Suppose you decide to make a steel door with your own hands or want to buy one, but the upholstery of metal doors in the store leaves much to be desired. Don’t be upset, sheathing a metal door yourself is not so difficult, and then we will tell you in detail how to sheathe the front door and slopes to it on both sides, with all the pros and cons of the options that exist today.

The upholstery of the metal entrance door speaks of the status of the owner of the house.

For those DIYers who want to surprise their loved ones with a high-quality steel door made at home with their own hands, there is a good step-by-step instruction with a detailed video, detailed photos and explanations, you can find it “here”.

How and with what to cover the entrance doors of an apartment or house: selection of materials and installation instructions

Covering the front door is done not only to restore (or change) its appearance. Decorative design, if you select the right materials, allows you to insulate the opening, increase its level of sound insulation and extend the service life of the canvas, protecting it from atmospheric factors.

Do-it-yourself restoration and renovation of a metal entrance door from the outside

Over time, the metal surface rusts and loses its attractive appearance. In this case, it is not necessary to buy a new product. You can clean the old structure, treat it with anti-corrosion compounds and decorate it with wooden or plastic strips, leatherette, plywood or MDF sheets, self-adhesive film. Painting can also be done.

For high-quality restoration you need to follow the following algorithm:

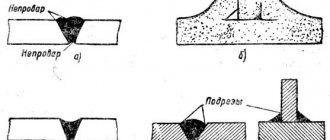

- Surface cleaning. Traces of rust and old paint should be removed from the metal. To do this, use a metal brush. There are also special attachments that are installed on a drill or grinder.

- Drying the fabric. Necessary for applying solutions and ensuring their good adhesion.

- Puttying uneven areas. Automotive putty will do.

- Surface grinding.

- Primer of the canvas.

- Restoration using the chosen method (painting, upholstery with leatherette, covering with MDF or plastic panels).

The sash should be renewed in its removed form. This way the work will be more accurate, faster and more convenient. It's better to work with a partner. Before starting restoration, it is recommended to watch videos from professional or home craftsmen, which describe different methods of updating the door leaf and give advice.

It is recommended to update the iron sash in a timely manner. This is important not only for its appearance, but also for its shelf life. If you take care of a metal structure and protect it from corrosion, then it will last longer.

Finish options

Before you start work, you should figure out how to cover the front door. There are quite a lot of methods, but when choosing the optimal one, you need to take into account local specifics.

Lining

Plastic panels are not suitable as a material for lining entrance doors, although they are sometimes used. Their main disadvantage is their rapid “burnout” under the influence of ultraviolet radiation. Therefore, only slats made of MDF or solid wood. If the samples are properly treated with special preparations, primarily antiseptics, then there will be no problems with the sash for a long time.

But here we cannot ignore the characteristics of different types of wood. To cover entrance doors made of metal or wood, if they are installed in a private house, you should focus on larch. It is maximally resistant to dampness, and when wet it only gains strength. But for finishing the panels covering the openings leading to the apartments, cheaper spruce or pine are also quite suitable.

Laminate

An equally popular material that attracts buyers with a variety of shades. After such finishing, no additional surface decoration will be required. Covering doors with these panels is done quickly by gluing them. But given the disadvantage of laminate - hygroscopicity - it is advisable to use it only at the entrance to the apartment.

Plywood

Naturally, we are talking only about multilayer sheet material. When choosing, you should take into account its variety; Among the budget options, FC and FSF products are suitable. The first does not like excess moisture, but does not contain phenol in the glue that holds the veneer together. Therefore, it should only be used for upholstering the entrance metal (wooden) door from the wrong side of the door. FSF sheets are recommended for installation outdoors, since the adhesive composition contains toxic components. But it is inert to moisture, therefore, in all respects it is suitable for the outer cladding of the sash.

The best option is shiplap plywood. But it is not widely used in everyday life due to its high cost.

MDF panels

One of the cheapest materials that can be used to quickly cover the front door. Further decoration of the canvas depends only on the imagination of the master - with film, painting, varnish (with or without tinting) and so on. But there is a significant disadvantage - a large specific gravity. Therefore, it is necessary to take into account the reliability of the loops. Moreover, if at the same time it is decided to insulate the sash.

Most likely, the awnings will have to be replaced. It is unlikely that this cladding option is suitable for a metal door with hidden hinges, especially if everything is done independently.

Fiberboard sheets

Another budget-friendly way to reconstruct paintings. But it is advisable to use only for apartment doors. Low mechanical strength and hygroscopicity make fiberboard unsuitable for cladding doors at the entrances to private buildings.

Viniplast

Sheet material is also quite cheap and easy to install. It is advisable to use it for cladding steel sheets, since at the same time it is an excellent insulation material. In order not to deal with the decoration of the metal entrance door in the future, you should focus on the modification of VD (decorative vinyl plastic).

Leather vinyl

There are many advantages - low cost, variety of textures and shades, inert to dampness, easy to clean. You can sheathe any fabric, and according to different patterns. Using nails with decorative caps, cords, ribbons, etc., the door is given a different texture; it is divided into rhombic, rectangular and other sectors depending on your own imagination.

But there are also disadvantages of covering the valves in this way - the low mechanical strength of the material and instability in the face of aggressive “chemistry”.

Leatherette

The traditional method of reconstructing paintings is one of the simplest and cheapest. However, this finish is short-lived due to brittleness at low temperatures and insufficient strength. As an option - for decorating paintings from the inside or at the entrance to the apartment.

