The best brands

For domestic needs, compositions with an upper temperature limit above +120° C are rarely used, this is due to the characteristics of the product’s operation.

Heat-resistant adhesives are used in the automotive and aviation industries, where special requirements are placed on gluing technology and the product itself. Popular adhesives used at home are presented below.

Superglue "" allows you to glue metal to various materials. The composition contains hardeners and epoxy resins. The product is resistant to low negative temperatures, oily substances, and solvents. Adhesive joints do not spread or decrease in volume during curing.

Refers to semi-professional and household products, it is a paste that can qualitatively combine ceramics, plastic and various metals. After final hardening, a very hard and at the same time fragile seam is formed; for this reason, the glue is recommended to be used only for products that will not be subject to change in shape during use. Primary hardening occurs at room temperature within 2 hours, final hardening occurs at a temperature of +80° C for one hour. Klen-812 should not come into contact with open fire. The product is packaged in 250 g containers, the price of one container is approximately 1,650 rubles.

VK-20

is polyurethane, thanks to the catalysts contained in the composition, it is resistant to short-term heating up to +1000 ° C. The adhesive is easy to use, the surfaces are joined within five days at room temperature. If it is necessary to speed up the process, you need to heat the product to +80° C. The glue has excellent adhesive properties, is waterproof, two-component (after combining the components, the product is suitable for use for seven hours).

It is made from special resins, methenamine, quinoline and organic solvents. The formed seam can withstand heating up to +200° C for eight days, +300° C for a maximum of five hours.

How to use:

- Apply a layer of BC-10T to the surface and leave for 60 minutes to remove the solvent;

- connect the surfaces and place under a press (pressure should be 5 kgf/m2);

- place the product in a heating cabinet for 2 hours at a temperature of +180° C;

- remove and let the structure cool at room temperature.

The product can be fully used after 12 hours. VS-10T is sold in containers of 300 g, the price of one is approximately 1950 rubles.

K-300-61

refers to special products, three-component, consists of an amine hardener, filler and epoxy-silicon resin. Consumption is approximately 200-300 g/m2. It is difficult to find on sale; it is sold wholesale in 1.7 liter metal containers.

The main criterion when choosing a composition is its adhesive characteristics; the porosity and roughness of the parts, the area to be bonded, as well as the conditions in which the product will be used are also assessed.

How to work with adhesive correctly

Connecting aluminum parts using an adhesive composition at home is much simpler and therefore more often used compared to welding. In order to properly glue metal surfaces, you will need sandpaper, a special compound and a degreaser (usually acetone is used for these purposes).

Epoxy metal Moment

Advice! Carry out all work in a well-ventilated room, wearing gloves and a respirator. Adhesives often contain components that can cause serious irritation of the mucous membranes of the respiratory system and eyes.

Before sanding surfaces with sandpaper, remove dirt, dust and grease stains using a brush or stiff-bristled brush.

Instructions for gluing surfaces:

- Free the joined areas from rust and dirt using sandpaper (preferably a fine-grained version).

- Remove grease by wiping the surface with acetone: oiling under the adhesive layer reduces adhesion by approximately 20%.

- Wait for the area to dry.

- Combine the adhesive with the hardener in a container specially designed for this purpose.

- Stir the resulting mass until it becomes absolutely uniform in color and viscosity. The finished mixture must be used within 10-60 minutes. The specific time is indicated by the manufacturer on the packaging.

- Apply glue to both surfaces in dots or in a thin strip and connect them, pressing them tightly against each other. You should not press the surfaces too hard, as this will lead to squeezing out the adhesive mass.

- Remove excess mixture with a dry rag. It is allowed to moisten it in water or solvent.

- Fix the position until the composition has completely hardened (about 15 minutes).

- Depending on the brand of glue and the ambient temperature, final hardening occurs after 2-24 hours.

Advice! Different brands take different times to set, ranging from five minutes to one hour. It is for this period of time that the product must be left alone and not touched.

When choosing an adhesive, you should pay attention to the following characteristics indicated on the packaging:

- heat resistance;

- resistance to moisture;

- curing time.

WURTH Liquid Metal

How to use it correctly

It’s not enough to just buy the first glue you come across and spread it on the two halves of the parts. A structure glued together in this way will serve you for an extremely short period of time. To glue things securely and without problems, remember the following rules:

- Do not forget to pre-prepare the surfaces to be glued by cleaning them from dirt and grease.

- Treat the surface to be glued carefully, applying the substance evenly over the entire area. Skipped areas will reduce the adhesion strength of the parts.

