An airlift (from the English airlift) is a technical device with which, using only a stream of compressed air, it is possible to pump out liquid media from wells even of considerable depth. The airlift (this is another name for this device) is highly versatile and can be successfully used to solve various problems, which, in particular, include:

- removal of wet sediments and excess sludge from primary and secondary settling tanks;

- ensuring circulation of activated sludge;

- pumping wastewater and other liquid media, including chemically aggressive ones.

Airlift in wastewater treatment plants

Advantages and disadvantages of airlift

An airlift, or airlift, is a special jet pump for a septic tank. You can do it yourself by first preparing two tubes and an air compressor. The flasks are placed in the wells along with a pump so that the liquid mixes with air or gas bubbles.

The Airlift pump is relatively inexpensive

The liquid that mixes with oxygen begins its upward movement, since it has a lower density than the air mixture.

If the liquid is filled with suspensions, it is purified. The individual features of the jet pump allow you to efficiently pump liquid or oil from the well. The main purpose of the airlift is to wash and pump out water containing sand. If the well is small, an airlift allows you to get a lot of liquid.

Advantages of an airlift:

- Simple device;

- Long service life;

- No moving elements;

- Ease of maintenance and repair;

- Possibility of simultaneous flushing of liquids.

The device also has disadvantages. These include low efficiency when compared with a simple pump. To immerse the airlift nozzle, it is necessary to deepen the well. To make an airlift with your own hands, you first need to study the diagram of its structure.

Pros and cons of equipment

Airlift as a technical device has many advantages:

- extreme simplicity, reliability, durability of the design due to the absence of rubbing parts and moving mechanisms that easily fail;

- ease of installation and dismantling of equipment (elements are connected via threads);

- work at any depth, with wells of any diameter;

- can be used as a backup source of water supply at industrial enterprises, sometimes such water supply becomes the only possible one;

- work with a wide variety of liquids, including aggressive and contaminated ones (this is possible due to the use of special materials in the production of pipes).

However, the equipment has some disadvantages:

- low efficiency and, as a result, low efficiency;

- liquid is supplied only in a vertical pipeline; airlift is not suitable for horizontal and slightly inclined pipelines;

- difficulties when working in a shallow well;

- contamination of the liquid medium by compressor oil;

- a significant increase in the oxygen content in the supplied liquid.

Do-it-yourself features

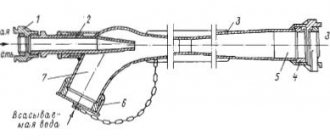

The airlift consists of hydraulic elements. One of the main parts is the suction device. Thanks to it, a uniform and dosed supply of liquid from the well is possible. Mixing of liquid and compressed air occurs due to the presence of a mixer. It also helps cleanse the liquid from suspended matter.

The movement of a two-phase or three-phase hydraulic mixture from the mixer to the air separator occurs through a flushing pipe.

The supply of compressed air from the compressor to the mixer occurs thanks to the air supply pipeline. When calculating an airlift for pumping liquid and suspensions, one should take into account the average speed and density of the flow, the ratio of the volume of pipes that are filled with air and liquid, as well as the phase speed and structure of the flow of liquid or gas. The correct operation of the airlift depends on the correct calculation of the geometric immersion.

The airlift consists of:

- A thin hose that supplies air to the well;

- A thick hose with which water rises;

- A hook-shaped metal pipe;

- Clamps that match the diameter of flexible hoses.

The Airlift pump can be purchased at a specialized store or ordered online.

The beginning of manufacturing work involves inserting a thin hose into a tube with a hook-shaped shape. The hose is secured with a clamp. Installing the upper end of a metal pipe involves attaching it to a flexible hose with a wider diameter. The upper end of the hose should be connected to the compressor and securely secured with clamps.

How to make your own airlift

If desired, every craftsman can make an airlift with his own hands, without turning to specialists for help. But to obtain a high-quality system, it is necessary to perform a series of mathematical calculations and determine the following properties:

- Depth of immersion of the mixer into the well.

- The thickness of the pipes supplying air to the well and pumping water out of it.

The height of liquid lift depends on the drilling depth.

To calculate the immersion depth of the mixer, you need to use the following formula: H = kh.

