The quality and productivity of processing on screw-cutting lathes depends on whether the cutting tool matches the workpiece being processed. Different types of cutters are used for turning wood, plastics, and metals. The danger of making the wrong choice is the high probability of cutter damage, lead screw deformation, and spindle breakage. Metal turning tools vary in size, shape, cutting edge hardness and other parameters. To choose the right tool and processing mode, you need to be well versed in its classification.

Cutter design

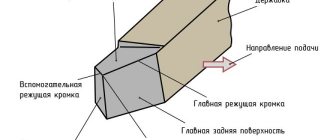

All turning tools consist of two structural elements:

- holders with a rectangular or square cross-section, which is used for fixation in the tool holder;

- head - a working part consisting of several cutting edges.

According to the shape of the holder, the cutters can be:

- straight;

- curved;

- bent;

- pulled back.

According to the method of production they are:

- Monolithic (solid).

- Napaynymi.

- With mechanical fastening of replaceable plates.

The working part is formed by several planes and cutting edges, the shape of which depends on the purpose of the tool. Most cutters are manufactured in left and right hand versions and are selected according to the feed direction.

Structure

Consists of two main components:

- Working head – sharpened at different angles.

- Holder (body) – fixed in the tool holder.

The main cutting edge does most of the work. Surfaces of the working part: front, two rear.

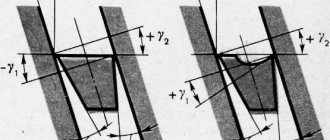

Angles

They are located in the main cutting plane, perpendicular to the main cutting edge, the main plane.

There are four main angles:

- Points.

- Cutting.

- Front.

- Main rear.

They are designated by Greek letters (alpha, beta, gamma).

Classification of incisors

We will analyze the main features by which metal turning tools for manually controlled machines, semi-automatic and CNC automatic machines are classified.

Working part material

Cutter heads for metal lathes are made from materials with high hardness and wear resistance.

Tool high-speed steels

The main alloying element in such alloys is tungsten (P9, P18). Some grades of high-speed steels also contain molybdenum (P6M5) and cobalt (P6M5K5). Monolithic cutters are mainly made from these relatively inexpensive alloys. They are used for processing workpieces made of ordinary non-hardened steels, non-ferrous materials and their alloys.

One of the significant disadvantages of high-speed steels is a decrease in hardness when heated above 200 °C. Cutters quickly lose their properties when machining at high spindle speeds and feeds, with insufficient coolant supply.

Hard alloys

The basis of all hard alloys is carbides. Cobalt is used as a binder. Due to the high price, carbide is produced primarily in the form of plates, which are soldered or mechanically secured to cutter heads. There are also monolithic carbide tools (centering tools, drills) of small size.

Hard alloys are produced by sintering and hot pressing. They have high hardness (86 – 92 HRA) and red resistance (up to 1150 °C), therefore they are used for the manufacture of parts from difficult-to-cut materials: cast iron, stainless steel, heat-resistant, titanium-containing and hardened steels. Based on their chemical composition, hard alloys are divided into the following groups:

- Tungsten-cobalt (VK3, VK6, VK8).

- Titanium tungsten cotalt (T15K6, T5K10).

- Titanium-tantalum-tungsten-cobalt (TT7K12, TT20K9).

Due to the high cost of tungsten, tungsten-free hard alloys based on titanium carbides and cyanides were created. Carbide inserts with wear-resistant coatings are produced as a separate group of materials and have the letter marking VP.

Most foreign manufacturers of hard alloys use their own markings. Most often, it does not contain information about the composition of the material and coating, since this information is considered a trade secret. Instead, manufacturers provide clear recommendations for use.

Hard alloys have a number of limitations and disadvantages in comparison with high-speed steels: they are low-tech and have low impact strength (prone to cracking upon impact). To sharpen metal turning tools with carbide tips, a specialized abrasive tool (mostly diamond) is used.

Processing quality

Some sources suggest dividing cutters into rough, semi-finish and finishing. In fact, the quality of processing (surface roughness) depends not only on the design features of the cutting tool, but also on the quality of its sharpening and the processing mode - feed per revolution and allowance. Therefore, the same cutter can be used for both roughing and finishing turning operations.

Types of incisors according to operations performed

Screw-cutting lathes are capable of performing many types of processing and can be used to produce parts of different shapes. Depending on the purpose (operation performed), cutters for them are divided into several types:

- Pass-throughs are used for processing external surfaces of cylindrical and conical shapes, forming chamfers. Feeding is performed parallel to the workpiece axis.