- Carefully read the instructions for use from the manufacturer.

Static rigid bonding

An excellent way for quick and durable gluing of parts that are not subject to serious physical stress during operation. These include:

- home furniture;

- shop windows;

- signs;

- racks in warehouses.

Note! Dynamic objects that are subject to significant physical stress cannot be glued together tightly using this method.

Deformation

Suitable for working with dynamic objects, the load on which is an order of magnitude higher than usual. You can also glue objects that are static if they are constantly affected by large temperature changes.

Epoxy resin

Using epoxy resin allows you to achieve:

- Creating an elastic seam at the joint.

- Protection against connection destruction due to temperature fluctuations.

- Acceleration of work on restoring a part, since the epoxy resin hardens quickly.

Self-tapping screw heads

The heads are:

- Expanding, used for soft metal, as the head enters it during screwing;

- Round, the head remains on the surface (screws for wood and metal);

- The head is flat and does not have a sleeve for screwing in with a screwdriver; it is tightened with a wrench and always remains on the surface.

To better understand the rating of any screw, let's take the HM10-60 screw as an example:

- H: means the head is shaped like a hexagon;

- M: means the pitch is ISO metric type (mechanical);

- 10: means the screw diameter is 10mm;

- 60: Screw length 60mm (under head).

How to glue plastic + plastic and metal + plastic

Suitable for gluing/gluing various types of materials: metals, most types of plastics, wood, without preliminary surface treatment with primers. 3M 760 Hybrid Adhesive Sealant is a one-component, isocyanate-free sealant that forms a durable, flexible bond that is resistant to a variety of chemicals. It cures quickly under the influence of atmospheric moisture and forms a flexible and durable connection, with very good adhesion to most materials. It is used in the production of vans and special equipment (for gluing external trim to sandwich panels), in truck bodies, in shipbuilding, in air conditioning and ventilation systems, in sandwich panels and in many other areas of industry; where maximum connection strength is required.

Shore hardness is 55, film formation time is 10-30 minutes. Application temperature: from +5C to +35C Can be used both indoors and outdoors, in conditions of 100% humidity and at temperatures from -40C to +100C. Full cure 3 mm per day.

Advantages of 3M 550 PU:— One-component (Does not require mixing);— Wet paintable;— High resistance to chemicals;— Excellent resistance to UV, environmental influences;— Low content of volatile substances;— Film formation 10-30 minutes;— Moisture-curing;—Has medium ductility/elasticity (Permanent elasticity);—Bonds to dissimilar materials (Good for materials with different coefficients of thermal expansion);—Curing 3 mm per day;—Can be painted immediately after application to the surface;— Gluing, sealing, sealing joints, water protection and shock absorption;— Cartridge (295 ml), “sausage” (600 ml) - suitable for conventional squeeze applicators;— Unlike silicone adhesives and liquid nails, 3M 760 does not shrink , does not dry out and does not collapse over time; etc. Consumption: 180 g/linear m with a joint width of 5 cm and a depth of 0.3 cm

Available colors: White, grey, black

Packaging:• Cartridge 295 ml• Foil tubes (“Sausage”) 600 ml

For questions regarding the purchase of industrial adhesives - sealants, other materials, or for technical advice, please contact our specialists by phone

Useful tips

Recommendations from experts will help you choose the most suitable composition for gluing aluminum, as well as make the connection of surfaces as high-quality and reliable as possible:

- Aluminum structures can be completely glued together with a two-component composition based on epoxy resin. But if you need to join the surfaces of an alloy that contains aluminum, then it is better to prefer a product containing methyl acrylate.

- For aluminum, only a special composition containing acids and alkalis is suitable. These components ensure the splitting of the oxide film, which significantly improves the adhesion of the adhesive.

- The use of epoxy resin-based adhesives is strictly prohibited if the product will in the future be used to store drinking water or food or come into contact with them.

The means used for gluing aluminum do not provoke oxidation of the metal, unlike gas welding. As a result, the repaired product will last much longer. Another positive point is the low cost of cold welding.

Source

Adhesive for concrete

The most common building material is concrete. Adhesive compositions for it are divided into two categories:

- Adhesives that are relevant when working with similar compounds, for example, glass, metal, rubber. In this case, glue is consumed more economically than concrete mortar.

- Compositions that can connect components of various types with each other.

Most concrete adhesives contain cement as the main component. Non-cement types include epoxy adhesives, which contain a mineral filler as a base.

Main characteristics of the quality composition:

- A good mixture will not skin within 20 minutes.

- The glue does not lose its properties within 1-4 hours.