PVC film

When deciding how to sheathe a door, it is worth considering this option. It has disadvantages - the fragility of the layer, weak mechanical strength and elasticity. The last factor will not make it possible to mask defects in the canvas in the form of depressions. But all this is fully compensated by the high speed of restoration, ease of surface care and low price of the film.

How can you frame the front door from the inside?

The door leaf is lined on the inside to give it a finished look and attractiveness. This also increases the soundproofing and thermal insulation qualities of the structure.

For finishing you can choose:

- laminated chipboard;

- MDF overlays;

- leatherette;

- genuine leather.

Each of the proposed materials has its own nuances. Therefore, you need to know the order and features of fastening different products.

Chipboard sheets up to 6–8 mm thick

6-8 mm laminated chipboard is the most budget-friendly cladding option. At the same time, it transforms the appearance of the canvas. The material is characterized by low moisture resistance. Therefore, when attaching it, the edges must be treated with sealant. Laminated chipboard is offered in different texture and color options. There are successful imitations of natural wood. The boards are attached with glue and additionally secured with self-tapping screws. Installation takes little time.

MDF overlays

MDF overlays are medium density boards. Used for finishing slopes and steel doors. They are offered in a wide variety of models in texture and surface color. They do not lose characteristics over time. They tolerate temperature changes well. They are safe and easy to maintain. Provide additional heat and sound insulation. Easy to install. Attached with glue and screws.

Leather or leatherette

Many people have no doubt about what can be used to cover an iron entrance door on the inside; they choose leatherette or leather. This gives the canvas an expensive look and improves the interior of the corridor. Leatherette is usually used due to its low cost, strength and durability. Foam rubber is placed between the base and the finishing material. It is attached with glue. Then leatherette is laid out on the canvas. The edges are wrapped and secured with special staples.

Specifics of finishing

The specific operating technology is determined by several factors:

But basically all the methods are similar and are performed according to a single algorithm.

It turns out that door trim is one of the best options for its reconstruction, which can be combined with insulation of the opening. In addition, any of the practiced techniques is completely doable independently, without outside help. And if the canvas has become dilapidated, do not rush to buy a new one - putting it in order, giving it a different look is not at all difficult, and it will cost much less.

Source

How to sheathe a door from the outside

The need to sheathe an external door may arise in different situations. More often than not, the owner of a residential building perceives a similar decision in 3 options. Firstly, when it is necessary to update the design of the installed entrance structure to give it a more modern, beautiful and elegant look. Secondly, if any flaws are discovered in the existing decorative coating that need to be hidden. Thirdly, in this case, when it is necessary to increase not only the aesthetic properties of the product, but also the level of heat and sound protection.

Sheathing materials

The choice is determined by the purpose of the work - preventing heat loss, protecting against loud sounds from outside, sealing cracks around the perimeter of the door frame or changing the appearance of the door leaf. The front door can be covered from the outside, from the inside, or from both sides.

Lining and MDF panels

Wooden lining will add elegance to the door leaf. The texture of wood, emphasized by paints and varnishes, forging, carving, decorative metal and polyurethane moldings. The wooden upholstery of the entrance doors, decorated with rows of beads and rivets, will add sophistication to the interior.

MDF panels are easy to process:

Decorating the front door with plastic clapboard will not improve the appearance of the door, but it is inexpensive, durable and practical.

Plywood

Plywood externally imitates solid wood. This material, treated with special compounds, is durable, resistant to moisture and tolerates temperature changes well.

The outer cladding of entrance doors should be made of shipboard (aviation) plywood:

The film of bakelite resin covering the outer surfaces can make work difficult: if it is necessary to stick stickers on the surface of decorative elements, the places where the glue is applied must be sanded.

Laminate

Glued-pressed wood fiber boards are initially designed to withstand loads. Their surface is easily and without consequences cleaned of dirt, resistant to damage - not afraid of the claws of even large dogs. With proper selection of panels, tongue-and-groove joints create the illusion of a monolithic coating.

From the outside, only an apartment door can be covered with laminate, since this material is intended for interior decoration and is not resistant to humidity, cold, and sudden temperature changes typical of outdoor conditions.

Leatherette

Decorative upholstery with cotton fabric with a layer of nitrocellulose is recommended for interior work: in a house, in an apartment, in an entrance. Leatherette is not afraid of moisture, but is sensitive to ultraviolet rays - it changes color and becomes harder. This material has already been discontinued.

Faux leather

For door upholstery, materials with a base impregnated with polymers are used: vinyl, PVC leather, vinylis. Faux leather is durable and practical. The specific smell inherent in it disappears within 1-2 weeks.

Artificial leather differs from leatherette:

Leatherette allows air to pass through, so wooden doors covered with it do not become moldy, and steel doors do not rust - excess moisture is removed through the pores of the artificial leather.

What are doors being decorated with now?

First of all, remember that lining a metal door on the outside and decorative finishing on the inside are not the same thing. Even if visually the materials look the same, their characteristics or at least the level of processing are completely different.

After all, do not forget, we are talking about entrance doors, where the outside cladding is regularly watered by rain, freezes and roasts in the sun, and from the inside the finishing of metal doors is in the comfortable conditions of a residential building. By the way, at this address you can learn about insulating iron doors with your own hands.

Diagram of a disassembled metal door.

