Anodic oxidation of titanium alloys using pulsed current

Anodic oxidation (anodizing) is used to improve the properties of a metal surface. Pulse anodizing (using a pulse current) is carried out to give the surface of the product greater physical wear resistance and protection against corrosion, including when interacting with other materials, and color anodizing (using a constant density current) is mainly for painting. Many metals can be anodized, but it is usually used to process products made of aluminum and titanium, as well as alloys based on them.

Color anodizing is primarily for decorative and marking purposes, since a thin layer of color provides only minimal corrosion protection.

To form an oxide film of increased thickness on titanium alloys, the industry uses pulsed anodization - the protective layer obtained with its help is characterized by increased hardness and the ability to retain lubricant, which allows the use of highly dispersed lubricant compositions, and also retains all the basic properties of the treated alloy without loss of strength or fatigue limit. It is worth noting that the coating obtained by this method has a number of advantages:

- Low coefficient of friction.

- Increased chemical resistance.

- Increased adsorption capacity.

- High temperature resistance.

- High breakdown voltage.

There are various methods of pulse anodizing, which allow, for example, at a high current density to obtain an even coating of increased hardness on titanium and its alloys - for titanium these are spark discharge conditions at a voltage of 80-250 V and a current density of 10-80 A/dm2.

The process of pulsed oxidation in industrial conditions usually consists of the following steps:

- Installation of workpieces on anodizing fixtures.

- Chemical degreasing of parts (in accordance with production instructions).

- Rinse in hot (40-50 degrees) running water by repeated dipping.

- Rinse in cold running water by repeated dipping.

- Direct anodizing.

- Rinse in cold running water by repeated dipping.

- Drying.

- Dismantling products from anodizing fixtures.

- Monitoring the result by inspecting and checking the thickness of the anodic coating (up to 5 μs - by assessing the breakdown voltage, higher - using a thickness gauge).

Let's look at one of the anodizing options in more detail. The following composition is used as an electrolyte: sulfuric acid (density 1.84) - 205 ml/l, orthophosphoric acid (density 1.7) - 15 ml/l, water - the rest. Electrolyte temperature 5 degrees C. Current pulse duration is 0.1-0.3 seconds, pulse frequency is 60-120 pulses/min, current density per pulse is 5-10 A/dm2. In this case, depending on the ratio of pulse duration and pause, films of varying thickness and quality are formed. At a current density of 1-2 A/dm2, the coating thickness will be 2-3 microns; with a powerful power source, a coating thickness of up to 20 microns can be obtained. (at current density up to 50 A/dm2). It is important that the use of modern rectifiers makes it possible to obtain coatings of much greater thickness - 20 microns or more due to improved pulse parameters. For example, Pulsar SMART rectifier units, manufactured by Navikom, based on MS 32A/300V power modules, allow the anodizing process to be carried out at high current densities (up to 160 and above A/dm2) and operating voltages up to 300 V, adjustable frequency (up to 200 Hz) and duration (from 1 ms) of pulses.

As is clear from the description above, the quality and thickness of the coating will primarily depend on the set of quality indicators of the pulses generated by the power source - the rectifier, which must provide pulses of the required parameters. Traditionally, thyristor converters of various types were used for anodizing, requiring additional elements for their operation: a power switch controlled by a multivibrator, an isolation transformer of the appropriate power in the source power supply network, an additional smoothing reactor and a direct valve at the source output to compensate for the back-EMF of the electrolyte bath. All these are forced measures based on the level of technology development of that time.

Instead of obsolete circuits, it is currently advisable to use modern inverter rectifiers. They not only provide higher quality pulses due to the use of today's current technical solutions, but also allow for much greater flexibility in setting parameters: current, voltage, duration and frequency, which makes it possible to create an oxide coating of almost any required thickness and quality.

An excellent solution for industrial enterprises would be to use rectifiers of the Pulsar SMART series from the Russian company, which has been supplying industrial rectifier units to the domestic and world markets for almost twenty years. The main advantages of rectifiers from Navikom for anodic oxidation:

- Pulse rise/fall 160 µs.

- Minimum pulse duration 1.2 ms.

- No surges or dips in the form of a current pulse.

- Pulse frequency up to 200 Hz.

