The gas flow regulator is used to reduce the pressure of gases such as carbon dioxide, argon, helium, welding mixture, which are in the cylinder and maintain the flow rate of these gases set by the welder.

It is impossible to weld metals without a gas regulator, and the abundance of products presented can easily confuse a novice welder. In this article we will tell you in detail about each series of PTK regulators so that you can buy the product that is right for you.

You can buy a gas flow regulator with two pressure gauges (one of them is called a pressure gauge-flow meter), or with a pressure gauge and a rotameter. In some cases there may be two rotameters, but we will talk about this below. The regulators are suitable for both semi-automatic MIG and TIG welding.

general information

In general terms, a reducer is a device that reduces the pressure in a gas cylinder. It is installed directly on the cylinder and is necessary every time you use a semiautomatic welding machine, if you generally weld in a protective or inert gas environment. Often two cylinders are used, each of which must have its own reducer installed.

Each type of gas has its own reducer. For your convenience, the device is marked with a specific color, which indicates the purpose of the gearbox. If the reducer is marked in black with a yellow inscription, it means it is intended for carbon dioxide (aka CO2 reducer). If the background is blue and the inscription is black, it means for oxygen. White markings and red signature - acetylene. And black markings with blue or white inscription are intended for acetylene or argon, respectively.

Another way to recognize the reducer you need is to remember the color of the cylinder. After all, it is also marked using color. For example, a black cylinder is often used for argon, a blue cylinder for oxygen. And so on by analogy with other colors.

Color coding

Essentially, a reducer is a pressure regulator for a welding mixture. It is a mandatory part of the equipment for semi-automatic welding machines that use the principle of welding in a protected gas environment. At least two gearboxes (each connected to its own cylinder) are used in a gas welding and cutting installation.

Of course, the best solution would be to choose only a reducer specifically designed for it for a cylinder with a certain gas. There is a strict color coding system:

- blue color with black inscription - oxygen;

- white with red text - acetylene;

- black with blue inscription - technical argon;

- black with white lettering - raw argon;

- black with yellow inscription - carbon dioxide (CO2).

Depending on whether you use gas welding, argon arc welding or carbon dioxide welding, choose the appropriate gearbox.

At the market or in a store, this can be easily done by color - the color of the welding gear matches the color of the cylinder for which it is intended. Blue is for oxygen, black is for argon (also suitable for carbon dioxide), and so on.

Gearbox selection

When choosing a gearbox for semi-automatic or any other welding, several parameters must be taken into account. And it’s worth starting with the working conditions. What exactly are you going to cook? And how often?

For home welders who use gas for rare work and short-term welding, any reducer that has the same thread as the cylinder can be suitable. Technical characteristics and cost are no longer important here.

If you perform simple welding work (assembling a barbecue or minor repairs), then a regular carbon dioxide reducer will do the job, even if it is installed on an oxygen cylinder. But keep in mind that this is a one-time solution and after welding you will have to throw away the device.

Speaking about models, we note the extremely popular and well-proven gearbox UR 6-6. It is designed for welding with carbon dioxide. It is inexpensive and has two full-fledged pressure gauges on board. One pressure gauge is designed to monitor pressure readings, and the second is designed to show gas flow. The AR-40-2 model is well suited for argon. This is a simple domestic gearbox. It works properly and does the job well.

Professionals assure that an argon reducer can be used with an oxygen cylinder, and vice versa. If you do home welding, you can check this statement. But our experience has shown that when using an oxygen reducer with an argon cylinder, the pressure can drop to a critical point. So use the devices as intended.

If you need a universal reducer for several types of gas, then take a closer look at the AR-40/U-30 model. It is designed for argon and carbon dioxide. Withstands temperature and pressure changes without problems.

These are relatively budget models. If finances allow, then pay attention to models not with pressure gauges, but with a rotameter. This device very accurately shows gas consumption without delays and with minimal errors. But this is a choice for a professional.