To make an airlift faster and more efficiently with your own hands, you should follow these instructions (it is suitable for pumping water from a well 20 m deep):

- To supply water, you need to take a 22-meter pipe with a thickness of 1.4 inches. It is immersed to the optimal depth, leaving the upper part above the ground.

- At a distance of 0.5 m from the ground, you need to make a hole in the pipe, and then fasten a tee with an internal thread. A short tube will be screwed into it to supply liquid.

- A 1 m long pipe is placed in the upper outlet of the tee. A hose will be passed through it to a depth of 20 m to supply compressed air flow. The inner hole of the hose has a diameter of 10 mm.

- The remaining part of the hose is connected to the outlet fitting of a compressor with 2 cylinders.

After completing the assembly of the structure, you need to start the compressor and supply a compressed air mass into the well in order to begin withdrawing liquid upward.

Using a similar technology, you can create a homemade compressor for a septic tank that will pump out wastewater with silt and sediment. It is impossible to make a pump without first calculating the parameters.

How the device works

An airlift is a technical device that uses compressed air to pump out liquids found in wells. The device is distinguished by high versatility. Using an airlift, primary and secondary wet sediments are removed, activated sludge is circulated, and wastewater and other liquid media are pumped.

Thanks to its optimal technical characteristics, the device can uniformly and meteredly supply the working medium into the water supply.

Thanks to the operation of the airlift, compressed air and the working environment are mixed. The hydraulic mixture undergoes a separation procedure into air and pulp. Compressed air is supplied to the mixer through a compressor to the pipeline.

Before using the Airlift pump, it is recommended to study its operating principle.

Operating principle of the device:

- The pipe is placed in the well;

- The lower part of the line is equipped with a pipe through which compressed air is supplied;

- A special device helps separate the hydraulic mixture into individual components.

Airlifts are used to equip wastewater treatment plants. They are also used to pump out oil found in underground sources. The device helps lift water from wells located at different depths. Aerolift is also used to clean septic tanks.

Specifics of equipment operation

Special requirements are put forward for airlifts operating in septic tanks. Here, these installations must transport wastewater from the receiving chamber to the aeration tank compartment not only efficiently, but also quickly. In this case, fermentation and the occurrence of an unpleasant odor can be avoided.

The normal operation of the septic tank is largely due to the reliability of the air lift.

Failures of this simple device are rare, but the equipment can fail due to improper use, for example, due to a malfunction of the mechanical filter. It, like the receiving chamber, must be promptly cleared of sediment. The aeration process may also be disrupted (air is pumped weakly or does not enter the compartments at all), and the tubes may be damaged. All these problems can be easily eliminated. #FORM#

Types of well pumping

A well is a common way to organize a water supply system that is autonomous. Well pumping is an important technological operation. By observing technological nuances, you can carry out the work yourself.

To get the cleanest water possible, pumping the well must be done after drilling has been done.

Pumping is necessary in order to get rid of sludge and clay solution. If the water inflow decreases and the first signs of deterioration in water quality appear, it is necessary to clean the water intake source.

Airlift pump may vary in size and color

There are several types of pumping:

- Pumping after drilling;

- Winter pumping;

- Pumping after winter.

One of the most common pumping methods is airlift. With the help of an airlift, cleaning can be done quickly and efficiently. The method involves placing a tube with a tube into the well, after which the compressor is turned on. Water must be supplied continuously.

An airlift is a kind of pump that is used to purify liquids in a well. Very often it is used for treatment facilities and autonomous water supply systems. The installation of an airlift can be done independently after the scheme of its operation and equipment have been studied. This technical device uses compressed air to operate, which moves water. Airlift promotes a uniform and dosed supply of water into the water supply system.

Principles of system calculation

A homemade airlift will perform its functions provided that the main characteristics are correctly calculated. To set up the system, you need to know the following parameters:

- The water level in a well is described by 2 main quantities: static level (H1) - the depth of the upper boundary of the water before the airlift operates, and dynamic level (H) - the depth to the water after the system starts.

- Depth of immersion of the air supply pipe. It consists of H and the depth of immersion in the water column (h), that is, H + h.

These parameters determine the choice of pressure that must be provided by the compressor.

In addition to the specified parameters, determining the performance of the installation is impossible without specifying some dimensions of the structural elements. The following quantities are important: the diameter of the well casing Ds, the diameter of the water-lifting pipe J and the diameter of the air duct Dv. These dimensions are interrelated and determine the volume of water raised (Vв).

