one, primarily in size. This is due to the fact that the binding starts from an inch. There's just one catch. If the pipe is 10 inches, this does not mean that its diameter is 2.54 * 10 = 25.4 mm. Its diameter will be about 33 millimeters. This is due to the fact that conversion to the metric system is accompanied by the addition of two wall thicknesses.

Pipe dies

To avoid such confusion with dies, they began to be produced separately for water pipes. It is quite easy to distinguish them from standard ones - on the body there is a marking in the form of the Latin letter “G”.

Thus, it turns out that there are lerks on G1/2, G ¾, and so on.

In general, pipe tools allow you to make cuts on a pipe with dimensions from G1/8 to G2.

Profile

According to the profile, there are metric, pipe inch dies, and trapezoidal threading tools. Each variety has its own characteristics:

Metric. As the name suggests, they cut metric threads. They are designated by the letter “M”, followed by a number indicating the thread diameter in millimeters. The standards provide for sizes up to 68 mm, each corresponding to a small or large step. Dimensions, designation examples, acceptance rules for such dies according to GOST 9740.

Read here: Wardrobe for a balcony: examples of ideal placement and combination (instructions + photos)

Pipe cylindrical. Visually easy to identify by the letter “G” on the body. This type of thread is measured using the English inch unit, which is 25.4 mm.

So, the designation G 1/2” means that we have a half-inch pipe thread. They are widely used for pipes of heating equipment and water supply systems. Size range from G 1/8” to G 2”.

Pipe conical. In order not to confuse them with other varieties, they are marked with the symbol “K”. They are used when it is necessary to obtain a conical threaded surface - in critical connections operating under pressure or machine components.

Trapezoidal. The cross-section of the threads is an equilateral trapezoid. They are common in power pairs that convert rotation into translational motion. The simplest example is the lead screw and nut of a machine and bench vice.

Classification of dies

Recently, tool steel has been used in the manufacture of dies, which is highly resistant to abrasion. A die for cutting external threads can be classified according to the following criteria:

- Form.

- Cutting method.

- Housing design.

The following dies are distinguished by shape:

- In the form of a square. The outer part of the housing can be square-shaped, thereby simplifying the transmission of force.

- Tubular ones have become very widespread.

- In the form of a hexagon.

- An instrument with a round body shape has also become widespread. They allow you to obtain threads of fine or coarse pitch, metric or inch type.

The thread cutting tool can be of the following type according to its design characteristics:

- Solid - a fairly simple instrument that has a solid body. Characterized by low cost and ease of use.

- Split ones have a complex shape of internal space.

- Sliding machines have a complex design that can be used for cutting threads on cylindrical surfaces of various diameters. This is achieved by creating a housing with moving elements.

According to the method of thread cutting, the tool is divided into the following groups:

- For round threads.

- For cylindrical.

- For tapered threads.

The most widely used tool is a round one, since it can be used for cutting threads in one pass.

Classification of leroks

Today, the industry produces a large variety of different dies for cutting screw connections. It is clear that they all differ in many ways. In addition to such an obvious difference as size, there are a number of other characteristics on the basis of which classification can be made:

- Form;

- Housing design;

- Thread cutting method.

There are, of course, other differences, but the above are the most obvious.

The following types can be distinguished by shape:

- Tubular;

- In the form of hexagons;

- In the form of a square;

- Round.

Dies for cutting metric and imperial threads

By design the following are distinguished:

- Solid;

- Split;

- Sliding.

According to the method of cutting threads, they are divided into the following types:

- For round threads. Manufactured according to GOST 13536-68;

- For cylindrical. Manufactured according to GOST 9740-71;

- For conical. Manufactured according to GOST 6211-81;

- For inch, the regulatory standard is GOST 61111-52, and for metric - GOST 9150-81.

Die holder

Round-shaped materials are most widespread. They allow you to make carvings in just one pass. For example, sliding dies for cutting threads of other shapes can guarantee quality only after three or four passes. However, they also have a drawback. For example, their use is recommended only when the requirements for threads on pipes or other objects are no higher than the second accuracy class.

Round dies (GOST 13536-68) allow you to produce threads of fine and coarse pitch, both in the metric and inch systems.

When working, it is important to take into account that the diameter of the chip holes and the dimensions of the thread itself are directly affected by the outer diameter of the die for cutting threads.

Die holder with electric drive

It can already be considered as an intermediate model for thread cutting between a hand-held mechanical tool and a machine. An electric thread-cutting die holder greatly facilitates the work of thread cutting and is more productive. There are different delivery options depending on the set of accessories and fixtures.

In their work, they use the same heads as manual models (of course, within the same brand and restrictions on thread diameter). The guide jaws in the head are not enough to ensure a stable position of the tool. Still, the “weakest” of them has a power of 750 Watts, but models from 1000 Watts are more often used.

If we consider that the transmission of rotation takes place with a powerful reduction gearbox, and 1 hp is equal to 735.5 watts, then holding a working tool in your hands is already problematic. Therefore, the kit includes a clamp-retainer. As an additional option, an oil pump can be supplied to supply special oil to the working area.