How to set gas flow correctly?

You need to understand the basic connection diagram. Conventionally, it can be divided into two parts. The first link connects the rotameter and the welding machine with a hose, the second link of the chain connects the welding machine and the TIG/MIG welding torch. By opening the gas flow valve, the first link is first filled - from the rotameter to the apparatus, gas fills the gas hose and rests against the electromagnetic gas valve in the welding machine, and by pressing the button on the torch, gas begins to flow from the apparatus and exit the torch. To accurately adjust the gas supply, we recommend doing this while you press the gas button on the burner, then the entire supply system will be completely filled and there will be no resistance.

Question 1. Welded joints (types, definition, advantages, disadvantages, application).

A welded joint is a permanent connection of several parts made by welding.

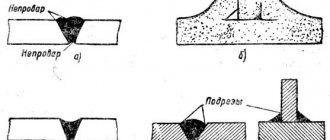

When welding, there are four types of joints: butt, corner, T, and overlap.

The butt connection has a number of advantages:

unlimited thickness of welded elements;

uniform stress distribution during force transmission;

minimal metal consumption to form a welded joint;

ease of seam quality control. Flaws

butt joint: the need for more precise assembly of elements for welding. .

Corner and T-joints are used when welding beams and trusses, increasing the rigidity of the structure. They can be either unilateral or bilateral. Corner and T-joints on both sides have high strength under static loads.

Lap joint has advantages

before other connections:

no bevel of edges for welding

ease of assembly of the connection (possibility of adjusting dimensions due to the amount of overlap).

increased consumption of base metal for overlap in the connection. Lap joints are used for metal with a thickness of no more than 6 mm. The amount of overlap (overlap) must be at least 3 times the thickness of the thinnest element being welded. When welding, the thickness of the lap joint should not exceed 12 mm;

Types and markings

For semi-automatic welding, a gearbox with a different number of chambers can be used. In the vast majority of cases, single-chamber modifications are used. But in some cases, the stability of equipment use at low temperatures is critical. In such a situation, two-chamber models are the most attractive. The compartments are usually arranged in a sequential pattern.

In any case, the gearbox must meet the following standards:

Carbon dioxide welding gearboxes are also distinguished according to the conditions of use. Ramp models are used in multi-station welding areas. Network devices receive gas flow from a stationary main, which communicates with a carbon dioxide industrial station. At small work sites, on construction sites and in everyday life, balloon gear units are used. They are mainly designed for a slightly lower specific consumption of CO2 and a small spread of gas pressure.

Opening and sealing of the intake valve assembly can occur using a direct or reverse method. The second variety has just been described above. In the “direct scenario,” the work steps change order. This solution is much less convenient. It is therefore used much less frequently.

The oxygen reducer is designed in almost the same way as its carbon dioxide analogue. The difference concerns mainly the methods of connection to the valves and the number of pressure gauges used (1 or 2). Oxygen reducers must meet increased performance requirements. The reason is simple: oxygen cannot be in a liquefied state, and therefore the pressure inside the cylinder sometimes reaches 200 atmospheres. For comparison: for carbon dioxide this figure is 70-80 atmospheres.

If you try to direct oxygen into the carbon dioxide reducer, the sealing membranes will gradually collapse. But the opposite replacement (injecting carbon dioxide through an oxygen reducer) is quite acceptable. You just need to understand that the oxygen reducer unit is connected to the cylinder via a clamp. Carbon dioxide, which is safe in terms of explosions and fires, is supplied when connected with a folding nut.

If the purity of the incoming substance is critical, special filters are needed.

Russian industry supplies various models of gearboxes. Level 6-6 is popular. The body is formed from a special alloy that perfectly withstands thermal and mechanical influences. Other parameters:

- gas pressure heterogeneity maximum 0.3;

- the safety block is triggered at 1200 kPa;

- thanks to two manometric units it is easier to influence the carbon dioxide pressure;

- maximum gas flow - 6 m3 per hour.

