A poly V-belt is a rubber product that has several wedges inside. Depending on the load of the products in question, different wedge shapes were made. Due to this characteristic, this belt is called poly-V-ribbed. The word begins with poly, which means many in Greek. And the end of the word wedge implies its technical features - longitudinal wedge-shaped strips located along the entire length of the surface. In other words, a serpentine belt is a type of drive belt that has many wedges.

Now let’s start looking at the dimensions of poly V-belts: profile, length and width. First, let's look at rubber products manufactured according to the domestic document TU 2563-040-70453527-2004.

What does a serpentine belt mean?

Polycline (from English “ribbed belt”) is the same as rivulet. Installed to transmit rotation of the drive shaft to the driven shafts of the generator and power steering pump. The poly V-belt has grooves located longitudinally.

There are several types of belts for transmitting rotational motion: crankshaft - generator - pump - power steering pump.

Classification according to the method of energy transfer:

- friction transmission;

- gear transmission.

Classification by type of belts:

- flat belts;

- wedge:

- CVT;

- ventilators;

- multi-stranded;

- poly V-belts;

- traction belts;

- toothed;

- transportation (conveyor belts);

- lingering;

- round belts (passic).

Applicability of BELTS

ATTENTION: on this page we tried to collect as much information as possible about the applicability of various belts on equipment. Due to the wide range of belts, we recommend contacting the managers of our company for quick selection and consultation by calling 977-02-02.

Applicability of Finwhale drive belts to domestic car models:

| № according to the catalog | Belt type | Length, mm | car model | Notes |

| BV113 | wedge | 713 | VAZ 2108-2115 | Carburetor |

| BV125 | wedge | 1025 | GAZ 21-3110; 2715-3302; UAZ 469(3151) and all modifications with UMZ engines | Engines ZMZ 21; 24; 402 |

| BV138 | wedge | 938 | VAZ 2101 -2107; 2121; AZLK 2141 iZh2126 with VAZ engine | Carburetor |

| BV150 | wedge | 1050 | GAZ 21-3110; 2715-3302; UAZ 469(3151) and all modifications with UMZ engines | Engines ZMZ 21; 24; 402 |

| BP600 | polywline | 700 | VAZ 2110-2112 | 16 valve engine |

| BP625 | polywline | 1225 | GAZ 3102-3110; 2715-3302 with engines of the ZMZ 406 family. | without power steering |

| BP638 | polywline | 738 | VAZ 2108-2115 | 8 valves, injector |

| BP675 | polywline | 1375 | GAZ 3102-3110; 2715-3302 with engines of the ZMZ 406 family. | + power steering |

Applicability of V-belts on garden equipment:

| BELT | APPLICABILITY OF THE BELT |

| A-710 | MK KROT until 1986 |

| A-750 | MK KROT after 1986 release |

| V(B)-850 | Motoblock FAVORITE, TERO-10 |

| A-900 | MK KROT with imported engine |

| A-1120 | Motoblock Salute |

| A-1180 | Motoblock MB-1 of all brands - forward drive |

| A-1213 | Motoblock MB-2 (Neva) |

| A-1320 | Snow blower SM-0.6 |

| A-1400 | Walk-behind tractor Votkinsk, blade mower for MB |

| Z(O)-1400 | Motoblock MB-1 of all brands – reverse gear |

| A-1560 | Motoblock brush ShchM-0.9 until 2009 |

| A-1900 | Motoblock brush ShchM-0.9 after 2009 |

This table shows examples of the applicability of poly-V-ribbed drive belts of section RK:

| Standard size | Applicability |

| 6РК 860 | YaMZ-236, 238 |

| 6RK-925 | UAZ-3160 |

| 6PK-1220 | Engine ZMZ-4061.10 (GAZ-3302); Engine ZMZ-4062.10; (GAZ-31029, 3110); UAZ-3160; |

| 6 RK-1250 | Industrial equipment |

| 6PK-1370 | GAZ (Volga, Gazelle, Sobol); engine ZMZ-406 |

| 6PK-1703 | Engine KAMAZ Euro-2 |

| 6PK-1790 | KAMAZ engine |

| 6РK-1630 | GAZ-560 |

| 6PK-1115 | VAZ-2110 |

| 6PK-698 | VAZ 2108-2110 |

| 5PK-1888 | VAZ-2123 “Chevrolet Niva” |

| 6RK-742 | VAZ-2110 |

| 6RK-882 | VAZ-1118 "Kalina" |

| 10PK-1250 | Machine tools (milling and grinding machines) |

| 24PK-1250 | Seeder "Brestselmash" |

| 16PK-1320 | Seeder "Gomselmash", combines "BIZON", "Case", KZR-10 |

V-belts for fans

| 8.5x8-833 | GAZ-53A, GAZ-53-92, ZMZ-53-11, UMZ-451MG, ED-181T |

| 8.5x8-850 | Kraz |

| 8.5x8-875 | Moskvich-412ie, -412e, Moskvich-2140, Moskvich-2137, 4ed-181T |

| 8.5x8x933 | Zaporozhets, T-4A, TD-75M |

| 8.5x8-1018 | GAZ-24, GAZ-13, GAZ-31, MEMZ-967P, MEMZ-968, (Zaporozhets) |

| 8.5x8-1030 | UMZ-451M, UMZ-4146.10, UMZ-417.10 |

| 8.5x8-1060 | ZMZ-402.10 |

| 8.5x8-1090 | ZMZ-402.10 |

| 8.5x8-1150 | D-260T |

| 8.5x8-1250 | Ural |

| 8.5x8-1280 | D-21A1, D-120, D-37E, D-144 |

| 8.5x8-1320 | Ural-744, KamAZ-740 |

| 8.5x8-1348 | GAZ-13 "Chaika", GAZ-71, GAZ-73, LAZ-42021, LiAZ-5256 |

| according to TU 38305-8-339-94 | |

| 10x8-715, 10x8-944 (external length) | VAZ cars |

| according to GOST 5813-93 | |

| 11x10-1045 | GAZ-53, BelAZ-75211, KrAZ-960, KrAZ-6443, ED-181T, 4ED-181T, EMZ-71, EMZ-73, EMZ-24D, EMZ-3402, EMZ-3403 |

| 11x10-1120 | SMD-23/24, SMD-31/32, SMD-31A/32A, ZIL-157KD, ZIL-114, Ural-744 |

| 11x10-1150 | GAZ-52-94 |

| 11x10-1180 | YaMZ-841, YaMZ-842, YaMZ-8423, YaMZ-840 |

| 11x10-1220 | ZIL-645, ZIL-157KD, ZMZ-505-10, ZMZ-14 |

| 11x10-1250 | D-240 (MTZ-80/82), SMD-Z101, D-241L (T-70s) |

| 11x10-1280 | ZIL-114, ZIL-117, ZIL-4104, ZIL-41 |

| 11x10-1400 | GAZ-66, PAZ-672, PAZ-3203, PAZ-3205, ZIL-118K, ZIL-118KA, LAZ-698, LAZ-4202, LiAZ-5251, LAZ-42021 |

| 11x10-1450 | ZMZ-66-92, ZMZ-3403, PAZ-672, PAZ-320G, LiAZ-5251, ZIL-157L, SMD-18N, SMD-14NG, (DT-75V), SMD-15N, SMD-18, SMD- 186, SMD-19/20, SMD-21/22 |

| 11x10-1500 | ZIL-555, SMD-14-21 |

| 11x10-1600 | ZMZ-65-06, ZMZ-3402, SMD-17K/18K, SMD-17KN/18KN, SMD-22, SMD-22-A |

| 11x10-1650 | ZIL-133 |

| 11x10-1775 | GAZ-66, GAZ-71, GAZ-73, PAZ-3205 |

| 12.5x9-1120 | SMD-60 (tr. T-150), SMD-62 (tr. T-150), SMD-74/75, SMD-74/75/76/78, SMD-66 (tr. DT-175S) |

| according to GOST 5813-93 | |

| 14x10-887 | MAZ-504, KrAZ-258, YaMZ-236, YaMZ-238 |

| 14x10-937 | MAZ-505, KrAZ-258, YaMZ-238NB(K-700), YaMZ-236, YaMZ-238 |

| 14x10-987 | MAZ-500, MAZ-504 |

| according to GOST 5813-93 | |

| 14x13-1280 | SMD-23/24, DON-1200, SMD-31/32, SMD-31A/32A, DON-1500, SMD-81(SK-10) |

| 14x13-1320 | YaMZ-240B (tr. K-701), KamAZ-740, KamAZ-741, YaMZ-8423 |

| 14x13-1600 | SMD-23/24, SMD-31/32, SMD-31A/32A, SMD-32-01 |

| according to GOST 5813-93 | |

| 16x11-1103 | ZIL-130, ZIL-157 |

| 16x11-1120 | GAZ-51, GAZ-52-04, SMD-60 (T-150), SMD-62 (T-150K), SMD-74/75, SMD-66 (DT-175s) |

| 16x11-1220 | D-50, D-50A (MTZ-50/52) |

| 16x11-1403 | D-65 |

| 16x11-1450 | SMD-60 (tr. T-150), SMD-62 (tr. T-150K), SMD-64, SMD-80, SMD-81 (SK-10), SMD-72/74/76/78, D -108, SMD-66 (DT-175S) |

| 16x11-1650 | D-160, SMD-72, D-108 |

| 19x12.5-1220 | SMD-1-1328 |

| 19x12.5-1450 | SMD-14NG (DT-75V), SMD-14, A-01M, (4-4M), A-41 (DT-75M) |

| 19x12.5-1550 | SMD-14K, SMD-15K |

| 21x14-1303 | ZIL-157, LAZ-697, LiAZ-677N, MoAZ-6507, MoAZ-7405 |

| 21x14-1450 | LAZ-697, BelAZ-540, BelAZ-531, BelAZ-7540, BelAZ-75482, BelAZ-75211, BelAZ-75231 |