- The maximum slip threshold is half a millimeter.

Epoxy adhesive

It is used in working with metal, stone, glass and tiles. Due to its versatility, it has been in maximum demand for many decades in all repair changes. Epoxy adhesive is used for making cement screeds, restoring surfaces and in rooms with high humidity levels.

Typically, such compositions are sold in metal packaging. You need to wait several hours for hardening (depending on the specific type of glue and air temperature).

Thanks to the use of this composition, a stable type of connection is created that is not affected by oils and solvents, which guarantees high-quality work with wood, metal and concrete.

At work and at home, situations arise when you need to glue two metal surfaces together. Welding, traditionally used to weld one metal part to another, and the high-precision work of machine operators have been replaced by new methods. When choosing how and what to glue metal to metal with, Loctite adhesive comes into focus. Due to its quick fixation, reliable connection of parts, and convenient application, the adhesive is in demand in workshops for repairing household appliances and vehicles. The glue is also used at home.

In Loctite products, rapid polymerization and adhesion strength are combined with other properties that are important for the operation of the glued part.

For difficult-to-glue materials, such as metal, its combination with plastic is used to connect plastic and elastomer. Low viscosity adhesive is applied in a thin layer, up to 0.25 mm. Strong adhesion is ensured by tightly connecting the parts. The glue is effective when gluing small parts - it sets in 2 to 10 seconds, withstands high temperatures (+120 °C) and low temperatures (-40 °C).

Medium-viscosity adhesive is designed to connect the surfaces of metals, plastics, and rubbers in different combinations. Loctite is applied to the metal surface after degreasing. Setting time from 30 seconds to 1 minute for mild steel, 40 – 80 seconds for aluminum, from 30 seconds to 1.5 minutes for zinc dichromate allows you to glue complex and large parts together. The manufacturer does not recommend using the composition in an environment rich in oxygen and other oxidizing agents.

You can glue different metals with a high adhesive agent. The resulting high-strength connection allows the use of abrasive processing of the resulting part.

Characteristics and properties of the material

The technical properties of metal adhesive directly depend on the manufacturer. When choosing a fixing composition, you must consider the following features:

- Drying conditions and time. Much depends on the specifics of the work and the place where the connection is made.

- The temperature at which the glue retains its properties. It is necessary to purchase a composition that can withstand further load, assembly, and processing.

- Surface application method and fixation technology. Some types of adhesives are designed for spot or full coverage of joints.

- Consistency (liquid, elastic) and packaging shape.

Another important nuance is the material with which the connection is provided. It is advisable to prefer a narrowly targeted type to universal adhesive, for example, intended for attaching plastic to metal, metal to glass.

Requirements for glue for metal

High-quality adhesive protects the surfaces to be joined from corrosion.

After application, a high-quality adhesive composition must meet the following requirements:

- reliable, durable connection;

- long-term retention of fixation;

- resistance to moisture, frost, heat;

- minimal shrinkage after drying;

- environmental friendliness and a minimum of toxic odors.

A good adhesive for metal products protects the coated surface from corrosion while maintaining chemical neutrality. To reduce adhesive shrinkage, alcohol, ethyl acetate with gasoline or acetone are added to the mixture.

Application area

These types of glue are used in many areas, ranging from industrial needs to household repairs. Most often this is construction, plumbing and car repairs, installation of floors, pipes, large and small products.

Static rigid bonding of metals

Adhesives for static bonding have high Shore hardness plus high mechanical strength. Glued structures are monolithic and have enormous resistance to surface shear. Static structural bonding of metals is applicable in those structures where dynamically changing loads do not occur:

How to remove glue from metal?

- The first type of the most effective means for cleaning metal from old glue is considered “Super Moment Anti-Glue”. It will help you completely get rid of universal PVA glue, instant glue and various polyurethane-based adhesives. The gel base allows it to be used even on a vertical surface.

- The second option is to use the pharmaceutical product "Dimexide". It is necessary to thoroughly moisten a cotton wool or cloth in this composition and treat the surface until the adhesive stain completely disappears.

- Not least in removing glue are such common products as: “White Spirit”, acetone, the cleaning component “Contact” and, of course, gasoline.

- Manicure and pedicure professionals use emulsions to soften acrylic. They will effectively help dissolve super glue from the metal surface.

Brushes for electric motor

Brushes, which are made of graphite, although they have a small format, are one of the most significant parts for power tools. Their main task is to supply and remove current to the slip rings and the rotating commutator. Carbon brushes are used to make electrical contact between nodes. As a result, these brushes reduce the wear of power tools, since in case of malfunction they can be easily replaced with new ones. The main task of these brushes for an electric motor is the uninterrupted performance of the assigned tasks.

