Group G23 STANDARD

INTERSTATE

GOST

24996-81

TURNING CUTTERS WITH MECHANICAL FASTENING OF REPLACEABLE PLATES. SECURED BY ROCKING PIN

Types and main sizes

Turning tools with mechanical clamped changeable polyhedral plates fixed by swing pin.

Types and basic dimensions

M KS 25.100.10

By Decree of the USSR State Committee on Standards dated November 18, 1981 No. 4988, the introduction date was set

from 01/01/84

1. This standard applies to turning tools with mechanical fastening of replaceable polyhedral inserts, secured by an oscillating pin, intended for use on numerically controlled machines and universal machines.

2. Cutters must be made of the following types:

1 - with triangular plates bent at an angle <р = 45°, right and left;

2 - the same. with an angle <р ■ 60°;

3 - the same. with angle <р - 90°;

4 - with square plates, straight lines with an angle <р = 45°;

5 - with square plates bent at an angle (p ■ 45°, right and left;

6 - the same. with angle <р = 60';

7 - with square plates, straight lines with an angle <р = 75°, right and left;

8 - with rhombic plates with an angle of 80° with an obtuse angle at the apex, straight, with an angle Ф ■ 75°, right and left;

9 - with rhombic plates with an angle of 80′, bent with an angle <р ■ 95°, right and left;

10 - with rhombic plates with an angle of 55°, straight with a corner <р ■ 63°, right and left;

11 - with rhombic plates with an angle of 5512, bent with an angle <р ■ 93°, right and left;

12 - straight with round plates;

13 - with round plates, bent, right and left.

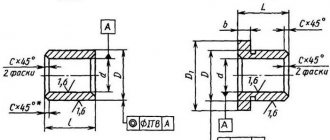

3. The main dimensions of the cutters must correspond to those indicated in the drawing. 1 - 13 and in table. 1 - 13.

Type I

Types of turning tools with replaceable inserts

The following types of cutting tools with replaceable inserts are distinguished:

- Boring cutters: have a cone-shaped holder and mechanical fastening for making through and blind holes in parts. They can also be used for cutting internal and external threads in cylindrical products. When making blind holes, the cutting edge should be positioned at an angle of 90°, for through holes - at an angle of 60°.

- Pass-through: used during external processing of metal parts. Their cutting edge is located at an angle of 45°.

- Shaped: necessary for processing shaped surfaces. These cutting tools are capable of ensuring the identical shape and dimensional accuracy of the processed workpieces. Shaped cutters are made from high-quality high-speed steels.

- Parting cutters: used for cutting workpieces into several parts. They are used when processing small and large bar parts. The main cutting edge of the tool is at an angle of 90°.

- Multi-faceted carbide cutters: equipped with polyhedron-shaped inserts.

- Grooving: intended for cutting grooves in cylindrical and conical products. They are characterized by high structural rigidity and high productivity. These tools are able to withstand high loads during turning operations.

The choice of the type of thread cutters with replaceable inserts depends on the type of technical operations performed during the processing of metal parts. The quality of the instrument depends on the precision of manufacturing and the professional skills of the craftsman.

GOST 20872-80, GOST 26476-85, GOST 26611-85, GOST 26613-2016

ALLIANCE LLC offers turning cutters with replaceable carbide inserts for delivery from stock and on order:

Sale of cutters with mechanical fastening of replaceable carbide inserts | Lathe cutters with replaceable inserts |

- Through cutter SVVNN 1616H-12F with mechanical fastening ISCAR

- Through cutter SVVBR 2525 М11-В1 with Sandvik mechanical fastening

- PCLNR 2525 M12 through cutter with Sandvik mechanical fastening

- Through cutter MVJNR 2525M-16 with mechanical fastening ISCAR

- Through cutter PRGNR 3225 P15 with Sandvik mechanical fastening

- Cutting cutter AR-416 with mechanical fastening 20x20x150mm

- Cutting cutter AR-589 with mechanical fastening 25x25x80 mm automatic

- Cutting cutter P38 08 with mechanical fastening 32x32x170 mm left

- Cutting cutter 25x20x150 with mechanical fastening of plates 5.5 mm thick

- Bent scoring cutter 20x20x150 with mechanical triangular plate TNUM-220408 (2103-0695)

- Pass-through cutter MPTNR 2022 K11 with mechanical fastening of a pentagonal plate 20x20x120 mm

- Straight cutter K.01.4927 25x25x150 with mechanical fastening of square plates 03111-120408 VOK-60.71 (SNGN-120408 VOK-60.71) with an angle of 45 degrees, clamp from above

- Straight cutter 25x25x150 with mechanical fastening of a square plate 03111-120408 VOK-60, SNUN-120408 VOK-71 with an angle of 45 degrees, clamp from above

- Straight cutter CSDNN 2525 M12 with mechanical fastening of square plate SNUN-120404 VOK-60, SNUN-120408 VOK-71 with an angle of 45 degrees, clamp from above

- Pass-through cutter bent right MPTNR 2022 K11 20x20x125 K11 with mechanical pentagonal plate PNUM-120408

- Pass-through cutter with mechanical fastening of a pentagonal plate 24x20x120 mm (T5K10)

- Pass-through cutter SPSPR 2520 M11 with mechanical fastening of a pentagonal plate 25x20x150mm (2102-0121)

- Pass-through cutter MPTNR 2525 M13 with mechanical fastening of a pentagonal plate 25x25x150mm

- Pass-through cutter PPTNR 2920 M11 with mechanical fastening of a pentagonal plate 29x20x150mm (2102-0257)