| 21x14-1650 | ZIL-130, ZIL-131, Ural-375, KAZ-608V, LAZ-697, LiAZ-677N, ZIL-MMZ-555 |

| 21x14-1735 | BelAZ-540A, BelAZ-548A, BelAZ-7548, BelAZ-75401, BelAZ-7523, BelAZ-7421, BelAZ-6411 |

| 21x14-1950 | BelAZ-548A, BelAZ-7548, BelAZ-7523, BelAZ-75232, BelAZ-75231 |

Fan V-belts with molded teeth without side facings TU 2564-431-00149311-2006

| No. | V-belt size | Applicability of V-belt |

| 1 | AVX 10-850 (I-8.5×850 Lp) | YaMZ engines |

| 2 | AVX 10-944La (I-10х8-944La) | VAZ-2105, VAZ-2106 and its modifications, VAZ-2107, Niva 2121 |

| 3 | AVX 13-900Lp (I-11х10-900Lp) | "GAZELLE" GAZ-2705, 3221, 3302 |

| 4 | AVX 13-1230Lp (I-11х10-1230Lp) | ZIL 5301 and its modification. (“Bull”), Ikarus-260 |

| 5 | AVX 13-1045(I-11×10-1045 Lp) | YaMZ engines |

| 6 | AVX 13-1400Lp(I-11х10-1400Lp) | PAZ-672, -695M, -696, -697M, -698, -3203, -3205, -4202, 42021, ZIL-118K, ZIL-118KA, ZIL-111, LiAZ-5256, GAZ-66 |

| 7 | AVX 17x10-887Lp (II-14x10-887Lp) | MAZ-504, KrAZ-256, KrAZ-258, K-70 |

| 8 | AVX 17x10-937Lp (II-14x10-937Lp) | MAZ-500, 504, 505, KrAZ-258, tr. K-700, combine harvesters YASK-170, 200, YaMZ-238ND, YaMZ-236 (238ND) |

| 9 | AVX 17x10-987Lp (II-14x10-987Lp) | MAZ-500, 504, KrAZ 257 and its modification. YaMZ; K-700 |

| 10 | AVX 17×13-1320Lp (I-14x13-1320Lp) | K-700, K-701, MAZ, KamAZ-740, KamAZ-741, |

| 11 | II-21x14-1650Lp | ZIL-MMZ 555, LAZ-6955, 695E, 697, Ural-375, KAVZ-608(V), MoAZ-6507, 7405, LiAZ 677(N), ZIL-130, -131, -157, -158 |

| 12 | II-21x14-1735Lp | BELAZ-7540, 7547, MAZ 544, 537 |

| 13 | II-21x14-1950Lp | BELAZ-7540, 7547 |

Poly V-belts

| No. | Belt size | Belt applicability (engine models, car brands and other equipment) |

| 1 | 6РК 860 | YaMZ-236, 238 |

| 2 | 6RK-925 | UAZ-3160 |

| 3 | 6PK-1220 | Engine ZMZ-4061.10 (GAZ-3302)Engine ZMZ-4062.10 (GAZ-31029, 3110), UAZ-3160 |

| 4 | 6 RK-1250 | Industrial equipment |

| 5 | 6PK-1370 | GAZ (Volga, Gazelle, Sobol) engine ZMZ -406 |

| 6 | 6PK-1703 | Engine KAMAZ Euro-2 |

| 7 | 6PK-1790 | KAMAZ engine |

| 8 | 6РK-1630 | GAZ-560 |

| 9 | 6PK-1115 | VAZ-2110 |

| 10 | 6PK-698 | VAZ 2108-2110 |

| 11 | 5PK-1888 | VAZ-2123 “Chevrolet Niva” |

| 12 | 6RK-742 | VAZ-2110 |

| 13 | 6RK-882 | VAZ-1118 "Kalina" |

| 14 | 10PK-1250 | Machine tools (milling and grinding machines) |

| 15 | 24PK-1250 | Seeder "Brestselmash" |

| 16 | 16PK-1320 | Seeder "Gomselmash", combines "BIZON", "Case", KZR-10 |

BELTS made by HanseGermany:

| Catalog no. | Belt type | Applicability | Note |

| HR 6PK-698 | poly-wedge | VAZ 2108- 2115i | |

| HR 6PK-742 | poly-wedge | VAZ 2110-2112i | |

| HR 6PK-1125 | poly-wedge | VAZ with air conditioning | |

| HR 6PK-1220 | poly-wedge | GA33102-3110, 2715-3302 MS, door. 406 | Without power steering |

| HR 6PK-1370 | poly-wedge | GAZ 3102-3110 PS, 2715-3302, engine 406 | With hydraulic booster |

| HR 6PK 1030 | poly-wedge | engine GAZ-560 (Steier) | without power steering |

| HR 6PK 1630 | poly-wedge | engine GAZ-560 (Steier) | with hydraulic booster |

| HR 5PK-1885 | poly-wedge | NIVA-Chevrolet | VAZ engines |

| HR AVX-10X875 | Wedge | Moskvich 412 | UMZ engines |

| HR AVX- 10×940 | Wedge | VAZ 2101-2107,2121, AZLK2141, IZH 2126 | VAZ engines |

| HR AVX-10X1018 | Wedge | GAZ 31029 doors 402 | |

| HR AVX-10x1030 | Wedge | GAZ 31029 doors 402 | |

| HR AVX-10X710 | Wedge | VAZ 2108-2115 1.3; 1.5 | Carburetor |

| HZ 011 008 | timing belt | VAZ 2108-2115 8v | 8 valve |

| HZ 011 010 | timing belt | VAZ 2110-2112 16v | 16 valve |

| HZ 011 005 | timing belt | VAZ 2105 |

Accepted notation scheme:

H – the first letter of the company name HANSE R – structure of HANSE numbers in the group of drive belts – V-belts and poly-V-belts. 6RK-698 – poly-wedge with 6 ribs, effective length 698 mm. AVX-10-875 – wedge, width 10 mm, effective length 875 mm. Z – structure of HANSE numbers in the group drive belts – timing belts.

| Russian-made cars | |||||

| Belt type | car model | applicability | year of issue | OEM | |

| Cars | |||||

| 5PK1885 | Niva Chevy | generator | – | 2123-1041020 | |

| 6PK698 | VAZ 21082i | generator | – | 21082-3701720-00 | |

| 6PK742 | VAZ 2110-12i | generator | – | 2110-3701720-00 | |

| 6PK1220 | GAZ 3110 MS 16V without gas | generator without power steering | – | 406.1308020 | |

| 6PK1370 | GAZ 3110 PS 16V with hydraulic | generator with power steering | – | 321.1110227 | |

| AVX10x710 | VAZ 2108-099 1.3; 1.5 | generator | – | 2108-3701720-01 | |

| AVX10x875 | AZLK 412 | generator | – | 412.1308020 | |

| AVX10x940 | VAZ 2101-07 | generator | – | 2107-1308020-00 | |

| AVX10x1013 | GAZ 2401, 2410 | generator | – | ||

| AVX10x1018 | GAZ 31029 eng.402 | generator | – | 4022.1308019 | |

| AVX10x1030 | GAZ 3302, 3110 eng.402 | generator | – | 4022.1308020 | |

| 6PK882 | Lada Kalina 1.8 | generator | – | ||

| HR-6PK1751 | GAS with engine Chrysler | generator | – | 04892519AB | |

| Freight | |||||

| 6PK1030 | GAZ 2705,3302 Steyr without hydraulic | generator (steyer door) | – | 2203557/0 | |

| 6PK1630 | GAZ 2705,3302 Steyr with hydraulic | generator (steyer door) | – | 2203577/0 | |

| AVX-10-833 | Gas 53 | generator | – | 321-1110227 | |

| AVX-10-1250 | Kamaz, Zil 5301 (Bull) | generator, water pump | – | ||

| AVX-10-1320 | Kamaz, Ural, Zil | generator, water pump | – | 740.1307170-20 | |

| AVX-13-1045 | Gas 3307 | cooling fan and water pump | – | 53-1308020 | |

| 14×10-937 | Maz, Kraz, YaMZ, K-699 | compressor | – | ||

| 14×10-887 | Maz, Kraz, YaMZ, K-700 | cooling pump | – | ||

| 14×13-987 | Maz, Kraz, YaMZ, K-701 | power steering | – | 503-3407209 | |

| 16x11-1103 | Zil 130,157, Liaz | generator and power steering | – | 130-3509250 | |

| 21x14-1650 | Zil 130,131, Laz, Kaz, Liaz, Ural | generator, water pump, compressor | – | 130-3509250-B | |

| Foreign cars | |||||

| Belt type | car model | applicability | year of issue | OEM | |

| Cars | |||||

| AVX10x950 | AUDI COUPE 1.8E | generator | 1989-91 | ||

| AUDI 80 1.6, 1.8, 1.8E, 1.9, | generator | 1986-91 | |||

| BMW 525E – E28 2.7 | generator | 1983-88 | |||

| HONDA PRELUDE 1.8 1.8 12V | generator | 1982-86 | |||

| 6PK1100 | HONDA ACCORD 1.8, 2.0, 2.3 | generator with air conditioning | 1998- | ||

| NISSAN MAXIMA QX V6 2.0, 3.0 | generator with air conditioning | 1995-96 | |||

| PEUGEOT 306 1.6, 1.8, 2.0 – 16V | generator without power steering | 1993-97 | |||

| PEUGEOT 405 1.6, 1.8, 2.0 – 16V | generator with air conditioning | 1994-95 | |||

| PEUGEOT 406 TD 1.9 | generator with power steering | 1995-99 | |||

| RENAULT CLIO 1.7, 1.8 | generator with power steering | 1990-96 | |||

| SKODA FABIA 1.9 SDI, TDI | generator with air conditioning | 1999- | |||

| VOLKSWAGEN GOLF lll 1.4, 1.6 | generator with power steering | 1991-95 | |||

| 4PK800 | HONDA CIVIC 1.3, 1.4,C12 1.5, 1.6 | generator, air conditioner | 1994-96 | ||