- High conversion efficiency, which allows for significant energy savings.

- Low pulsation coefficient, which in the case of anodizing work significantly improves the quality of the oxide layer.

- High stability of maintaining process current parameters.

- Flexibility of adjustments and clarity of control.

- Own service department, providing prompt and high-quality solutions to issues related to the operation of rectifiers throughout the entire service life.

Pulsar SMART rectifiers manufactured by Navicom LLC are designed in accordance with the requirements of Russian and international standards and are intended to solve a wide range of industrial problems. At the same time, Navicom specialists are always ready to adapt the capabilities of rectifiers to customer requirements to meet their needs.

Technology and methods of anodizing titanium

Anodizing titanium at home. The process of anodic oxidation of titanium alloy surfaces. Advantages and disadvantages of the procedure. Methods for performing oxide anodizing yourself.

Anodizing a metal is an electrochemical treatment that results in the formation of an oxide film on the surface of the treated object. The barrier coating perfectly protects the titanium product from oxides and rust, and also has a decorative appearance. The procedure for anodizing metal alloys can be carried out independently, using improvised means.

Purpose of titanium anodizing

During the anodizing process, a titanium product is covered with an oxide film, which is formed from the metal itself as a result of an electrochemical reaction.

Anodizing titanium products is also called anodic oxidation. If we compare anodizing in industrial production using special equipment and self-coating with an oxide film, then, of course, the second method is somewhat inferior in quality of the result. But nevertheless, metal processed at home acquires a number of undeniable advantages:

- The oxide film performs protective functions, preventing moisture from penetrating the metal base of the product. The barrier prevents the formation of corrosion, which extends the service life of household items made of titanium alloy.

- Anodizing titanium strengthens the surface of the product and makes it more resistant to various types of external damage.

- Metal products after anodic oxidation partially or completely lose their ability to conduct electric current.

- Cookware with an oxide coating can withstand prolonged heating, has non-stick properties and does not emit toxic substances during cooking.

- If a titanium product has undergone oxide treatment, this is not an obstacle to other types of processing through galvanization.

- Regulating the current strength and the components of the electrolytic fluid makes it possible to make the oxide coating not only more durable, but also more beautiful. The use of dyes will give the product an attractive appearance.

Online piercing store 69 LEVEL

Titanium in body piercing jewelry is commonly referred to as Ti6AL 4VEli Gr23 alloy with ASTM F-136 specification. Ti6AL 4VEli Gr23 alloy is the most common titanium alloy used in medicine, as well as in the military, space and chemical industries. Due to the wide range of applications of the alloy, different specifications have been developed for each of them.

The most common alloy specifications are developed by the American company ASTM, according to which most metallurgical factories operate. In addition, pure titanium Grade1 of ASTM F-67 specification, also used in medicine, is sometimes used for piercing.

Specifications ASTM F-136 and ASTM F-67 are standards that describe the chemical, mechanical and metallurgical requirements for the use of titanium products for implantation purposes without changing the chemical composition. Unscrupulous piercing manufacturers often replace titanium Ti6AL 4VEli Gr23 with a “dirtier” analogue Ti6AL 4V Gr5, in which the tolerances for impurities are greatly increased.

In the table you can see the chemical composition of titanium alloys, where Grade1 is pure titanium, Grade2 is its analogue with a large permissible amount of impurities.

| Chemical composition | ||||

| Chemical element | ASTM Grade | |||

| (Acceptable values) | 1 | 2 | 5 | 23 |

| N, Nitrogen | 0,03 | 0,03 | 0,05 | 0,03 |

| C, Carbon | 0,1 | 0,1 | 0,1 | 0,08 |

| H, Hydrogen | 0,015 | 0,015 | 0,0125 | 0,0125 |

| Fe, Iron | 0,2 | 0,3 | 0,4 | 0,25 |

| Oxygen | 0,18 | 0,25 | 0,20 | 0.13 |

| Al, Aluminum | 5,5-6,75 | 5,5-6.5 | ||

| V, Vanadium | 3,5-4,5 | 3,5-4,5 | ||

| Ti, Titanium | Bal. | Bal. | Bal. | Bal. |

What color should titanium be?

Titanium alloy can have various shades, from dark gray to almost silver (which in appearance is indistinguishable from surgical steel).