- Pass-through cutter with mechanical fastening of a pentagonal plate 29x25x140mm (2102-1045)

- Pass-through cutter with mechanical fastening of a pentagonal plate 30x20x130mm (T15K6)

- Pass-through cutter MPTNR 3225 P13 with mechanical fastening of a pentagonal plate 32x25x170 mm

- Bent cutter MSSCR 3232 P15 32x32x170mm with square plate SNUM-150412

- Pass-through cutter with mechanical fastening of a pentagonal plate 40x25x200mm

- Pass-through cutter with mechanical fastening of a pentagonal plate 45x32x200 mm BISON (2102-0277)

- Pass-through cutter CKJNR 2525 M19 with mechanical fastening of a corrugated rhombic plate (slate) 25x25x100 mm

- Pass-through cutter CKJNR 2525 M19 with mechanical fastening of a corrugated rhombic plate (slate) 25x25x150mm (2101-0643)

- Pass-through cutter CKNNR 2525 M19 with mechanical fastening of a corrugated rhombic plate (slate) 25x25x150mm

- Pass-through cutter K014274 with mechanical fastening of a corrugated rhombic plate (slate) 25x25x100 mmφ=93 deg.

- Pass-through cutter CKJNL 2525 M19 with mechanical fastening of a corrugated rhombic plate (slate) 25x25x150mm left

- Pass-through cutter CKJNR 3225 P19 with mechanical fastening of a corrugated rhombic plate (slate) 32x25x170 mm

- Pass-through cutter CKNNR 3225 P19 with mechanical fastening of a corrugated rhombic plate (slate) 32x25x170 mm (2101-0813)

- Pass-through cutter CKJNL 3232 P19 with mechanical fastening of a corrugated rhombic plate (slate) 32x32x170 mm left

- Pass-through cutter PCLNR 2022 K12 with mechanical fastening of a rhombic plate 20x20x120 mm

- Pass-through cutter PCLNR 2525 M12 with mechanical fastening of a rhombic plate 25x25x150mm (K014977 25x25 95 L)

- Pass-through cutter PCLNR 2525 H12 with mechanical fastening of a rhombic plate 25x25x100 mm

- Pass-through cutter CCLNR 2525 M12 - 092 VOK with mechanical fastening of a rhombic plate 25x25x150mm

- Pass-through cutter PCLNL 2525 M12 with mechanical fastening of a rhombic plate 25x25x150mm left

- Pass-through cutter PCLNR 3225 P12 with mechanical fastening of a rhombic plate 32x25x170 mm

- Pass-through cutter PCLNR P16 with mechanical fastening of a rhombic plate 32x25x170 mm (4334) φ=95 deg.

- Pass-through cutter MDJNR 3225 P15 with mechanical fastening of a rhombic plate 32x25x170 mm (2100-4019)

- Pass-through cutter PCLNR 3232 P19 with mechanical fastening of a rhombic plate 32x32x170

- Pass-through cutter PDJNR 4032 P15 with mechanical fastening of a rhombic plate 40x32x200 mm

- Pass-through cutter PCLNR 4032 P19 with mechanical fastening of a rhombic plate 40x32x200 mm

- Pass-through cutter with mechanical fastening of a triangular plate 20x20x120 mmtype 1 (2100-1031)

- Through cutter CTAPR 2022 K type 4 with mechanical fastening of a triangular plate 20x20x120 mm (2100-1105)

- Through cutter CTFNR 2022 K16-H2 with mechanical fastening of a triangular plate 20x20x120 mm

- Bent cutter MSDNR 2520 M12 25x20x150mm right with mechanical fastening of tetrahedral plate SNUM-120408 GOST 20872-80, GOST 26476-85, GOST 26611-85, GOST 26613-2016

- Through cutter CTGNR 2022 K16-H2 with mechanical fastening of a triangular plate 20x20x120 mm

- Pass-through cutter CTAPR 2525 M16-H2 with mechanical fastening of a triangular plate 25x25x150mm

- Through cutter CTGNR 2525 M16-H2 with mechanical fastening of a triangular plate 25x25x150mm

- Through cutter CTFNR 2525 M16-H2 with mechanical fastening of a triangular plate 25x25x150mm

- Pass-through cutter PTGNR 2525 M22 with mechanical fastening of a triangular plate 25x25x150mm

- Cutter cutter CTGPR 2525 M16-H1 with mechanical fastening of a triangular plate 25x25x150mm

- Pass-through cutter MTJNR 2525 M22 with mechanical fastening of a triangular plate 25x25x150mm

- Pass-through cutter MTNNR 2525 M22 with mechanical fastening of a triangular plate 25x25x150mm

- Pass-through persistent bent cutter PTGNL 2525 M22 25x25x150 with a triangular plate with hole 220408, angle 90 degrees

- Pass-through cutter persistent bent left PTGNL 2525 M22 25x25x150 with a triangular plate with a hole TNUM-220408 at an angle of 90 degrees

- bent push-through cutter 32x32x170 with mechanical fastening of plates 5x6x30 T15K6 for external thread, left (P 41 09 L)

- Pass-through cutter PTGNR 2525 M16 with mechanical fastening of a triangular plate 25x25x150mm KORLOY

- Pass-through cutter with mechanical fastening of a triangular plate 32x25x170 mm (2103-0717)

- Pass-through cutter with mechanical fastening of a triangular plate 32x25x170 mm (2103-0718) left

- Pass-through cutter with mechanical fastening of a triangular plate 32x32x170 mm (2103-0726) left

