The entrance door is an important element of the enclosing structure of a residential or office space. This product protects an apartment or private house from unauthorized entry, and also has increased heat-insulating and sound-absorbing properties. In order to choose the most suitable product that will satisfy all the requirements placed on it, the owner of a residential premises needs to understand the structure of the front door.

Rice. 1. Entrance doors to the store

The structure of the door leaf

The door leaf is the main enclosing element of filling the opening, which is manufactured in accordance with the conditions of ensuring burglary resistance, fire safety and other requirements for similar structures. All metal sheets installed in apartments have the following structure:

- A rectangular frame made of a square pipe or a U-shaped plate, the dimensions of which correspond to the linear dimensions of the canvas. This part is manufactured on a pre-prepared slipway to maintain geometry and eliminate defects during production.

- On the outside, a steel sheet with a thickness of 1.5 to 3.0 mm is welded to the frame, depending on the protection class of the product.

- On the inside, the frame is crossed by several stiffening ribs made of steel angles or profiles of a different shape, with an increased moment of inertia to ensure bending work.

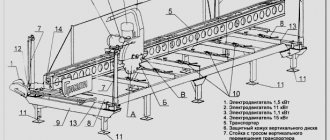

Rice. 2. Assembly in the workshop

- The inner surface of the canvas is usually arranged based on aesthetic considerations, fitting into the decoration of the premises. Thus, the most popular solution is to install an MDF panel with laminated film of different textures and shades.

- The empty space between the steel sheet and the MDF panel is filled with effective non-flammable insulation, which simultaneously plays the role of sound insulation and fire barrier.

- Considering that for increased burglary resistance, the locking device activates the crossbars along the entire perimeter of the door leaf; a traction mechanism with solid metal rods is located in the center.

- In order to make access to the room difficult, the location of the lock is reinforced with an additional steel plate on the inside of the sheet.

- The metal entrance door must also protect the room from drafts, which is why sealing tape is glued around the perimeter of its door slats.

- The canvas is attached to the box through standard hinges, but to ensure free opening of the heavy element without effort, each of them is equipped with a ball bearing that eliminates friction.

- The burglary resistance of the door leaf is guaranteed by the quality of the edging clamping strip, as well as the tightness of its fit to the frame.

- To prevent intruders from dismantling the door if the hinges are cut, the design has special pins at the points where it interfaces with the frame on the hanger side.

Rice. 3. Complete set

If all the above elements are made of high-quality steel, and the welded joints are made with control of the uniformity of the seams, such a door leaf can last for several decades.

Door frame device

The second important element of a metal entrance door is the frame, or supporting frame. This part is designed to transfer the force from the movement of the door and external forces to the load-bearing wall. The frame is made of steel profiles with rebates to tightly close the door, and its design has the following distinctive features:

- The internal dimensions of the frame correspond to the external dimensions of the canvas, and its outline in the profile has protrusions for a tight fit of the elements to each other.

- The frame consists of 4 profile linear elements - two racks, a threshold and a lintel.

- Each of the box parts is made using two rectangular profile pipes with dimensions 50 x 25 mm - 60 x 30 mm.

- The posts are connected to the cross bars using resistance spot welding, which does not contribute to metal deformation under the influence of high temperatures.

Rice. 4. Canvas frame

- To strengthen the frame, some manufacturers weld steel plates into the two upper corners, which subsequently prevent the box from losing its orthogonality.

- The stand to which the door hangers are welded may have a more rigid structure, since it is on it that a couple of forces act when opening the door. On the same element there are holes for steel pins, blocking the possibility of dismantling.

- The opposite rack is equipped with holes for the bolts of the locking mechanisms.

- A small cross-section profile, usually 16 x 10 mm, is welded along the entire perimeter of the frame to form a quarter into which the border strip rests through a layer of sealant.

- On the outside of the box, which is installed in alignment with the wall, there are steel platbands, rigidly connected to the supporting frame by welding. These elements, in addition to aesthetic considerations, have a practical function, since if you try to break in, it is almost impossible to get to the fastening elements of the box to the end of the wall.

Rice. 5. MDF panel

Fastening the door frame to the load-bearing wall can be done either through through drilling followed by the installation of exhaust wedge anchors, or through mounting plates. In the second case, steel squares with a thickness of 2 - 3 mm and dimensions of 40 x 40 mm or 50 x 50 mm with mounting holes are welded along the entire perimeter of the linear elements. The installation step of such elements along the height of the rack and lintel is 300 - 500 mm, depending on the mass of the entire structure.