The color of a titanium alloy depends on the amount of iron impurity in it (for example, the Steel and Silver brand has an iron content of 0.042% with an allowable 0.25% in Gr23 and 0.4% in Gr5), which makes the alloy very light and ideal for anodizing, and , of course, depends on the quality of polishing (the better the polishing, the lighter the product).

If the iron content in the alloy is high (but still acceptable, for example 0.2%) - the piercing jewelry will have a dark tint and will anodize very poorly after about 65 volts (the jewelry will become dark gray matte with a pink or purple tint, to turquoise, and Moreover, such decoration will definitely not reach green).

What is titanium anodizing?

As you understood above, titanium can be anodized, that is, you can give titanium jewelry the color you want.

By passing a direct current of the required voltage through the titanium jewelry in distilled water (with a special anti-scale agent), a thin film of titanium oxide of the desired color is formed on it.

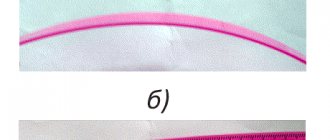

It makes the jewelry smoother at the micro level, which has a good effect on healing. Jewelry that has already been anodized, for example blue, can always be anodized again with a higher voltage, for example, gold.

On the contrary, it is impossible to make a blue tint out of gold. The service life of anodizing depends on the place where the jewelry is worn, for example, in the tongue it will begin to wear off after a few months, and in the earlobe anodizing will remain good for several years.

Why do you need mirror polishing for jewelry?

We all know that poorly polished jewelry can scratch the canal, and also secretions can accumulate in the irregularities of the jewelry, which are a breeding ground for bacteria, which increases the healing time of the puncture.

But the quality of polishing also greatly influences the occurrence of allergies to aluminum, vanadium and impurities contained in minimal quantities in ASTM F-136 titanium alloy.

With high-quality polishing of jewelry at the micro level, the surface of the jewelry becomes as smooth as possible, which makes it possible to form an oxide film that prevents the diffusion of titanium alloy atoms into the puncture.

What is black titanium?

It is impossible to anodize titanium jewelry black, but there are PVD and IP coatings. In terms of durability and appearance, these coatings are the same and it is impossible to determine on the finished product how it was applied. Only the coating technology differs.

PVD (Physical Vapor Deposition) is a method of applying a durable and wear-resistant layer in a vacuum by condensing vapor from particles of the substance selected for spraying. This results in the formation of a thin and very durable molecular film (PVD coating) with a thickness of 1 to 3 microns, due to which the jewelry becomes smooth and scratch-resistant.

IP (Ion plating) is the process of directing a stream of ions of the substance chosen for plating onto the metal, which form a very durable thin layer 1-2 microns thick, which makes the jewelry smooth and scratch-resistant.

To cover piercing jewelry, pure titanium (for spraying black, as well as all colors of anodized titanium), pure gold and zirconium, which are completely hypoallergenic, are used as sprayed material.

Ways and methods

Cold method

According to the equation, the optimal temperature at which it is necessary to carry out anodizing processes using this technology is 0 °C. However, variations from –10 to +10 °C are permissible. It is at these temperatures that a strong and intact oxide film is formed on the surface of a titanium alloy part. The cold method allows you to carry out the procedure of solid anodic oxidation at home.

With proper adjustment of the current, sputtering can be carried out using electroplating using gold, copper or chromium as the material. Such a barrier coating will protect titanium products from oxides and rust, which extends its service life to several decades.

The main disadvantage of this anodizing technology is the impossibility of further painting the treated object.

Warm method

The technology involves the use of organic dyes, thanks to which the metal can be given an amazingly beautiful decorative look. Both ready-made coloring compositions and available dyes from a home medicine cabinet are suitable: iodine, brilliant green, potassium permanganate, iodinol, etc.

Unfortunately, this technology is not designed for hard anodizing. The barrier properties of the oxide film are very weak, as is the protection from mechanical damage. However, upon further painting, the oxide coating exhibits high adhesive abilities. Enamel paints adhere perfectly to such a coating, and in turn provide the titanium product with reliable protection against corrosion.

Titanium

golubka_mia

What is titanium?