There are certain restrictions on using an electric clamp. And the point is not even that it is not always possible to connect to the network on the site. An electric manual die holder has a weight of 5 kg and quite significant dimensions compared to a mechanical one (especially with a clamp). Therefore, when cutting threads during repair of an existing pipeline, its use is simply impossible.

The main purpose is the laying of new routes and work on site or use in the preparation of pipes in a workshop (although portable threading machines can already be used for this).

As a continuation of the topic, there are compact portable thread cutting machines.

This is an ideal solution for a workshop or procurement area if you have to work with significant volumes. Their power in watts is no different from a household vacuum cleaner or hair dryer (from 1.5 kW), but it is enough to provide high performance when working with a pipe up to 4 inches. They are already equipped with a pipe cutter, deburring device, automatic oil supply (more precisely, its circulation from the pan through a filter system) and can be installed on a workbench or on removable legs. a pipe bender yourself.

Marking

The markings, which are usually placed on the shank, help the specialist to distinguish between different types of taps and quickly find the right one. For example, a metric type will be marked with the letter M, and its size will be measured in millimeters. Manufacturers offer a wide range of this device, so you can find a tap on sale that allows you to achieve almost any thread.

Pipe taps are recognized by the letter G, but are measured in inches. There are both common sizes and rare ones. The master selects them based on the specifics of the work. The conical type of tap is designated by the first letter of the name - K.

Conical (inch) tools

These are the same devices as in the previous case. Only on the pipe they make not a cylindrical thread, but a conical one. The body is marked in the form of the letter “K”.

All such products, like the taps themselves, are made from three types of steel:

- R6M5;

- 9ХС;

- CSU.

These types of steel are the most commonly used today. But a species like P18 is quite rare, but it was very common during the Soviet era.

It should be noted right away that all old products that have the USSR quality mark on their body are of better quality than modern ones.

Conical dies

Quality of the tools used

On sale you can find dies made from a wide variety of alloys. The following metals can be used in manufacturing:

- High-speed steel 9ХС and ХСС, Р6М5. Today it is found on sale more often than other steels. This is due to its exceptional performance and relatively low cost. Less commonly used is P18 steel, which was common at the time of the existence of the USSR.

- The quality of a tool largely depends on the precision of its production. If the shape accuracy is poor, or there are defects on the surface, then this indicates poor quality of the tool.

The cost of the tool may depend on a fairly large number of factors. As a rule, instruments from foreign manufacturers are much more expensive than domestic ones.

Types of dies

This instrument is classified by body shape and design. Depending on the shape of the case, there are the following types of dies:

- tubular;

- square;

- hexagonal;

- round.

The design of the die is most characterized by the design of the housing, which can be:

- whole;

- sliding;

- split.

Let's briefly look at the most popular designs. The most widely used die is a round die, with which you can cut threads of no more than the second accuracy class; it is used for cutting metric, pipe and inch threads with large, regular or fine pitch. When working manually, this type of tool is fixed in the driver with locking screws; when working by machine, it is fixed in special thread-cutting chucks. Using screws you can change the diameter of the thread being cut.

The outer diameter of a round die depends on the diameter of the thread and chip holes. The larger the diameter of the chip holes, the easier it is to remove chips. But, accordingly, a greater consumption of material is required, and larger sizes of components - knobs, chucks, etc.

To obtain threads of a high class of accuracy (metric, conical, pipe), solid dies are used, which have the highest rigidity indicators. The disadvantage is reduced wear resistance compared to tools in other types of housings.

Sliding dies. They consist of two parts, which are installed in the clamp and secured there with a screw and a cracker. The screw adjusts the thread diameter. As a rule, a die is sold with a set of dies of various diameters. Split strips are also adjustable, but their disadvantage is low rigidity and, accordingly, a decrease in thread accuracy. Also, this type of dies is slightly springy, which leads to a change in diameter within 0.1 - 0.3 mm.

Terms of use

To create a screw on a pipe, you will need a set of appropriate dies, knobs and a special clamp. For thread cutting, the most suitable set of dies is selected depending on the diameter of the pipe and the required pitch of the turns. Some parameters can be determined by visual inspection of the surface, but there must also be appropriate markings on the surface of the housing. Do not forget that the screw being created can be left or right.

The entire process of creating a screw on a pipe can be divided into several main stages:

- Work should begin with preparing the pipe. The metal surface must not have rust or serious defects. Cleaning can be done fairly quickly using special devices.

- A chamfer is removed from the end surface. This work can be done using a file.

- As with a tap, the surface should be lubricated with oil or some other similar substance. Without a lubricant, high loads may occur during operation, which will lead to deformation of the cutting edge.

- The die is fixed in a special die holder. Attention is paid to how strong the fastening is, since a high load can be transferred to the main part of the tool.

- During operation, one hand rotates the tool, the other - presses it. For a tool to cut into metal, there must be a significant impact on it.