Laminate

Finishing metal doors with laminate flooring has long ceased to be a curiosity. After all, the flooring was initially designed for quite serious loads:

Finishing an iron door with laminate flooring is a good and inexpensive option.

- It will not be difficult to wash an iron door finished with laminate from whitewash, to remove dirt or traces of shoes, because on the floor this coating is subjected to even greater tests;

- Any laminate will easily withstand the claws of pets; even a large dog is not able to scratch such a coating;

- A big plus from a design point of view is the same finish of the floor, slopes and door leaf;

- The thickness of the planks ranges from 6 to 12 mm, the weight of the cladding is also not large, which is an additional advantage when choosing;

- The planks are connected according to the tongue-and-groove principle, and after splicing they form a smooth monolithic surface, in which even the seams are difficult to feel;

- To fix it on the canvas, it is enough to clean and treat the steel sheet with primer, after which you can safely glue the planks, for example, onto liquid nails;

- If the doors from the inside are not sheathed with a solid steel sheet, then the laminate strips are attached to the bars of the internal sheathing, and in order to hide the unflattering cut and screws, a plastic U-shaped profile is glued along the edge.

It is quite possible for an amateur to decorate the inside of a door with laminate flooring.

Now let's move on to the pitfalls; there are plenty of them here too. Let's start with the fact that laminate flooring, no matter how expensive and elegant it may be, was originally created as an internal covering, which means it is not designed for sudden temperature changes, frost and excessive humidity.

Accordingly, they can only be used to decorate doors from the inside. Exterior finishing is possible only in multi-storey buildings with relatively warm entrances.

If you decide to opt for laminate, then keep in mind: this material is divided into 7 classes. If the marking starts with 2, then this material is made for apartments and private houses (21,22,23). Everything that begins with three (31,32,33,34) is designed for commercial organizations, offices and shopping centers.

The classification of laminate flooring depends on the level of wear resistance.

When buying, you don’t need to listen to the consultant’s persuasion. The fact is that visually classes 21 and 34 may not be any different, and if you are not going to dance on your doors or wash them with a fire hose, then take the twenty-first class, and the thinnest slats (6 mm), the price will please you.

MDF panels

MDF panels are solid large door linings; professionals call these panels cards. Now upholstering a metal door with such cards takes up almost half of the market.

Finishing metal entrance doors with MDF panels is now considered the most popular.

The material itself is made from wood dust and, according to the manufacturers, does not contain any harmful additives. Wood dust is poured into molds, pressed and fried under high pressure, as a result of which the natural glue lignin is released, which turns the compressed mass into a monolithic sheet.

Before sheathing the canvas, you need to decide which panel you want to see. You can sheathe a metal entrance door with pure MDF, laminated or veneered.

To be honest, blank MDF sheets are not suitable for decorating a door leaf. The top layer of the sheet is practically not protected, its appearance is rather mediocre and the most you can do is paint it with something, but you won’t achieve much beauty.

Pure MDF and chipboard panels in comparison.

There is an important point here; it’s better to forget about such a common material as chipboard right away; you shouldn’t even think about how to decorate a metal door with chipboard sheets. This material is not suitable for either external or internal cladding of entrance doors; the sheet will begin to delaminate within a year.

The most common is laminated MDF; such cards have quite a lot of advantages:

- Laminated MDF card is resistant to fading;

- Finishing a metal door with your own hands will not be difficult for you, and both external and internal finishing are done equally simply;

- For finishing work you need a minimum of tools. If you are covering only the door leaf, without slopes, then a drill and a screwdriver are enough;

- Washing MDF card from stains and other troubles is as easy as laminate flooring;

- The door trim does not require additional adjustment or modification; the product is immediately sold with fixed dimensions according to door standards. If your canvas is not standard, then you can use several small cards or order a panel according to your size;

- In serial factory doors, MDF panels are inserted into special grooves, so before disassembling the old door, see if you have such grooves. The principle is simple, the side clamp is removed, after which the old panel is moved to the side and pulled out, and the new one is inserted in its place.

Decor options for MDF door cards.

When choosing a new MDF “shirt” for your doors, keep in mind that the interior decoration can be done with any panels, but the outside of the doors can only be clad with a special MDF panel. The back of the outer cards is green, and the back of the inner ones is yellow. The result of such an error is shown in the photo below.

The result of the wrong choice of MDF card.

In the elite sector, MDF panels covered with natural wood veneer are used to decorate entrance doors. Veneer is a thin slice of wood, so if you use it to cover an MDF panel, it will be no different from a natural board.

It turns out that for reasonable money you can make yourself luxury wooden doors, for example, from oak. Of course, a veneered card is not cheap, but compared to a natural solid card, the difference will be at least 2 times.

But there is a small but significant subtlety here: if you want to get truly natural veneer, then look among domestic or Belarusian manufacturers.

Veneered MDF panels are practically no different from natural wood.

Most European companies produce cards covered with so-called eco-veneer. If you don’t go into details and brush away the advertising tinsel, then eco-veneer is just high-quality plastic that contains some percentage of wood.

There is also veneer under the tricky name “Fine Line”. So, if you are offered, for example, a “Golden Oak” veneer panel made using fine-line technology, then know that cunning manufacturers took inexpensive poplar or linden, cut the veneer from it, and after painting and processing, this veneer suddenly became golden oak

The story is approximately the same with multi-veneer, but it is visible to the naked eye. The design there is quite abstract, cubes, waves, circles and a lot of other options, but this is natural wood, only pressed, glued and cut, this is not for everybody.