Titanium (Ti - Titanium )

is an element of the secondary subgroup of the fourth group, the fourth period of the periodic table of chemical elements of D. I. Mendeleev. Titan was discovered in 1790. William Gregor, clergyman and amateur geologist, in Cornwall, England.

However, it was not refined until 1910, refined, or produced in commercial quantities until the early 50s. Since that time, titanium production has increased by about 8% per year and from the early 60s it began to be used not only in the military industry, but also for commercial purposes.

While pure titanium was prized for its combination of high strength, lightness and excellent durability, aerospace applications required even stronger materials.

In the 1950s, a high-strength alloy called 6-4 (6% aluminum, 4% vanadium, 90% titanium) was developed and immediately found use in the production of cars and aircraft frames.

Titanium is the most “elven” material, named after Titania, the queen of the elves from W. Shakespeare’s play “A Midsummer Night’s Dream.”

The name was given to the material for two reasons: because of its amazing lightness and because of the unusual shades of titanium oxide, which amazed scientists who first obtained titanium oxide in the laboratory.

There are three grades of titanium used in the medical industry: G1, G5 and

G23

.

Titanium G1

is designed for dental purposes. It has a low degree of polishing, which increases its implantability. That is, it grows into the body.

This property is successfully used for dental prosthetics, but makes it undesirable for jewelry for piercing and body modification. Titanium G23 is used for these decorations

. This material is also used to make pacemakers and other medical implants.

Titanium G23

has the highest degree of biocompatibility; a more biocompatible material has not yet been obtained.

Products made from Titanium G23 are 100% safe for health and are recommended by the International Piercers Association for installation in fresh punctures and accelerating the healing of problematic punctures.

Titanium G5 is a surgical alloy also used in transplantology. Although its purity and biocompatibility are lower than Titanium G23, it is optimal for piercing purposes. This is the golden mean in terms of price/quality ratio between Titanium G23 and Titanium G1.

If your body is not prone to the formation of keloid scars (otherwise, piercing is generally contraindicated for you), Titanium G5 jewelry will be quite sufficient even for a fresh piercing. In any case, the biocompatibility of Titanium G5 is higher than that of 585 gold or 316L surgical steel.

Titanium production is very high-tech and expensive. It is approximately 16 times more expensive than steel production. In addition, titanium alloys are difficult to machine. Therefore, real titanium jewelry cannot be cheap.

Anodizing, electrochemical oxidation - the formation of a protective oxide film on the surface of metal products.

Titanium anodizing not only creates a highly durable film on the metal surface, but also serves aesthetic purposes. Black titanium anodizing has a unique pearlescent hue, and colored titanium anodizing has bright, rich colors and can also be obtained with an iridescent iridescent finish.

Titanium anodizing is so strong that it cannot be scraped off even with a rasp. Titanium anodizing technology was created for the military and aerospace industries and is unmatched in its durability. So if you can't afford to buy titanium jewelry, you can buy cheaper and nicer titanium anodized pieces.

Another Zircon Gold coating is successfully used in the jewelry industry -

titanium anodizing with a gold effect without the participation of gold.

Such coating can be distinguished from gold only by sawing the product or carrying out an analysis in the laboratory. You can buy a cheaper (and more durable) product and successfully wear your “gold” without fear of it darkening, wearing off or causing an allergic reaction. Just don’t show anyone that there is no sample on it. golubka_mia

An old legend about a Broken Heart says. In ancient times, when human love was pure and considered sacred, two lovers lived in the world. The girl wanted to give her lover her heart so that it would never be separated from her beloved and went to the witch. The sorceress said: “I will make you a heart of crystal. It will always be with your lover, but if he cheats on you, your heart will break, and its fragments will scatter throughout the world.” The girl believed in the sincere and pure love of her lover and easily agreed to the witch’s conditions. Years passed. Love kept the lovers young and beautiful, but the witch grew old. She envied the girl's beauty, with the help of witchcraft she turned into her double and seduced her lover. The girl returned and found an ugly old witch in the arms of her lover. Her crystal heart broke at that very moment and scattered throughout the world in countless fragments, but the light of love in it did not go out. Until now, lovers find its fragments and Great Love is kindled in their hearts. Antique style ring and earrings. Metal - cupronickel. The coating is blackened silver. Inserts - red and white Swarovski crystals.

Attention! Limited quantity of goods.