| HONDA CRX VTEC ESI 1.6 | generator | 1992-97 | |||

| HONDA HR-V 1.6 16V | generator | 1999- | |||

| OPEL OMEGA TD 2.5 | air conditioner | 1998- | |||

| SANTANA SUZUKI VITARA 1.6 | air conditioner | 1988- | |||

| SUZUKI VITARA 1.6 | generator | 1991- | |||

| 5PK1100 | HONDA ACCORD SOHC, DOHC 1.8 16V, 2.0, 2.2, 2.3 VTEC | generator with air conditioning | 1993-96 | ||

| HONDA NSX 3.0 V6 | generator | 1990- | |||

| RENAULT KANGOO 1.4, 1.6 16V | generator | 1999- | |||

| RENAULT LAGUNA 16S 1.6 16V | generator | 1998- | |||

| RENAULT MEGANE 16V 1.4/1.6 | generator | 1998-99 | |||

| RENAULT New CLIO 1.4, 1.6 16V | generator | 1999- | |||

| TOYOTA CAMRY 1.8, 2.0 | generator with air conditioning | 1986-88 | |||

| TOYOTA CARINA 2.0 D | power steering | 1988-92 | |||

| TOYOTA CARINA E 2.0 16V | generator with air conditioning | 1992-98 | |||

| TOYOTA COROLLA Break D 1.8 D | power steering | 1987-92 | |||

| 5PK1125 | BMW 740 D (E38) 4.0 D | air conditioner | 1998- | ||

| MITSUBISHI COLT 16V 1.6, 1.8 | air conditioner | 1992-96 | |||

| MITSUBISHI LANCER 1.6, 1.8I 16V | air conditioning with power steering | 1993-96 | |||

| MITSUBISHI LANCER Break 1.6 16V | air conditioner | 1992-96 | |||

| MITSUBISHI PAJERO 3.0 V6 | generator | 1991- | |||

| RENAULT LAGUNA 1.8 16V | generator without air conditioner | 1998- | |||

| TOYOTA CAMRY TD 1.8 TD | power steering | 1983-86 | |||

| TOYOTA CARINA E 2.0 16V | generator | 1992-98 | |||

| TOYOTA CARINA II D 2.0 | Power steering without air conditioning | 1984-88 | |||

| 4PK925 | MAZDA 323 1.8 16V, 1.9 16V DOHC | generator | 1998- | ||

| MAZDA 323 2.0 V6 | power steering | 1994-98 | |||

| MAZDA 626 1.8, 2.0 16V DOHC | generator | 1992-97 | |||

| MAZDA 626 2.5 V6 | power steering | 1992-97 | |||

| MITSUBISHI GALANT 2.0I 8V 2.0I 16V, 2.0 TURBO | air conditioner | 1988-93 | |||

| MITSUBISHI GALANT 2.5 V6 | power steering | 1993-95 | |||

| SUZUKI GRAND VITARA 2.5 V6 | generator | 1998- | |||

| 5PK925 | TOYOTA CELICA 1.6 16V | power steering | 1985-89 | ||

| TOYOTA COROLLA 1.3 12V | Power steering without air conditioning | 1992-95 | |||

| TOYOTA COROLLA 1.3 16V, 1.6 GT | power steering | 1992-97 | |||

| 5PK1200 | NISSAN Almera 1.5 8V | generator with air conditioning | 2003- | ||

| NISSAN Micra 1.5 8V | generator with air conditioning | 2005- | |||

| PEUGEOT 605 TD 2.1 | generator with air conditioning | 1989-94 | |||

| RENAULT MEGANE II 1.4, 1.5, 1.6 16V | generator with air conditioning | 2002- | |||

| RENAULT Clio 1.5 8V; 1.4, 1.6 16V | generator with air conditioning | 2001-03 | |||

| TOYOTA CAMRY TD 1.8, 2.0 | Power steering with air conditioning | 1983-86 | |||

| TOYOTA CARINA D 2.0 | generator with air conditioning | 1988-92 | |||

| TOYOTA CARINA II D 2.0 | generator with air conditioning | 1984-88 | |||

| TOYOTA COROLLA Break D 1.8 | Power steering with air conditioning | 1987-92 | |||

| 4PK1000 | MAZDA 323 1.3, 16V | air conditioning compressor | 1989-94 | ||

| MAZDA 323 1.3, 1.5, 1.6 16V | Power steering with air conditioning | 1998-00 | |||

| RENAULT CLIO 1.4, 1.6 | Power steering without air conditioning | 1998-99 | |||

| RENAULT KANGOO 1.4 | Power steering without air conditioning | 1997-98 | |||

| 4PK1100 | NISSAN ALMERA 1.6 16V | generator with air conditioning | 1995- | ||

| TOYOTA 4 RUNNER 2.7 16V | power steering | 1995-99 | |||

| TOYOTA COASTER 2.7 16V | power steering | 1993-99 | |||

| TOYOTA CRESSIDA 2.0 | generator | 1984-87 | |||

| 4PK850 | AUDI A4 1.6, 1.8, 1.9 TDI | air conditioning compressor | 1995-96 | ||

| BMW 316I, 318I | air conditioning compressor | 1990-93 | |||

| CHRYSLER NEON 2.0 16V DOHC, SOHC | generator | 1994- | |||

| HONDA CIVIC – 1.4I, 1.5I, 1.6I, VTEC SOHC | power steering | 1995- | |||

| HONDA CIVIC 1.6 VTEC/DOHC | air conditioning compressor | 1990-92 | |||

| HONDA CR-V (2.0 16V DOHC) | Air conditioner | 1997- | |||

| HYUNDAI LANTRA/ELANTRA 1.5 12V, 1.6, 1.8, 2.0 16V | Air conditioner | 1997- | |||

| NISSAN ALMERA 2.0 16V | power steering | 1996- | |||

| TOYOTA CARINA 1.6, 1.8 16V | Air conditioner | 1988-92 | |||

| TOYOTA CELICA 1.6 | Air conditioner | 1989-94 | |||

| TOYOTA COROLLA 1.6, 1.8 | air conditioning compressor | 1997- | |||

| VOLKSWAGEN PASSAT 1.6, 1.8 20V, 1.9 TDI | air conditioning compressor | 1996-97 | |||

| 6PK1050 | HONDA ACCORD TYPE R VTEC DOHC 2.2 | generator with air conditioning | 1998- | ||

| HONDA PRELUDE VTEC 2.2 VTEC 16V DOHC | air conditioning compressor | 1996- | |||

| RENAULT CLIO 1.7, 1.8 | generator with power steering | 1990- | |||

| TOYOTA CAMRY V6 3.0 | generator with air conditioning | 1991-96 | |||

| 6PK1150 | MITSUBISHI GALANT 2.5 V6 | generator with air conditioning | 1993-95 | ||

| RENAULT MEGANE 2.0 | generator | 1995-99 | |||

| VOLKSWAGEN GOLF III 1.4, 1.6, 1.8, 2.0 8V, 2.0 16V; 1.9 D, TD, SDI, TDI, | generator with power steering | 1991-95 | |||

| VOLKSWAGEN PASSAT 1.6, 1.6I, 1.8, 1.8I, 2.0I 8V, 2.0 16V; 1.9 D, TD, TDI | generator with air conditioning | 1993-96 | |||

| VOLKSWAGEN POLO CLASSIC/BERLINE/VARIANT 1.6 | generator with air conditioning | 1996-97 | |||

| 3PK630 | TOYOTA COROLLA 1.6 16V | power steering | 1998- | 99363-80630 | |

| 3PK760 | HONDA Civic II Shuttle 1.6i 16V | generator | 1988-89 | ||

| HONDA Civic III 1.4, 1.5i, 1.6i 16V | generator | 1987-91 | |||

| MAZDA 626 III 1.8, 2.0 16V | generator | 1987-92 | |||

| TOYOTA Camry 1.8i, 2.0, 2.2GL, 2.5 | power steering | 1997-00 | |||

| TOYOTA Celica 2.0 Gti, 2.0 16V | power steering | 1989-94 | |||

| TOYOTA RAV 4 2.0 16V | power steering | 1994-00 | |||

| 5PK1110 | MITSUBISHI Galant V 1.8 GLSi | air conditioner | 1992- | ||

| MITSUBISHI LANCER IV 1.8 GTi 16V | Power steering with air conditioning | 1192-93 | |||

| TOYOTA CAMRY 2.0 GLI 16V, 2.2 | generator with air conditioning | 1986-88 | |||

| TOYOTA CARINA E 2.0 GLI | generator with air conditioning | 1993-97 | |||

| TOYOTA COROLLA 1.8 D | power steering | 1987-92 | |||

| TOYOTA RAV 4 2.0 16V | generator with air conditioning | 1994-00 | |||

| 4PK815 | HONDA CIVIC IV 1.5 i 16V, 1.6 16V | power steering | 1991-95 | ||

| Nissan Primera 1.6 | generator with air conditioning | 1990-96 | |||

| NISSAN PRIMERA 1.6, 1.6 16V | power steering | 1990-96 | |||

| 4PK890 | AUDI 80 2.8; 2.8 QUATTRO | generator | 1991-96 | ||

| BMW 316I, 318I, 1.6 16V,1.8 16V | air conditioner | 1995-00 | |||

| BMW 518I 1.8 | air conditioner | 1995-96 | |||

| BMW COMPACT 1.6, 1.8 16V | air conditioner | 1995-98 | |||

| MAZDA MX5 1.6 16V, 1.8 16V DOHC | generator | 1994-98 | |||

| SUBARU FORESTER (SF) 2.0 | air conditioner | 1997- | |||

| SUBARU IMPREZA 1.6i, 2.0, 2.0i 4WD (EJ16) | air conditioner | 1995-00 | |||

| SUBARU LEGACY I 1800 4WD, 2000 4WD | air conditioner | 1989-94 | |||

| SUBARU LEGACY II 2.0i, 2.0i 4WD, 2.2i | air conditioner | 1994-99 | |||

| 4PK915 | HONDA ACCORD 1.6 16V SOHC, 2.0 16V | air conditioner | 1985-89 | ||

| HONDA LEGEND 2.5 V6, 2.7 V6 | air conditioner | 1986-90 | |||

| HYUNDAI LANTRA 1.6, 1.8 16V | air conditioner | 1990-95 | |||

| NISSAN ALMERA 1.4 16V | generator | 1995-00 | |||

| Nissan Primera 1.6 | generator | 1990-96 | |||

| NISSAN SUNNY 1.4, 1.6 16V | generator | 1988-91 | |||

| TOYOTA 4 RUNNER 2.7 16V | air conditioner | 1996-00 | |||

| TOYOTA SUPRA, SUPRA TURBO 3.0I, 3.0 Turbo | air conditioner | 1986-93 | |||

| 4PK990 | HYUNDAI LANTRA 1.8 16V | generator | 1990-95 | ||

| HYUNDAI SONATA 2.0 16V | generator | 1993-98 | |||

| MAZDA 323 1.1, 1.3, 1.5, 1.3 16V, 1.6i, 1.6 Turbo, 1.8 16V | air conditioning with power steering | 1987-99 | |||