- Scoring machines are used for trimming parts. The cutter is fed perpendicular to the axis of the workpiece.

- Passing thrust cutters perform all of the above operations. They are widely used in the manufacture of stepped shafts.

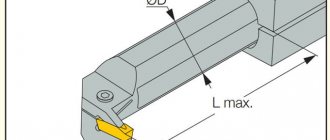

- Boring cutters are used for processing internal cylindrical and conical surfaces. One of the features of their design is a massive holder. Dimensional accuracy depends on the rigidity of this element.

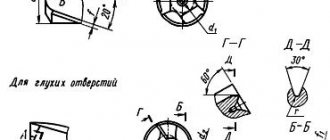

- Threaded (external and internal) cutters are used for cutting metric and pipe threads. Their sharpening angles are 60° and 55°, respectively. For persistent and trapezoidal threads, specialized shaped cutters are used.

- Cutting machines are used for cutting workpieces.

- Slotting (groove) cutters are used for turning external and internal grooves (for the exit of the grinding wheel, for installing retaining rings, etc.)

- Shaped – highly specialized tools of various shapes for creating profile surfaces.

- Cutters for contour turning. This type of tool appeared relatively recently and is used mainly on CNC machines for finishing complex surfaces. Such cutters are equipped with diamond-shaped plates, have an acute sharpening angle and are designed to work with small allowances (up to 2 mm).

Rating of the best turning tools for 2022

The product review was compiled based on customer reviews of online tool stores and the Yandex Market platform. There are three categories: according to cost - cheap, expensive, sets consisting of 6 or 12 tools.

Cheap (from 68 to 265 rubles)

5th place Boring through 25x25 VK8

Price: 265 rubles.

Manufacturer: Russian brand “INIGS”.

Type – boring through. Specifications (mm):

- holder 25*25;

- length 200;

- weight 980 g.

Alloy – VK8 (cobalt 8%, tungsten 92%). GOST standards – 18882-73.

Used when boring through holes (conical, cylindrical). Can be used on objects made of alloy steel, stainless steel (of varying hardness), cast iron, non-ferrous alloys, plastic, titanium.

Boring through 25x25 VK8

Advantages:

- wide application on different materials;

- durable composition;

- standard parameters.

Flaws:

- not identified.

4th place Straight through 20x12 T5K10

Price: 68 rubles.

Manufacturer – Kanashsky IZ (Russia).

Type – straight through.

Parameters (mm):

- length – 120;

- holder section – 20*12;

- weight – 0.2 kg.

Alloy – T5K10. Used for chamfering, turning parts from non-rigid materials, stepped shafts, protruding parts.

Straight through 20x12 T5K10

Advantages:

- easy to find in stores;

- performs many functions;

- compliance with GOST standards.

Flaws:

- not identified.

3rd place Trimming bent 16x10x100 T5K10 2112-0086

Cost: 102 rubles.

(Russia).

Type – bent scoring with soldered plates. Right feed direction.

Parameters (mm):

- length – 100;

- width – 16;

- weight – 400 g.

Materials: plate – T5K10, holder – steel 45. Compliance with GOST – 2112-0086.

Functionality: ledges (at right, sharp angles), turning along the axis, processing of end parts.

Bent trim 16x10x100 T5K10 2112-0086

Advantages:

- compliance with the requirements;

- universal alloy;

- wide application;

- you can work at higher modes.

Flaws:

- not identified.

2nd place Bent 25x16x140 T5K10 2102-0005

Price: 235 rubles.

Manufacturer – Russia.

Type – bent through.

Specifications (mm):

- length – 140;

- width – 16;

- weight – 400 g.

T5K10 alloy is used. The product is made according to GOST parameters.

Functions: roughing and finishing, cutting ends and sides, stepped parts.

Bent 25x16x140 T5K10 2102-0005

Advantages:

- hard alloy;

- compliance with GOST;

- performs many functions;

- easy to find on sale.

Flaws:

- not identified.

1 place Straight through 16x10x100 T5K10 2100-0401

Cost: 99 rubles.

Product from a Russian manufacturer. Refers to the type of straight line.

Parameters (mm):

- length (L) – 100;

- width – 20;

- weight – 380 g.

Material – T5K10. Manufactured according to GOST 18878-73, designated 2100-0013.

It is used when processing various shapes and materials.

Straight through 16x10x100 T5K10 2100-0401

Advantages:

- universal application;

- quality composition;

- Russian manufacturer;

- low price.

Flaws:

- not identified.