Welcome to the mystical, mysterious world of the Lilith online store. We provide courier delivery throughout Russia, Ukraine and Belarus and postal delivery throughout Russia. You can go to the store product page by clicking on the picture.

Page 3

Anodizing titanium at home

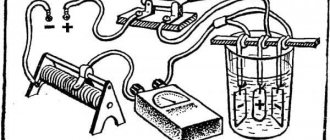

At home, anodizing is carried out according to the following scheme:

- An electrolyte is placed in a container that is not electrically conductive (glass or plastic).

- An electrical circuit is assembled, where a power supply (battery) can act as a source of electric current with a constant voltage.

- The titanium product to be processed is connected with a clamp to a positive charge, and then placed in a reservoir with an electrolytic solution.

- Stainless steel lead plates are attached to the negative charge and then also immersed in the electrolyte.

If there are several parts connected to “-”, they must be located at the same distance from the titanium alloy.

- The circuit is activated by an electrical current source, after which the titanium part begins to release oxygen, which promotes the formation of an oxide coating.

Do not forget about the preliminary preparation of a titanium alloy product for the anodizing procedure. Parts must be cleaned of dirt and rust, then polished and rinsed with clean water. The titanium alloy must spend several hours in an alkaline solution, after which the surface of the product is thoroughly degreased.

Only after the above preparatory measures can titanium be immersed in an electrolyte and anodizing begin.

If you have experience with the titanium anodizing procedure at home, you can share it in the comments.

How to care for titanium jewelry

Titanium jewelry is experiencing a new wave of popularity. There are many reasons for this: they are incredibly strong, durable and wear-resistant. And also bright: anodizing allows you to paint metal products in a wide variety of colors, which is atypical for the jewelry world.

But nothing lasts forever, not even titanium. Jewelry made from this metal can also lose its brightness, become scratched, or become damaged over time. In order to preserve their original appearance longer, it is important to provide proper care.

Clean regularly

You can use dishwashing liquid to clean titanium jewelry. You will need very little: a couple of drops per liter of water. It is better to choose a standard product without adding balm, cream or aggressive components. An ammonia cleaning solution can be used for the same purpose.

Cleaning is carried out according to the following scheme:

- Find a clean container and pour room temperature water into it. Add a couple of drops of detergent and stir. Whipping the foam is not necessary.

- Immerse titanium jewelry in the solution. It is advisable that the products are completely covered with water. Wait 5-6 minutes.

- Remove jewelry from the cleaning solution and rinse under running water. If this is not done, the products will remain sticky.

- Take tissue paper or soft cloth. Wipe the jewelry and check if there are any traces of dirt left on them.

Commercial products, such as special sprays, can also be used to clean titanium products. It is sprayed onto the metal surface, left for a couple of minutes, then wiped with a napkin.

Harsh cleaning products containing chlorine must not be used. This may damage the decoration.

Anodized titanium

When cleaning anodized titanium jewelry, you need to be especially careful. The algorithm is as follows:

- Soak the jewelry in the cleaning solution for a few minutes to remove dirt. But do not rub contaminated areas, otherwise you may disturb the color layer. Rinse with water.

- Soak jewelry items for a couple of minutes in an ammonia solution. Then blot very gently with a clean cloth, much like you would clean your glasses.

- Rinse the jewelry again with water and wipe dry.

If after cleaning at home the color layer is still damaged, contact a workshop that works with titanium jewelry. In most cases, the product can be anodized again.

Jewelry with stones

Choose a cleaning method that is suitable for your gemstones. Some of them do not like prolonged contact with moisture or detergents. Pearls, opal and turquoise are especially vulnerable.

If you are unsure how to clean a particular type of gemstone, be careful not to soak your jewelry in the cleaning solution for long periods of time. It is better to wipe the product with a soft damp cloth.

Polish

Non-anodized titanium jewelry can be polished using special polishes. This will help eliminate dull color, make scratches less noticeable, or get rid of them completely. It is prohibited to use polish for colored jewelry.

Another popular solution is titanium wax or varnish. It is applied in a small amount to the fabric and then rubbed into the product in a circular motion. Then wipe off the remaining product with a clean napkin.