Brushes for electric motors are made using various methods from coal and graphite, to which copper impurities are added. With the help of modern manufacturing technologies, carbon brushes for electric motors of various equipment last as long as possible, while maintaining their power. In addition, brushes for power tools are convenient and easy to use.

How to glue metal to metal

There are several types of glue that are most often used when gluing metal surfaces to each other:

Bonding metal to metal

- Epoxy adhesive. This type has the highest water resistance. Consists of two types of epoxy resins that are mixed with each other;

- Super glue Moment for metal “Moment Super Epoxy Metal” - applied in a thin layer, tightly glues metal surfaces;

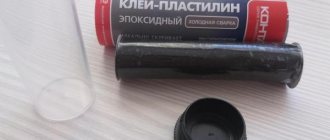

- Cold welding, consisting of two tubes with substances for various purposes - one with an active adhesive agent, the other with a special substance for hardening;

- Double-sided tape - glues metal to metal and other surfaces.

Regardless of the type of glue used, the actions during preparation and directly gluing metal surfaces, you need to do the following:

- Clean and degrease the surfaces; if there is a need to get rid of traces of corrosion, pre-sand the surface;

- Study the instructions for the glue if available; if cold welding of two substances is used, it is necessary, without deviating from the recommendations of the instructions, to mix them;

- Apply a thin layer of glue to both surfaces so that when the surfaces are compressed, the remaining glue does not come out;

- Squeeze the surfaces with force and wait until the glue sets. The time, as a rule, indicated in the instructions for using the glue, ranges from 5 seconds to a minute. You can place something heavy on the surface if their dimensions allow this, or use special clamps or a vice;

- If there is a glue seam left that may interfere with further use, you can carefully sand it with sandpaper;

- For small products, you can use double-sided tape in cases where the surfaces will not be subject to intense mechanical use. To do this, glue a strip of tape onto one surface with the sticky side, then remove the protective film and place the second surface on the adhesive base that appears and press. In this case, there is no need to wait for it to harden; you can immediately start using the glued object.

Preparing surfaces for gluing

An important step that affects the reliability and durability of the connection is the preparation of the surfaces to be joined before gluing them. The adhesive composition cannot adhere properly to a dirty or rusty surface, so you should first go over the joint with 120-240 grit sandpaper. If there is any hard coating such as paint, varnish or other, it must also be removed. Sandpaper will leave small risks, you should not be afraid of them. They are needed for good adhesion of glue and metal. After mechanical treatment, the parts are thoroughly degreased with solvent or acetone.

You can use any solvent, since it cannot damage metal parts. However, do not use gasoline or any paint thinners.

They leave a thin layer of additives on the metal surface, which will prevent the metal from bonding firmly. After degreasing, and waiting for the surface to dry, you can begin the gluing operation. Depending on the type of seam, a distinction is made between static and deformation bonding.

Degreasing metal surfaces

How to tightly glue plastic

This method will help even if the glue needs to be removed from your hands.

There are many different companies that produce a similar product - among them the most popular are Anti-Glue Moment, Anti-Glue Second

As you can see, gluing metal to various surfaces is not so difficult - even in the hardware departments of supermarkets you can find almost any type of glue. The instructions are simple, even a person far from construction and repair can follow them; you just need to strictly follow all the tips recommended by the manufacturer.

What glue to use to glue plastic to: plastic, metal, chipboard, tile, concrete

The modern world is unthinkable without plastic products; the lightweight material is used everywhere: construction, decorations, furniture, dishes, decorative elements, household appliances. Polymer products do not rust, are beautiful, but not always durable. Therefore, breakage of plastic items occurs frequently; every time something is dropped, the problem arises of how to restore the broken product.

Don’t be upset - there are no eternal objects, and you shouldn’t throw away a broken thing. Today there are no problems in repairing any material, even polymer. You just need to think about how to glue your favorite thing together.

Cold welding for stainless steel

In recent years, a glue called cold welding has become very popular. It is actively used for connecting metal parts, and in addition to metal, it can firmly connect wood, rubber, plastic, glass, etc. A distinctive feature of cold welding is that it can glue not only homogeneous objects, but also dissimilar ones. This glue can easily connect both rubber and metal and plastic and glass. Cold welding is a universal adhesive. It is capable of creating a strong connection, so strong that the repaired product can function in exactly the same way as it functioned before the breakdown.

