Welding seams must be of high quality in order to obtain a reliable, durable connection of parts and assemblies. During their creation, safety measures must be observed and the health of the welder must be maintained. The eyes are most exposed to the harmful effects of bright radiation and high temperatures that occur during such work. Their protection is provided by a light filter for the welding helmet.

The work of a welder is dangerous and special equipment is used for protection.

GOST regulating the characteristics of light filters

There is a special GOST 12.4.035-78 that regulates the requirements for welding helmets. Although it was developed more than 40 years ago, during this time the necessary changes were made to it, so it is still in effect today. Here we describe the basic technical requirements for welding helmets, goggles, shields, the light filters used in them and other important nuances.

There is a GOST with requirements for light filters.

List of markings

When indicating technical characteristics, the following designations are applied to the mask:

- The degree of shading is the main indicator indicating for what work the specified protective glass is suitable. In Russia, this parameter is marked with the letter C, and abroad – DIN. The higher the number, the lower the glass throughput and vice versa.

- Level of light dispersion. It characterizes the speed of the filter’s response to changes in the light flux, which increases with increasing welding current. This indicator is taken into account only for models with auto-darkening filters. There are 3 degrees, if the number 1 is indicated, then the protection works quickly, the image clarity is high.

- Uniformity of shading. In the production of colored glass, compounds of different metals are used. If the technology has been violated, they are poorly homogenized, so the material turns out to be heterogeneous, as a result, some areas of the filter will be darkened more, others less. The guarantee of high quality is 1st class.

- Optical view of glass. This indicator is influenced by the materials used for its manufacture. If the number 1 is indicated, then this filter provides darkness regardless of the angle at which the light beam hits it. The welder needs to think about the production process, and not about how to correctly turn his head in relation to the work site.

For high-quality eye protection, choose masks from reliable manufacturers with appropriate markings.

Table of correspondence between welding method and degree of darkness

According to international standards, the darkening level of filters is indicated by numbers from 9 to 13 DIN. They correspond to the Russian classification C4-C8. For example, 9 DIN = C4, and 13 DIN = C8.

Filter shades are indicated by numbers.

When choosing the degree of darkness, be sure to take into account the welding method.

To simplify this process, they act in accordance with the recommendations of international EN 379-2003, Russian GOST R 12.4.035-78.

Table: recommended shading values depending on the type of welding used

| Welding method | Current, A | |||||||

| 40 | 70 | 125 | 175 | 225 | 300 | 400 | 500 | |

| Piece electrode | 8 | 9 | 10 | 11 | 12 | 12 | 13 | 14 |

| Semi-automatic, in protective gases (carbon dioxide, nitrogen) | 8 | 9 | 10 | 11 | 12 | 12 | 13 | 13 |

| Tungsten electrode in argon environment | 9 | 10 | 10 | 11 | 12 | 12 | 14 | 14 |

| Semi-automatic, in protective gases (helium, argon) | 8 | 9 | 10 | 11 | 11 | 12 | 13 | 14 |

| MIG/with light alloys | 9 | 9 | 10 | 11 | 12 | 12 | 14 | 14 |

| Arc cutting | 10 | 10 | 10 | 11 | 12 | 13 | 14 | 15 |

| Plasma cutting | – | – | 10 | 12 | 12 | 13 | – | – |

| Microplasma cutting | 8 | 8 | 10 | 11 | 12 | 12 | – | – |

We recommend reading: How to install a hood above a welding table

Table of filters for welding helmets

When welding metals, powerful infrared and ultraviolet radiation occurs, and visible light rays are actively formed. The higher the current in the working zone of the arc, the higher the flux intensity.

Visible light exceeds the maximum norm by tens of thousands of times. Ultraviolet radiation from welding can be tolerated from 6 s to 45 s without harm to the eyes, depending on the distance and arc current.

The effect of infrared rays is not immediately noticeable, but they also cause great harm. Protective glass, the use of which is absolutely necessary for a welder, can reduce damage to health. The rules of safe work clearly remind us of this.