| MITSUBISHI COLT 16V 1.6,1.8 | generator | 1988-92 | |||

| MITSUBISHI ECLIPSE 2.0 16V | generator | 1991- | |||

| MITSUBISHI GALANT 2.0 16V | generator | 1993- | |||

| MITSUBISHI LANCER 16V 1.6/1.8 | generator | 1988-92 | |||

| MITSUBISHI PAJERO, Shogun, Montero 3.5 V6 | power steering | 1994-00 | |||

| MITSUBISHI SPACE GEAR 2.0, 2.4 | generator | 1995- | |||

| MITSUBISHI SPACE WAGON 2.0 16V, 2.4 | generator | 1992- | |||

| Buses and Trucks | |||||

| AVX 13×750 | Truck | IVECO – Daily I 49.12 2.5 Tdi 8V; 59.12 2.5 Tdi 8V | water pump with air conditioner | 1990-96 | |

| Truck | HANOMAG F122 L, F 140 L, F 141 L | Dynamo | 1967-75 | ||

| AVX 13×775 | Bus | IKARUS | generator | ||

| AVX 13×900 | Truck | BERLIET 130B, 130 TB, 150B | air compressor | 1978- | |

| Truck | ERF A, B, C Series 265 ROLLS | fan | 1980-86 | ||

| Truck | MERCEDES-BENZ T2/LN1 507D, 507DK | power steering | 1986-89 | ||

| Truck | SAVIEM HR15, JN60, JN90, JN95, JP11, JP13, JR19, JR21, JX21 | air compressor | 1975-80 | ||

| Truck | SAVIEM SG2 | fan | 1968-80 | ||

| Bus | NEOPLAN 122/3 SKYLINER; 122/3 SKYLINER N 316 SHD | generator | 1990- | ||

| Bus | RENAULT VI E7C, 798 | air compressor | 1973-82 | ||

| Bus | SAVIEM E7C, 798, SC8, | air compressor | 1973-80 | ||

| AVX 13×925 | Truck | MERCEDES-BENZ LK/LN2 709; 709K; 809K; 811; 811K; 814F | power steering | 1984-90 | |

| Bus | MERCEDES-BENZ LK/LN2 814O,814LO, LK/LN2 817O,817LO, LK/LN2 1117O,1117LO | power steering | 1986- | ||

| Bus | RENAULT VI S150TI | air compressor | 1986- | ||

| Bus | VAN HOOL EOS | generator | 1990- | ||

| AVX 13×950 | Truck | HANOMAG-HENSCHEL F122L, F141 L, F122L, F141 LH | hydraulic pump | 1967-75 | |

| Truck | IVECO EUROCARGO 60E10, 60E12, 60E14, 60E14K, 65E10, 180E21T | generator | 1991- | ||

| Truck | IVECO P/PA 190-32AHW | air compressor | 1983-85 | ||

| Truck | MERCEDES BENZ LK/LN2 709 | power steering | 1984-90 | ||

| Bus | BERLIET CRUISAIR 2A, 3A, PR100B | guide roller | 1974-75 | ||

| Bus | Eurobus | generator | |||

| AVX 13×1125 | Truck | BERLIET TR280, TR280A, TLR280 | fan | 1973-82 | |

| Truck | HOTCHKISS DP60-70-80 (4,236PERKINS) | dynamo | 1967- | ||

| Truck | MAN M90 24.192FNL, 24.192FNLL, 24.192FVL (D0826LF01, D0826LF05, D0826LF07) | generator | 1989-96 | ||

| Truck | SAVIEM PX28 (MDS06,35,40) | fan | 1979-80 | ||

| Truck | SAVIEM SG2 (712) | fan, vacuum pump | 1968-80 | ||

| Truck | SAVIEM TP3 (712) | water pump | 1973-82 | ||

| Truck | SCANIA 142 Series (DS14) | generator | 1981-88 | ||

| Truck | SEDDON ATKINSON 200 Series (D358) | air compressor | 1975-84 | ||

| Truck | STEYR-DAIMLER-PUCH 990 (WD6143.01) | hydraulic pump | 1970-79 | ||

| AVX 13×1225 | Truck | BARREIROS C14, C16 (MWM) | air compressor | 1975-83 | |

| Truck | HANOMAG-HENSCHEL F221LEL, F221LNL F (6R1315, 524) | water pump, fan, dynamo | 1970-75 | ||

| Truck | MAN F2000 27.403DFAC, 27.403 DFAK, 27.403 DFAS, 27.403 DFC, 32.343VFC | fan | 1994- | ||

| Truck | MAN F90 26.242DF, 26.242DFS, 26.262DF, 26.262DFA (D2866F/240, D2865LF/260) | water pump | 1988-90 | ||

| Truck | RENAULT VI PREMIUM DISTRIBUTION 260.16, 260.18, 260.19 (MIDR06.20.45C/4) | air conditioner | 1996- | ||

| Truck | SCANIA 142 Series (DS14) | generator | 1981-88 | ||

| AVX 13×1250 | Truck | MAN M90 12.152F, 12.152FL, 12.152FK, 12.152FS, 12.152FLS (D0826F01, D0826F02) | air conditioner | 1988-94 | |

| Truck | MERCEDES-BENZ LP608, LPL608 (0M314.910, 0M314.944) | generator, water pump | 1969-77 | ||

| Truck | MERCEDES-BENZ LPKF709, LPKF808,LPS608,LPLS608 (0M314.910, 0M314.944) | generator | 1969-84 | ||

| Truck | SAVIEM SM340 (D2858M4) | generator | 1973-79 | ||

| Truck | SCANIA 82 Series (DS8, DSI8) | air conditioner | 1981-85 | ||

| AVX 13×1450 | Truck | BERLIET GB231, GC231, GF231, GR231 (20126; MIDS06.20.30) | generator | 1979-80 | |

| Truck | HANOMAG F161SL, F201S-2 MF (6R1112, 562) | air compressor, water pump, fan | 1967-75 | ||

| Truck | IVECO P/PA 190-30N, 190-30NT (Fiat-8210.22.175) | fan | 1987-93 | ||

| Truck | MAN F2000 19.293FAC, 19.293FAK, 19.293FAS, 19.463FAC, 19.463 FAK, 19.463FAS | air conditioner | 1994- | ||

| AVX 13×1475 | Truck | ERF A,B,C Series (6LXBGARDNER; 290CUMMINS) | generator | 1980-86 | |

| Truck | FODEN CUMMINS NT 240 | generator | 1978- | ||

| Truck | MAN F90 19.242FK, 19.242FS, 19.242FLS, 19.242FLLS, 24.242DF, 24.242DFK, 24.242DFS, 24.242FNL | generator | 1990-96 | ||

| Truck | MERCEDES BENZ LP813 (0M353.904, 0M353.981) | generator | 1973-84 | ||

| Truck | MERCEDES BENZ LPS 913 (0M353.904) | dynamo | 1969-84 | ||

| Truck | SAURER PREMIUM POUTE 9G (4F) | air compressor | 1965-80 | ||

| Truck | SEDDON ATKINSON T38C (E290CUMMINS) | fan | 1975-81 | ||

| AVX 10-1000 | Truck | AVIA 1000, 1250 (4.108 PERKINS) | generator | 1976- | |

| Truck | EBRO F275 (4.108) | generator | 1977-87 | ||

| Truck | HANOMAG-HENSCHEL F140T, F150M, F220BMU, F141, 151, 161 SU,H | dynamo, water pump | 1967-75 | ||

| Truck | IVECO M 115-17, 115-17H (Fiat-8060.24.601, Fiat-8060.25.600) | generator | 1983-91 | ||

| Bus | Otoel | generator | |||

| AVX 13-1310 | Bus | Otoel | compressor | ||

| AVX 10-1310 | Bus | Otoel | compressor | ||

| Name | applicability |

| 3PK-630 | Toyota Avensis, Carina II,E, Corolla, Celica |

| 3PK-760 | Toyota Avensis, Carina II,E, Camry, RAV4/ Honda Civic 88-91, CRX/ Mazda 626 87-92 |

| 4PK-1000 | Mazda 323 (BG,BA,BJ) 89-/ Nissan Sunny II/ Suzuki Baleno/ Renault Clio 98- |

| 4PK-1100 | Nissan Almera 95-00/ Fiat Croma 87-96/ Subaru Leone 84-90 |

| 4PK-800 | Nissan Primera (P11) 96-/ Honda Civic 95-01 |

| 4PK-815 | Honda Civic 88-96, CRX/ Nissan Almera, Primera/ Peugeot 205, 309/ Suzuki Vitara |

| 4PK-850 | Audi A4/ Peugeot 205, 306/ Honda Civic/ Toyota Carina E/ Nissan Primera/ Subaru |