Don't get dirty

In order for titanium jewelry to retain its original appearance longer, it must be removed every time you:

- wash the dishes;

- working in the garden;

- cook;

- doing the cleaning.

Contaminants on jewelry accumulate gradually. They “eat up” the shine and make the color of the metal less bright and saturated. To avoid having to thoroughly clean the product every time, you can use a soft cloth to remove light dirt.

Wear carefully

For your safety, never wear titanium rings while playing sports or working with electrical equipment or open machinery. This is not only harmful for the decoration, but also dangerous for its owner. If the titanium ring accidentally gets caught on a protruding element, there is a high risk of injury.

If the jewelry contains other metals in addition to titanium, such as gold or platinum, it should be removed before visiting the pool or shower. Chlorine contained in water can damage the product.

You will find more useful and interesting articles about jewelry and decorations on our website: DragZoloto.ru

Anodizing titanium at home

The topic was created for the exchange of experience, so don’t be shy, write, throw links, I’ve done it myself and seen a lot on the Internet, but I won’t be able to find, watch, or read everything.

I had to pull out information on anodizing from an old computer. I think it will be useful. I started to try it myself, after reading the topics from the workshop, but there was not enough information, I had to experiment a lot.

What you need for anodizing at home: Power supply 2-5A DC adjustable from 1 to 150V in 1V steps. I use a 2A auto-transformer with a rectifier. A meter for this very voltage. I have a dial voltmeter on the LATR body, it is mainly used as an indicator of the LATR operation and a digital tester for precise control. A container for electrolyte for anodizing. Depending on the electrolyte, it is made of glass, plastic, or metal. I have a thermos flask made of stainless steel, which also serves as a cathode. The electrodes and anode must be made of titanium with the possibility of fastening the workpiece. The fasteners must also be titanium. The cathode can be made of any metal. Wires to connect it all. The electrolyte itself, i.e. any conductive liquid, cola, sprite, vinegar, etc. I don’t recommend salt and soda, ulcers can form at voltages above 30V. I’ve been using citric acid lately, it doesn’t smell. The same kit is suitable for anodizing aluminum.

Let's start with the fact that not all grades of titanium are suitable for anodizing. The greatest range of colors and rich colors can be obtained on alloys VT-20 and VT-6. On alloys containing molybdenum and chromium, the quality of anode films is lower. Alloys containing manganese, such as OT-4 is not very suitable for anodizing due to the small range of colors and especially due to the unevenness of the coating (photos will be below). Pure titanium also has a limited range of colors. This is mainly a theory, you know, not many sellers know the brand of titanium, but you can’t determine it on the tooth, you need to try anodizing it. Further, the pictures of color and voltage correspondence do not correspond to the truth; more precisely, they correspond to certain conditions, i.e. the electrolyte used, electrolyte temperature, current density, grade of titanium, which are not specified.

Anodizing titanium alloys makes it possible to obtain various interference-colored oxide films (brown-yellow, blue, cyan, various shades of yellow, including pink, crimson, and also various shades of green). On titanium alloys, it is possible to obtain differently colored surface areas. This can be achieved by successively immersing the product in the electrolyte with a corresponding decrease in the applied voltage. You can also use the method of re-anodizing the product with appropriate surface insulation. The anodizing process starts at a higher voltage. The peculiarity of this coloring is that differently colored areas of the surface can be located nearby without affecting each other.

In fact, now I only got saturated green on XZ brand wire, I never got pink, I only got crimson at 170V, when I should have gotten a protective layer of gray or dark gray color. But the XZ titanium brand is generally mysterious

This is OT-4, electrolyte vinegar, voltage 75V, time 5 minutes. In reality, the color is from floor paint to gold, but in spots. The surface is prepared, I will write more about surface preparation.

Here is the famous brand XZ and an attempt to obtain a protective coating, not a decorative one. The attempt was almost a success, the coating is noticeably harder than the surface of titanium. And almost because the coating is non-uniform and under the same conditions and one piece of titanium is very different. I also know the reason, the electrolyte during the experiments got very hot, and for high-quality coating it must be cold. While I’m getting ready to write further, I suggest watching the video, albeit without sound. It’s not very good, but you can see how the color changes depending on the voltage. There will be a second video soon, it will be better visible. The current source is an autotransformer with a 2A rectifier, the electrolyte is citric acid, the grade of titanium is not known

The result is an iridescent gray-green-crimson coating, which I’ve been trying to photograph for two hours now. The eye sees it, but the lens doesn’t. I’ll have to wait until tomorrow.