Types of protective welding masks

Now there are many different welding helmets on sale, so before purchasing you need to understand their purpose and select a model in accordance with the type of work being performed.

With fixed filter

Such models were popular before. They have a simple fastening system. To assess the condition of the seam and the overall result of the work, the welder must constantly raise the mask by hand and lower it by nodding his head. The advantage of this solution is the simplicity of the design. But when the mask is lifted, the eyes remain completely unprotected.

Models with a fixed filter used to be popular.

When removing slag, there is a danger of damaging your eyesight, so you must wear protective glasses separately.

With rising glass

This is a more convenient model. Manufacturers have taken care to provide better protection for the welder. After the filters for the masks are lifted, a plastic shield remains, which protects against the possibility of damage by scale while cleaning the seam from slag.

Welding helmet with rising glass.

Chameleon masks

It uses liquid crystal filters that automatically change the dimming level in accordance with the power of the light flux. The chameleon masks are adjusted taking into account the brightness and other characteristics of the welding arc.

They consist of the following elements:

- several layers of crystals, between which there is polymer protection;

- power source (batteries or solar cells);

- arc detection sensors - in most models there are 2 of them, but in expensive ones there are more;

- control panel - with its help you set the degree of darkness, sensitivity, time.

Chameleon masks use liquid crystal filters.

This light filter is attached to the shield with screws; if necessary, it is easy to replace.

Masks with filter and air supply system

If work is performed in difficult conditions and a lot of harmful gases are released, it is better to use masks equipped with an air supply system. Outwardly, they resemble a gas mask. Some of them can be used for underwater welding. Due to their complex design, they are more expensive than other models.

Welding mask with air supply system.

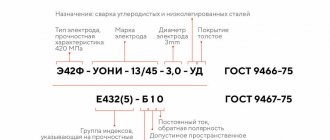

Marking of filters for welding helmets

What types of light filters are there for welding helmets? Which one should you choose to protect the welder’s eyes? Interesting questions, let's try to figure it out!

Types of glass

A light filter for a welding helmet protects human eyes from thermal, infrared, ultraviolet radiation and splashes of molten metal.

When welding, cheap filters with a fixed degree of darkness (colored glass), expensive automatic filters for a welding mask (popularly called a chameleon) and polymer materials are used.

Tinted glass. To reduce light transmittance, impurities of non-ferrous metals (copper and nickel) are added to the material. Its light transmittance depends on the content of impurities in glass.

There are Russian and international markings for the degree of darkness. The domestic classification is marked from C4 to C8, which corresponds to the European 9-13 DIN. The table (below) will help you understand the correspondence of markings.

Glass Chameleon. Automatic windows use a liquid crystal screen. Liquid crystals change the construction sequence when the light voltage changes, thereby achieving different darkening. Modern filters have from 1 to 3 layers of LCD glass.

Polymer materials. They have high ductility and darkening ability.

Welding masks use combined materials, polymer film for protection against mechanical damage, and glass. Which, if necessary, are easily replaced.

:

Differences in glass darkness

The domestic industry supplies the market with light filters for welding marked C4-C8, corresponding to the European classification 9-13 DIN. Light-tinted glass C4 and C8 have no external differences. But C4 has less protection.

https://www.youtube.com/watch?v=-h0XS41YlDc

When choosing (purchasing), you can check the filter for counterfeit using a fluorescent lamp. Through glass C4 the filament of the light bulb will be clearly visible, but through glass C8 it will be difficult to see. If there are no differences, then it is better to refuse the purchase.

Pros advise having 2-3 filters with different protection for a welder’s mask. Then during welding work you can choose the best option.

The table (below) will help you select the degree of darkening of welding filters depending on the welding current and type of welding.

https://www.youtube.com/watch?v=e_jPUis7iJg

The table shows the recommended values. Depending on the weld, you can choose a shade that is one number less or more.

Sometimes, glass for electric welding marked E.1-E.5 comes on sale.

Chameleon light filter for welding helmet

Automatic liquid crystal filters have advantages over their fixed counterparts. Extensive settings adjust the dimming to any brightness and arc diameter.