Varieties of multi-veneer.

Leather upholstery

Many people associate quilted door trim with Soviet design. Indeed, if you take cheap dermantin and upholster the doors with it, the look will not be the best, but do not rush to discard this option; with a reasonable approach, quilted upholstery can look luxurious.

Nowadays you won’t find doors trimmed with natural soft leather because they are very expensive. A new material called eco-leather is used for upholstery; this material is a synthetic coating that visually and to the touch is no different from real leather.

In addition to its solid appearance, quilted cladding has two tangible advantages: firstly, additional insulation, and secondly, serious sound insulation. Although for domestic cats and dogs, quilted upholstery is first in line to be torn apart.

The carriage screed belongs to the elite finishing of entrance doors.

The easiest way is to take eco-leather and cover it with a sheet of plywood, and use foam rubber as a filler. If you want to get a truly luxurious door, then there is a carriage tie for this; it is more difficult to make, but the result is worth it.

Detailed instructions for budget door trim and arranging a luxurious carriage frame with video and step-by-step photos are available here.

If you decide to buy soft panels for doors, then keep in mind: high-quality upholstery is made from solid canvas. If you are offered a quilted panel sewn from pieces, then know that this is a cheap, low-quality product.

Powder coating

Powder coating of doors cannot be done at home with your own hands. This is a high-tech process: the metal is cleaned, processed and special paint is applied, after which the door is “fried” in ovens, as a result the surface acquires unique protection.

A fine-crystalline film is formed on the surface of the metal, which is easy to clean and reliably protects the doors from corrosion. Manufacturers claim that such a lining cannot be scratched; we do not know whether these claims are true, but powder paint can withstand animal claws without problems.

Hammer paint is a good alternative to powder coating.

Hammer paint can be a good alternative to powder coating; you can use it to paint your doors yourself and the look will be no worse than powder coating. At “this address” you will learn how to properly disassemble doors, how to wash metal from rust, and most importantly, how to paint the doors yourself.

Lining

Lining has been used for various types of finishing for about 100 years, and despite such an advanced age, it is still among the leaders. Neat wooden planks are connected using tongue-and-groove technology. The lining has quite a lot of advantages.

- Lining can be used for both external and internal finishing of doors, although for external finishing the wood will have to be treated with a complex primer and varnished for external work;

- The material is 100% environmentally friendly;

- Natural wood will never go out of fashion; with proper care, such doors will always look fresh and original;

- The technology for installing lining is quite simple and accessible to any home craftsman; we can assure you that even if you have never dealt with lining, within a day you will cover your front door with it;

- The slats can be combined as you wish, as a result your door will have an original pattern.

Various options for door trim with clapboard.

When finishing iron doors with clapboard, novice craftsmen often do not know how to fix the strips to the metal. So from the inside, the lining is hemmed to a pre-fixed wooden sheathing, which in turn is attached to the stiffeners and the internal frame of the doors.

The outer cladding is prepared separately, first the lining is screwed with small self-tapping screws to a plywood sheet, and then this shield is attached to a metal sheet. In order to securely fasten the facade shield, you will need to drill a dozen holes in the metal sheet and screw it on the inside with self-tapping screws.

For those who are going to do everything with their own hands, there are good instructions that describe in detail how to decorate the front door in four relatively simple ways, it is located “here”.

By the way, lining is not only made of wood; now they produce many options for plastic lining. Theoretically, it is possible to cover doors with plastic, but not everyone likes such cladding, plus the strength of plastic is not high.

Plastic lining.

What is better to choose for the entrance group

In addition to the characteristics of the upholstery material, when choosing, you need to take into account the conditions at the location where the door is installed.

How to sheathe the outside of the front door:

You can sheathe the canvas from the inside with any upholstery materials, both soft and hard.

When upholstering the outside, you can lay an insulating layer of batting, felt, foam rubber, polystyrene foam, mineral wool, etc. Insulating the door lining from the inside threatens to shift the dew point, which causes condensation to form on the surfaces of the door structure, mold, and rust.

When choosing a material for upholstery, you need to consider how suitable this option is for self-installation, whether you have the necessary tools, and experience in finishing work. It is necessary to take into account the service life of the trim, as well as the possibility of replacing the trim in the future and the cost of such work.

Work execution development

It is quite natural that the design of the work used for cladding is determined, above all, by the chosen finishing material. With all this, it is very important to note that all of the above methods for designing an external iron door can be carried out both by the owner of a residential building on his own, and by inviting professional finishers. Any of these two options has very significant advantages. When doing the work yourself, the owner saves money, but his time is wasted, and in addition, there is a rather serious risk of getting a bad final result.

Calling a specialized company will naturally cost more. But, in this case, the owner receives not only well-made cladding, but also warranty obligations from the company with which he enters into a contract. Of course, any of the outlined options is intensively used in practice, and the final choice of method for finishing an outdoor aquatic structure always remains with its owner.

Preparatory work

The process of preparing the door leaf is the same for all materials. Consumables are purchased with a small reserve.

Before sheathing a metal door, you need to:

If necessary, the structure can be washed; detergents are selected depending on the material. Detected defects are eliminated: fungus, mold, rust stains. A moisture-proof, antiseptic or other coating is applied to the canvas.

The sheathing material must be unrolled 1-2 days before the start of work so that the folds on it straighten out.

To sheathe the front door with your own hands, you will need gloves and a set of tools.