It seems you can see better here, the sound was also removed, I screwed up with the sound track, all my comments disappeared. If anyone is interested, ask, I’ll try to answer promptly (sp.zdel, I apologize, I’ll only be near the Internet on Friday)

Now about surface preparation. I read on one of the forums that preparation is not needed. Perhaps this is suitable for small parts such as screws, pins, bolts. For larger parts, surface preparation is important. The coating turns out to be more saturated in color, more uniform and more durable.

How this is done in production: V. Preparing the surface of products for anodizing Parts and products are mounted on titanium hangers and secured with titanium clamps or bolts, which ensures good contact of structural elements with copper rods. Degreasing of ground and sandblasted products is carried out in a 1% solution of sulfanol NP-3 at 40-50°C for 1-2 minutes. or in a 1% solution of KM-1 70-80OS, 1-2 min. Degreasing of polished parts is carried out in a mixture of acids: 10 - 75 g CrO3 + 100 ml H2SO4 (specific gravity 1.84), at room temperature, treatment duration up to 1 min. This composition can also be used to remove fingerprints and other grease stains from anodized polished products. After degreasing, the parts are washed by repeatedly immersing them, first in hot (80-90°C), then in cold water. Water exchange - 1 volume per hour. Pickling is carried out in the following solutions: 1. 10% nitric acid (specific gravity 1.34) + 2% hydrofluoric acid (40%); 2. 44% nitric acid (specific gravity 1.34) + 10% hydrofluoric acid (40%). The solution temperature is room temperature. Etching duration is 1-2 minutes. Note: The first solution is used only for etching titanium and low-alloy titanium alloys. Refining is carried out to remove oxide layers and contributes to obtaining bright and pure tones of anodic oxide films. Upgrading is carried out in a solution of the following composition (ml/l): Nitric acid (specific gravity 1.4) 700 + 50; Hydrofluoric acid (specific gravity 1.13) 200 + 20; Water rest Mode: solution temperature not higher than 28°C, processing time from 30 s to 10 min.

Features of metal painting

A huge number of dyeing methods have expanded the color base.

Depending on the method of applying the paint and varnish coating and the oils, acids and varying degrees of heating used, it is possible to create any color, even lemon color. All paint application options are divided into two types:

- mechanical;

- chemical.

When applying paint mechanically, various powders are used, which are sprayed, splashed, hammered in using special tools. This option is not distinguished by quality, beauty or uniqueness, but is appreciated by car enthusiasts due to its low cost. In addition, mechanical painting can be easily done at any service station or even with your own hands if you have the necessary equipment.

The use of the chemical method requires experience and knowledge of the sequence of the entire procedure. The first thing to do is to strip the metal surface of the old paintwork. Next, the damaged areas of the primer are restored, which are previously cleaned of rust. After the metal acquires an ideal surface, it is degreased. Small oil removal parts are placed in solvents such as gasoline, ethyl or ether. The treated parts are immersed in boiling water and only then subjected to chemical staining.

Applying a paint coating is not enough if you want the metal to acquire an elegant look and shine of the surface and remain so even with frequent use. This problem is solved by oxidizing the steel.

This procedure involves rubbing the surface with mixtures such as:

- nitric acid mixed with alcohol, water and copper sulfate in the form of sawdust;

- inky-nut-colored acid, including iron and antimony;

- silver nitrate with added water;

- olive oil with antimony chloride.

After applying one of these mixtures to a metal surface, it is subjected to heat treatment. The result of the work will depend mainly on how well the part was cleaned from grease, dust and dirt.

This method is often used to protect weapons and car parts from scratches and chips. Protection can be achieved in other less effective but cheaper ways. For example, many people do metal bluing with oil at home, which, thanks to the crystalline structure of the protective layer of paint, penetrates and creates shine and an additional layer of protection.

If you are doing all the work yourself, then it is important to remember that after drying the painted metal will look darker than when wet. Therefore, taking into account such features, you need to adjust the color in an acceptable direction.