Chameleon has several layers of crystals located in layers of polymer protection, a power supply and control unit, and arc detection sensors.

An automatic light filter is not a complicated device:

- the device is attached to the mask with two screws;

- Powered by a solar panel and replaceable batteries;

- has 3 control devices:

- Shade control 5-13 DIN and 9-13 DIN. The location is external (on the left side of the mask) or internal (on the filter itself).

- sensitivity (moment of automatic dimming) is adjusted depending on the time of day (day, night).

- dimming time adjustment (long, medium and short).

:

Malfunctions of automatic light filters and solutions

- Uneven dimming. Adjust the distance between the glass and your eyes.

- The filter flickers or dims poorly.

The protective glass is dirty or damaged (clean, replace). At low current, set the switch to the “Long” position (slow). - Low sensitivity. It's getting colder outside, the thermometer is less than -5°.

- Bad visibility.

Dirty protection glass. Bad light. Incorrect dimming level setting.

:

For your home, you shouldn’t buy a welder’s mask with an automatic light filter from a well-known brand. It’s stupid to pay 15-40 thousand rubles for a model that you will have to use a couple of times a year.

It’s better to buy a Chinese model (good), prices start at 3 thousand rubles. Well-known manufacturers are TECMEN (Tekmen) and Resanta.

The domestic industry supplies the market with light filters for welding marked C4-C8, corresponding to the European classification 9-13 DIN. Light-tinted glass C4 and C8 have no external differences. But C4 has less protection.

Classification of light filters by degree of darkness:

| Degree of darkening according to international classification | Degree of darkening according to domestic classification |

| 9 DIN | C4 |

| 10 DIN | C4 - C5 |

| 11 DIN | C5 |

| 12 DIN | C6 - C7 |

| 13 DIN | C8 |

When choosing (purchasing), you can check the filter for counterfeit using a fluorescent lamp. Through glass C4 the filament of the light bulb will be clearly visible, but through glass C8 it will be difficult to see. If there are no differences, then it is better to refuse the purchase. Pros advise having 2-3 filters with different protection for a welder’s mask. Then during welding work you can choose the best option.

The table below will help you select the degree of darkening of welding filters depending on the welding current and type of welding.

The work of a welder involves health risks.

When a welding arc occurs, the worker’s skin and eyes are exposed to infrared and ultraviolet radiation, heat, and may also be damaged by specks of molten metal. A protective helmet protects the worker’s face from mechanical impact, and light filters on the welding mask reduce the effect of radiation on the eyes to zero.

Manufacturers produce different welding glasses, whose classification is determined by many factors, for example, the equipment used for work. One thing is certain: the choice of a light filter for a welding helmet directly depends on the degree of darkness of the glass.

Types of filters

Initially, simple tinted glass was used to protect against negative factors arising during welding, but they were ineffective and made such work more difficult. New technologies are constantly emerging, so filters have been invented that reliably protect the eyes and provide sufficient visibility.

Constant dimming

During production, copper and nickel are added to the composition of such glasses. This allows them to reflect most of the ultraviolet and infrared radiation. When purchasing such glass, take into account the model of the mask, because seats have different parameters. Based on the marking, a product is selected that corresponds to the type of work being performed. If the type of welding changes, you have to insert another light filter into the mask, and this is time-consuming and inconvenient.

When making permanent darkening filters, copper is added.

Chameleon screens

A professional welder has from 1 to 3 such glasses that can regulate the darkening. Making the settings does not take much time, it is easy to do. When changing the type of welding, there is no need to rearrange the glass, just reconfigure it. This is convenient, but the cost of such screens is high.

Many factors influence quality work. Chameleon screens are sensitive to:

- temperature changes;

- vibrations;

- shock loads;

- cleanliness of the outer glass;

- long period of non-use.

Chameleon screens are capable of adjusting dimming.

There is no need to remove such a mask after welding work. Without bright lighting, the glass becomes transparent and does not interfere with the view when removing slag.