Tools

They are selected depending on the specifics of the work, the material of the door leaf and the material with which the door is finished.

Standard set of tools:

To dismantle the fittings, you will need a set of screwdrivers and pliers; for accurate upholstery work, you will need a marker and a construction pencil.

Using a professional tool, such as a furniture stapler, will help speed up the process. The screwdriver can be replaced with a drill with a special attachment,

Powder coating of the external surface of the entrance door

Spraying of a special powder composition onto the outside of the door is carried out only in workshop conditions, using a high-thermal oven for this purpose. In order for the spraying to be carried out in compliance with all necessary standards, the door blank, the surface of which is previously coated with a special powder, is placed in an oven heated to four hundred degrees Celsius.

Under the influence of such an environment, the powder melts. After maintaining a certain time interval, the door blank is removed and forcedly cooled. At the end of this procedure, the applied powder coating acquires a characteristic strength, which in its properties is higher than the strength of other coating mixtures.

Which paint to choose for a metal door: types and characteristics of paints

It is generally accepted that metal doors treated with powder using the technology described above are able to withstand the onslaught of great force, even with the use of mechanical force.

Door trim technology

The work begins with finishing the end: it is painted to match, and with double-sided upholstery it is finished with a strip of upholstery material so that it extends onto both sides. A roller is fixed around the perimeter of the door, covering the gaps between the jamb and the door, a bundle of insulation is laid in the middle of the upholstery strip and crimped in the middle.

How to sheathe the front door - stages of work:

Preliminary marking with a pencil or marker the location of upholstery nails and moldings will make installation easier.

You can change the upholstery of the front door yourself, but experienced professionals can quickly and efficiently finish the doors.

Source

Entrance door trim options

The theater begins with a coat rack, and the house begins with a door. The memory of the owner begins to take shape even on the threshold of his home. The first thing the guest's gaze lingers on is the paneling. The decor of the front door is of fundamental importance when decorating the entire room. At the same time, in addition to the aesthetic component, the cladding carries a multifunctional load. Underneath it are hidden insulating materials that protect the room from cold and noise from the street.

What materials are suitable for upholstery?

To update the door structure, spending a minimum of time and effort, you can simply paint the door in any color. Sheathing a wooden door is more labor-intensive and time-consuming.

Different materials are suitable for upholstering wooden doors with your own hands.

Instructions for finishing the front door from the inside

Finishing the entrance door opening from the inside begins immediately after installing the door block. First, the slopes are finished with plasterboard or MDF boards and the trim is installed. Then the threshold is set. Upon completion of the above work, they begin finishing the doors. Below are instructions on how to properly paint, upholster and trim doors.

Door painting

The simplest and cheapest solution for finishing doors is painting them.

Tools and materials

To carry out door painting work you will need:

- dye;

- Screwdriver Set;

- cuvette;

- paint roller (you can paint with a brush, which takes longer, but then a ditch is not needed);

- old newspapers or a piece of plastic film.

Painting instructions

Painting doors begins with removing the handle, locks and peephole - if this is not done, you will have to fiddle around for a long time to remove the paint from them. Covering the fittings with masking tape helps, but traces of paint still remain, albeit barely noticeable. Therefore, it is better to remove everything unnecessary.

Then newspapers or film are spread under the door to protect the floor from paint drips.

The surface of the door is washed, degreased, and then treated with sandpaper. This procedure is carried out with both wooden and metal doors. After the door leaf has completely dried, paint is applied in 2-3 layers. The process ends with installing the fittings in place.

Dermantine upholstery

The process of door upholstery, with instructions and several technologies, is described in detail in the article posted on our website “Do-it-yourself door upholstery with dermantine.”

Door trim

For door trim, each type of finishing material uses its own technologies. Here we will look at how to decorate the inside of the front door with your own hands using solid overlays made of natural wood, composite plastic, MDF panels, laminated chipboards, and plywood.

Tools and materials

To trim the doors you will need:

- overlay made of natural wood, MDF, chipboard or plywood;

- screwdriver with a set of bits (cross No. 7 and slotted) and drills for metal (diameter 2.8 mm, 3 mm and 10 mm);

- primer for metal;

- roulette;

- hammer;

- clamps;

- paint brush;

- acetone or white spirit;

- insulation if it is planned to carry out heat and sound insulation;

- self-tapping screws;

- sandpaper P120-P150;

- glue;

- plastic plugs.

Instructions for attaching solid door trims

The plates are attached to the surface of the doors in two ways:

- on the frame - when insulating the door leaf from the inside;

- with self-tapping screws or glue without insulation (the method is used mainly for exterior finishing).

Regardless of the method of fastening and the type of material chosen, the door leaf is prepared for installation of decorative finishing:

- handles, locks, and peepholes are removed;

- the metal is cleaned with sandpaper;

- degreased with acetone or white spirit;

- primed with primer.

The wooden door is cleaned, degreased, and then puttied - small cracks are repaired.

The step-by-step algorithm for fastening with self-tapping screws is as follows:

- Markings are made on the overlay for screws: 3 on top and bottom, 5 on the sides. In this case, it is necessary to ensure that the fasteners do not get on the fittings;

- holes are drilled in the plate with a 2.8 mm drill;

- the lining is applied to the door and secured to it with clamps;

- metal is drilled through the finished holes;

- manually, using a drill with a diameter of 10 mm, recesses for the screw heads are drilled into the plate;

- the cover is secured with hardware;

- on the reverse side, through the holes in the door, holes are cut out in the slab for locks, a handle and a peephole. To do this, you can use a large drill (under the peephole); crown or cutter for locks and handle;

- fittings are installed;

- Using a hammer, plastic plugs are driven onto the heads of the self-tapping screws.