- Pass-through cutter with mechanical fastening of a triangular plate 40x32x200 mm (2103-0732) left

- Pass-through cutter MSSCR 1616 H9 with mechanical fastening of a tetrahedral plate 16x16x100 mm

- Pass-through cutter with mechanical fastening of a tetrahedral plate 25x20x140 (2102-0185)

- Pass-through cutter PSSPR 2520 M15 with mechanical fastening of a tetrahedral plate 25x20x150mm

- Pass-through cutter MSDNR 2520 M12 with mechanical fastening of a tetrahedral plate 25x20x150mm

- Pass-through cutter MSSNR 2520 M12 with mechanical fastening of a tetrahedral plate 25x20x150mm

- Pass-through cutter with mechanical fastening of a tetrahedral plate 25x20x150mm K01 4895 75 deg

- Straight cutter KO 14893 2525 25x20x150 with mechanical fastening of a square plate with a processing angle of 45 degrees

- Pass-through cutter with mechanical fastening of a tetrahedral plate 25x25x150mm (2100-1331) with a WOK plate

- Pass-through cutter CSDNN 2525 M12 with a FOC plate with mechanical fastening of a tetrahedral plate 25x25x150mm

- Pass-through cutter CSКPR 2525 M12 with mechanical fastening of a tetrahedral plate 25x25x150mm

- Pass-through cutter MSSNR 2525 M12 with mechanical fastening of a tetrahedral plate 25x25x150mm

- Pass-through cutter MSSNL 2525 M15 with mechanical fastening of a tetrahedral plate 25x25x150mm

- Pass-through cutter MSSCR 2525 M15 with mechanical fastening of a tetrahedral plate 25x25x150 (KO 14912)

- Pass-through cutter PSSNR 2525 M12 with mechanical fastening of a tetrahedral plate 25x25x150 mm

- Bent pass cutter MSSNR 2520 M12 25x20x150 with mechanical fastening of a square plate

- Pass-through cutter with mechanical fastening of a tetrahedral plate 28x20x135

- Cutter 28x20x140 with mechanical fastening of a square plate 15x15mm KNT-16

- Cutter 28x20x140 with a square smooth plate KNT16 with chamfers at the corners 15x15 mm

- Pass-through cutter with mechanical fastening of a tetrahedral plate 29x20x150mm (2102-0187)

- Pass-through cutter with mechanical fastening of a tetrahedral plate 29x20x150mm (0307)

- Pass-through cutter with mechanical fastening of a tetrahedral plate 29x20x150mm (2102-0187) without plate

- Bent pass cutter 2102-0193 2925 29x25x150 with mechanical fastening of a square plate

- Pass-through cutter MSSNR 3225 P15 with mechanical fastening of a tetrahedral plate 32x25x170 mm

- Pass-through cutter with mechanical fastening of a tetrahedral plate 32x32x170 mm (KO 14912) 45 degrees

- Pass-through cutter MSSCR 3232 P15 with mechanical fastening of a tetrahedral plate 32x32x170 mm

- Pass-through cutter with mechanical fastening of a tetrahedral plate 36x25x170 mm (2102-0197) P15

- Pass-through cutter MSSСR 4040 R19 with mechanical fastening of a tetrahedral plate 40x40x200 mm

- Pass-through cutter with mechanical fastening of a hexagonal plate 29x20x150mm (2102-0217)

- Pass-through cutter with mechanical fastening of a hexagonal plate 29x20x150mm (2102-0217) without plate

- Pass-through cutter with mechanical fastening of a hexagonal plate (broken trihedron) 20x20x120 mm1031

- Through cutter MWLNR 2022 K08 with mechanical fastening of a hexagonal plate (broken trihedron) 20x20x120 mm

- Pass-through cutter PWSNR 2022 K06 with mechanical fastening of a hexagonal plate (broken trihedron) 20x20x120 mm

- Pass-through cutter with mechanical fastening of a hexagonal plate (broken trihedron) 24x20x120 mm (2102-0303)

- Pass-through cutter MWLNR 2520 M8 (M02L012520M08) with mechanical fastening of a hexagonal plate (broken trihedron) 25x20x150 mm

- Pass-through cutter with mechanical fastening of a hexagonal plate (broken trihedron) 25x20x150

- Pass-through cutter MWLNL 2520 M8 with mechanical fastening of a hexagonal plate (broken trihedron) 25x20x150mm (2102-0306) left

- Pass-through cutter with mechanical fastening of a hexagonal plate (broken trihedron) 25x25x80 4001-04 Automatic

- Through cutter 25x25x150 MWLNR 2525 M8 with mechanical fastening of a hexagonal plate (broken trihedron)

- Pass-through cutter with mechanical fastening of a hexagonal plate (broken trihedron) 25x25x150 MWLNR 2525 M10

- Pass-through cutter with mechanical fastening of a hexagonal plate (broken trihedron) 25x25x150 MWLNL 2525 M8 left

- Pass-through cutter MWLNL 2525 M10 with mechanical fastening of a hexagonal plate (broken trihedron) 25x25x150 left

- Pass-through cutter PWLNR 2525 M10 with mechanical fastening of a hexagonal plate (broken trihedron) 25x25x150mm

- Pass-through cutter MWLNR 2920 M8 with mechanical fastening of a hexagonal plate (broken trihedron) 29x20x150mm (2102-0307)

- Pass-through cutter with mechanical fastening of a hexagonal plate (broken trihedron) 29x22x140 (2103-1010) left