If the usual functionality is not enough, it is necessary to use not simple gearboxes, but control devices with rotameters . They show gas consumption immediately. The cost of such devices, however, is noticeably higher. The hole inside the throttle is carefully calibrated.

Sometimes the gas flow is heated by an electrical module.

Buy gearboxes for gas welding and cutting in Ukraine inexpensively with delivery

Online store TD Ukrservice offers a wide range of Binzel

,

Fronius

,

Donmet

at prices and with a guarantee from the manufacturer. To make your purchase not only profitable, but also convenient and fast, we have developed a system of filters that will allow you to select the optimal model in a matter of seconds. If you have any questions, you can always contact the company’s managers. They will be happy to provide all the necessary consultations and offer the most optimal device option.

TD Ukrservice always means high-quality and original products, competitive prices and timely delivery to any corner of our country.

Basic operating principles.

These devices have their own principles of operation, which are determined by their characteristics. For example, gearboxes based on direct action have a special operating characteristic - as the pressure in the supply cylinder decreases, the outlet pressure gradually increases. Gearboxes differ in their design, operating principle, and the main parts are usually almost the same for all gearboxes.

Today, both double-chamber and single-chamber gearboxes are used. The gas pressure in these types of reducers is reduced gradually, sequentially immediately in the chambers to carry out the pressure reduction process. The advantages of this type of gearbox are that they provide much more constant pressure, which is necessary for the operation of the equipment, are resistant to freezing and can work even in the most difficult conditions. But their disadvantage is the greater complexity of the design. For this reason, these types of reducers are used only when gas pressure must be maintained with the highest precision during welding.

Content:

When welding and cutting metals, constant pressure is required; the gas pressure during operation must be much less than the existing gas pressure in the pipeline and gas pipeline. In order to reduce the gas pressure from a cylinder or gas pipeline, welding reducers are used. A reducer is a special device that reduces gas pressure. Gas is taken from the cylinder and its constant pressure is created, which is very important in the welding process. Regardless of changes in pressure in the cylinder or in the gas pipeline itself, the pressure of the gas supplied through the reducer will always be the same.

Gearboxes are divided into several categories; for this purpose, a special GOST dated 1989 was developed. Today gearboxes are divided according to the principle of their operation. Gearboxes are divided into direct and reverse acting devices. The second category of dividing gearboxes: according to their purpose and installation location. So, they are divided into ramp, balloon and network.

One of the divisions of reducers: according to reducing gas. Its type depends on the gas on which the reducer operates.

Gearboxes are also divided according to the number of pressure reduction stages, as well as the available methods for setting the operating pressure. Thus, gearboxes can be single-stage, the pressure in them is set using a spring method, two-stage with the same method of setting the pressure, and also single-stage, in which a pneumatic pressure sensor is installed.

Is interchangeability possible?

Some types of welding gears are interchangeable, but not all. So, instead of a specialized CO2 reducer for welding, it is permissible to use an oxygen one, but a reverse replacement is absolutely forbidden.

Oxygen is a chemically active substance, a strong oxidizing agent, so special metals and alloys are used to work with them. In addition, oxygen is pumped into gas cylinders under pressure that exceeds the same parameter for carbon dioxide by more than 2 times.

A welding reducer for carbon dioxide screwed onto an oxygen cylinder can last, depending on its quality, from several hours to a couple of weeks. But the sealing membranes, the main structural element, will inevitably be completely destroyed, as a result of which the device will begin to etch.

To avoid erroneous actions by the welder, different threads are made on gearboxes for flammable and non-flammable gases. For flammable - left, for non-flammable, respectively, right.

Similar threads are found in cylinders for cutting and welding. In this case, the oxygen reducer has a right-hand thread. Oxygen does not burn on its own, but supports combustion. It is explosive under certain conditions.