Filler

“Le Grand” uses exclusively high-quality and safe materials as filler for metal structures, such as 50 mm thick mineral wool (slab) . The distinctive properties of the mineral slab are:

— Environmentally friendly structure;

— Low thermal conductivity;

— Excellent sound insulation.

Expanded polystyrene (foam) is used in the production of doors for outdoor use.

What determines the thickness of the sash?

A door leaf can have several classes of protection against penetration and burglary, which affects the number of steel elements of which it consists. Manufacturers produce three main types of sashes:

- In the standard version of the classic entrance door, the thickness of the structure, consisting of a profile frame, a steel sheet on the outside and an MDF panel on the inside, is 60 - 75 mm, which is due to the design decision of the finishing on the room side.

- This rule works if the door is installed between the apartment and the staircase-elevator hall, that is, a room with a slight temperature difference. When it comes to constructing a door bordering an outdoor space, then, in accordance with the thermal engineering calculations and determination of the heat transfer resistance of the enclosing structure, more effective insulation is placed in the body of the leaf. In this case, the frame profile is artificially increased, and the door can have a thickness of 100 to 120 mm.

Rice. 6. Door to the cottage

- When a homeowner wants to protect his premises as much as possible from unauthorized entry, the sash can consist of two metal plates - an outer and an inner one, onto which, in turn, an MDF panel is attached. The thickness of such a door can be about 80 - 90 mm.

It should be taken into account that increased burglary resistance always significantly increases the mass of the canvas, which leads to increased inertia in the event of its slamming. If an element on bearing suspensions weighs 200 kilograms or more, then the force of inertia can seriously injure a person, therefore the operation of such elements requires compliance with safety precautions.

Video description

Video on how to choose the right steel door:

Torex

Pros:

- Application of advanced technologies.

- The manufacturer is included in the rating of entrance doors in the elite segment of the market.

- Rich model range.

- High performance.

- Stylish design.

Minuses:

- High price tag.

Elbor

Advantages:

- The company's brand is the standard of quality, reliability, and prestige.

- Almost half a century on the door market.

- Maximum burglary resistance.

- High levels of noise and heat insulation.

- Stylish design.

Flaws:

- High price.

- Pre-order required.

Note! If we consider various sources, today’s rating of steel doors includes quite a lot of manufacturers. However, not all of them are trustworthy. Therefore, the installer company is primarily responsible for operation, warranty and service obligations.

Why are stiffeners needed?

If there is an attempt to break into the door, but the lock or hinges do not budge. Attackers may resort to brute force and try to deform the canvas with strong blows with a sledgehammer. In order to withstand such influences, developers introduce stiffening ribs into the design of the canvas, which have the following design features:

- Reinforcement can be made along the long side - along the height of the canvas - profiles are welded from the bottom to the top of the frame in the amount of 1 - 2 elements.

- The transverse arrangement of the ribs is in increments of 400 - 500 mm along the width of the sash, fastening is carried out to both frame posts.

- The most effective is the mutually perpendicular arrangement of the stiffening ribs, when they are fixed both in the longitudinal and transverse directions.

Rice. 7. Stiffening ribs

Each new model released into production must undergo bench tests, on the basis of which the product receives a certificate of compliance with a certain protection class, and the presence of stiffeners allows the consumer to be confident in increased strength characteristics.

Necessary materials, tools

The most expensive thing you will need is metal. All other components and materials will not be too expensive, of course, excluding decorative finishes. If you roughly estimate the amount for all expenses, then you will need no more than 100-150 dollars. At this price it is impossible to purchase even dubious Chinese products.

As for the materials needed for work, there are few of them. You need to purchase a profile pipe - suitable with a cross section of 20x40 mm. The pipe should be purchased in quantities of 20 linear meters - this volume is quite enough to produce a block of standard sizes (about 1 m wide and 2 m long). It is not difficult to calculate the amount of material for other dimensions. In case of any incomprehensible situations, it is worth looking at the sketch - today you can find a lot of drawings of metal doors and use them for assembly.

Sheet metal is also required. Its thickness must be at least 2.5 mm. The overall dimensions are the size of the future door, or rather the opening.

You should also prepare the hinges; you should choose models that are equipped with a bearing. These components are purchased in quantities of three. The canvas will be quite heavy, so three loops are the most reliable option.