For stainless steel, incremental welding provides a stronger connection. However, if the connection does not require high strength characteristics and it will not bear high loads, it can be glued without problems using cold welding. Cold welding adhesive is many times superior to almost all other adhesives.

Cold welding has gained enormous popularity due to the fact that to use it it is not necessary to have any narrow range of knowledge, and it does not require tools. For example, to repair a small car part, you can use several methods. However, cold welding will not require dismantling the part. Using cold welding, you significantly save your time, because preparing the composition for use does not take more than five minutes, and the initial drying time is only a few hours. The main requirement that must be observed is not to use the product until the compound is completely dry.

The plasticity of the glue allows you to replace lost parts. Using a softened plastic substance like plasticine, you can mold the necessary part and replace it. Since cold welding contains a metal filler, the strength of the new molded part will not be inferior to the original one. Therefore, cold welding, in addition to universal, can be specialized, for example, for stainless steel and galvanization, for aluminum, cast iron, etc.

Types of glue for metal products

Of the many types of glue designed to glue metal to metal, several groups can be distinguished:

- Double-sided tape. It is produced in the form of a synthetic tape of various thicknesses with an adhesive composition applied to both sides. The width of the tape is selected based on the desired width of the adhesive joint. It has a high degree of convenience for gluing metal parts. The thickness of the tape allows you to obtain a sealed glued seam in the event of a loose fitting of the parts. The disadvantages of double-sided tape include the low strength of the glued seam and low durability.

- One-component mixtures. Presented in the form of a variety of adhesives based on rubber or silicone. The composition that makes it possible to glue parts together polymerizes in air or under the influence of moisture in the air. The hardened composition resembles dense rubber. The most versatile in use, they allow you to glue not only metal, but also products made from other materials. Among the disadvantages, it is worth noting the low strength of the adhesive seam and the need for careful preparation of the surfaces to be bonded.

- Two-component adhesive. Polyurethane or epoxy resin is used as a base. Special hardeners are used for polymerization. They can be either liquid (for example, “moment” glue) or in the form of a paste (cold welding). It has excellent adhesive properties, the seam is strong and durable. Allows you to connect workpieces made of different materials. Two-component compounds form the strongest and most durable seam, which sets much faster than a one-component one.

How to properly connect metal surfaces

Before you begin gluing, you need to properly prepare the surfaces, remove signs of corrosion and traces of contamination from the parts. Do not use solvents or gasoline, so as not to leave an unnecessary layer of additives.

Then you should thoroughly mix the cold welding components. Next, the finished mixture must be applied to the surfaces that need to be glued. The next step is to press the metal parts together or put them under a press.

Treating surfaces with a special primer, which will first degrease them and improve adhesion, will help improve the quality of gluing.

Static rigid bonding of metals

Applicable in structures that are not subject to dynamic deformation. The mixtures used for such gluing form a very hard and durable seam that can withstand heavy loads. In fact, two parts after such gluing form a monolithic structure that is very resistant to shear rupture. In this case, glue such as PURAFLEX 9155 or Maple-812 is used.

The disadvantage of a rigid connection of parts is the fragility of the seam, therefore those structures that are subject to deformation require deformation gluing and the choice of a different adhesive.

Rigid bonding is most widely used in construction and machine tool production.

Preparing surfaces for gluing

Deformation bonding of metals

Expansion joints are used if the structure to be glued experiences various types of deformation or vibration. The gluing is quite plastic and can stretch a little. The compositions used for such gluing are most often based on polyurethanes or epoxy resins with plasticizers. We can recommend gluing agents such as PURAFLEX 9140 or VK-20. They are indispensable when assembling structures subject to vibrations. Most often they are used in the assembly of doors, cabins, and elevators.

Epoxy resin

The basis of most compounds capable of gluing various parts is epoxy resin. It has high adhesion to almost any material, such as metal, plastic, glass, ceramics. Under the influence of hardeners, the epoxy resin polymerizes and becomes hard. When brought to a solid state using the correct technology, epoxy resin without fillers is absolutely harmless to organisms. However, its use in industrial settings is limited due to the fact that when rejected, some part remains in its original form.

Uncured epoxy resin is a strong poison and can cause irreparable harm to the body.

Depending on the amount of filler and plasticizer, epoxy resin can be used to glue metal together to create either a static rigid seam or an elastic deformation one.