- Pass-through cutter with mechanical fastening of a 6-sided plate (broken trihedron) 29x25x150mm (2103-0313)

- Pass-through cutter MWLNR 3225 P8 with mechanical fastening of a hexagonal plate (broken trihedron) 32x25x170

- Pass-through cutter MWLNR 3225 P10 with mechanical fastening of a hexagonal plate (broken trihedron) 32x25x170

- Pass-through cutter with mechanical fastening of a hexagonal plate (broken trihedron) 32x25x170 (2102-0316)

- Pass-through cutter MWLNL 3225 P10 with mechanical fastening of a hexagonal plate (broken trihedron) 32x25x170 left

- Pass-through cutter DWLNR 3232 P12 with mechanical fastening of a hexagonal plate (broken trihedron) 32x32x170 (2102-0321)

- Pass-through cutter MWLNR 3232 P12 with mechanical fastening of a hexagonal plate (broken trihedron) 32x32x170

- Pass-through cutter with mechanical fastening of a hexagonal plate (broken trihedron) 32x32x170 (2102-0321)

- Pass-through cutter MWLNL 3232 R12 with mechanical fastening of a hexagonal plate (broken trihedron) 32x32x170 left

- bent push-through cutter 32x32x170 with mechanical fastening of plates 5x6x30 T15K6 for external thread, left (P 41 09 L)

- Pass-through cutter with mechanical fastening of a hexagonal plate (broken trihedron) 35x20x170 (2103-1011)

- Pass-through cutter MWLNR 4032 R12 with mechanical fastening of a hexagonal plate (broken trihedron) 40x32x200mm

- Pass-through cutter with mechanical fastening of a hexagonal plate (broken trihedron) 45x32x200 mm (2102-0327) Bison

- straight cutter 16x16x100 with insert of superhard alloy based on boron nitride (composite 01) with insert in plan 45°, 15°

- Boring cutter 25x23x200 with a round holder with mechanical fastening with a round CBN plate d6x4mm

- Boring cutter with mechanical fastening of a square plate 20(D)x18(h)x170 mm (L)

- Boring cutter with mechanical fastening of a square plate 25(D)x23(h)x200 mm (L) (2140-0352) (without plates)

- Boring cutter with mechanical fastening of a square plate 26(D)х23(h)х240 (L) (2145-0605) for through holes

- Boring cutter with mechanical fastening of a square plate 26 (D) x 23 (h) x 240 (L) (2145-0552) for blind holes

- Boring cutter S32U-PSWNR16 with mechanical fastening of a square plate 32 (D) x 27 (h) x 350 (L)

- Boring cutter S40U-CKLNL 19 with mechanical fastening of a corrugated rhombic plate (slate) 40(D)х32(h)х350 (L) left

- Boring cutter S20K-MCLNL 12-B h12 with mechanical fastening of rhombic plate 20x19x125 left

- Boring cutter S20K-MCLNR 12-B h12 with mechanical fastening of a rhombic plate 20x19x125

- Boring cutter S25M-MCLNL 12-B h12 with mechanical fastening of rhombic plate 25x23x150mm left

- Boring cutter S25M-MCLNR 12-B h12 with mechanical fastening of a rhombic plate 25x23x160

- Boring cutter S25R-DCLNL 12-B h12 with mechanical fastening of rhombic plate 25x23x200 mm left

- Boring cutter S25X-MCLNR 12-B h12 with mechanical fastening of a rhombic plate 25x23x220

- Boring cutter S25X-PCLNR 12-B h12 with mechanical fastening of a rhombic plate 25x23x220

- Boring cutter S25X-MCLNL 12-B h12 with mechanical fastening of rhombic plate 25x23x220 left

- Boring cutter S32X-MCLNR 12-B h12 with mechanical fastening of a rhombic plate 32x30x220

- Boring cutter S32X-PCLNR 12-B h12 with mechanical fastening of a rhombic plate 32x30x220

- Boring cutter S32Q-MCLNL 12-B h12 with mechanical fastening of rhombic plate 32x30x180 left

- Boring cutter S32X-MCLNL 12-B h12 with mechanical fastening of rhombic plate 32x30x220 left

- Boring cutter with mechanical fastening of rhombic plate 32(D)x30.5(h)x160(L)

- Boring cutter A32T-DCLNR 12 with mechanical fastening of a rhombic insert 32x30x300 Sandvik Coromant

- Boring cutter with mechanical fastening of a triangular plate 18(D)x18(h)x180

- Boring cutter with mechanical fastening of a triangular plate 18(D)x18(h)x150mm

- Boring cutter with mechanical fastening of a triangular plate 30x25x205 left

- Boring cutter with mechanical fastening of a triangular plate 01111-160408 VOK71 32x30x250 MIZIR-122-32-16

- Boring cutter with mechanical fastening of a hexagonal plate (broken triangle) 16(D)х14(h)х200

- Boring cutter with mechanical fastening of a hexagonal plate (broken triangle) 20(D)x18(h)x160(L) (T15K6)

- Boring cutter with mechanical fastening of a hexagonal plate (broken triangle) 20(D)x18(h)x200(L)

- Boring cutter with mechanical fastening of a hexagonal plate (broken triangle) 20(D)х18(h)х240 S20S-PWLNR 06

- Boring cutter with mechanical fastening of a hexagonal plate (broken triangle) 25(D)х18(h)х200 mm (2145-0553)

- Boring cutter with mechanical fastening of a hexagonal plate (broken triangle) 26(D)х23(h)х240 (2145-0555)

- Boring cutter with mechanical fastening of hexagonal plate (broken triangle) 32(D)х24(h)х240 S32S-PWLNR 08