Expensive

They differ in structure - they have threaded plates, functionality - processing of wooden and metal objects.

5th place HSS Line Profi 16 mm Narex 819316

Cost: 7,230 rubles.

(Czech Republic).

Purpose – processing of wooden blanks. Consists of a handle (elongated shape, material – light natural beech), a brass cap. There is a steel blade and a hard alloy roller.

Dimensions (mm):

- total length – 395;

- plate diameter – 16;

- blade – 150;

- handle – 315.

Product weight (packed) – 360 g.

The product is made of HSS steel with hardness HRC 64 (blade), natural beech (handle). The surface is ground and polished.

HSS Line Profi 16 mm Narex 819316

Advantages:

- high quality steel;

- blade strength;

- for wooden elements;

- comfortable handle shape made of natural wood.

Flaws:

- high price.

4th place Cutting groove for replaceable inserts MGEHR1010-1.5

Price: 903 rubles.

Manufacturer – . Designed for processing metal elements. Features: Replaceable plates (MGMN150).

Dimensions (mm):

- length – 100;

- width – 10;

- height – 10.

Weight – 100 g. Made in right-hand version (R).

Functions: processing of external grooves, cutting of the required size.

Cutting groove for replaceable inserts MGEHR1010-1.5

Advantages:

- replaceable plates;

- GOST standards;

- available for sale.

Flaws:

- plates must be purchased separately.

3rd place Cutting tool for replaceable inserts ZQ2525R-4

Cost: 1,283 rubles.

The product is manufactured.

Purpose: cutting grooves, cutting metal elements. Features: replaceable inserts with one cutting side, rigid structure, low deformation.

Parameters (cm):

- length – 15;

- width – 2.5;

- height – 2.5;

- plate width – 0.4.

Weight – 720 g. Depth of the resulting groove – 2 cm.

Correct execution of the product. Plate type – SP400.

Cutting machine for replaceable inserts ZQ2525R-4

Advantages:

- processing of metal parts;

- high-quality element designs;

- long-term use;

- one functional side of the plate.

Flaws:

- not identified.

2nd place For replacement inserts for external turning 25mm WWLNR2525M08

Price: 1,283 rubles.

.

Features: W-trigonal shape of the plate, angle – 95⁰, fastening W-clamp with a wedge clamp on a pin.

Dimensions (cm):

- total length – 15;

- holder section – 2.5*2.5;

- width – 7.

Weight – 850 g.

Product brand – WWLNR, plate – WN-0804.

Functions: chamfering, trimming, external turning.

For indexable inserts for external turning 25mm WWLNR2525M08

Advantages:

- reliable fastening;

- plate shape;

- functional;

- durability of materials.

Flaws:

- plates are not included.

1 place Thrust and contour pass-through for replaceable inserts MDJNR1616H11

Cost: 1,074 rubles.

The product is manufactured (Russia).

It differs: fastening system – M (combined clamp), main angle 93⁰, right-hand feeding direction.

Characteristics (cm):

- length – 10;

- width, height – 1.6;

- cutter length (working part) – 3.15.

Weight – 230 g. Suitable plates DN-1104.

Functions: contouring, longitudinal, transverse turning.

Pass-through thrust and contour for replaceable inserts MDJNR1616H11

Advantages:

- performs many tasks;

- suitable for roughing;

- combined fastening.

Flaws:

- not found.

Sets

They consist of several items (from 5 to 12 pieces) and have different functionality (working on metal, wood).

5th place Woodworking set Enkor 10430, 8 items

Price: 7,440 rubles.

Manufactured (Russia, Voronezh) in China.

The set consists of 8 tools. Sold in a light-colored wooden box with a hinged lid. Contents - instructions for use.

The tools consist of a blade, a handle, and a ferrule.

Materials: blades - high-speed steel, handle - wood with a multi-layer cherry varnish coating.

Case parameters (cm):

- length – 44.5;

- width – 31.5;

- height – 4.5.

The weight of the box with tools is 2.6 kg.

Functionality: roughing, cutting off excess parts, facing, turning rounded shapes.

Woodworking set Enkor 10430, 8 items

Advantages:

- the number of different blade shapes in one set;

- comfortable handle;

- easy to store and transport;

- suitable as a gift for a beginner;

- attractive tool design.

Flaws:

- sharpening required.

4th place Set METALMASTER 18978, 5 pieces, wood

Cost: 11,499 rubles.

Manufacturer – (Russia).

Consists of 5 tools, wooden box with lid. There is a company logo sticker on the top of the lid. Bottom sides - the inscription “Made in Russia”, compliance with GOST.