Epoxy resin

Improved bonding quality

As mentioned earlier, the preliminary preparation of surfaces has a great influence on how the composition will glue the metal. Using sandpaper, the surface must be thoroughly cleaned of rust and other solid contaminants. The cleaning process also requires removing paint, old glue, and other layers covering the bare metal surface. It is best to use 120–240 sandpaper grit; it will create the necessary scratches on which the glue will cling more strongly. After mechanical cleaning of the surface, it is thoroughly degreased using solvent or acetone. It is not recommended to use gasoline, kerosene or other paint thinners; they leave a thin layer of foreign material on the surface of the workpieces being glued, which will prevent them from gluing well.

Additional measures that will allow metal parts to be glued together better are the use of special primers. They are applied to the surface to be glued before they are directly glued and serve to improve adhesion between the adhesive composition and the material.

Glue BF-2

For example, no matter how good the adhesion between epoxy resin and a metal surface is, BF-2 glue has the greatest adhesion to metal among the available adhesives. Therefore, this primer is widely used among yachtsmen, where it is necessary that the epoxy firmly glues two parts together and the seam is not afraid of moisture. To do this, apply a thin layer of BF-2 to the carefully prepared areas to be glued. Its layer is dried for an hour and a half at a temperature of 130 to 180 degrees. The main thing is that the glue layer dries and does not burn or overheat. Next, you can glue it with epoxy resin according to the instructions; the glued seam with this connection will be much stronger than without the use of BF-2.

Bonding materials with different linear expansion coefficients

Different coefficients of linear expansion of materials lead to the fact that during heating and cooling, the adhesive joint experiences significant load deformation. It would be logical to reason that the seam itself should be quite elastic. Such materials are best glued together with a polyurethane-based mixture. In principle, no difference is visible when gluing materials with different coefficients of expansion and deformation bonding. The main difference is that in the first case the adhesive joint must withstand higher temperatures.

Glue selection

Which glue is better to use, what are the selection criteria? If you need to firmly glue metal to rubber, you should look for a product with enhanced adhesion that gives a reliable seam, while being elastic

It is also important to consider a number of factors:

- humidity and temperature in the rooms where gluing will be done and then the product will be used;

- load on the bonded surfaces;

- the need for high aesthetic properties of the finished product;

- the degree of chemical aggressiveness of the glue, taking into account the type of metal.

When purchasing, it is important to clarify in the instructions or on the packaging that the manufacturer guarantees the suitability of the composition for rubber and metals and alloys. Universal means are not always suitable for such a complex joint, as well as for joining other dissimilar materials

After drying, the seam should not peel off from the base, must be heat-resistant and not change strength when exposed to low temperatures.

For cars, it is often recommended to buy products such as “liquid rubber”. They can perfectly glue rubber surfaces, as if becoming part of them, and therefore are outwardly invisible. The water resistance of the glue is another important point when choosing; this property is required by almost every user, especially the car owner. If necessary, you can buy glue that will allow you to use the parts even under water.

When joining rubber and metal, it is important to prevent corrosion, therefore high-quality glue always has a mark on the safety of the composition. A separate type of adhesive is considered to be products for silicone rubber, which is soft and pliable.

On the tube of such glue there is an inscription “for elastic materials”.

The best brands for gluing

How to glue metal or other complex materials to rubber? For this purpose, you should purchase only proven formulations:

- 88CA. Resin glue based on organic solvents, contains phenol-formaldehyde resin, nefras, ethyl acetate. It fits perfectly both on painted materials and on concrete, glass, wood, and is suitable for dissimilar substrates. The composition is waterproof, does not peel off from moisture, and does not produce toxic fumes after drying. Does not interact with metal and therefore does not provoke corrosion.

- U425-3. The properties are similar to the product described above, since it has a similar composition. Used for gluing followed by vulcanization if required.

- 4NB-UV. The glue is oil-resistant, waterproof, but can withstand heating only up to +60 degrees, while it is frost-resistant - it is not damaged by freezing down to -40 degrees. They can be used to glue rubber, rubber-fabric materials, and metal. This composition forms a very elastic seam and has residual stickiness. It is ideal for repairing various rubber products, boats, and chemical protection suits.

- Radical. This glue can even serve in sea water; it is not destroyed by the action of salts and alkalis, which is why it is popular among fishermen (used for repairing any boats).

- The moment is rubber. Suitable for hard and foam rubber, provides high strength, resistance to water and oils, and elasticity of the adhesive seam.

Also, for complex surfaces, adhesives such as Super-NN, Rogneda, Loctite Super Fast are often used. Some users make their own rubber adhesives to save money. To do this, soft rubber is crushed and filled with aviation gasoline to completely cover the mass. After 2-3 days, the liquid is filtered. After standing in a warm place for another couple of days, the glue will be ready.