| 4PK-890 | BMW E36 316-318, E34/ Mazda 323 (BG,BA,BJ)/ Mitsubishi Galant 95-/ Subaru Legacy |

| 4PK-915 | Nissan Almera, Primera 93-98, Sunny 92-/ Mitsubishi Galant 88-92 |

| 4PK-925 | Mazda 626 (GE), 323 (BA), Xedos/ Mitsubishi Galant 92-/ Suzuki Vitara |

| 4PK-990 | Peugeot 405/ Mazda 323 94-98/ Mitsubishi Pajero/ Ford Escort/ Nissan Sunny II |

| 5PK-1100 | Honda Accord 90-98/ Toyota Carina II-E, Corolla/ Renault Megane |

| 5PK-1110 | Toyota Camry, Avensis, Carina E, RAV4, Corolla/ Mitsubishi Galant, Lancer |

| 5PK-1125 | Toyota Avensis, Carina E/ Mitsubishi Lancer 92-, Pajero/ Volvo S40/ Lada |

| 5PK-1200 | Toyota Avensis, Carina II, E, Camry, Corolla/ Chrysler Voyager 95-01 |

| 5PK-1885 | CHEVROLET-NIVA |

| 5PK-868 | DAEWOO ESPERO (KLEJ), LANOS (KLAT), NEXIA (KLETN), FORD MONDEO I-II, LAND ROVER FREELANDER (LN), ROVER 75 (RJ), SUBARU FORESTER (SG), IMPREZA (GD, GG), OUTBACK, TOYOTA COROLLA (_E10_) |

| 5PK-925 | Mitsubishi Galant (E5)/ Toyota Corolla (E10)/ Fiat Ducato, Tipo, Tempra |

| 6PK-1030 | GAZ 3302, 2705 doors. STEYR |

| 6PK-1042 | AUDI A3, FORD GALAXY, NISSAN ALMERA, SKODA OCTAVIA (1Z#), TOYOTA CAMRY (_V1_), VW GOLF III-V, JETTA III, PASSAT, TOURAN |

| 6PK-1050 | Audi A3, VW Golf, Opel Signum 04- |

| 6PK-1100 | VW Golf III, Vento/ Peugeot 306,405,806/ Nissan Maxima/ Fiat Ducato |

| 6PK-1150 | VW Golf III, Passat (B3,B4), Polo, Vento/ Peugeot 306, 405/Volvo 440, 460, 480 |

| 6PK-1220 | GAZ 3110 MS |

| 6PK-1230 | SCORPIO, SIERRA |

| 6PK-1275 | GAZ engine 40524, 40525, UAZ 40904 without air conditioning, FORD SCORPIO I, HONDA CIVIC EU, OPEL ASTRA H, VOLVO 850, S70, V70 |

| 6PK-1370 | GAZ3110 PS |

| 6PK-1388 | CITROEN BERLINGO, XSARA, FIAT GRANDE PUNTO, PEUGEOT 306, PARTNER |

| 6PK-1413 | GAZelle engine 40524, Volga 40525 with power steering, FORD FOCUS, OPEL VECTRA C, RENAULT 19, ROVER 800 |

| 6PK-1630 | GAZ 3302, 2705 doors. STEYR |

| 6PK-1751 | GAS engine STYER/VAG: VOLGA S engine, CHRYSLER. VW T4, LT28-46 96-/ Citro C5/ Renault Clio 98-/ Skoda Fabia 00- |

| 6PK-698 | VAZ 2110i 16V |

| 6PK-742 | VAZ 2108-10i 8V |

| 6PK-882 | VAZ LADA KALINA 1.8 |

| 6PK-950 | HONDA PRELUDE V (BB), NISSAN MICRA (K11), SKODA OCTAVIA (1Z#), VW GOLF V (1K1), GOLF V PLUS (5M1), TOURAN |

| AVX10x1000 | Opel Vectra A, Omega A/ Ford Sierra, Scorpio I/ Volvo 740-940/ Peugeot 605/ Otoel |

| AVX10x1013 | BMW E30, E34/ VW LT28-35/ Volvo 740-960/ Renault Trafic/ GAZ 31029 eng.402 |

| AVX10x1018 | GAZ 31029 eng.402 |

| AVX10x1030 | GAZ 31029 eng.402 |

| AVX10x1250 | KamAZ, dv. MTZ, ZIL 133GYA, Ural-4320, SAAB, Ford, Renault |

| AVX10x1310 | see Catalog/ EUROBASS, Otoel |

| AVX10x1320 | YaMZ-740, KAMAZ-740, Ural-843, Ural-744, 1320, 4320, 43223, ZIL-133GYA |

| AVX10x710 | VAZ 2108-099 1.3; 1.5 |

| AVX10x833 | GAZ-53 |

| AVX10x875 | Opel Kadett E, Ascona C, Astra F, Corsa A/ BMW E30,E28/ Volvo 240, 740/ Moskvitch 412, UZOtoel, LIAZ |

| AVX10x940 | VAZ 2101 |

| AVX10x950 | AUDI, BMW, HONDA, OPEL, VW |

| AVX11x10x1250 | D-240 (MTZ-80.82), SMD-31-01, D-241-L, ZIL-645, ZMZ-14, YaMZ-840,841,842, MAZ-14, ZIL-157KD, Ikarus |

| AVX11x10x1280 | Otoel |

| AVX11x10x1400 | ZIL-118K(KA), LiAZ-5256(5251), GAZ-66, YaMZ-8401, PAZ-672(3203,3205), LAZ-695(698, 695Н, 699Р,4202,42021), special vehicles, YaMZ- 8401(generator) |

| AVX11x10x1500 | PAZ-3205, ZIL-118, LiAZ-5256 (525625), LAZ 42022 (4207, 525231), SMD-18N (DT-75, TB-1M, TLT-100 tractors), SMD-21/22 (Niva combines ”, “Sibiryak”), SMD-25 (LTZ-155 tractor) |

| AVX11x10x1775 | GAZ-66, (71.73), PAZ-3302, 3205, K-710, Otoel |

| AVX12.5x10x1400 | LIAZ |

| AVX12.5x10x1500 | LIAZ |

| AVX13x1045 | GAZ 3307 |

| AVX13x10x875 | UZOtoel, LIAZ |

| AVX13x1125 | MAZDA 323 III, TOYOTA HIACE, VW T4/ IKARUS, MAN, SCANIA, SETRA-KASSBOHRER, STEYR |

| AVX13x1250 | VW T3/ Nissan Patrol/ Saab 9000/ Toyota Hiace/ IKARUS, MAN, SCANIA, SETRA-KASSBOHRER, STEYR |

| AVX13x1225 | VW Transporter III -92/ Ford Sierra/ MAN, IKARUS |

| AVX13x1310 | MB Truck, Iveco |

| AVX13x1400 | MB SK2544, 2644, VOLVO 760 |

| AVX13x1450 | Opel Frontera A, Monterey/ Iveco/ Man/ DAF, IKARUS, IVECO, MAN, SCANIA, SAVIEM-MAN, UNIC-IVECO, VAUXHALL |

| AVX13x1475 | ERF A,B,C Series (6LXBGARDNER; 290CUMMINS)/ ERF DAF, IVECO, MAN, VOLVO |

| AVX13x750 | MB W460-463, W123/ Mitsubishi L300/ Fiat Croma, Tipo, Tempra |

| AVX13x775 | IKARUS |

| AVX13x900 | Ford Scorpio I, Sierra/ Volvo 940, 960/ Mazda 323, 626/ Nissan Patrol/ NEOPLAN, DAF, BEDFORD, VOLVO, MAN, DAF |

| AVX13x925 | Opel Vectra A, Kadett E, Astra F/ Audi A100(C3)/ Volvo 740,960/ Mitsubishi Pajero/ IKARUS |

| AVX13x950 | VW Golf II, Passat (B3,B4)/ Mitsubishi Pajero/ Toyota Avensis, Carina E/ EUROBAS |

| AVX14x10x887 | YaMZ-236 (238 water pump), MAZ-504, KrAZ-258, Ural-4320-10, K-700 |

| AVX14x10x937 | MAZ-505, KrAZ-258, YaMZ-238NB(K-700), YaMZ-236, YaMZ-238(ND), 7511, Ural-4320-31, YASK-170(200) combines |

| AVX14x13x987 | MAZ-500, MAZ-504, YaMZ-236, YaMZ-238, KRAZ-257, K-700 |

| AVX16x11x1103 | ZIL 130.157, LIAZ |

| AVX21x14x1650 | ZIL-130, Ural-375, KAZ-608V, LAZ-697, LiAZ-677N, ZIL-508.10(509.10) |

| HZ 011 005 | VAZ 2105 |

| HZ 011 008 | VAZ 2108-10i 8V |

FAN BELTS GOST 5813-93: | |

| Belt size | Engine make, car |

| 8.5x8x600 | Snowmobile "Lynx" |

| 8.5x8x665 | Snowmobile "Buran", YaMZ-238AK, EK (combine "Don") |

| 8.5x8x833 | GAZ-53A, GAZ-53-92, ZMZ 53-11, UMZ-451 MG, Moskvich 2138, 2136 |

| 8.5x8x850 | Moskvich-2136 (2138), YaMZ-236 (238, generator) |

| 8.5x8x875 | Moskvich-412-E (IE), 4ED-181T, Moskvich-2137 (2140), SMD-900, 1800 |

| OAVX10-875 | Moskvich-412-E (IE), 4ED-181T, Moskvich-2137 (2140), SMD-900, 1800 |

| 8.5x8x925 | |

| 8.5x8x933 | MEMZ-966 (ZAZ-966), A-OGM (T-4A), A-41 (DT-75M) |

| 8.5x8x1018 | Volga GAZ-24, “Chaika” GAZ-13 (31), MEMZ-968 (Zaporozhets), ErAZ-762V, SMD-60 |

| 8.5x8x1030 | Volga 2410, 31029, RAF, GAZelle, UMZ-451M, 414.10, 416.10, 417.10 |