- Boring cutter with mechanical fastening of a hexagonal plate (broken triangle) 32(D)х24(h)х280 S32T-PWLNR 08

- External thread cutter with mechanical fastening 25x16x150mm

- External thread cutter with mechanical fastening 25x16x125

- External thread cutter with mechanical fastening 25x25x80 AR-591 Automatic

- Thread cutter SER 2525 M16 25x25x150 for external threads with mechanical fastening of triangular plates 16 ER

- Thread cutter SEL 2525 M16 SMOXH for external thread with mechanical fastening 25x25x150mm left

- Thread cutter SER 2525 M22 25x25x150 for external threads with mechanical fastening of triangular plates 22 ER

- Thread cutter for external thread with mechanical fastening 32x25 3660-0562

- Thread cutter for internal thread with mechanical fastening Ф25х25х150мм Т15К6

- Thread cutter 25x16x150 02-361 for external threads with mechanical fastening of rhombic plates 080412 MS2210-372 (2008-0561)

- Thread cutter SIR 0025 R22 25x25x150 for internal threads with a round holder with mechanical fastening of triangular plates 22 IR

- Boring cutter with mechanical fastening of round plate HEXANIT-R (COMPOSITE 10) Ф25х23хL=200

- Boring cutter with mechanical fastening of a triangular insert STM (COMPOSITE 05) Ф25х23хL=200

- Pass-through cutter with mechanical fastening of round plate HEXANIT-R (COMPOSITE 10) 25x20x125 45 deg. +6 replaceable plates

- Pass-through cutter with mechanical fastening of round plate HEXANIT-R (COMPOSITE 10) 20x20x125 45 deg.

- Pass-through cutter with mechanical fastening of round plate HEXANIT-R (COMPOSITE 10) 25x20x125 45 deg.

- Pass-through cutter with mechanical fastening of a square plate HEXANIT-R (COMPOSITE 10) 20x20x125 +20 replaceable inserts

- Pass-through cutter with mechanical fastening of a square plate HEXANIT-R (COMPOSITE 10) 20x20x125 +18 replaceable inserts

- Pass-through cutter with mechanical fastening of the plate HEXANIT-R (COMPOSITE 10) 25x20x130

- Boring cutter 25x20x170 REO 8100 with mechanical fastening of CBN-R inserts for processing hardened steel, high-strength cast iron and other materials with hardness up to NZS 60-64

- Scoring cutter with fur. fastening ELBOR-R (COMPOSITE 01) 20x20x125 45 deg. (10 inserts) REO 80.00.00

- Scoring cutter with fur. fastening ELBOR-R (COMPOSITE 01) 25x20x170 mm4 5 degrees (10 inserts) REO 80.00

- Scoring cutter with fur. fastening ELBOR-R (COMPOSITE 01) 32x25x170 mm45 degrees (10 inserts) IS204-03

- Passable cutter with fur. fastening ELBOR-R (COMPOSITE 01) 16x16x125 45 degrees (10 inserts)

- Passable cutter with fur. fastening ELBOR-R (COMPOSITE 01) 16x16x100 mm 45 degrees (10 inserts)

- Passable cutter with fur. fastening ELBOR-R (COMPOSITE 01) 20x16x120 mm 45 degrees (10 inserts)

- Passable cutter with fur. fastening ELBOR-R (COMPOSITE 01) 20x20x120 mm 45 degrees (10 inserts) REO 80.00

- Passable cutter with fur. fastening ELBOR-R (COMPOSITE 01) 25x20x150 mm 45 degrees (10 inserts d=8 mm)

- Passable cutter with fur. fastening ELBOR-R (COMPOSITE 01) 25x20x150 mm 45 degrees (10 inserts d=10 mm)

- Passable cutter with fur. fastening ELBOR-R (COMPOSITE 01) 25x20x170 mm (10 inserts) REO 82.00

- Boring cutter with fur. fastening ELBOR-R (COMPOSITE 01) 16x16x125 45 degrees (10 inserts) REO 94.00.00

- Boring cutter with fur. fastening with ELBOR-R (COMPOSITE 01) 20x16x125 45 degrees (10 inserts) REO 94.00

- Boring cutter with fur. fastening ELBOR-R (COMPOSITE 01) 25x20x170 mm45 degrees (10 inserts d=8 mm)

- Boring cutter with fur. fastening ELBOR-R (COMPOSITE 01) 25x20x170 mm45 degrees (10 inserts d=9 mm)

- Boring cutter for coordinate boring. machines with fur. fastening ELBOR-R (COMPOSITE 01) d=10, Ltot.=80 (5 inserts d=3.6 mm)

- Boring cutter for coordinate boring. machines with fur. fastening ELBOR-R (COMPOSITE 01) d=10, Ltot.=80 (7 inserts d=3.6 mm)

- Boring cutter for coordinate boring. machines with fur. fastening ELBOR-R (COMPOSITE 01) d=10, Ltot.=80 (10 inserts d=3.6 mm)

- Boring cutter for coordinate boring. machines with fur. fastening ELBOR-R (COMPOSITE 01) d=14, Ltot.=60 (10 inserts d=3.6 mm)

- Boring cutter for coordinate boring. machines with fur. fastening ELBOR-R (COMPOSITE 01) d=16, Ltot.=80 (10 inserts d=3.6 mm)

- Screw M8x1.25 for mech cutter. fastening with a cylindrical head d=12mm, Ltot.=37mm lto head=30mm and hexagonal socket 5mm