How to choose a good glue

It's no secret that the thing that works best is the one that fulfills only its purpose. The same situation applies to metal glue. Depending on what characteristics the seam must meet, you need to select an adhesive suitable for this purpose. For example, the “Maple-812” product will allow you to glue together many different materials. The seam is very strong, but hard and fragile. Because of this, it can be used for products that are not subject to subsequent deformation or vibration. BK-20, on a polyurethane basis, forms an elastic and strong adhesive joint, so it is not afraid of deformation and vibration. Below we will discuss in what cases it is better to use one or another adhesive composition.

Maple-812

Deciding on the material

It turns out that there are different types of polymer, so sometimes all our attempts to glue a polymer product together do not lead to the desired result.

It is impossible to determine the type of polymer by eye or touch, so let’s inspect our product for markings that resemble a Mobius Loop with different meanings. Types of polymer can be seen in the photo. Depending on the marking, you can choose glue today for any product. But even in the case when an advertisement invites you to purchase a universal miracle glue, you should not count on effective gluing; perhaps this is just a PR trick.

Having “recognized” the polymer material more closely, you need to select your own solvent for its type:

- Brand PA66 is glued using a solvent containing formic acid.

- The PMMA grade requires dichloroethane.

- ABS - acetone glue is suitable.

Varieties

In order to glue metal surfaces, there are several types of glue:

- Epoxy. It is available in the form of a paste or two-component liquid. It contains resin and elements that promote rapid hardening. It withstands high temperatures, moisture and is resistant to wear. It could be "Moment" or BF-2.

- Double-sided tape, which comes in various shapes and sizes. The choice of type depends on the surface area and its dimensions. Gluing occurs easily, and the resulting seam is not exposed to environmental factors. Best suited for working with sheet material.

- Cold welding (heat-resistant glue). It is a powerful adhesive that can be one- or two-component. The essence of the action is penetration deep into the bonded surfaces due to deformation of the welding mass. The material is not sensitive to high temperatures. An example is Poxipol glue.

Characteristics of popular brands

There are several adhesive compositions that allow you to qualitatively, firmly and reliably connect aluminum with aluminum or other materials:

- Mastix . The mixture is suitable not only for gluing aluminum surfaces, but also for sealing joints. And also for repairing products made of ferrous and non-ferrous metals. The composition allows high-quality gluing of parts at low ambient temperatures; its working range is from –50 to +145° C. In addition, Mastix reliably and quickly bonds wet surfaces. The average cost of a 50 g bottle is 30 rubles.

- Cosmopur 819 is a polyurethane material that allows for strong and reliable bonding of aluminum to aluminum by creating a ductile seam between the surfaces. Ideal for bridging gaps and gluing corners. Cosmopur 819 is most often used for joining structural parts. Price for 300 ml is approximately 500 rubles.

- ASTROhimACE-9305 is a cold welding that allows you to instantly eliminate various breakdowns. The glue qualitatively connects surfaces made of aluminum and its alloys at temperatures from –50 to +145° C. The composition is most often used to restore broken fragments of parts, for example, threads. One package costs on average 80 rubles.

- “Epoxy Metal Moment” is a two-component adhesive that reliably holds together not only aluminum surfaces, but also combinations of other metals with wood, marble, and glass. The composition effectively eliminates gaps and cracks. The price for a 50 ml package is approximately 350 rubles.

- Abro Steel is a universal cold welding product from the American manufacturer of the same name. It serves as the best option for repairing sanitary and household equipment and tanks for storing liquids, as it ensures perfect tightness. The composition is used to connect metal, wood, ceramics, as well as materials of different types to each other. The adhesive is highly sensitive to the cleanliness of the areas being bonded. If storage was incorrect, the composition will not be able to be used for its intended purpose. Price - approximately 150 rubles for 57 grams.

- PERMATEX Cold Weld is a two-component heat-resistant adhesive based on epoxy resin, hardens very quickly, is fireproof, and perfectly bonds various materials, including aluminum. Polymerization of the composition occurs within 15 minutes, the material can withstand prolonged heating up to +149° C, short-term heating up to +177°. The formed seam is very resistant to shear and tear loads. The cost of a 56 g package is about 300 rubles.

- “Titanium” is characterized by its low cost and resistance to any mechanical loads. A 310 ml bottle costs about 250 rubles.

- WURTH LiquidMetal is a cyanoacrylate composition from a German manufacturer. It is the best option for connecting metal surfaces of various parts. It hardens very quickly, making it ideal for quick repairs. It forms an invisible seam, which makes it possible to glue not only metal products, but also transparent materials. The price of a 20 g bottle is approximately 100 rubles.