| OAVX10-1030 | Volga 2410, 31029, RAF, GAZelle, UMZ-451M, 414.10, 416.10, 417.10 |

| 8.5x8x1120 | engine D-245 |

| 8.5x8x1235 | washing machine "Vesta" |

| 8.5x8x1250 | KamAZ, dv. MTZ, washing machine "Vesta", ZIL 133GYA, Ural-4320 |

| 8.5x8x1280 | D-21, A1, D-120, D-37E, D-144 D-463-10, “Ikarus” |

| 8.5x8x1320 | KamAZ-740 (pump), URAL-744, 1320, 4320, 43223, ZIL 133GYA |

| OAVX10-1320 | KamAZ-740 (pump), URAL-744, 1320, 4320, 43223, ZIL 133GYA |

| 10х8х715** | VAZ-2108, 2109 |

| 10x8x820** | car "Oka" |

| 10х8х944** | VAZ-2101–2107, “Niva” 2121 |

| OAVX10-944 | VAZ-2101–2107, “Niva” 2121 Price reduced by 20%!!! |

| 11x10x750 | TATRA, "Ikarus" |

| 11x10x900 | GAZelle, GAZ-14, YaMZ-8423.10 (K701M), YaMZ-7511 |

| OAVX13-900 | GAZelle, GAZ-14, YaMZ-8423.10 (K701M), YaMZ-7511 |

| 11x10x950 | YaMZ-236(238), D-65, YaMZ-7511 |

| 11x10x950s tooth. | |

| 11x10x1045 | GAZ-53, BelAZ-75211, KrAZ-960(6443), YaMZ-236M2 (238M2), GAZ-3307, YaMZ-238ND, ED-181T, 4ED 181T, EMZ-71(73, 24D, 3402, 3403), YaMZ-7511 |

| 11x10x1045s tooth. | |

| OAVX13-1045 | With molded tooth |

| 11x10x1100 (1090) | “Ikarus”, MAZ 6422, SMD 23/24(31/32, 31A/32A), ZIL 157 KD, ZIL-114, URAL-744 |

| 11x10x1180 | K-701M, YaMZ-8401 (pump), TMZ-8421 (8423, 8424), YaMZ-238AK, EK (Don combine) |

| 11x10x1230 | ZIL-“Bull”, ZIL-645, ZMZ-14, ZMZ-505-10, ZIL 157KD |

| 11x10x1250 | D-240(MTZ-80.82), SMD-31-01, D-241-L, ZIL 645 |

| 11x10x1400 | PAZ-672 (3203,3205); LAZ-695 (4202, 42021); special vehicles, ZIL-118K (KA), LiAZ-5256, GAZ-66, YaMZ-8401 (generator) |

| 11x10x1400s tooth. | |

| 11x10x1450 | PAZ-672, LiAZ-5251, ZIL-157L, DT-75V, SMD-19/20, SMD-18 New products!!! |

| 11x10x1500 | PAZ-3205, SMD-18N (DT-75 tractor), SMD-21/22, (combination “Niva”, “Sibiryak”), SMD-25 |

| OAVX13-1500 | |

| 11x10x1600 | ZMZ-65-06, ZMZ-3402, SMD-17K/18K (17KN/18KN), SMD-22, SMD-22-A |

| 11x10x1775 | GAZ-66(71.73); PAZ-3205 |

| 12.5x9x975 | D-54 |

| 14x10x887 | YaMZ-236 (238, pump); MAZ-504, KrAZ-258 |

| 14x10x887s tooth. | |

| 14x10x937 | MAZ-505, KrAZ-258, YaMZ-238ND (K-700 tractor), YaMZ-236 (238, 238ND, compressor), YASK-170 combine harvester (200) |

| 14x10x937s tooth. | |

| 14x10x987 | MAZ-500, MAZ-504 |

| 14x10x987s tooth. | |

| 14x10x1037 | |

| 14x10x1037s tooth. | YaMZ-236(238), T-142, dv. A-01M |

| 14x13x1180s tooth. | PAZ-3205, YaMZ-8401 (BelAZ, pump), YaMZ-238AK, EK (Don combine) |

| 14x13x1280s teeth. | engine SMD-31-01 and SMD-31V for KSK and DON combines |

| 14x13x1320s tooth. | YaMZ-240BM2 (tractor K-701), KamAZ-740, KamAZ-741, TMZ-8421 (8423, 8424, generator); |

| 14x13x1600 | YaMZ-238AK, EK (Don combine, fan drive), SMD-23/24 (31A/32A) |

| 14x13x1600s tooth. | |

| 16x11x1163s teeth. | engines D-54, D-75T |

| 16x11x1220 with tooth | Tractor D-50, D-50A (MTZ-50/52), dv. D-240 |

| 16x11x1403s teeth. | D-65 engine |

| 16x11x1450 | tractor T-150, 150K, spare combine harvester SK-10, DT-175S New products!!! |

| 19x12.5x973s teeth. | MAZ-200, LAZ-210, KrAZ-214 |

| 19x12.5x1220 with teeth. | engine SMD-1-1328 |

| 19x12.5x1450 with teeth. | "Ikarus", A-01M, D-61, A-41, D-440, D-463-10, D-464, SMD-18N |

| 19x12.5x1550 teeth. | SMD-14K, SMD-15K, SMD-18 |

| 21x14x1303s teeth. | ZIL-157(158), LAZ-697, LiAZ-677N, MoAZ-6507 (7405) |

| 21x14x1450s tooth. | LAZ-697, BelAZ-540, BelAZ-531, BelAZ-7540, BelAZ-75482, BelAZ-75231 |

| 21x14x1650s tooth. | ZIL-130, URAL-375, KAZ-608V, LAZ-697, LiAZ-677N, ZIL-508.10, 509.10 |

| 21x14x1735s tooth. | BelAZ-540A (548A, 7548, 75401, 7523, 7421, 6411) |

Characteristics of poly V-belt:

- high efficiency, about 98%;

- used in high-speed, highly loaded units;

- Poly V-belts (PR) operate with minimal noise than conventional belts;

- Wide range, can be used on shafts with small diameters, less than 20 mm.

- The wear threshold is high, long service life.

Thanks to its geometry and quality of materials, a poly V-belt or ridge belt transmits power with virtually no loss. Where such belts are installed, there must be tensioners.

Poly V-belts

List of technical documentation: TU 2563-040-70453527-2004 (K, L, M); TU 2563-027-00152106-01 (RK).

Application of poly V-belts:

- Appliances;

- Automotive industry;

- agricultural equipment;

- industrial equipment.

Conditions for using poly V-belts:

- for power transmission: up to 120 kW;

- permissible linear speed: up to 60 m/s;

- ambient temperature: -30°С ÷ +60°С.

Examples of designations : poly V-belt 10K-1250, where 10 is the number of ribs of the poly V-belt, K is the section of the poly V-belt, 1250 is the length in mm (calculated for sections K, L, M and effective for section RK).

Table No. 1. Dimensions of sections of poly V- , mm

| Size designation | RK | TO | L | M |

| t (step) | 2,4 | 4,8 | 9,5 | |

| Pb (step) | 3,56 | |||

| H (full profile height) | – | 4,6 | 9,75 | 17 |

| H1 (height of truncated profile) | 5,5 | – | – | – |

Table No. 2. Lengths of poly V-belts, mm

| RK | TO | L | M |

| Any length in the range from 975 to 2100* | 500 | 1250 | 2000 |

| 560 | 1320 | 2120* | |

| 630 | 1400* | 2240* | |

| 710 | 1600* | 2500* | |

| 730 | 1700* | 2800* | |

| 800 | 1800* | 3000* | |

| 900 | 2000* | 3150* | |

| 1005* | 2120* | 3350* | |

| 1120* | 2240* | 3550* | |

| 1180* | 2500* | 4000* | |

| 1250* | 2800* | 7650* | |

| 1320* | 3000 | ||

| 1400* | 3150* | ||

| 1500* | 3350* | ||

| 1600* | 3550* | ||

| 1700* | |||

| 1800* | |||

| 1900* | |||

| 2000* |

* – poly V-belts are manufactured to order in an agreed batch size.

Note:

At the Customer's request, poly V-belts can be manufactured in any non-standard length within the specified length range.

Table No. 3. Poly V-belts are widely used in the automotive industry, household appliances, industrial and agricultural equipment.

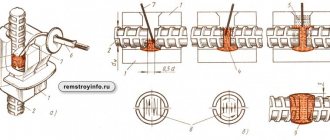

Structure of a poly V-belt:

- Bearing layer. This layer is made of durable composite material threads. The threads are distributed evenly around the perimeter of the product. They are both durable and capable of slightly extending. Attached securely to the base layer. At large stretches, belts with such threads evenly distribute the load over the entire belt area, which promotes smooth energy transfer.

- Coating. This layer must be flexible and have a long service life. This coating reliably protects the supporting layer.

- The basis. The base consists of rows of parallel V-shaped grooves. Such teeth create good adhesion to the shaft pulley. The base layer is made of a durable material, such as polychloroprene elastomer, covered with transversely reinforcing fibers.

Brook belt

It is noteworthy that the poly V-belt has another, slightly less common name.

Due to its appearance, namely due to the presence of many straight stripes-wedges and grooves-grooves between them, reminiscent of rivulets, this drive belt began to be called rivulet. Actually, the number of such streams varies depending on how much power the product must transmit: the more wedges a poly V-belt has, the more reliable its adhesion to the pulleys. Consequently, the load is distributed most evenly over the entire length, and this allows you to extend the service life. The minimum number of wedges that a ripple belt can have is only 3 pieces. However, such products are used extremely rarely, since their transmitting power is low. Basically, in the drives of various mechanisms, for example, passenger cars, poly V-belts are installed, in which the number of strands starts from 4 and reaches 7. In more powerful and heavier types of machines, as a rule, rivet belts are installed, having from 8 to 10 wedges. For trucks and other heavy equipment, the number of these streams can reach almost any value that is necessary.