Thus, with Dc up to 100 mm, Vc within 1-2 l/s is provided at J - 40 mm and Dv - 12 mm, and Vc is about 3 l/s with J - 50 mm and Dv - 13-20 mm. An increase in productivity occurs with larger well sizes, which makes it possible to use pipes of larger diameter. For example, Vc of the order of 9-12 l/s with Ds - up to 200 mm is achieved with J - 85-90 mm and Dv - 14-30 mm, and 22-32 l/s with Ds - 250 mm, J - 120-126 mm, Dv - 40-50 mm.

The immersion depth h is directly related to the total height of water rise. Thus, with a lifting height of up to 15 m, the ratio 100h/(h +H) is chosen to be about 67-72%; in the range of 16-30 m - 60-65%; 30-60 m - 50-59%; 60-90 m - 44-49%.

In addition, the h/H ratio determines the airlift efficiency. The maximum value of the coefficient (about 37.8%) can be expected at h/H - 2.2-2.25. At h/H=8.7 efficiency minimal (within 26.4-26.6%).

The pressure at the start of compressor operation is determined by the static level, that is, the height of the water column equal to H1, and during operation it can be reduced to a value corresponding to the dynamic level H. In this case, the H level is always significantly lower than the H1 level.

Another parameter that needs to be determined when designing a system is the required volume of air (Vв). It is usually calculated in the form: cubic meter of air for each cubic meter of water raised. The calculation is carried out according to the formula: Vв=Н/Сlg0.1(h+10), where C is the tabular coefficient associated with the amount of pipe immersion (it has a value from 8.4 to 14.3 when the immersion changes from 35 to 75%).

Airlifts - features of work in septic tanks

Airlift is the simplest in design and at the same time very effective device, which has found application in many industrial sectors today, as well as in everyday life. It is used to lift water and various liquids, and the device behaves well even when working with suspensions (liquids mixed with small particles of dirt).

Modernized airlifts can be used for pumping liquids with an aggressive chemical composition or solid particles in high concentrations. Such models are used in metallurgical and mining enterprises.

Well, in domestic sewer systems, these devices are widely used in autonomous biological treatment plants. Not a single modern treatment device today can do without several airlifts that facilitate the movement of sludge and water inside the septic tank.

How much power does the compressor need?

The power of an air compressor is quite easy to calculate. It is necessary that the compressor power be in accordance with the pressure created by the water column in the well at the depth of water intake. As you know, when diving, every 10 m of water increases the pressure by 1 atmosphere. That is, if in a 50 m well the water is at a level of 30 m, then the air must be supplied at a pressure of more than 2 atm. It is not necessary to increase the pressure too much; about 0.2 atm is enough. This is explained by the fact that at very high pressure, more air than water will flow from the compressor through the supply hose. Be sure to adjust the air pressure from the compressor during a test pumping of water, find the most effective value.

Assembling the airlift

We perform all actions sequentially. We insert a curved metal tube into the smaller diameter hose. Secure the tube with a clamp. We insert the other end of the curved tube into a larger diameter hose from the side. The lower part of the larger diameter hose remains open - water will flow here. The hoses must be securely fixed relative to each other. To do this, you can use metal wire, plastic ties, and electrical tape. We connect the upper end of the thin hose to the compressor and secure it with a clamp. To check the functionality of the assembled device, lower it to its maximum working depth.

four-channel airlift

Air, entering from a narrow hose into a wide one, will rush upward, periodically filling the entire volume of the hose with a gas “piston”. A certain amount of water will remain on top of the “piston” and will be raised to the surface. This tendency of gas to rise in liquid is explained by the large difference in density. It is different for different gases and liquids. For example, the density of water is 800 times greater than the density of air. You can calculate what the buoyant force will be.

Why is an aerator needed in the cleaning system?

It is this element that provides air supply inside the cleaning chamber, which increases the activity of microorganism colonies

The design of the water purification system is aimed at processing and purifying waste sewer streams from accumulations. The structure consists of a tank containing:

It’s clear why pumps and pipes are needed, but compressors for septic tanks raise questions. But it is this element that provides air supply inside the cleaning chamber, which helps to increase the activity of colonies of microorganisms responsible for processing and decomposing waste. Compressors for septic tanks, as shown in the video, force air masses inside, accelerating the process of dissolving biological accumulations.