Glass with diopters

To work with small parts, special magnifying lenses are installed. They are also needed in cases where the welder has poor eyesight. It is inconvenient to wear glasses under a mask, so he selects glasses with the necessary diopters. Such elements cannot protect the eyes on their own; they are installed together with other light filters.

Glass for welding helmet with diopters.

Mask glass parameters

Welding glasses can be characterized by four main characteristics. They affect image quality, darkness, etc. According to modern standards, product parameters are indicated on the outside of the mask. They are presented as 4 digits separated by a fraction. These are numbers from 1 to 3. One means the highest indicator.

- Optical class. This parameter is responsible for image quality. Here the role is played by the material from which the glass is made and the film glued on top of it. If the parameter is marked with one, then everything is clearly visible through the glass. If it is a two, then there are distortions. If it is a three, then the glass is completely unclear.

- Scattering of light. This parameter is very important for masks with the “Chameleon” filter. It shows the quality of the liquid crystals used in the filter. If it is marked “1”, then the mask will have a clear picture, if “2” means there will be distortions, and if “3” means the image will be cloudy.

- Homogeneity. This indicator is responsible for the uniformity of glass darkening and what differences can occur in different areas of the viewing window. This effect can be seen especially clearly when an arc occurs. So, “1” means that the maximum difference will be no more than 0.1 DIN, “2” - 0.2 DIN, “3” - 0.3 DIN.

- Dependence of darkening on angle. The parameter shows the dependence of the filter darkening on the angle of incidence of the flash. If it is equal to one, then the dependence is minimal. The maximum dependence is indicated by three.

Thus, before you buy a mask, you should pay attention to the parameters indicated on it. Of course, it is best to choose a shield that has the best performance. This will ensure a clear image and maximum eye protection.

Criteria for selecting welding filters

To choose a product yourself, take into account the following characteristics:

- Appearance. There must be no damage. The documentation must include information about the optical class of filters and the manufacturer. If this data is not available, and you only learn the characteristics from the seller’s words, then it is better to refuse to purchase such a mask.

- Number of settings, their varieties. High-quality chameleon glass has 3 adjustable parameters: dimming level, light sensitivity level and shutdown delay time.

- Dimensions. In different models of masks, the size of the glass seat may vary, but most often it is 110x90 or 120x70 mm. This is taken into account when purchasing a replacement filter, otherwise you will not be able to insert it into its place.

- Glass type. Its dimming can be constant or change with fluctuations in the intensity of the luminous flux. If the same welding work is carried out, then a permanent darkening filter is used, because it is cheap, but can still protect the welder’s eyes. When working with frequently changing current strength, it is better to purchase a chameleon.

- Additional protection. A polymer film is glued to the glass, which protects it from mechanical damage resulting from impacts from various solid particles and objects.

Recommended reading: Choosing a chameleon mask

To choose a light filter yourself, you need to consider the type of glass.

Why use filters

When welding, the electric arc gives off a very bright glow that simply blinds a person. A flash of light of such intensity can cause burns to the surface of the eye (as welders say, catching a “bunny”), prolonged or frequent repetition of such glare leads to very painful irritation (“sand in the eyes”). If light of such strength constantly affects the cornea, it will lead to complete loss of vision. This is the first reason why protection is used when welding.

Also, without the use of light filters, it is impossible to simply control the welding process, and with sufficient darkness, you can clearly see what is happening in the weld pool.

During welding of parts by electric welding, other radiation is also released in the ultraviolet and infrared spectra. They, just like bright light, “harm” vision, although not as intensely.

And finally, splashes of molten metal and hot slag also pose a danger to the eyes.

Protective glass for masks differs mainly in the degree of darkening.

Characteristics tables for accurate selection

When choosing a mask, be sure to take into account the type and purpose of the light filter installed in it. To facilitate this process, special tables are used.

Table: purpose of glass installed in the welding helmet

| Title of works | Glass marking |

| Auxiliary processes when performing gas welding work | B1, B2, B3 |

| Welding work | G1, G2, G3 |

| Electric welding | from E1 to E5 |

| For all chameleon glasses | from C3 to C8 |

Don't buy a cheap product.