For example, there are products consisting of 12 wedges, as well as 16 wedges and even 20 rivulets. Of course, the poly V-belt pulleys, like the drives themselves, will differ in width in each case, and the number of clutch strips in them will correspond to the number of rivulets. In addition, poly V-belts can be combined with several pulleys at once, since they are characterized by reverse bending during installation, and they are also capable of semi-cross transmission with non-parallel shafts. These properties are achieved due to their unique design, which also allows:

- Transmit power up to 20 kW per edge

- Operate at rotation speeds up to 60 meters per second

- Operate at temperatures from -30°C to +80°C

- Withstand exposure to many aggressive environments

- Provide 98% efficiency

At the same time, ripple belts are resistant to vibration and also make virtually no noise when rotating. They maintain fairly high gear ratios and provide the least imbalance, since the gear mechanism for this type of product already has the smallest dimensions compared, for example, with conventional wedge products. The fact is that poly V-belt pulleys are smaller in width and have a lower mass of rotating elements. In addition, they are resistant to all weather conditions and wear. Due to these characteristics, they are used in a variety of industries:

- In cars and trucks

- In agricultural machinery and units

- In machines and equipment

- In household and special equipment

- In medical devices

V-ribbed belt profiles

Poly V-belts, like any other types of drive belts, have a fairly large size range. Their main parameters are length, width and height. Actually, the last two parameters form a special classification called a profile. The profiles of poly V-belts also differ in the shape of the wedges. In particular, profiles PH, PJ, PK, PL and PM imply a truncated trapezoidal profile. But the profiles of poly V-belts K, L, M imply a full type of profile with a sharp wedge shape. The height of the teeth, as well as the distance between them, that is, the pitch, will differ in each of these profiles:

| Profile | PH | P.J. | PK | P.L. | P.M. | TO | L | M |

| Height | 1.6mm | 2.34mm | 3.56mm | 4.70mm | 9.4mm | 4.6mm | 9.75mm | 17mm |

| Step | 2.7mm | 3.8mm | 5.4mm | 9.0mm | 14.2mm | 2.4mm | 4.8mm | 9.5mm |

| Length | 1140 -2404mm | 356 —2489mm | 360 —2550mm | 991 - 6096mm | 2286 —16764mm | 500 -2000mm | 1250 —3550mm | 2000 —7650mm |

| Speed | 60m/s | 50m/s | 40m/s | 35m/s | 60m/s | |||

Actually, the profiles of poly V-belts PH, PJ, PK, PL, RM are considered international, but K, L, M are already domestic. In Russia, the technical specifications are considered the manufacturing standard for ripple belts. However, they may differ depending on the specific manufacturer. For example, there are TU 38-105763-89, as well as TU 2563-040-70453527-2004. In Europe, poly-V-belts are produced according to the German standard DIN 7867 and the British ISO 9982. The profiles of the poly-V-belts themselves, the number of strands, as well as their length, are applied to a flat face to indicate a specific standard size. It looks like this:

Designation of imported poly V-belts using the example of belt 6 PJ 2000

| 6 | P.J. | 2000 |

| Number of streams | Product profile | Strap length |

Designation of domestic poly V-belts using the example of belt 8 M 7650

| 8 | M | 7650 |

| Number of streams | Product profile | Strap length |

Both Russian and foreign profiles of poly-V-belts are equally good at transmitting torque between shafts in a wide variety of machines and mechanisms due to their high-quality adhesion to drive pulleys. These products are capable of operating in any climatic conditions and under the influence of fairly large mechanical loads, showing high resistance to wear. In addition, drive poly-V belts are inertia-free, that is, they do not slip both during startup and during stopping of any mechanism due to their unique design.

Where is the longitudinal groove belt used?

Ribbed or multi-ribbed belts have a wide range of applications:

- in units operating under high loads;

- in designs with high gear ratios;

- in structures with high angular velocities;

- in designs with small diameter belt shafts.

PRs are in demand in the automotive industry, tractor, machine tool, metallurgical, chemical, household, and nuclear energy industries.

Such a simple element in belt drives as a belt solves many issues. Thanks to the use of a high-quality rivulet-type belt, the following indicators are improved:

- Reduced noise levels.

- Increased turnaround time.

In order not to reduce the life of the alternator belt, you should monitor the operation of the alternator overrunning clutch.

Dimensions and geometry

V-ribbed belts for a car generator come in different sizes, depending on the equipment. Ribbed belts can also be installed in the design of air conditioners, gas distribution mechanisms (GRM), etc.

Belt size table according to GOST:

GOST dimensions of ribbed belts

Worn poly V-belt

No matter how high-quality the product is, when its service life expires, it is subject to significant mechanical wear. A worn-out part in the design of a car assembly can affect the quality and safety of movement and the operation of the engine.

For those who do not yet know that you can diagnose the main components of a car with your own hands, we have prepared material: How to diagnose a car using a laptop.

Therefore, it is recommended to periodically carry out diagnostics of belts:

- Inspection of external condition. Visual inspection is the main way to detect mechanical damage. If thread delamination or cracks appear, it must be replaced as quickly as possible.

- Inspect not only the belt, but also the pulleys. If there are chips on the pulleys, they create scuffs on the side surfaces of the belt, which leads to very rapid wear.

- Inspect the pulleys for oil. Oil and other fuel and lubricant products should not be present on the surfaces of pulleys and belts.

- In addition, it is necessary to regularly inspect the tension rollers. Make sure that the tension rollers hold the belt properly.

- Check the belt tension level.

The belt and tension rollers should be checked every 15 thousand km. When replacing the belt, it is recommended to change the tension rollers as well.

When a heavily worn belt, not only a rivulet V-belt, but also other types, extraneous noise appears.

Car repair and maintenance professionals recommend changing the alternator belt at least every 50,000 km. The belt must be tensioned so that the deflection coefficient is no more than 0.5 cm. If it is impossible to tension so that the deflection is less than 0.5 cm, then the problem is in the rollers.

Important! Inspect the belt when purchasing to ensure there are no burrs or cracks. Even expensive belts need to be inspected. All types of goods have their own percentage of defects.

V-belts: types, markings and belt selection

09/05/2018 |

Reviews: 3 | 40704 V-belts are used in belt drives, and among all belts this type is the most popular. Unlike flat belts, their cross-section is trapezoidal or wedge-shaped.

Typically belts consist of:

- Stretch layer (rubber layer);

- Elastic layer (rubber);

- Supporting layer (cord cord for belts of cord design);

- Supporting layer (fabric frame for belts of cord fabric construction);

- Compression layer (consists of rubber);

- Wrapper.

Why are V-belts capable of transmitting greater loads than flat ones?

As in other belt drives, the torque from the drive V-pulley to the belt and from it to the driven pulley is carried out due to friction forces. But in a V-belt drive, the working surfaces are the side surfaces of the belt. In this case, the contact patch is much larger than in a flat belt.

This means more friction force and, therefore, more transmitted torque. To increase the contact patch it is not necessary to increase the diameter of the pulley. It makes more sense, from the point of view of the dimensions of the structure, to choose a pulley of small diameter, but with several belts. In this case they say multi-strand pulley.

Advantages of using V-belts

- Simplicity of design.

A belt and two pulleys are simpler than a gear or chain drive, the parts of which are structurally more complex and require greater manufacturing precision. The simplicity of the design means it is cheap. - Easy to care for.

The belt drive does not require special care and lasts until the belt wears out. - Silence.

The belt is made of rubber or other similar materials that perfectly dampen any noise. In a chain one, the noise level will always be higher. - Ability to withstand excessive loads without transmission failure.

When the force on the pulley is higher than the calculated one, the V-belt or any other belt will simply slip. In a chain drive, overload will lead to breaking the chain or licking off the key; in a gear drive, it will lead to chipping of the teeth. - Ability to transmit forces over significant distances.

If you use a chain drive, the chain has significantly more weight compared to a belt drive, which will require additional drive power.

Types of belts

Standard profile V-belts:

Z/10, A/13, B/17, C/22, 25x, D/32, E40

Narrow V-belts:

SPZ, SPA, SPB, SPC, 3V/9N, 5V/15N, 8V/25N

V-belt length marking

L or La

This is the length along the outer (top) side.

Lw, Lp, Ld

The calculated (working) length of the belt (this is the length along the neutral line, that is, along the belt tension line - along the cord).

Li

Length along the inner (bottom) side.

How V-belts are marked

There are several types of V-belt markings:

- According to GOST 1284-89;

- According to the European standard DIN 2215;

- According to the international ISO standard;

- According to American RMA standard.

Designation of V-belts according to GOST 1284-89

Manufacturers in the CIS countries adhere to this marking. And also the Chinese, who supply their goods to this market. According to it, the designation of a V-belt indicates the profile and estimated length - Lp (Lw or Ld in Western catalogs)

. The estimated length is the length of the belt measured along the cord.

Designation example: Belt D(G) 2500 GOST 1284.1, where:

- D(G) – profile designation;

- 2500 – estimated belt length in mm.

In European markings, profiles are designated not by letters, but by numbers; the belt designation indicates the length along the inner edge - Li, since the length of the inner edge can be directly measured.

Designation example: Belt 25×2000, where:

- 25 – profile number;

- 2000 – internal belt length.

ISO marking is almost identical to GOST, only the profiles are designated in Latin letters. The estimated length is also indicated by the profile (cord) - Lp (Lw or Ld in Western catalogues).

Designation example: Belt SPZ 2000 Lw, where:

- SPZ – profile designation;

- 2000 – estimated belt length;

- Lw - length marking.

In the USA, letters are used to designate a profile. But the geometric dimensions of the profile are indicated in inches.

The length of the belt is measured, as in Europe - along the inner edge.

Designation example: Belt B 43, where:

- B - belt profile;

- 43 – internal belt length in inches.