When attaching the lining on both sides, you can use the method shown in the photo, where the screws are not visible.

Fastening with self-tapping screws for double-sided finishing with slabs.

Here, first, through holes are drilled through the entire door to attach the internal lining. The plate is attached to the surface with a self-tapping screw. In this case, it is necessary to select the length of the hardware so that it does not come out.

The outer cover will hide the caps of the fastening elements. And it itself will be fastened with self-tapping screws screwed into the vestibule, in which the heads of the hardware will be hidden by a seal.

This option allows you to use insulation that fits under the inner panel.

Instructions for finishing the door outside

The technological process of attaching the cladding from the outside is identical to the work on the inside. The only thing that needs to be taken into account here are completely different requirements for the facing material. It must withstand seasonal temperature fluctuations, be resistant to moisture and sunlight, have increased strength against mechanical stress, and at the same time be beautiful and stylish.

Leatherette upholstery

In the past, leatherette trim was considered a luxury. Now this is a more affordable decor option, and it is very popular. Its neat appearance, good heat and sound insulation properties make leatherette an excellent solution for covering a door.

Wooden

Wooden doors can be finished on both the inside and outside. There are some differences in technology.

In the case of working with wooden products from the inside, they begin by determining how the door will open - inward or outward. This determines the choice of size and location of the sealing rollers.

-yourself upholstery on the inside of

From the outside, the upholstery process looks like this:

Metal

Covering metal doors with leatherette is a more complicated matter. Most modern manufacturers supply doors that already have interior finishing. But some inexpensive models do not have such elements and require independent upholstery.

Scheme of interior decoration of a metal door:

If desired, create a pattern on the canvas using decorative elements.

Scheme metal door trim

detailed instructions

Before the procedure, carefully unscrew the door fittings. The fabric is removed from the hinges and the surface is inspected for damage. For ease of operation, we recommend laying the structure horizontally - on a table or on stools. The metal is sanded with sandpaper, degreased and primed, the wood is cleaned of dirt, and cracks are sealed with putty.

How to sheathe with clapboard

The length of the sash is measured, and the strips are prepared according to size. The ends of the material are sanded and then polished. The lining is mounted on a wooden door from the bottom edge, checking the accuracy of the location with a level. The dies are nailed down with finishing nails. Miniature fasteners hardly stand out against the background of the coating. The screws look too rough. When installing, the panels are fixed tightly, the side parts are covered with protective corners.

Due to their strength, metal doors are more difficult to sheath than wooden types. The lining elements are mounted on a frame made of slats. Pre-mark the holes. The sheathing with guides is screwed to the base using screws.

Beautiful entrance door Source smk24.ru

Installation of panels on a metal door begins from the lower end. Details of decorative finishing are carefully strung onto the frame. A layer of insulation is placed between the canvas and the lining (in the lathing slats).

After assembly is completed, the ends of the panels are leveled with fine sandpaper. The wood is coated with varnish or protective stain. Leave until completely dry, after which the fittings are mounted and hung on the hinges.

How to upholster with leatherette

The procedure is easier to carry out for a wooden door. Insulation and upholstery material are cut according to the parameters of the sash. For leatherette, leave 2 cm for allowances. The raw materials are fixed to the surface using a furniture stapler.

The upholstery is nailed to the wooden door with special decorative nails. Fasteners are selected to match the color of the fittings or coating. The fabric is laid so that there is an equal allowance on all sides. The edges are carefully folded, stretching the fabric evenly. When fixing, maintain an equal interval.

Leatherette on the door Source remprof-sp.blizko.ru

Cladding

The lining is ideal for upholstery of wood and metal products, entrance and external surfaces. The slats are easy to assemble due to the fact that they are equipped with special grooves.

Wooden

You can cover a wooden door with clapboard yourself and at a minimum cost. The technology is quite simple:

Metal

This process is more complex. Preparation is the same as in the first case. The slats are cut to the required size.

There are two ways to attach them to the door leaf:

The work is completed by sanding the ends, varnishing and then installing the necessary fittings.

Source

Materials for external door trim

Not every finishing material can be perfectly used to sheathe a door from the outside. This is explained quite simply - constant contact with the external environment, as a result of which the completed cladding will be subject to constant action of various natural causes, starting with temperature changes and ending with ultraviolet radiation from the sun and precipitation. This is precisely why various leatherettes, leatherette and other similar finishing materials are very rarely used for similar purposes, because they simply do not have sufficient strength for long-term use under similar conditions.

As a result, the outer door trim is often made from the following materials:

- MDF overlays made of panels with a special water-resistant and durable coating. This material has long been very popular because it allows you to get a fashionably designed product that can last a long time. The fundamental advantage of MDF panels is the ability to use them on your own;

- Lining, laminate and solid wood. All of the materials listed are made from wood. Therefore, their use in order to sheathe the outside door of a house from the street can be effective in the development of additional protection with the use of special impregnations, varnishes or other decorative compounds. If these works are carried out correctly, it is completely possible to create a decent and precious design for the external entrance door, capable of decorating the facade of virtually any building;

- Vinorite polymer film. This material appeared relatively recently, but has already gained quite a popularity both among manufacturers of external iron doors and among owners of similar products. The introduction of vinorite can hardly be called a real covering, because the development of film fixation involves, rather, sticking it on. However, if the work is carried out correctly, it is possible to obtain a reliable and durable protective and decorative coating, which, according to a number of characteristics, is recognized as anti-vandal.