If you don’t have the money for a good chameleon glass, it’s better to buy a high-quality model with permanent dimming.

Even if the light filter for a welder’s mask has all the documentation, when purchasing it is better to check whether it is a fake or not. It is enough to point the glass at the switched on lamp. If the dimming level is C4, then the filament should be clearly visible through the filter. When marked C8, it will be almost invisible. If there is no difference, then it is better to refuse to purchase a light filter.

Possible faults

The design of glass for welding with automatic change in the degree of darkness is relatively complex, so some problems sometimes arise during the operation of the filter. Most of them can be eliminated with self-repair.

Correctable

Do-it-yourself faults:

- Uneven dimming. It may differ on the left and right sides. To correct this problem, it is enough to adjust the distance between the glass and the welder’s eyes.

- Filter flickering or lack of dimming. If it is not damaged, then the reason is most often contamination of the glass surface. Cleaning fixes the problem. When working with low current, it is recommended to set the setting to “slow”. The batteries may run out, they will have to be replaced, and if they are solar cells, then they will have to be taken out into the light for a while.

- Low photosensitivity. Such a malfunction most often appears at sub-zero temperatures. For most masks, this threshold is -5°C.

- Bad visibility. The reasons for this malfunction are most often associated with dirty glass or incorrect settings.

Uneven dimming and flickering of the filter can be corrected yourself.

Unrepairable

If the problems that arise during the operation of the light filter are related to its mechanical damage or manufacturing defects, then they cannot be eliminated. In such cases, the glass is replaced. This is not difficult to do, because... It is attached to the mask using 2 screws.

Rules for using filters

To ensure that a welder wearing a mask is not only comfortable, but also safe, the following rules are adhered to when performing work:

- Before you start welding, you must check the functionality of the light filter using a lighter. If it gets dark, then everything is fine, in other cases the malfunction is due to damage to the glass or a breakdown of the power supply.

- You cannot use chameleon filters if they do not have an outer or inner layer.

- If there are scratches or cracks on the glass surface, use of the product is prohibited. This is dangerous for your eyesight.

- To clean filters for welding helmets from dirt, use only a soft cloth. This should not be done with abrasives or sharp objects.

We recommend reading: How to make an oscillator yourself

Before welding, you need to check the functionality of the light filter.

The best manufacturers of welding equipment

If welding is rarely done at home, and the duration of such work is short, then you can limit yourself to buying an inexpensive Chinese light filter, but you should not count on its high quality. It is better for professionals not to save money and purchase products from popular, reliable manufacturers:

- 3M is an American company that produces not only light filters, but also shields, masks, and plates. All products are of high quality, so the manufacturer occupies a leading position in the Russian and world markets.

- Svarog is a popular Russian company that produces protective equipment and welding equipment. The advantage of their products is their affordable price and high quality.

- FUBAG is a German manufacturer that produces equipment and protective equipment for various industries and construction. Offers a large selection of replacement light filters and welding helmets.

- Quattro Elementi is an Italian manufacturer. It produces modern models with fixed filters and those that can change the level of darkness in accordance with the strength of the light flux.

- BRIMA is another German company popular in Russia, offering protective equipment used for welding by both amateurs and professionals.

The 3M company produces masks and light filters.

The best models of masks with a light filter

It is impossible to say unequivocally which model is better: when choosing a mask, they are guided by the working conditions and the preferences of the welder.

Budget variations

Amateurs who perform welding work of low complexity and infrequently should not buy a professional model. It is enough to buy an inexpensive one. Among the most popular it should be noted:

- Brima HA-1005. This is a classic inexpensive model, in which there is a fixed light filter; the glass must be raised and lowered manually. The body is made of heat-resistant plastic and weighs only 800 g.

- Quattro Elementi Lambda. The glass has a fixed degree of shading level 11 DIN. Weight – 490 g, there is a shield for protection from smoke. The forehead pad has an antibacterial coating. The mask is made of heat-resistant plastic, so it is resistant to wear and does not burn through.