In addition, additional fittings, thermal insulation, and materials for decorative finishing are required. Don’t forget about consumables – these are circles for power tools, welding electrodes, drills, consumables for jigsaws.

The tools you should prepare are a welding machine, a welding table, a grinder, an electric drill, and a jigsaw.

Features of fabric insulation

Considering that, in accordance with the thermal engineering calculations, the entrance doors are part of the enclosing structures, insulation is placed in the body of the door leaf, which prevents the penetration of cold into the room and eliminates heat loss. The thermal insulation of the canvas is a non-flammable material, and it is fixed in the sash according to the following algorithm:

- Before closing the cavity in the sash with an MDF panel, the space is filled with soft mineral wool, taking into account the corners and metal elements inside the frame. This material is characterized by high porosity, low volumetric weight, non-flammability, the ability to absorb vibrations and thermal properties.

- After the door leaf is completely filled with insulation from the inside, it is necessary to organize wind protection and noise absorption in the vestibules, and this problem is easily solved with the help of silicone, rubber or felt tape. Depending on the complexity of the cross-section of the rebate, the manufacturer can arrange from one to 3 sealing contours around the perimeter of the door.

The last stage of insulation is finishing the slopes from the inside. The fact is that, despite the presence of foam in the installation gaps, the perimeter of the door is a cold bridge, and it can be avoided by insulating the space between the decorative part of the slope and the wall.

Rice. 8. Thermal insulation inside the sash

All 3 levels of insulation made from high-quality materials will help to extinguish not only extraneous sounds or prevent the penetration of cold, but also completely cut off any odors from the outside of the room.

Features of installing door locks

Locking mechanisms are an important component of every external door, since the security of the apartment depends on their level of complexity. Most often, breaking into metal doors is done not by brute force, but by selecting a master key to the lock cylinder, and intruders freely enter the apartment by simply opening the door. To select the right lock, the owner of the premises must follow some rules:

- The quality and cost of the locking equipment should be on par with the door itself. So, if a sash with increased burglary resistance is equipped with a cheap and simple lock without any security levels, then this particular device will become the weak link in the entire structure.

- The level of safety for residents in the house increases with the presence of an internal rotary latch, since such a mechanism does not have a through drive, and it is almost impossible to open it from the outside.

- Many vigilant householders often install 2 or even 3 locks along the height of the door leaf, as this greatly increases the chances of saving property in the room in the event of a break-in attempt. There are also interconnected mechanisms on the market, when one of them locks the door around the perimeter with steel crossbars, and the second key blocks access to the first well.

- Professionals in the field of law enforcement give ordinary people recommendations on installing different types of locks on the same blade, whose cylinders differ in the type of key used. This is due to the fact that if an attacker has the opportunity to pick up the key to the lock, then a second locking mechanism of a similar design will seem even easier for him to break into. If the same blade is equipped with both rotary and lever mechanisms, then unauthorized entry in a short time is almost impossible.

Rice. 9. High-tech lock

In general, the lock must have a unique opening system with an increased level of secrecy and a reprogrammable cylinder. The use of high-tech and expensive mechanisms will increase the homeowner’s chances of protecting his own property.

Finishing

Making a metal door with your own hands is not all. It must be formatted accordingly. With blocks installed in outbuildings it is quite simple; as a rule, they are painted. But if we are talking about a door at the entrance to a residential building (apartment), then it is advisable to decorate it. The choice of option is at the discretion of the owner, and some recommendations will help with this.

How you can finish the canvas:

- Solid materials - multi-layer plywood, fiberboard, vinyl plastic, wooden lining, laminate, MDF followed by varnish coating (colorless or with tinting components).

- Leatherette and leatherette are used to cover the sash.

- The water door to the apartment can be covered with decorative film. Since the impact of atmospheric factors is minimal, this finish will last a long time. And taking into account the low cost and simplicity of design, it is one of the best solutions.

Additional security elements installed on the front door

Different manufacturers have been competing with each other for many years, positioning their products as the most reliable on the market. Due to the fact that a change in the fundamental design of the canvas or box inevitably entails an increase in price, developers are introducing additional elements that increase the level of safety:

- Door hangers can be either hidden or open. It is believed that the hinges hidden inside the canvas and the box reduce the risk of them being cut off during a break-in. It must be said that these parts are intended solely to ensure comfort when opening, since attackers never try to cut them off, knowing that the opening filling kit is blocked by steel crossbars along the inner perimeter.