The choice of option for cladding a street entrance door made of alloy always remains with the owner of the home. Naturally, the final decision is influenced, as usual, by several reasons, including the cost of the material and work with it, the appearance of the cladding being created, as well as the durability and other performance properties of the decorative coating.

Sheathing methods inside and outside

Decorative cladding is most relevant for metal doors, which are often installed at the entrance to an apartment or house. Such fabrics are superior to their analogues: their protection indicators and service life are higher. However, cold metal does not always harmonize with the warm colors of the hallway. To make the door look organically in the setting, it is sheathed on the inside. Old wooden, fiberboard and chipboard canvases can also be decorated.

To improve aesthetics, doors are painted, covered with decorative films or covered with leather. The most economical and energy-consuming method seems to be cladding with linings made of plastic, wood, MDF and chipboard. The panels are easy to install, low maintenance, and durable. Many increase the protection and thermal conductivity of the door.

Covering iron entrance doors

In fact, an iron door is installed in any house or apartment. It brings a sense of security and protection of property from strangers. With the arrival of cold weather comes the problem of saving heat indoors. The question arises: How to sheathe an iron entrance door so as not to spoil the decorative design of the entire room?

Example of lined iron entrance doors

What materials can you use?

For cladding, linings made of natural or artificial materials are used - wood, plastic, MDF, chipboard and PVC plates.

Natural wood

Natural wood paneling is a premium method. Fragments or solids of hard wood are used: beech, ash, oak to decorate iron doors. The advantages of natural panels include aesthetics, but labor costs during processing and extraction explain the high cost.

Advantages of natural wood cladding:

Solid wood and fragments are easily restored. To increase moisture resistance, they are treated with protective coatings. Antiseptic impregnations provide protection against microorganisms. The natural origin of the material means the variability of its characteristics. Weight and density change due to the hygroscopicity of wood, where swelling occurs even in rooms with low humidity.

Fiberboards are produced by pressing wood chips under thermal influence. For protection they are treated with veneer, painted or laminated. Painted boards are used in interior decoration, veneered boards are used in exterior decoration. Laminated products are universal and have decent performance characteristics in the price-quality ratio.

Advantages:

A wider range of textures and colors in relation to natural wood, but less resistance to chemical treatment. Cleaning with abrasives is unacceptable. Inexpensive panels have low moisture resistance. They are not subject to fragmentary restoration after damage - dismantling is required.

Chipboard, plywood, OSB

When thermally pressing laminated boards, binder resins of non-mineral origin are used. The materials are sanded on both sides and veneered with phenol-formaldehyde glue. Marine plywood is treated with frost-resistant varnish, which makes it suitable for outdoor use. A wide classification of chipboard, OSB and plywood allows you to choose the material for any room and work.

Advantages:

The heat and sound insulation properties of chipboard are higher than those of plywood, but the material is less moisture resistant and aesthetically pleasing. OSB, while low in price and environmentally friendly, has lower decorative parameters due to the pressing of large chips. Layered slabs are vapor-tight and resistant to microorganisms.

Plastic covers

Solid composite plastic overlays are used for finishing entrance doors. Due to the absence of a decorative layer, they are resistant to atmospheric phenomena: the coating does not crack or peel.

Advantages:

Among the disadvantages is the low representation of finishing materials on the market. Homogeneous texture limits design possibilities. The products are low-strength compared to other materials.

PVC and fiberboard panels

A solid decorative fabric is formed from PVC and fiberboard panels up to 50 cm wide. Sheathing is possible only with a uniform texture, but the problem is solved by installing decorative overlays. Experts are skeptical about this method of door design, but in practice they highlight its significant advantages:

To clean, just wipe with a damp cloth. Damaged fragments can be easily replaced. The service life of fiberboard is shorter, but it is not subject to deformation. PVC panels are not resistant to shock loads.

Laminate

Floor coverings are initially prepared for high loads. Laminate finishing will not be damaged even by the claws of pets. The fragments are mounted through a tongue and groove with a longitudinal displacement.

Advantages:

Cons: high price, susceptible to moisture. Due to the narrow dimensional grid, it is difficult to calculate the amount of material needed, which leads to a large balance. For the same reason, fragments require trimming. Metal doors are sheathed after installing the gusset.

Coniferous lining

Unlike laminate, lining is more resistant to moisture, so it is suitable for interior work in rooms with high humidity. The canvas is formed from edged pine or spruce boards up to 20 mm thick. It is attached to a metal frame, so it is suitable for covering metal doors.

Advantages:

Popular materials

A huge variety of materials are used to update the front door. The choice of raw materials depends on the technology used in the design of the canvas. Let's look at the strengths and weaknesses of popular types.

Natural wood

Metal and wooden entrance doors are sheathed with natural raw materials. For decoration, both solid wood and fragments of elite species (oak, beech) are used. Natural material looks very beautiful and expensive. The service life of the canvas increases to 50 years. The wood is resistant to household chemicals and frost. Even a thin panel improves noise and heat insulation in the room.

Coniferous lining is inferior to oak and beech in decorativeness, but not in practicality. The cladding is produced in the form of thin boards. The parts are assembled like a mosaic, hiding a dilapidated metal or wooden door.