- COSMO PU-200.280 COSMOFEN DUO is a two-component high-strength polyurethane-based adhesive that does not contain solvents. It has excellent heat resistance and can withstand environmental factors. After complete curing, the seam can be painted. Used for gluing gypsum fiber boards, wood, sanded fiberglass plastic, aluminum, laminate, as well as for restoring and filling construction joints no more than 0.8 cm wide. A 900 g bottle costs approximately 800 rubles.

How to glue plastic

The type of plastic has been determined and the required glue has been selected. How to properly glue plastic objects:

- Parts should be cleaned. If necessary, degrease the item with soap solution or ethyl alcohol. A clean surface has greater adhesion and objects will be easier to stick to.

- It doesn't hurt to lightly sand the surfaces to roughen them up. This way the glue will stick better.

- Two-component compositions are mixed only after surface preparation.

- If parts are coated with glue using a brush, then use an object with artificial bristles.

- The glue is applied in such an amount that when compressed, its excess does not protrude to the surface.

- You need to squeeze objects together firmly, but carefully.

- The duration of adhesion of materials depends on the selected adhesive.

Advice! Use a needle to glue a thin crack.

Sometimes you need to attach a variety of materials to plastic: wood, glass or metal. In this case, the glue must take into account the characteristics of the two surfaces being connected, and not just the plastic.

Glue Super moment

Tips for working with plastic:

- For external work, waterproof glue is used.

- Despite the high temperature that the glue can withstand, plastic objects themselves should not be exposed to it.

- When working with contact adhesive, it is necessary to ventilate the room.

- The best adhesive for marking 7 (O) is epoxy. This type is also suitable for polystyrene.

- If there is no marking on the product, then proceed from this: for plastic toys and artificial glass, polystyrene is used mainly; For bottles, buckets and boxes, glue designed for polypropylene and polyethylene is suitable.

Take the time to study the labeling of plastic products and glue. If repairing small toys like Lego is a simple process, then for more serious work the familiar Secunda glue may not be suitable for everyone.

Epoxy resin

Epoxy resin can also bond metal surfaces. This resin has a composition that includes two components. They are mixed into polymers. Epoxy resin has a high strength composition. Using this composition you can glue any types of metals. Moisture that gets on the epoxy resin has no effect on it. Therefore, it can be used for outdoor work. Nowadays, a large number of types of artificial resins are produced. For different types of metal, you can select different resin compositions.

Effective options

When visiting a hardware store to purchase glue for metal, your eyes literally run wide from the variety. In such a situation, it is difficult to choose the right product, which confuses most buyers. To avoid finding yourself in a similar situation, choose one of the most effective options presented below.

Epoxy

Adhesive mixtures made on the basis of resin and various fillers, among the advantages of which are:

- wear resistance;

- resistance to moisture;

- They can easily tolerate significant temperature changes.

Cold welding

The action of cold welding is based on the penetration of the adhesive mass into the material of the part, which, when solidified, creates an effect similar to a welding seam. Parts connected in this way are difficult to separate from each other, and the seam itself can withstand ultra-high temperatures.

Double-sided tape

A special tape coated with high-quality adhesive. It is used to connect both halves of metal parts and parts made of different materials. A structure fixed in this way is highly durable, and the joint successfully withstands external influences.

Anaerobic

A separate group of adhesives for metal, the work of which is based on the hardening of the adhesive only when access to oxygen is stopped. Such a connection becomes completely sealed, and its strength is not inferior to other types of adhesives.

Cyanoacrylate

Cyanoacrylate adhesive belongs to the category of universal products used for joining materials of various origins. Advantages of the mixture:

- strong seam;

- the mass hardens quickly;

- the seam remains stable over a long period of time.

Flaws:

- when the ambient temperature exceeds 100 °C, the strength of the connection is destroyed;

- not suitable for gluing parts between which there are large gaps.

Benefits of Metal Adhesive in Achieving Production Goals

At all times, different methods were used to connect two metals together. This includes riveting, welding, cold welding, and recently another method has emerged - gluing. The chemical industry has moved forward, and many components have emerged that can tightly join two pieces of metal.

This method is better than the previous ones. You can buy iron glue at any hardware store. Without much skill, connect two elements, and they will hold firmly. No welding, electricity or welding machines required. Only a small tube.

Using a welding machine you can join metal to metal, but you need a good machine and uninterrupted electricity. In addition, you need to know how to use it. You can buy glue at a hardware store, and, following safety precautions, connect the necessary elements according to the instructions. This is the advantage of this method.