Anodic oxidation of titanium alloys using pulsed current

Anodic oxidation (anodizing) is used to improve the properties of a metal surface. Pulse anodizing (using a pulse current) is carried out to give the surface of the product greater physical wear resistance and protection against corrosion, including when interacting with other materials, and color anodizing (using a constant density current) is mainly for painting. Many metals can be anodized, but it is usually used to process products made of aluminum and titanium, as well as alloys based on them.

Color anodizing is primarily for decorative and marking purposes, since a thin layer of color provides only minimal corrosion protection.

To form an oxide film of increased thickness on titanium alloys, the industry uses pulsed anodization - the protective layer obtained with its help is characterized by increased hardness and the ability to retain lubricant, which allows the use of highly dispersed lubricant compositions, and also retains all the basic properties of the treated alloy without loss of strength or fatigue limit. It is worth noting that the coating obtained by this method has a number of advantages:

- Low coefficient of friction.

- Increased chemical resistance.

- Increased adsorption capacity.

- High temperature resistance.

- High breakdown voltage.

There are various methods of pulse anodizing, which allow, for example, at a high current density to obtain an even coating of increased hardness on titanium and its alloys - for titanium these are spark discharge conditions at a voltage of 80-250 V and a current density of 10-80 A/dm2.

The process of pulsed oxidation in industrial conditions usually consists of the following steps:

- Installation of workpieces on anodizing fixtures.

- Chemical degreasing of parts (in accordance with production instructions).

- Rinse in hot (40-50 degrees) running water by repeated dipping.

- Rinse in cold running water by repeated dipping.

- Direct anodizing.

- Rinse in cold running water by repeated dipping.

- Drying.

- Dismantling products from anodizing fixtures.

- Monitoring the result by inspecting and checking the thickness of the anodic coating (up to 5 μs - by assessing the breakdown voltage, higher - using a thickness gauge).

Let's look at one of the anodizing options in more detail. The following composition is used as an electrolyte: sulfuric acid (density 1.84) - 205 ml/l, orthophosphoric acid (density 1.7) - 15 ml/l, water - the rest. Electrolyte temperature 5 degrees C. Current pulse duration is 0.1-0.3 seconds, pulse frequency is 60-120 pulses/min, current density per pulse is 5-10 A/dm2. In this case, depending on the ratio of pulse duration and pause, films of varying thickness and quality are formed. At a current density of 1-2 A/dm2, the coating thickness will be 2-3 microns; with a powerful power source, a coating thickness of up to 20 microns can be obtained. (at current density up to 50 A/dm2). It is important that the use of modern rectifiers makes it possible to obtain coatings of much greater thickness - 20 microns or more due to improved pulse parameters. For example, Pulsar SMART rectifier units, manufactured by Navikom, based on MS 32A/300V power modules, allow the anodizing process to be carried out at high current densities (up to 160 and above A/dm2) and operating voltages up to 300 V, adjustable frequency (up to 200 Hz) and duration (from 1 ms) of pulses.

Chemical oxidation

This process involves the processing of metals with solutions, mixtures, melts of chemical elements (oxides such as chromium oxides). This oxidation allows for the so-called passivation of the metal surface. It involves the creation of an inactive (passive) formation in a metal layer close to the surface. A thin surface layer is created that protects the main part of the structure.

They keep it there for a certain time, which allows the oxidation-reduction reaction to fully occur. Then the part is thoroughly washed, subjected to natural drying, and final processing.

Chemical oxidation of steel

To create an acid bath, three types of chemically active acids are used: hydrochloric, nitric, and orthophosphoric. The acceleration of the chemical reaction is stimulated by adding manganese, potassium, and chromium compounds to the acid solution. The oxidation reaction occurs at a solution temperature in the range from 30 °C to 100 °C.

The use of solutions based on alkaline compounds allows the use of additives of sodium nitrate and manganese dioxide compounds. In this case, the solution temperature must be increased to 180 °C, and with additives up to 300 °C.

After the procedure, the part is washed and dried. Sometimes potassium bichromate is used to consolidate the chemical reaction process. To increase the shelf life of the formed film, chemical oxidation with oiling is carried out. Sometimes this process is called chemical oxidation. The final coating with oil results in a reliable anti-corrosion coating with a striking, highly decorative black color.