Profile marking Width, mm Height, mmGOST ISO DIN RMA Wa Wp Wi TClassic beltsNarrow

| 0 | Z | 10 | — | 10 | 8,5 | 6,1 | 6 |

| A | A | 13 | A | 13 (½”) | 11 | 7,8 | 8 (5/16”) |

| B | B | 17 | B | 17 (21/32”) | 14 | 9,4 | 11 (13/32”) |

| IN | C | 22 | C | 22 (7/8″) | 19 | 12,9 | 14 (17/32”) |

| G | D | 32 | D | 32 (1 ¼”) | 27 | 19,2 | 20 (3/4”) |

| D | E | 40 | E | 40 (1 ½”) | 32 | 22,4 | 25 (29/32”) |

| У0 | SPZ | — | — | 10 | 8,5 | 4 | 8 |

| UA | SPA | — | — | 13 | 11 | 5,6 | 10 |

| UB | SPB | — | — | 17 | 14 | 7,1 | 13 |

| UV | SPC | — | — | 22 | 19 | 9,3 | 15 |

The length of a domestic and Chinese-made belt must be measured along the cord (it is clearly visible on the side edges). Another way is to measure the internal or external length, and then find the working length from the manufacturer's catalogs.

The length of a European or American V-belt must be measured along the inner edge.

Measuring the geometric dimensions of the profile does not cause any difficulties. All measurements must be carried out with the belt in a free (not tensioned) state.

How to choose a V-belt

It is highly recommended to select a belt in strict accordance with the documentation for the equipment in which it is used. Belts from different manufacturers that have the same geometric dimensions may differ in strength characteristics.

If it is not possible to supply exactly the same belt, it is necessary, in accordance with the manufacturers’ catalogs, to select the closest analogue in size. In the case of an American belt, do not forget to convert its length and profile dimensions from inches to millimeters (for this you need to multiply by 25.4).

Types of wear on V-belts

We list the factors due to which the belt drive can fail, as well as the reasons for their occurrence:

- Excessive stretching caused by:

- Inconsistency between the cross-sectional area of the belt and the resulting loads;

- Poor quality belt;

- The belt length does not correspond to the required design length.

- Increased wear caused by:

- Inconsistency between the area of the side faces and the resulting loads;

- Mismatch between the belt profile and the pulley profile;

- Pulley misalignment;

- Jamming of pulleys.

With proper selection and operation of the belt drive, it will serve for years.

Alignment and tension of V-belts

When installing a belt drive, parameters such as alignment and tension of the V-belts are very important. Deviations from the design values should not exceed tolerances according to the manufacturer’s recommendations.

Otherwise, increased wear of the belt will be observed, the service life is much shorter than that indicated in its passport.

When replacing a belt and during its operation, it is recommended to measure the tension and alignment of the pulleys using measuring tools.

V belt meters

V-belt manufacturers

There are many belt manufacturers, which can be divided into three categories:

- Premium:

Optibelt, GATES, Contitech, BANDO, SKF; - Standard:

Rubena, STOMIL, Fenner TOP DRIVE; - Economy:

China and domestic manufacturers.

As with other components, we recommend installing original premium quality belts on critical components where downtime and stoppages are unacceptable.

We offer products in various price categories from European, Japanese, American and Chinese manufacturers. If necessary, our specialists will select the required transmission in a complex in accordance with the provided initial data.

Prices

Cost of poly V-belts:

- for AUDI cars - BOSCH belt - from 251 rubles;

- for Porsche cars - Contitech 3РК600 belt - from 255 rubles;

- for Ford cars - BOSCH belt - from 253 rubles;

- for Citroen - Skf belt - from 259 rubles;

- for Alfa Romeo - Bosch belt - from 250 rubles;

- for BMW - Skf - from 250 rubles;

- for Cadillac cars - Gates belt - from 825 rubles;

- for a Hummer car - Contitech belt - from RUB 2,701;

- for Jaguar - Dayco belt - from 305 rubles;

Then the list continues, approximately in the same price range - from 250 rubles for 2022. VAZ LADA, AUDI, BMW, Mercedes, cars from Korea or China, etc., do not require large investments to replace the belt. For Rolls-Royce, Bentley, Ferrari and other top world cars, accordingly, belts cannot be bought in ordinary car stores.

Equipment / Project - TURNING / Pulleys: theory, online calculator, practice. / Calculation of the length of the drive poly-V-belt. Online calculator.

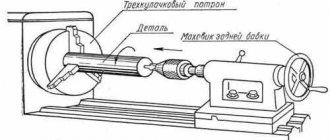

In previous articles, we calculated and manufactured pulleys for a lathe. Next, we mounted the frame and electric motor on a new base.

Now it's time to select the drive belt. Even at the pulley design stage, we decided on the type of belt that will be used in our machine. This is a poly-V-belt with a “RK” section. Accordingly, after we receive the calculated value of the belt length, we will be able to select the closest nominal value to the calculated value from the table of standard sizes.

So, let's start measuring the center distance between the engine shafts and the headstock. It was 241 millimeters.

Now you can start calculating the length of the drive belt. The formula for calculating the length is given below:

where a is the center distance, D1 and D2 are the diameters of the pulleys.

For example, our calculation. Let's start with the initial data. The diameter of the electric motor pulley is 60 millimeters, the diameter of the driven shaft pulley (headstock shaft) is 97 millimeters, and we know the center distance, it is 241 millimeters. We substitute our values into the formula and get a belt length of 730 millimeters.

L = 2×241 + (3.14/2) x (60 + 97) + ((97 – 60)/4×241) = 730.04 mm

For the convenience of carrying out calculations, we suggest using an online calculator; the formula for calculating the length of the belt is included in it, so all that remains is to enter the initial data and click the “Calculate” button.

How to use a calculator. All parameters that we enter must be in millimeters. In fields D1 and D2 we enter the diameters of our pulleys. These are 60 and 97 millimeters, respectively. Next, enter the value of the center distance, this is 241 millimeters. Now click the “Calculate” button. After this, the estimated belt length is displayed in the field below and we obtain the desired value.

Next, from the table of standard sizes, in accordance with the section of the belt, we will select the closest nominal length. In our case, the belt section is “RK”, the calculated length is 730 millimeters. It turns out that this is the nominal size - 730 millimeters. But we will need a reserve to put on the belt, so we may have to buy the next standard size, which is 755 millimeters.

| Section | Range of standardized belt lengths |

| PH | 1140, 1219, 1260, 1580, 1600, 1653, 1845, 1874, 1890, 1915, 1930, 1951, 1980, 1992, 2404 |

| P.J. | 356, 381, 406, 432, 457, 483, 508, 559, 584, 610, 660, 686, 711, 737, 762, 786, 813, 838, 864, 889, 914, 965, 991, 1016, 1054, 1092, 1143, 1168, 1194, 1219, 1245, 1270, 1295, 1321, 1372, 1397, 1461, 1473, 1549, 1600, 1626, 1651, 1702, 1753, 1778, 1854, 1930, 1956, 1981, 2022, 2083, 2210, 2286, 2337, 2489 |

| PK | 527, 630, 648, 698, 730, 755, 770, 810, 830, 880, 920, 960, 1000, 1035, 1130, 1205, 1280, 1314, 1397, 1420, 1460, 1480, 1520, 1549, 1610, 1645, 1725, 1843, 1885, 1980, 2031, 2080, 2164, 2236, 2550 |

| P.L. | 991, 1041, 1149, 1168, 1194, 1219, 1270, 1295, 1321, 1334, 1346, 1372, 1397, 1422, 1435, 1473, 1499, 1562, 1613, 1651, 1664, 1715, 1727, 1765, 1803, 1841, 1943, 1956, 1981, 2022, 2070, 2096, 2134, 2197, 2235, 2324, 2362, 2477, 2515, 2705, 2743, 2845, 2895, 2921, 2997, 3085, 3124, 3289, 3327, 3492, 3696, 4051, 4191, 4470, 4622, 5029, 5385, 6096 |

| P.M. | 2286, 2388, 2515, 2693, 2832, 2921, 3010, 3124, 3327, 3531, 3734, 4089, 4191, 4470, 4648, 5029, 5410, 6121, 6883, 7646, 8408, 9169, 9931, 10693, 12217, 13741, 15266, 16764 |

At an auto parts store we purchased a belt manufactured by OJSC BRT 6K-742-02. Its length is 742 millimeters. It goes to the generator of the VAZ ten. So, as practice shows, today you can buy a belt of even intermediate sizes.

We intentionally purchased a six-strand belt. Since we plan to make two or three rivulet belts from one belt. We will cut the belt with a linoleum knife. To cut the belt efficiently, we will use a large cylinder. We turn the belt inside out, put it on the cylinder and run it along the middle stream with a knife.

As a result, it turns out that the cost of the belt is less than one hundred rubles per piece.

After the work was done, the idea arose to make a reverse calculator. For example, there is an electric motor with a pulley and there is a response mechanism also with a pulley; we know their diameters. There is a belt or even a couple. It is necessary to find what the center distance will be if one or another drive belt is used. The inverse formula for calculating the center distance is as follows:

Also, as in the previous case, to make arithmetic operations easier, we suggest using an online calculator.

How to use a calculator. All parameters that we enter must also be in millimeters. In fields D1 and D2 we enter the diameters of our pulleys. For example, these are 60 and 97 millimeters, respectively. Next, enter the value “L” - the length of the belt that we have in stock, our value is 742 millimeters. Or the length of the belt that we are planning to purchase. Now click the “Calculate” button. After this, in the field below we obtain the desired value of the center distance equal to xxx millimeters.

Online calculators for all occasions, we recommend that you familiarize yourself with:

Calculation of the diameters of belt drive pulleys. Online calculator,

Calculation of the amount of oil for gasoline,

Calculation of oil for the fuel mixture - container without volume marking,

Calculation of ammeter shunt resistance,

Online calculator - Ohm's law (current, voltage, resistance) + Power,

Calculation of a transformer with a toroidal magnetic core,

Calculation of a transformer with an armored magnetic core.