- Screw M6x1 for mech cutter. fastening with a cylindrical head d=10mm, Ltot.=32mm lto head=25mm and hexagonal socket 5mm

- Screw M6x1 for mech cutter. fastening with a cylindrical head d=10mm, Ltot.=30mm lto head=22mm and hexagonal socket 5mm

- Screw M8x1.25 for mech cutter. fastening with a cylindrical head d=13mm, Ltot.=44mm lto head=36mm and hexagonal socket 6mm

- Screw M5x0.8 for mech cutter. fastening with a cylindrical head d=9mm, Ltot.=24mm lto head=17mm and hexagonal socket 4mm

- Screw M8x1.25 for mech cutter. fastening with a cylindrical head d=14mm, Ltot.=28mm lto head=20mm and hexagonal socket 6mm

- Screw M6x1 for mech cutter. fastening with a cylindrical head d=10mm, Ltot.=37mm lto head=30mm and hexagonal socket 5mm

- Screw M8x1.25 for mech cutter. fastening with a cylindrical head d=12mm, Ltotal=40mm lto head=32mm and hexagonal socket 6mm

- Screw M6x1 for mech cutter. fastening with a cylindrical head d=10mm, Ltot.=27mm lto head=20mm and hexagonal socket 5mm

- Screw M8x1 for mech cutter. fastening with a cylindrical head d=8mm, Ltot.=21mm lto head=15mm and hexagonal socket 4mm

- Screw M8x1.25 for mech cutter. fastening with a cylindrical head d=13mm, Ltot.=48mm lto head=40mm and hexagonal socket 6mm

- Screw M8x1.25 for mech cutter. fastening with a cylindrical head d=13mm, Ltot.=37mm lto head=30mm and hexagonal socket 5mm

- Screw M8x1.25 for mech cutter. fastening with a cylindrical head d=12mm, Ltot.=32mm lto head=25mm and hexagonal socket 5mm

- Screw M8x1 for mech cutter. fastening with multi-directional thread Ltot.=30mm and hexagonal sockets for 4mm wrench

- Screw M8x1 for mech cutter. fastening with multi-directional thread Ltot.=25mm and hexagonal sockets for wrench 4mm

- SANDVIK cutters and holders

- cutter (holder PCLNR 12 S25T) with mechanical fastening of rhombic inserts 80° CNMM, CNMG, CNMA, CNGA right (Sandvik) lever clamping by the hole, angle 95°

- cutter (holder PCLNR 2525M12) 25x25 with mechanical fastening of rhombic inserts 80° CNMM, CNMG, CNMA, CNGA right (Sandvik) lever clamp for the hole, angle 95°

- cutter (holder PCLNR 2525M19) 25x25 with mechanical fastening of rhombic inserts 80° CNMM, CNMG, CNMA, CNGA right (Sandvik) lever clamp for the hole, angle 95°

- cutter (holder PTGNL 2525M16) 25x25 with mechanical fastening of triangular inserts TNMM, TNMG, TNMA, TNGA left (Sandvik) clamping with a lever for the hole

- boring cutter (holder PTFNR 12 CA16) with mechanical fastening of triangular inserts TNMM, TNMG, TNMA, TNGA right (Sandvik) wedge fastening

- boring cutter (holder PTFNR 1616 H16) with mechanical fastening of triangular inserts TNMM, TNMG, TNMA, TNGA right (Sandvik) wedge fastening

- boring cutter (holder PTFNR 20 CA22) with mechanical fastening of triangular inserts TNMM, TNMG, TNMA, TNGA right (Sandvik) wedge fastening

- boring cutter (holder PDNNL 2525 M15) 25x25 with mechanical fastening of rhombic inserts 55° left (Sandvik)

- boring cutter (holder PDJNL 2525 M15) 25x25 with mechanical fastening of rhombic inserts 55° left (Sandvik)

- boring cutter (holder PDJNR 2525 M15) 25x25 with mechanical fastening of rhombic inserts 55° right (Sandvik)

- cutter (holder PSKNR 2525M12) 25x25 with mechanical fastening of square inserts TNMM, TNMG, TNMA, TNGA right (Sandvik) clamping with a lever by the hole, angle 75°

- cutter (holder PSSNI 2020K12) 20x20 with mechanical fastening of square inserts TNMM, TNMG, TNMA, TNGA right (Sandvik) clamping with a lever by the hole, angle 75°

- cutter CSDNN 2525 M12-CE 25x25x150 with mechanical fastening with square inserts SNEX-1207 (TaeguTec)

- cutter (holder L166F-2525-310) 25x25 with mechanical insert fastening (Sandvik)

- cutter (holder SSBCR1616M09) 16x16 with mechanical fastening of inserts (Sandvik)

- cutter (holder SSBCR1616H09 HG) 16x16 with mechanical fastening of inserts (Sandvik)

- cutter (holder SPEL 609.039 (611091R002) SU with mechanical fastening of inserts (Sandvik)

- cutter (holder SPEL 609.046 (6.1209 1L302) with mechanical fastening of inserts (Sandvik)

- cutter (holder SCLCR 09M S25T) with mechanical fastening of inserts (Sandvik)

- cutter (holder SCFCL 11 S16R) with mechanical fastening of inserts (Sandvik)

- cutter (holder CSDPN 2020K12) with mechanical fastening of inserts (Sandvik)

- cutter (holder CSKPR 2525M12) with mechanical fastening of inserts (Sandvik)

- cutter (holder R 142.0-20-161 340 129992 R1) with mechanical fastening of inserts (Sandvik)