- It is recommended to make two turns in the direction of the thread and one turn in the opposite direction. This ensures that the resulting chips are removed from the cutting zone, which facilitates the movement of the tool.

Higher quality threads can only be obtained by using a split die. This is due to the fact that the design has a locking ring with which the diameter is adjusted.

When carrying out work, it should be taken into account that there are several types of screw connections:

- Triangular.

- Trapezoidal.

- Rectangular.

- Persistent.

The thrust type of connection is characterized by the fact that constant one-sided pressure is exerted on the elements being connected. That is why the coils must have high strength. The rectangular type of connection is characterized by the fact that it is used to combine moving structural elements.

In conclusion, we note that there are quite a large number of sets of dies on sale. If thread cutting work is carried out frequently, then you should purchase kits from well-known manufacturers who use high-quality steel when creating tools.

Die

or popularly

lerka

- a thread-cutting tool for cutting external threads manually or by machine (on a machine) [1] [2].

Previously, the name die

was used in relation to a typesetting and adjustable thread-cutting tool, preferably

of larger diameters

[

source not specified 426 days

].

The die

has a non-separable shape and has a threaded hole with grooves; the cut thread is more accurate than that of dies. Currently, the division into dies and lerks has ceased to exist.

Read also: Staples for staplers, types, sizes, stationery

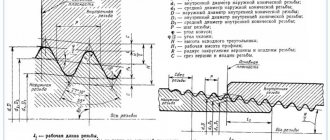

Dies are designed for cutting or calibrating external threads in one pass. The most common dies are for cutting threads with a diameter of up to 52 mm. The die is a hardened nut with axial holes that form cutting edges. As a rule, 3-6 chip holes are made on the dies to remove chips. The thickness of the die is 8-10 turns. The cutting part of the die is made in the form of an internal cone. The length of the fence part is 2-3 turns. Dies are made from alloy steels (9ХС, ХВСГФ), high-speed steels (Р18, Р6М5, Р6М5К5, Р6М5К8), and more recently from hard alloys. They are marked with the designation and degree of accuracy of the thread being cut, and the grade of steel (9ХС is not indicated).

Types of dies

:

solid

,

split

and

sliding

(clamp).

Depending on the shape of the outer surface, dies are round

,

square

,

hexagonal

,

or prismatic

.

Round dies

— secured for use in gates with locking screws or mounted in thread-cutting chucks. For this purpose, there are conical recesses and an angular groove on the outer cylinder of the die. The latter allows you to cut the die with a grinding wheel along the bridge and partially adjust the diameter. For round split dies, knobs with five screws are used, with the help of which the diameter of the thread being cut is adjusted.

Solid dies

— due to their high rigidity, they make it possible to obtain high-quality threads (metric, conical), but have low wear resistance.

Sliding dies

- installed in dies that have special guides for this purpose. The die consists of two parts, secured in the die frame with a block and a screw. This screw adjusts the diameter of the thread being cut. The die comes with a set of dies, which allows you to make threads of different sizes.

Split dies

— they can spring back a little, changing the diameter of the thread being cut by 0.1-0.3 mm. Due to their low rigidity, split dies do not produce clean and accurate threads.

All about dies

A die or die is a device used to cut external threads of various types. It is represented by a small nut on which there is an edge and a chip outlet. The threaded device can have thread pitch sizes from eight to ten.

Thread pitch is the distance between adjacent threaded threads.

The working area of dies is iron pipes and rods. Threads come in conical and cylindrical shapes. To obtain a high-quality thread, you need to cut in one pass. The die has a cutting edge. To make cylindrical threads, dies with two parts of the working area are used - calibrating and cutting. The calibrating part forms the final diameter and thread profile.

Classification of dies

Ledgers are divided into: tubular, square, round and hexagonal.

They are also divided by structure:

- solid;

- sliding (prismatic);

- cut.

The round lecher is the most widely used. It is threaded in one pass, and not in several, like sliding ones. These dies can cut threads at different pitches. They can also be used to cut pipe and inch threads. The working part of round dies is not subjected to grinding. The outside diameter will depend on the size of the chip guards and the size of thread required.

Left die and other specialized models

In their work, professionals use, in addition to the usual traditional dies, special ones. They allow for more precise carving. They also come in different types: metric, left-hand, pipe, conical pipe and others. A metric die is needed in cases where the thread must be made metric (hence the name). All measurements will be in millimeters. There is also a special marking - “M”. You can often see the following values on such dies - M 8, M 10.

Then you need to keep in mind that these devices can make threads with diameters of 8 and 10 mm. The carving occurs step by step, but each step is equal to the distance between the turns. It is also necessary to pay attention to the fact that each die differs in its main pitch in the thread. The step is not only the main one, but also an additional one. Example: die M 12, the main pitch is 1.75. In addition, you can find markings such as: M 12-1.5; M 12-1; M 12-0.75; M 12-0.5. The distance of each turn will be smaller if the step itself is smaller.