Specifications (mm):

- blade length – 150;

- handle length – 330;

- blade width – 24.

Material: blade – steel R6M5 (hardness HRC 64), wooden handle – birch.

The set includes cutters:

- Cut-off.

- Right oblique.

- Rip-off.

- Section 30 mm.

- Section 12 mm.

The tools are manufactured according to GOST 19265-73 standards and are intended for working with wooden products.

Set METALMASTER 18978, 5 pieces, wood

Advantages:

- quality steel;

- high hardness;

- comfortable handle;

- popular assortment;

- beautiful wooden case.

Flaws:

- only 5 items.

3rd place Set Proma (25330808), 11 pcs

Price: 4.020-4.455 rubles.

Manufactured (Czech Republic).

Consists of 11 items, with a soldered VK8 plate. Suitable for Proma SM-300,350 lathes, mini-machines from other companies.

Dimensions (cm):

- length – 8 (9 pieces), 12.5 (2 pieces);

- cross section – 0.8*0.8.

Weight (with packaging) – 0.600 kg.

Packaging – cardboard box (length – 16 cm, width – 6 cm). Each tool is packaged in an individual zip bag.

Equipment:

- Passing straight.

- Passing bent right.

- Boring passage.

- Boring persistent.

- Shaped.

- Threaded (external thread).

- Grooved.

- Passing bent left.

- Cut-off.

- Tortsovy.

Functions: longitudinal grinding, trimming, cutting, external threading, chamfering.

Proma set (25330808), 11 pcs.

Advantages:

- a large set of items;

- performs basic types of work on the machine;

- simple packaging;

- affordable price.

Flaws:

- needs sharpening;

- no internal thread cutting.

2nd place Cutters for lathe FD 150/E, 6 x 6 x 60 mm, 6 pcs. Proxxon (24524)

Cost: 6,072 rubles.

Manufacturer: German.

It is used when processing metal and plastic elements.

Consists of 6 tools, packaged in a wooden box with a retractable lid.

Product parameters (cm):

- length – 6;

- cross section – 0.6*0.6.

Material: cobalt high-speed steel (HSS), case-hardened.

Suitable for the tool holder of the FD 150/E lathe.

Cutters for lathe FD 150/E, 6 x 6 x 60 mm, 6 pcs. Proxxon (24524)

Advantages:

- common types of incisors;

- quality work;

- durability of products;

- convenient packaging.

Flaws:

- recommended only for a specific machine.

1 piece Set of turning tools for metal 10x10 VK8 12 pcs

Price: 5.627 rubles.

The set consists of 12 pieces with soldered plates and a wooden box. retractable cover.

Equipment:

- Passage bent.

- Passing straight.

- Grooved internal.

- Left trim.

- Cut-off.

- Passing persistent straight double-sided right.

- Passing persistent straight double-sided left.

- Boring (blind holes).

- Boring (through holes).

- Trimming.

- Passing bent left.

- Threaded (external thread).

Material – hard alloy VK8.

Compliance with GOST standards. Suitable for household machines.

Weight (packed) – 1.3 kg.

Set of turning tools for metal 10x10 VK8 12pcs

Advantages:

- a large number of tools;

- high-quality alloy;

- multifunctional;

- convenient storage, carrying;

- Suitable for most machine models.

Flaws:

- not identified.

Features of mechanically fastened carbide inserts

Cutters with mechanically fastened inserts are currently considered the most popular for turning. They have a wide range of technological advantages compared to brazed tools. Replaceable inserts have high quality factory sharpening and multiple cutting edges. When one of them wears out, the plate is placed in a different position. This saves a large amount of machine time. Holders and inserts are unified and standardized, but not interchangeable. Modern hard alloys from which the tool is made consist of finely dispersed carbides, and therefore are characterized by increased impact strength and wear resistance.

You can request additional information on choosing cutting tools for CNC machines from Multicut consultants by phone or online chat.

APPENDIX 1 Recommended

The maximum deviations of the width of the working part of keyway slotting cutters must correspond to those indicated in the table.

| Keyway width | Maximum deviation for tolerance ranges for the width of the keyway | |

| From 3 to 6 | +0,015 | +0,055 |

| +0,005 | +0,045 | |

| St. 6 to 10 | +0,020 | +0,065 |

| +0,010 | +0,055 | |

| St. 10 to 20 | +0,025 | +0,075 |

| +0,015 | +0,065 | |

(Changed edition, Amendment No. 5).