Natural wood must be protected from external influences. The material swells in humid outdoor conditions, is eaten by insects and is attacked by fungus. The coating must be treated with antiseptic impregnations or painted (varnished). Contact with sharp objects causes damage that can be repaired.

Natural wood Source zpu-tmb.ru

MDF

Composite boards are made from compressed wood chips. To prevent the material from collapsing from impact, the top is covered with a decorative protective layer. Veneer is used for the outside of the door; lamination is sufficient for the inside.

MDF is produced in the form of slats with grooves or overlays that are fixed to the canvas. The material is suitable for decorating metal and wooden doors. Visually and to the touch, the panels resemble natural wood. The doors are decorated with panels, milling and inserts.

MDF has high strength and moisture resistance. The raw material tolerates low temperatures without loss of appearance. Among the disadvantages, users note a fear of abrasives and the impossibility of restoration after damage.

Composite material Source okoshkin.dn.ua

Chipboard

Pressed boards are an inexpensive analogue of MDF. The panels are covered on top with a decorative film that imitates natural texture. For outdoor use, models treated with frost-resistant varnish are required. On average, the material will last up to 15 years.

Chipboard has very low resistance to mechanical damage. The top layer loses its attractiveness when kicked or touched by heavy objects. When washing, it is prohibited to use abrasives and aggressive household chemicals. Scratches and gouges on the surface cannot be repaired.

Raw materials for finishing entrance panels Source postroika.biz

Plastic linings

If you don’t know how to cover the outside of a street door, we recommend choosing an inexpensive composite plastic finish. Waterproof raw materials do not rot and are not afraid of temperature changes. Overlays are available in different colors and thicknesses, so your wooden or metal door will become unique. The material has clear and easy installation.

Composite decor Source open-market.com.ua

Required Tools

After selecting the material, consider the subtleties of its processing. For example, for natural wood panels you will need antiseptic impregnation, varnish or other protective coating. Necessary tools for paneling or slabs:

If products are fixed with an adhesive base, then epoxy glue or liquid nails are recommended. If you need to cut parts, you will need scissors or a hacksaw. To dismantle the fittings, you need a screwdriver and pliers.

How to sheathe an iron door

After the final choice of material for finishing the iron door leaf, you should think about how to perfectly, quickly and directly create a doorway that is heat-resistant, while at the same time the external appearance should be completely combined with the interior of the room. Sheathing the door from the inside with your own hands is not difficult, you just need to be precise in your measurements and avoid making mistakes. Not only the appearance, but also the properties will depend on the accuracy of the work.

Finishing iron sheet with clapboard

For greater convenience, covering the material should remove the door from its hinges. After that:

- You need to prepare the canvas. There should be no dust, nets, pieces of dirt or cement mortar remaining after repairs on the surface of the door.

- Next, you should treat the door with a metal corrosion inhibitor. If there are traces of rust, they need to be cleaned with sandpaper, covered with a primer, and after drying, apply paint. Only when the paint has dried can you begin the upcoming actions.

- Take measurements and find the places where the locking mechanism, peephole, and handles are located.

- A sheathing of wood slats is installed in the iron sheet around the entire perimeter of the door. For this purpose, gluers are used, fixed with screws.

- Insulation (mineral wool, penoplex) is inserted into the resulting cells.

- The lining is fixed on top of the wood slats using “watery nails” (it is better to use them). Everything should be created alternately and slowly. The material should fit very tightly to each other.

After finishing the work, the resulting surface is opened with varnish. The final step is to install the lock and hardware.

An example of covering an iron door with clapboard

Laminate cladding

Sheathing an iron door with laminate is easy. To do this you will need:

- Watery nails.

- Wood slats.

- Electronic jigsaw.

After the door is removed from its hinges and laid horizontally, the door leaf is prepared - all rusty spots are cleaned and treated, dust and debris are removed. After this, the fabric is assembled from the laminate. Using an electronic jigsaw, the blade is adjusted to the size of the door leaf where it needs to be mounted (accordingly, the iron corners of the door remain outside the finish - the panel is laid inside the corners). A frame made of wood slats is glued onto the door using watery nails (they must be treated against the action of water). A laminated panel is glued onto the frame and everything is left to dry.

The process of installing laminate on a door

Design options for laminated doors

After drying, the door is put on the hinges, holes are made for the locks, the locking device is assembled and the necessary fittings are hung. The video shows the process of covering an iron door with laminate.

Covering an iron door with leatherette

Sheathing an iron door with leatherette with your own hands is not difficult. At first, you should create the doors unsullied. After this, glue is applied. First, foam rubber is glued - like insulation; after drying, glue for the material is applied from the end along the perimeter of the door leaf. After sewing the door, everything should be left to dry. The last step will be to remove the remaining glue and hang the fittings.

The process of finishing a door with leatherette

MDF for iron door cladding

At the very beginning of the work, you should prepare the door leaf. It must be free of traces of rye, dust and debris. The alloy is covered with vinyl film on top. This is done for good adhesion of the alloy to MDF.

Example of doors covered with MDF

- MDF panels are commercially available in various sizes. In order to purchase an MDF panel, you should take measurements of your door from the inside.

- Next, you need to apply glue, for example, watery nails, to the inside of the panel.

- After this, the panel is applied to the iron base, fixed and left for a day to dry.

- Upon completion, the lock and fittings are attached.