- Contour incisors

- Contour cutter PDJNTR 2022 K15 20x20x125 with mechanical fastening of a rhombic plate VK8 with an angle of 55 degrees

- contour cutter 20x20x125 with mechanical edge. rhombus. VK8 plates with an angle of 55º

- contour cutter 25x25x125 with mechanical fastening of rhombic plates T15K6 with an angle of 63º

- Gear cutters

- gear cutter 25x18x140 1BISON KNB with a round insert d 10x25mm equipped with STM elbor-R, with an upper bevel of 30º (composite 01)

- gear cutter 25x18x140 1BISON KNB with a round insert d 10x25mm equipped with STM elbor-R, with an upper bevel of 30º (composite 01)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

We supply cutters to all regions of the Russian Federation, Belarus and Kazakhstan through transport companies

price lists

return to the main page of the site

Nuances of choosing a cutter

When purchasing cutting tools, you need to pay attention to the following criteria:

- A type of cutting tool. Different types of cutters differ in profile shape, determined by the technical features of carbide inserts.

- Dimensional characteristics. The different dimensions of products processed on a lathe determine the dimensions of the cutting tool. For modern types of cutters, you can select workpieces with distinctive dimensional characteristics.

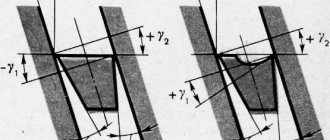

- Back angle value. This indicator affects the accuracy of finishing of the material. The surface cutting cleanliness is directly proportional to the clearance angle. This parameter is taken into account when turning metal workpieces with soft surfaces.

- Accuracy class. This parameter is used to calculate the accuracy of the cutting performed. According to GOST 9253-59, 3 main accuracy classes are established for plates. When measuring this parameter, it is possible to cut workpieces with tools with different tolerance values.

If these criteria are not taken into account, then the thread cutters will not be able to be firmly fixed on the lathe and produce precise processing of metal parts.

When purchasing cutting tools, it is important to choose the right inserts. These parts are made of hard metal alloys. The ratio of metals determines the operating characteristics of the cutting tool. There are 2 main types of plates:

- With increased strength. They are resistant to vibration, shock and other physical stress that occurs during cutting. It is recommended to purchase this category of plates if you need to cut a large amount of metal from the workpiece.

- With increased heat resistance. They can withstand high temperatures that arise during long-term processing of workpieces and exposure to frictional forces. Heat-resistant plates are fixed mechanically. They are used when working at high speeds.

Materials of manufacture are indicated on the markings of carbide inserts. Each alloy has a unique image. In the manufacture of cutting parts, tungsten is used, which has high strength and resistance to large temperature changes. Additionally, titanium carbide or cobalt can be used. Plates made of ceramic materials are used during finishing or semi-finishing of metal products. They can be used for cutting workpieces made of heat-resistant alloys. The percentage of these components determines the category of replacement plates. On the marking, titanium is designated by the letter “T”, cobalt by the symbol “K”. Example of marking: T14K7 (percentage of titanium carbide - 14%, cobalt - 7%).

For large volumes of turning work, it is recommended to purchase a set of turning tools with replaceable inserts, which will allow you to quickly adjust the tool during various technological operations. When choosing sets, it is important to consider the manufacturer's brand. The most popular replacement plates on the market are from the following companies:

- LLC “Instrument-Service”: a Ukrainian company that produces parts for cutting tools.

- Interpipe: is the largest organization for the production of pipe and threaded connections in Eastern Europe. The products are manufactured at the Novomoskovsk pipe plant, located in the Ukrainian city of Dnepr.

- BDS-Machinen: German company producing devices and parts for magnetic drilling machines.

- Proxxon: an organization that develops parts for cutting small workpieces. Production takes place in Germany.

- Ceratizit: a company producing metal-cutting tools and their main components. The headquarters is located in Luxembourg.

The cost of a set of turning tools depends on the manufacturer's costs and the financial policies of suppliers. Imported parts have the highest price. The average price of a set is 15,000 rubles. Additionally, you can purchase certain types of plates. Their average price is 164 rubles.

Cutting modes

Cutting modes are a set of parameters that determine the conditions for processing parts using a turning tool. The cutting process is influenced by the following factors:

- Cutting speed is the path of movement of the machined surface of the workpiece relative to the cutting edge per unit time. Measured in m/min or m/s. In the drawings it is designated by the Latin letter V.

- Feed is the path traveled by the cutting edge in 1 stroke or revolution of the workpiece being processed. Measured in mm/rev. In the drawings it is marked with the Latin symbol S.

- Depth of cut is the distance between the machined and machined surfaces. It shows the amount of metal layer being removed. In the diagrams it is denoted by the Latin letter t.

- The cross-sectional area of the cut layer is the product of the cutting depth and the feed. It is a nominal value and affects the presence of roughness. In the diagrams it is indicated by the Latin symbol f.

These parameters are tabular values and are specified in GOST 25762-83.

Download GOST 25762-83

Each type of cutting tools with mechanically fastened inserts has additional cutting modes. Cutting cutters carry out transverse movements, boring tools move longitudinally relative to the surface of the workpiece. During operation, the average speed of the cutting edges is tenths of mm. The feed is 0.1 mm/rev.