- "Burevestnik NN-U1". This model is made of polyethylene, has an adjustable headband, and is secured with a button. With its help, work is performed at temperatures from -45 to +40°C, so it is used both indoors and outdoors.

Professional protection

If the work is carried out constantly, and the mode and type of welding is often changed, you will need a professional mask.

The most popular models:

- 3M Speedglas 9100XX MP Air. Designed for comprehensive protection, allowing you to work in difficult conditions. The body is made of heat-resistant polycarbonate, an air supply is provided, and a filter is installed. Provides good visibility, reliably protects not only the eyes, but also the ears, face, and respiratory organs. The range of glass darkening is within 5-13 DIN, the filter is replaceable.

- "Fubag BLITZ 9-13 Chameleon." A modern filter can automatically change the darkening within 9-13 DIN. The screen provides reliable protection from light and heat radiation. The durable polyamide nylon body is impact resistant. The mask can be used at temperatures not lower than -10°C. The design is non-separable, so the filter cannot be changed.

- "Zubr Expert 11079". It is lightweight and highly durable. Provides dimming within 9-13 DIN. Powered by batteries and solar cells. Operating temperature range -5°С…+55°С.

When performing welding work, the safety of the welder is of great importance, so you need to choose the right mask. It must have high-quality light filters installed. Chameleons have many advantages, but they are not designed to work in the cold and are expensive. For non-professionals, it is better to buy a high-quality mask with glass that is permanently darkened than a cheap model with automatic adjustment.

The design and principle of operation of the Chameleon mask

The Chameleon mask is classified as personal protective equipment. The main purpose of the product is to prevent damage to the skin and eyes from IR and UV radiation, harmful smoke, sparks, gases and drops of metal formed during welding work.

This type differs from ordinary masks in its ability to create varying degrees of darkness. This happens automatically based on sensor signals. The shading material is not dark glass, but LCD screens separated by polarizing films.

Technical innovations used in the manufacture of the Chameleon make the product more expensive, but significantly increase the degree of protection.

To understand the principle of operation of a protective mask, you should familiarize yourself with its design. The design consists of a body fixed with an adjustable headband.

The product completely covers the face, neck, chin and upper part of the head. In the eye area there is a screen with a block of light filters made on the basis of crystals. At the top of the window there is a solar panel and arc sensors.

There are special regulators on the body. Their number depends on the options that a particular model is equipped with. Most often, regulators for auto-darkening and fixing the mask on the head are installed.

The protective function is provided by a block of light filters. It includes several layers of films placed in a vacuum. The change of filters occurs after a signal is given by the sensors. The functionality of the automatic mode depends on the voltage level supplied to the device. The response time of light filters is from 1/10000 to 1/35000 sec.

The Chameleon mask has a limited operating temperature range. The lower limit reaches from -5 to -10 degrees. The lower the indicator, the slower the filter works.

The advantage of a welding mask is the convenient method of fixation. Using the headband, the product is securely fixed, leaving both hands free. There is no need to lift the screen before or after ignition. Thanks to the parameters, not only the eyes are protected, but the entire face, neck, and head are protected. The dimming setting is carried out taking into account the type of work.

The Chameleon mask has some special features. For example, the response time of sensors changes under the influence of sub-zero temperatures. The cost of products of this type is higher than conventional personal protective equipment.

How the mask works

The protective mechanism is triggered after the reaction of sensors located on the front side of the case. As soon as ignition occurs, the electric arcs transmit an impulse to the electronic board. The signal is converted there. The filter unit is powered by solar or lithium batteries.

Under the influence of electric current, the filter films are rearranged in such a way that infrared and ultraviolet radiation do not pass through them.

After the radiation stops, the sensors again react by stopping the signal to the board, which in turn turns off the power from the filter block. The screen of the protective equipment becomes transparent.

Reference! Even when inactive, the mask filters invisible and polarizing light. This eliminates exposure of the welder’s eyes to the sun, glare, and radiation from hot metal.

Chameleon has the ability to enable the grinding mode. This option is useful when working with spark-producing tools (grinder, etc.). This feature prevents glass from darkening erroneously in response to sparks.