- A metal rod that prevents the door leaf from being dismantled from the hangers if they are cut. This element is tightly welded to the end of the leaf from the hinge side and, when closing the sash, fits into a hole specially prepared for it, completely blocking the door from moving.

- An optical or electronic peephole is another security element that allows the owner of the premises to see the person in front of the door from the outside. The wide viewing angle of the element does not allow an attacker to hide in the hall, and vigilant owners can protect their lives and property.

Rice. 10. Peephole in the front door

To ensure an increased level of security, some premises owners install sensors on the doors that send a signal to the private security console. This measure leads to the fact that if an attacker was able to open the door, he will inevitably break the magnetic connection between the electronic elements, automatically sending a call to the remote control.

Assembly of the structure

Essentially, it all comes down to hanging the sash, checking its position, the operation of the locks and adjustments (if necessary). All that remains is to install the handle, lock and peephole. If the door design includes crossbars and lower (upper) stops, then you need to make markings.

The sash is covered, and the places for drilling holes are marked on the jamb. After readiness, their coincidence with the fixing elements is checked. This applies to both the main canvas and the additional, small one.

The final “touch” is installing the manufactured door into the opening and lubricating all rubbing parts (which many people forget about). After this, we can state that everything is complete, the work has been completed.

For those who have skills in working with metals and want to get a high-quality iron door at low cost, making it yourself is the best option. Moreover, the drawing, diagram, and external finishing are chosen not by the manufacturer, but by the craftsman. This means that the entrance to the house will not only be reliably protected, but also designed in an original way, and the block structure will fit perfectly into the interior of a particular building.

How is the door finished on the outside?

If the inside of the door leaf is finished to match the interior of the room and harmonizes with the interior elements of filling the openings, then on the outside the finishing options are somewhat simpler. Most often, manufacturers resort to the following types of finishing of the outer part of the structure:

- Regular metal paint is the simplest and cheapest option. The high-quality composition prevents the canvas from corrosion and has a decent appearance.

- Overlay panel made of MDF or natural wood. This element is most often installed in cottages or other places where the front door leads straight outside. The finishing can be done to replicate any wood structure and in a wide variety of shades.

- Leatherette or genuine leather - used in apartments, similar to old doors. It plays the role of additional insulation due to the presence of a felt pad between the decorative material and the steel sheet.

Rice. 11. Exterior decoration

The presence of external decoration of the front door indicates the status of the owner of the apartment, but, at the same time, provides unnecessary information for attackers about his wealth, which is an increased risk.

Preparation and measurements

So, the standard size of a doorway in most apartments is 2000x800 or 2000x900 mm. If the existing opening is smaller or larger, then the canvas can be made to a special size. When taking measurements, you should make sure that it is the wall that is being measured, and not concrete or plaster.

If the height of the box is slightly more than 2000 mm, then it is necessary to provide an additional frame on top, or in the side of the opening if its width is more than 900 mm. In addition, you should remember about a gap of several tens of millimeters on each side of the box. This gap is necessary for blowing in seams.

If the opening width is more than 1500 mm, then experts recommend making a collapsible box rather than a solid one. In cottages, in addition to the door leaf, two or more modules with glass are installed in wide openings, which make the structure more reliable and durable and perform a decorative function.

Click to open in full size.

During the preparation process, it is also worth starting to develop a drawing of a metal door. If the door leaf is unique and exclusive, then the drawing is made with your own hands. If the opening is standard, and the door structure will be a standard solution, then standard drawings can be used.

conclusions

All entrance doors have almost the same internal structure, and the consumer’s choice is most often made based on considerations of aesthetics, good price and additional elements. Before purchasing a product that is intended to last for 20–30 years, you must carefully study the market of competing manufacturers and customer reviews of the products of each plant. Based on the results of this analysis, any householder can choose a high-quality door for his apartment, cottage or office that meets all the requirements for it.

Manufacturers rating

Based on price, quality, richness of assortment, exclusivity of design, practicality of design, consumer reviews and expert opinions, the modern rating of manufacturers of metal entrance doors is as follows:

Became

Pros:

- The optimal combination of price and quality.

- Big choice.

- High strength.

- Anti-burglary system.

- Constant updating of the model range.

Minuses:

- Insufficient quality of service.

Neman

Advantages:

- Only certified and patented products.

- Affordable price.

- Stylish design.

- Strict quality control.

- Using fittings from the best manufacturers.

- Alloy steel blades.

- Two castles.

Flaws:

- Inexpensive models are not very reliable.