Advantages and disadvantages of incisors

Thread cutters with replaceable inserts have the following advantages:

- low cost: cost less than solid type incisors;

- allow you to save a large amount of time resources during the preparation of cutting tools for various technological operations;

- the plates are able to withstand high loads because they are made of carbide materials;

- cutting cutters can be used to process parts with small dimensions and uneven terrain;

- the cutting tool can be readjusted if necessary;

- high service life of the holders, which allows the tool to be firmly secured to the lathe;

- do not require additional sharpening or soldering;

- during processing, reduce cutting force and temperature by 35 - 40%;

- provide the ability to change cutting modes on the fly;

- unification of all cutter models: allows you to select the right insert for processing workpieces made of certain types of metals.

Experts highlight the following disadvantages of cutters with replaceable inserts:

- due to the presence of many fasteners for carbide inserts, the total weight of the cutting tool increases;

- cutters are not able to provide optimal geometric parameters of the cutting edge due to the different shapes of the plates and the peculiarities of their fastening;

- high complexity of manufacturing cutting tools.

The quality of a thread cutter depends on the type of processing and cutting mode. The cutter retains its benefits longer at low cutting speeds and during internal cross turning. The cutting tool wears out faster during external longitudinal turning. To increase its durability, lubricating and cooling media are used. You can also increase the rigidity of the tool by increasing the area of the holder.

Modern turning tools

Home Articles Modern turning tools with replaceable inserts

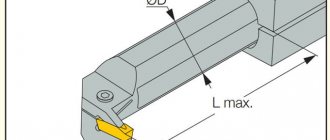

Today, turning tools with replaceable inserts are very popular. The holder of such cutters does not come into contact with the material and does not wear out, which allows you to use the tool longer. Unlike those tools that are produced in a one-piece version, here you can change the plate on which the cutting edge is located to start performing a different type of work. This significantly speeds up the work process. If a part is worn out or broken, it can be easily replaced without interrupting the production process for a long time. Buying replacement inserts for cutters is much cheaper than purchasing the entire tool. Thanks to these properties, turning holders with replaceable inserts have become indispensable in production.

A cutting cutter with replaceable inserts has the following number of advantages:

● quick change of working cutting part;

● good compatibility with tools and units;

● high reliability even during intensive work;

● re-adjustment of cutting tools;

● relatively low cost of replacement parts.

The only disadvantages that can be noted are that these products can break if the plate is fastened incorrectly, and the products themselves are less durable, although in economic terms they are much more profitable.

There are cutters with inserts made of carbide and high-speed steel. These types of materials appear in almost all types of instruments. Which one to take depends on what materials you will be working with. High speed steel is good for soft metals. It is relatively cheap, but performs very poorly when working with refractory and hardened workpieces. Lathe cutters with carbide inserts are more expensive, but they work with all types of metal and can withstand both temperature increases during active work and shocks.

Otherwise, the choice depends on the type of work for which the tool is taken. The features of its sharpening and other factors that turn out to be very important for the technologically correct execution of actions depend on this.

Cutters with plates made of carbide, as well as those made of high-speed steel, have several varieties, which depend on what kind of work they will be intended for.

Here are the following varieties:

■ Mechanical thread cutter - this tool can be used to cut internal and external threads on cylindrical workpieces.

■ Boring cutters with mechanical fastening - they are used to bore through and blind holes in workpieces. Depending on what kind of hole you have to work with, there are persistent ones, which grind blind holes, including processing the bottom, as well as through ones, for through processing. You can also use pass-through machines to process cylindrical surfaces.

■ Shaped - this is one of the most complex types that goes beyond accepted standards, as it has an individual profile. Some of them are made to order, so they have a lot of processing options.

■ Cut-off cutter with mechanical fastening – used for cutting off excess parts, both large and small, from workpieces. Mainly used for rod blanks.

■ Slotted – used for cutting circular grooves over the entire surface of the workpiece.

■ Fillet – used for turning the transition surface, which is located along the entire radius between the shaft steps.

Currently, carbide tools are the most progressive and widely used for industrial purposes. This material has high hardness and heat resistance. For metal working tools, carbide alloys are manufactured in the form of plates with various shapes and sizes. Installation of such plates is quite simple, and their increased level of wear resistance guarantees stable operation and saves money.

Carbide, high-speed and alloy steel materials are characterized by increased hardness and heat resistance compared to tool steel, so processing of workpieces is possible at high rotation speeds. Metal turning tools made from this material are more fragile. To determine the grade of carbide cutting element, they usually use special cards that describe the types of all areas of application under various processing methods and conditions.

Carbide alloys allow you to work at high cutting speeds of the workpiece; they are divided into the following categories:

◆ Metal-ceramic:

— Tungsten alloys are made from tungsten and cobalt carbides. Used for processing viscous materials, milling solid surfaces, boring cast iron under loads.

- Titanium tungsten. The material consists of tungsten and titanium carbides with the addition of cobalt. Suitable for rough and fine boring and cutting of steel.

— Titanium tantalum tungsten. In addition to titanium and tungsten, the alloy contains tantalum. Due to its high toughness, wear resistance and impact resistance, it is indispensable for working with steel forgings.

◆ Mineral-ceramic – a synthetically derived alumina-based alloy. It has high heat resistance, but has a fragile structure. Microlite plates can heat up to 1200 degrees without losing their hardness.

The ISO World company offers cutting tools for milling, turning and drilling, interchangeable and brazed inserts of various types from well-known global manufacturers. In order to buy a turning tool for metal, you need to familiarize yourself with the catalog presented on the ISO World website. The availability of new models of tools from well-known global manufacturers will pleasantly surprise the customer. Managers of the ISO World company are always happy to answer all your questions and provide advice about the product by calling +7 (8482) 999-111. You can also contact us by filling out the question form or directly order products from the site.